Professional Documents

Culture Documents

RA - Installation of GRP Tanks

RA - Installation of GRP Tanks

Uploaded by

Sundarapandian NeelamegamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA - Installation of GRP Tanks

RA - Installation of GRP Tanks

Uploaded by

Sundarapandian NeelamegamCopyright:

Available Formats

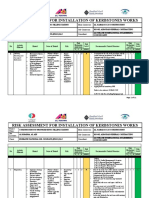

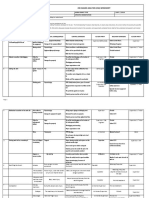

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Additional Risk

No. Hazard Title Hazard Detail Causes Consequences Existing Controls Controls Planned/

P A E R RI Required P A E R RI

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

PTW shall be

followed.

OSHAD approved third PTW shall be

party certificates required obtained only by

for equipment and competent and

operator authorized person.

Road Safety Procedure Only approved

to be strictly adhered. /certified vehicles and

Appropriate PPE shall be equipment shall be

worn by all personnel used

Unauthorized

entry (PTW has Appropriate Fire All the vehicles in the

not obtained) Extinguisher (DCP) shall working area shall

Unsafe driving be available on all have reverse alarm.

Speeding vehicles/equipment and Tool Box Talks to be

Poor road in site in an easily conducted prior to

Fatigue condition start the job

Mobilization accessible location.

Fall of load Untrained/

equipment, Injury/ Fatality Softeners to be used Additional Risk be

Vehicles should

No. Hazard Title Run

HazardoverDetail Unlicensed

Causes Consequences Existing Controlsthe load Controls Planned/

1. Transporting Incident/Accident while securing entering one by one

Vehicle collision drivers 3C 2C - 3C Required 1C 1C - 1C

of Materials Asset / Equipment damage to avoid damage. to the location

Falling into Inexperienced/

to Site excavations Untrained Competent Vehicle in good

workers drivers/operators shall be mechanical condition.

Materials not assigned for the task. Ensure load is

properly loaded/ Ensure effective properly secured with

secured

supervision and conduct slings/chains

Absence of

inspection. Approach ways to be

guide/escort

Vehicle to be inspected maintained in good

for safety. conditions and traffic

Do not over speed and warning signs to be

sudden breaks. posted.

All loads shall be All

properly secured. vehicles/equipment

Ensure road worthiness entering the work

and sufficient room for area to be monitored /

operating. marshaled by trained

banks-man

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

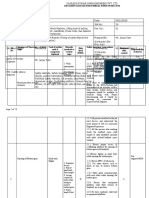

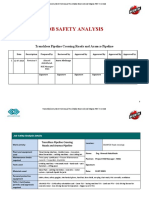

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Should be set up with a

4 vertical to 1 horizontal

slope(4:1)

Inspection and

The ladder should

Maintenance to be

extend minimum one

Over loading registered and recorded

Person/material meter from the top

Obstructing by the store keeper. Additional Risk

falling from for safe movement

No. Hazard Title Hazard the access Step ladder must fully

2. Working height. Detail Causes Consequences

Sprain and train Existing Controls Controls Planned/

Heavy materials

way 4C 3C 2C 3C open and lock and the Requirednot be carried 1C 1C 1C 1C

Over reaching Facture should

with ladder Slippery or

Injury to the person

devices to be as per

Do not erect in

uneven manufacturer.

slippery, uneven

surface. Defective ladder should

surface

not be used and report it

immediately.

Do not work from the top

of two rungs

1.msds to be available

on the work place 1. store the material

in the sealed

2. Storage together with

condition.

the inert gases and

highly inflammable 2.do not store the

substance is not allowed material near ignition

Improper works Fire, source

3. Open storge of 3.protection to be carried

USES OF with SDS 4C 3C 2C 3C 3.foam and dry

material. Skin problem, Injury. out from direct sunlight.

CHEMICAL recommendatio storage fire

Fire. n. Waterproofing chemicals

extinguisher to be

are not allowed to shift in

provided near storage

open condition and

areas

allowed to shift in closed

4.storage

containers.

compatibility to be

Provide eye wash facility.

done

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

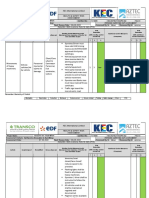

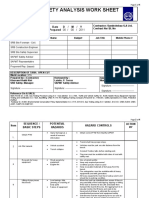

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Adequate PPE s must be

worn by all employees

Heavy objects, equipment

Provide materials

and materials are to be

handling safety training

handled by mechanical

Improper to workers, lift with your

means (forklift, crane, etc..)

handling leg not with your back,

or use multiple persons if not

Lack of training TBT for manual handling

too heavy

Using improper Back injury Additional

be Risk to

communicated

Installation Task Analysis for the lifting

No.

