Professional Documents

Culture Documents

Document1 2

Document1 2

Uploaded by

Mathi MukilanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Document1 2

Document1 2

Uploaded by

Mathi MukilanCopyright:

Available Formats

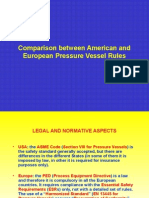

In ASME Section VIII Division 1, which covers the design and construction of pressure vessels, there are

requirements and guidelines for solution annealing of materials. The specific clauses related to solution

annealing can be found primarily in the sections addressing materials, heat treatment, and fabrication.

Here are some key points regarding solution annealing in ASME Section VIII Division 1:

1. Material Requirements (Article 2): The selection of materials for pressure vessel construction is

critical, and the materials must meet specified requirements for chemical composition, mechanical

properties, and heat treatment. The applicable material specifications, such as ASTM standards,

often include guidelines for solution annealing where required.

2. Heat Treatment (Article 6): This section outlines the requirements for heat treatment of

materials used in pressure vessel construction. It may specify the temperature ranges, holding

times, and cooling rates for solution annealing of specific materials or material grades.

3. Fabrication (Article 9): The fabrication of pressure vessels must be carried out in accordance

with approved procedures and standards. This may include requirements for post-weld heat

treatment (PWHT), which can involve solution annealing for certain materials or weldments to

relieve residual stresses and ensure desired material properties.

4. Quality Control and Inspection (Article 12): ASME Section VIII Division 1 also includes

requirements for quality control and inspection during the fabrication process. This may involve

verifying that the correct heat treatment procedures, including solution annealing, have been

followed and documented according to specified requirements.

5. Non-destructive Examination (Article 7): Non-destructive examination (NDE) methods such as

radiographic testing, ultrasonic testing, and dye penetrant testing are often used to assess the

quality and integrity of pressure vessel welds and materials. These examinations may be

conducted after solution annealing to ensure the absence of defects or discontinuities that could

compromise the vessel's performance or safety.

It's important to consult the specific edition of ASME Section VIII Division 1 that applies to your project,

as requirements and guidelines may vary between editions and updates. Additionally, compliance with

ASME codes and standards typically requires the involvement of qualified engineers and inspectors

familiar with pressure vessel design, fabrication, and quality assurance practices.

You might also like

- ASTM D638 10 - Standard Test Method For Tensile Properties of PlasticsDocument16 pagesASTM D638 10 - Standard Test Method For Tensile Properties of PlasticsAndre SpirimNo ratings yet

- SSPC-QP 6 PDFDocument6 pagesSSPC-QP 6 PDFPrasanthRNairNo ratings yet

- New Heat ExchangerDocument12 pagesNew Heat ExchangerMosaddek100% (1)

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsFrom EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsNo ratings yet

- Experiment 9: Isolation and Isomerization of Lycopene From Tomato Paste Date Performed: 6 Feb 2014 Date Submitted: 11 Feb 2014Document6 pagesExperiment 9: Isolation and Isomerization of Lycopene From Tomato Paste Date Performed: 6 Feb 2014 Date Submitted: 11 Feb 2014Haida HamidNo ratings yet

- Percent Copper in Brass - YouTube Version PDFDocument4 pagesPercent Copper in Brass - YouTube Version PDFEugene LeeNo ratings yet

- Pressure Vessel Design ASME SEC VIII DIV 1Document1 pagePressure Vessel Design ASME SEC VIII DIV 1sreenvasmallaNo ratings yet

- Pressure Vessel Design IS 2825Document1 pagePressure Vessel Design IS 2825sreenvasmallaNo ratings yet

- 5 - Module 5Document47 pages5 - Module 5Ahmed Shaban Kotb100% (1)

- Codes For PaperDocument4 pagesCodes For PaperSubyyalNo ratings yet

- ASME Section I & Section VIIIDocument59 pagesASME Section I & Section VIIIknizam1971No ratings yet

- Standards & Its Description OverviewDocument8 pagesStandards & Its Description OverviewBalakumarNo ratings yet

- Asme Sec V BriefDocument10 pagesAsme Sec V Briefnazarasim25% (4)

- ASME VIII Div 1 ReportDocument12 pagesASME VIII Div 1 ReportAmir Zamri100% (2)

- ASME Codes and Standards - A Summary - Welding & NDTDocument15 pagesASME Codes and Standards - A Summary - Welding & NDTTin Aung KyiNo ratings yet

- Pressure Vessel, Asme CodeDocument10 pagesPressure Vessel, Asme Codeabhi_mohit2005100% (1)