4. Hazard Title of Hazard Detail

Gathering of tools Causes Consequences Existing Controls Controls Planned/

workers

GRP Panel equipment Cuts and abrasions 4C 3C 2C 3C load to be conducted for 1C 1C 1C 1C

and materials Required

Keep the materials near

Not wearing Equipment/ material damaged Close Supervision

Tanks the location where it is

suitable PPE Tripping hazards shall be

being utilized, be mindful

eliminated via Good

lifting of of the person next to

Housekeeping.

materials with you, keep away your

more than 20 Training provided in HSE hands and feet from

kgs of weight inductions and tool box talks pinching points

– workers to lift with their Maintain adequate work

knees and not their backs supervision

Maximum lifting load weight

for single person should not

more 20Kg.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Rest Area

Heat stroke. Cool Drinking water

Dehydration. Mid-Day Break Rule

Burns. implemented

Confusion. Ensure all operatives are

Heat Stress acclimatized of the

Falling working environment.

Nausea Drinking water

availability and Appropriate training

Stroke Additional Risk

No. Hazard Title Hazard Detail Causes Consequences operatives to drink

Existing Controls water shall be Planned/

Controls given to all

5. Exhaustion Heat Stroke

Working in hot 4C 3C 2C 3C as frequently as employees

Required working in 1C 1C 1C 1C

Heat Stroke Collapse Fatality

weather possible. high temperature.

Rapid weak Heat related illness

Take regular breaks in Medical assistance

pulse ORS to be utilized

hot weather.

Head ache.

When feel unwell, inform

Weakness

to supervisor.

Mussels Appropriate training shall

Cramps be given to all

Vomiting employees working in

Fall of person high temperature.

Unconscious Medical assistance ORS

to be utilized

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

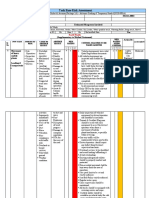

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

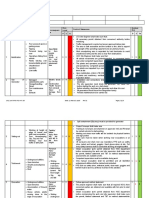

Supervisor to keep an All Scaffolds shall be

eye out for problems. erected by the

Scaffolding shall be tie competent( 3rd party

off. trained & certified)

Ladders in good erectors under the

Unauthorize condition, adequately supervision of

d scaffolding secured (lashed) and competent

inspector Scaffolding collapse. placed on firm surface. supervisor.

Fall from use for Slips / Trip Provide edge protection Mobile Scaffolding

work on height, inspect Falling objects for all work at edge on Additional

and Risk

independent

No.

6. heightTitle

Hazard with Hazard Detail

Slip and trip

Causes

scaffolding. Consequences

Collapse of temporary Existing

roof. Controls Controls

should bePlanned/

inspected

3C 3C - 3C Handrails to be used for Required

by authorized 3rd 1C 1C - 1C

mobile Improper platform.

Scaffolding Personal Injury, scaffolding. party certificate

Scaffolding scaffolding.

collapse. Proper Housekeeping holder of scaffolding

Edge Partial or complete

Safety helmets and inspector.

protection is disability, protective footwear. Appropriate load

not proper. Cross bracing shall be rating.

provided. Workers instructed

Base jacks shall be on not to interfere with

proper surface. or misuse scaffold

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Hazardous substances

to be stored according to

Material Safety Data

Sheet provided by

Adequate Firefighting

supplier.

equipment’s are

Substances to be in

available near to the

original container with

storage.

clear labels and hazard

Avoid storing the

warnings – no decanting

package in a place

Restricted access. Store

Hazardous and AdditionaltoRisk

exposed direct

Paint Fire injuries to be locked except

No.

7. Hazard Title

chemical HazardStorage

Detail Causes Consequences Existing Controls Controls

sunlight;Planned/

store it in

explosion property damage 3C 3C - 3C when in use Required 1C 1C - 1C

Materials well ventilated, cool

Storage spillage environmental pollution Ensure minimum

and dark place

chemicals stored at site.

Drinking water bottles

Designated storage area

should not use for

will be provided for

storage of chemicals.

chemical storage.

Ensure proper label

Spill tray shall be

available at all

providing to avoid

containers.

chemical spillages.

Incompatible Paints

should not store

altogether.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Lack of

adequate

access

control

Lack of site HSE Site induction

induction should be conducted

Lack of to all personnel prior

adequate to site entry.

training Induction tag should Refresher training

given to be conspicuously should be

operators by displayed on their conducted to

Collision

an approved helmet. operators in line

Plant and existing Additional Risk

third-party Personnel injury All operatives with the training

No. Hazard Title structure

Hazard Detail Causes Consequences Existing Controls Controls Planned/

8. Equipment inspection Asset and equipment deployed to site must matrix for the

Run over 5C 4C - 3C Requiredproject. 1C 1C - 1C

and company. damage have a valid license

Falling into

Operatives Unauthorize Overturning of equipment. and a third-party Adequate

excavation. supervision must be

d entry Fatality certificate

Incompetent competency. ensured at every

operatives All operators deployed stage of the task

Lack of for task at site must be being performed

compliance trained and competent

to site traffic enough to carry out the

rules task safely and

Unawarenes effectively

s of hazard

associated

job to be

performed.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Adequate PPE s must be Provide materials

worn by all employees handling safety

Heavy objects, training to workers, lift

equipment and materials with your leg not with

are to be handled by your back,

mechanical means TBT for manual

(forklift, crane, etc..) or handling be

Improper

use multiple persons if communicated to

handling

Slip ,trip, fall not too heavy workers

Lack of training

Fall of Task Analysis for the Keep the materials

Using improper Back injury lifting load to be Additional

near Risk

the location

materials

No.

9. Hazard

Manual Title Hazard Detail

Ergonomics equipment

Causes Consequences

Cuts and abrasions Existing

conducted Controls

for Controls

where it Planned/

is being

2C 2C - 3C 1C 1C - 1C

handling Fall of material Not wearing Equipment/ material damaged Close Supervision

Required

utilized, be mindful of

Leakage and suitable PPE

Tripping hazards shall be the person next to

Spillage lifting of you, keep away your

eliminated via Good

materials with

Housekeeping. hands and feet from

more than 20

kgs of weight Training provided in HSE pinching points

inductions and tool box Maintain adequate

talks – workers to lift with work supervision

their knees and not their

backs

Maximum lifting load

weight for single person

should not more 20Kg.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Loose clothing,

Hot Work Permit should

dangling earrings,

be in place

rings; bracelets and

Only competent/ trained

other jewelries are

and certified person shall

not being worn.

operate machine/ tool

All electrical tools

Damaged, fabricated,

must be check by

modified tools/ machines

competent electrician

shall not be used

and color code

Machines/ power and accordingly.

hand tools shall be in

Injuries Damage tools

Burn, Lack of PPE good condition and

Electrocution equipment must be

Hot Work Entanglement adherence

Fire

inspected by user before Additional Risk

removed from site

No.

10. Hazard Title Hazard Detail Causes

Driving error Consequences Existing Controls

use Controls Planned/

Activity Electrocution Cutting 3C 3C - 3C immediately.

Required 1C 1C - 1C

Bad weather Suitable PPE shall be

(Cutting, grinding, Fire Puncture and color coded.

welding) Blind spot worn including face

explosion Burns Fire extinguishers

shield and goggles.

CO2, DCP shall be

Safety guards and safety

provided closed to the

devices shall be in place.

proximity but not less

All electrical cables and

than 10-meter

extensions are in proper

distance.

condition.

Use only machines/

Suitable and sufficient

tools that are in

fire- fighting equipment

compliance to

shall be in place.

standards, double

Refresher training to be

insulated or grounded

provide if required.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Proper inspection and Adherence to

maintenance should manufacturer’s

be ensured recommendation

Color coding regime to Proper storage of

Inadequate be maintained tools

training Correct use of PPE Job rotation to

Electrocution Poor Safety/guard device in reduce exposure to

Noise supervision place vibration

Vibration Lack of Ensure to wear Earing Earing Protection

Personnel injury Additional Risk

Hand Trip hazard maintenance protection to reduce

No.

11. Hazard tools

Title / Hazard

Dust Detail Causes

Lack of

Consequences

Fatality Existing Controls

noise exposure Controls Planned/

Power tools / Burns 4C 3C 2C 3C Required 1C 1C 1C 1C

Ejection inspection Equipment must be

equipment Equipment damage

Fire & Incompetent suitable for the task

Property damage

Explosion user Adequate supervision

Flying object Lack of Equipment must be

safety device used by a competent

in place person

Adequate training,

instruction and

information must be

given to equipment

users

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Rest Area

Cool Drinking water

Mid-Day Break Rule

Heat stroke. implemented

Confusion. Ensure all operatives are

Heat Stress acclimatized of the

Nausea working environment.