- Asme Code StandardsDocument34 pagesAsme Code StandardsPandu Pratama YudhaNo ratings yet

- Project of Design by Group 3Document54 pagesProject of Design by Group 3etayhailu100% (4)

- Chapter-4: A Commentary For Understanding and Applying The Principles of The Asme Boiler and Pressure Vessel CodeDocument26 pagesChapter-4: A Commentary For Understanding and Applying The Principles of The Asme Boiler and Pressure Vessel CodeAbhinav OjhaNo ratings yet

- Asme Codes and Standard A SummaryDocument20 pagesAsme Codes and Standard A Summarymawatwalharsh549No ratings yet

- Asme Codes & Standards: Engineering Departemen By: RamadityaDocument34 pagesAsme Codes & Standards: Engineering Departemen By: RamadityaRamaditya Putera KlesindoNo ratings yet

- Mech - Stds. - 1Document65 pagesMech - Stds. - 1Amarendra Mani TiwariNo ratings yet

- B 03 Marine Air ReceiversDocument9 pagesB 03 Marine Air ReceiversarunNo ratings yet

- 07 Codes and Standards 30-03-07 PDFDocument6 pages07 Codes and Standards 30-03-07 PDFvineet chandra khanduriNo ratings yet

- Pressure VesselDocument3 pagesPressure Vesselzahid_497No ratings yet

- Gas TurbineDocument7 pagesGas TurbinebharathwajamechNo ratings yet

- Vessels For High Pressure Dust CollectorsDocument4 pagesVessels For High Pressure Dust CollectorsWade ColemanNo ratings yet

- A Primer On Asme Section Viii, Div. 1 MaterialsDocument1 pageA Primer On Asme Section Viii, Div. 1 MaterialsCITRIXNo ratings yet

- Pa 3 PDFDocument0 pagesPa 3 PDFNageswara Rao BavisettyNo ratings yet

- ASMECODESSTANDARDSDocument34 pagesASMECODESSTANDARDSqaisarabbas9002No ratings yet

- ASME Section I and VIII FundamentalsDocument59 pagesASME Section I and VIII FundamentalsAnatolie6No ratings yet

- Basic Training Material For QADocument10 pagesBasic Training Material For QANilesh GhodekarNo ratings yet

- American Society of Mechanical EngineersDocument4 pagesAmerican Society of Mechanical Engineersb3 qualNo ratings yet

- Pressure Req DesignDocument12 pagesPressure Req DesignAbhinav PathakNo ratings yet

- General Guide - Codes and StandardsDocument4 pagesGeneral Guide - Codes and StandardsmanuyemNo ratings yet

- Pressure Vessel Inspection and DesignDocument48 pagesPressure Vessel Inspection and DesignMohammed Raje100% (2)

- DDD StandardsDocument33 pagesDDD StandardsAnonymous fBXlhQnsqNo ratings yet

- Codes and Standards:: The Welding InstituteDocument0 pagesCodes and Standards:: The Welding InstituteBhavani PrasadNo ratings yet

- Pip Vessm001 Specification For Small Pressure Vessels and Heat Exchangers With Limited Design ConditionsDocument12 pagesPip Vessm001 Specification For Small Pressure Vessels and Heat Exchangers With Limited Design ConditionsAmit SharmaNo ratings yet

- M 650 U 4Document30 pagesM 650 U 4dzardoniNo ratings yet

- DesignDocument10 pagesDesignkefiyalew agegnNo ratings yet

- Chapter 5 Code Design - Pressure VesselDocument11 pagesChapter 5 Code Design - Pressure VesselEDWARD T CHENJERAINo ratings yet

- Pressure Vessel PlateDocument71 pagesPressure Vessel PlateVILLANUEVA_DANIEL2064100% (2)

- ASME Code General ReviewDocument33 pagesASME Code General Reviewaike_5No ratings yet

- 11-Quality Assurance - HariharanDocument29 pages11-Quality Assurance - Hariharanabhinay soniNo ratings yet

- Dutyies of Welding InspectorDocument30 pagesDutyies of Welding InspectorMorg Actus100% (1)

- ASMEvs PEDDocument15 pagesASMEvs PEDAlfonsoNo ratings yet

- Standards and Codes: Asme Section ViiiDocument44 pagesStandards and Codes: Asme Section ViiiNitin LuhadiyaNo ratings yet

- Welding Codes and How They're UsedDocument5 pagesWelding Codes and How They're UsedPasquale CutriNo ratings yet

- Design and Material Issues in Relation To Pressure Vessel CodesDocument10 pagesDesign and Material Issues in Relation To Pressure Vessel Codesrajkamal_eNo ratings yet

- Code & Standard For ASME U & Stamp.Document21 pagesCode & Standard For ASME U & Stamp.Md Anamul HoqueNo ratings yet

- ASME Section 1 Section VIII FundamentalsDocument56 pagesASME Section 1 Section VIII FundamentalsXuan Man NguyenNo ratings yet

- Chapter 1 & 2Document13 pagesChapter 1 & 2koxabey137No ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Guidelines for Laboratory Design: Health, Safety, and Environmental ConsiderationsFrom EverandGuidelines for Laboratory Design: Health, Safety, and Environmental ConsiderationsNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- WBPSC Assistant Engineer 2019 Civil EnglishDocument15 pagesWBPSC Assistant Engineer 2019 Civil EnglishBiki Rawdy DasNo ratings yet

- Electro - 2: Jonathan Shehan (BSC) 0772310428 - 1Document15 pagesElectro - 2: Jonathan Shehan (BSC) 0772310428 - 1Senuja ChammithaNo ratings yet

- Thermal Analysis With FLIR Cameras and MATLABDocument24 pagesThermal Analysis With FLIR Cameras and MATLABCARLOS LOPEZNo ratings yet

- Flyash Kinetics Revised v1Document43 pagesFlyash Kinetics Revised v1jarol22No ratings yet

- SPE 77752 Cement Pulsation Treatment in WellsDocument16 pagesSPE 77752 Cement Pulsation Treatment in WellsAfnan Mukhtar SyauqiNo ratings yet

- EC2 Paragraph 6.2.2Document3 pagesEC2 Paragraph 6.2.2lollazzoNo ratings yet

- 412-00 Climate Control - EMTCDocument2 pages412-00 Climate Control - EMTCDimitrios PapadopoulosNo ratings yet

- CH 01Document26 pagesCH 01SamVanyaNo ratings yet

- Metallurgy of Carbon SteelDocument5 pagesMetallurgy of Carbon SteelMadhavan SoundararajanNo ratings yet

- Hydraulic OilsDocument6 pagesHydraulic OilsGeorgina SuleNo ratings yet

- Fluid Dynamics and Turbomachines: WEEK 1: AssignmentDocument16 pagesFluid Dynamics and Turbomachines: WEEK 1: AssignmentBossNo ratings yet

- This Study Resource Was: Submitted By: Engr. Ritchie ArdaniDocument3 pagesThis Study Resource Was: Submitted By: Engr. Ritchie ArdaniClint Baring ArranchadoNo ratings yet

- Wind Loads On Buildings - Mwfrs (Envelope Procedure) : Chapter C28Document5 pagesWind Loads On Buildings - Mwfrs (Envelope Procedure) : Chapter C28Van Len TranNo ratings yet

- History MatchDocument78 pagesHistory MatchGustaf100% (2)

- Question Chapter 8Document5 pagesQuestion Chapter 8Mohamed AshrafNo ratings yet

- Organic Hydronium-Ion Battery With Ultralong LifeDocument7 pagesOrganic Hydronium-Ion Battery With Ultralong LifeNoisy RequiemNo ratings yet

- Kolboe1969 PDFDocument7 pagesKolboe1969 PDFRastraPatriaNo ratings yet

- PHY132 Lab1Document14 pagesPHY132 Lab1Patrick HayesNo ratings yet

- UIC Physics 105: Practice Final ExamDocument7 pagesUIC Physics 105: Practice Final ExamnetrunnrNo ratings yet

- About Chute SpillwayDocument15 pagesAbout Chute SpillwayPrem Singh RawatNo ratings yet

- Cep 202107 Optimize-ReboilerDocument11 pagesCep 202107 Optimize-Reboilerammar fahmiNo ratings yet

- Determining The Rate of InfiltrationDocument3 pagesDetermining The Rate of InfiltrationEdgar Henri NicolasNo ratings yet

- CHM207 Lab Report Eks.3Document8 pagesCHM207 Lab Report Eks.3Akmal HakimNo ratings yet

- Tam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Document9 pagesTam-Sc-2-B Doorsheet Removal and Reinstallation: February 2003 © Chevrontexaco 1 of 9Herlys Pereira100% (1)

- Modulation Solutions For Nematicon PropagationDocument10 pagesModulation Solutions For Nematicon PropagationIsmael ArceNo ratings yet

- KBT Assignment 01Document10 pagesKBT Assignment 01Fadhilah DevaniNo ratings yet

- DuffyDocument13 pagesDuffyThejaswiniNo ratings yet