Stroke Drinking water

Dehydration. availability and Appropriate training

Exhaustion

Burns. Heat operatives to drink water Additional Risk to all

shall be given

No. Hazard Title Hazard Detail Collapse

Causes Stroke

Consequences Existing Controls Controls Planned/

12. Working in hot as frequently as employees working in

Falling Rapid weak Fatality 3C 2C - 3C Required 1C 1C - 1C

weather possible. high temperature.

Fall of person pulse Heat related illness

Take regular breaks in Medical assistance

Head ache. ORS to be utilized

hot weather.

Weakness

When feel unwell, inform

Mussels

to supervisor.

Cramps

Appropriate training shall

Vomiting

be given to all

Unconscious

employees working in

high temperature.

Medical assistance ORS

to be utilized

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Weather condition must

be monitored daily, work

Poor visibility ban timings

implemented strictly

Slippery floor during summertime from

Heat stress June 15-September 15 Provide heat stress

Working in

illness Fatality of the year 12:30- training and

adverse weather Additional

Dust Consequences

Injury 3:00PM for all external emergencyRiskresponse

condition e.g.

No.

13. Adverse

Hazard Title Hazard Detail Causes Existing Controls

works, heat stress Controls Planned/

training to workers,

sand storm, high struck by Work Delay, 3C - 4C 3C Required 1C 1C - 1C

weather prevention program TWL level monitored

wind, extreme lightning Property damage implemented, stop all every 2 hours and

temperature, rain, fall from

lifting operation during communicated to

thunderstorm heights & thunderstorm, all work at workers

falling object heights activity not

due to high limited to roof work and

wind scaffolding works are

not allowed during

heavy rain.

Daily clean-up is to be

performed

Slips and Trips Walkways will be kept

Waste Sharp-edge Injuries clear at all times Personnel will wear

14. Housekeeping &

Managemen waste disposal cuttings Cut 3C 2C 3C 3C Proper disposal of suitable PPE at all 1C 1C - 1C

t Accumulation of Broken bone wastes as per contractor times

waste

Waste Management

Plan.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

ACTIVITIY TITLE: Installation of GRP tank

* Risk Assessment Residual Risk

Delay in notification / First aid shall be In case of any

response provided if necessary emergency workers

Movement of shall report

Lack of common All work will be stopped

heavy and staff / workers Additional Risk

immediately to AD

resources

No. Hazard Title equipment

Hazard Detail Causes Act

15. Emergency Unsafe Consequences

Lack of or inadequate Existing Controls

assembled in nearest Controls

Port Planned/

Control Room

Collision of 4C 2C - 4D assembly point Required

on 800112 1C 1C - 1C

Response and Condition emergency equipment

mobile

Language barrier

equipment

Fatality

Personal Injury

Implement the additional risk controls identified

Risk control-1 TBT should be conducted prior to the star of the activity Date 11/02/2024 Implemented by PM/HSE

11/02/2024

Risk control-2 Competent and trained operators to be deployed at site. Date Implemented by PM/HSE

All Scaffolding structures shall be erected by 3rd party certified scaffolding 11/02/2024

Risk control-3 Date Implemented by PM/HSE

erectors and shall be inspected by 3rd party certified scaffolding inspector

implemented strictly during summertime from June 15-September 15 of the year 11/02/2024

Risk control-4 Date Implemented by PM/HSE

12:30-3:00PM for all external works.

Daily clean-up is to be performed 11/02/2024

Risk control-5 Date Implemented by PM/HSE

Walkways will be kept clear at all time.

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

Risk Assessment

11/02/2024

Risk control-6 Ensure to wear Earing protection to reduce noise exposure Date Implemented by PM/HSE

It is important to monitor risk controls and review risk assessments regularly. Review is required when there is a change in the process, relevant legal changes, and where a cause for concern has arisen. Reviews could be

scheduled on an annual basis. If the risk assessment has substantially changed a new risk assessment is warranted.

Review date 11/02/2024 Reviewed by Sundar Authorized by Tariq al sebai

Notes: Include legal and advisory documentation that supports this risk assessment be listed. Such documentation includes Acts, Regulations, Standards, where applicable. If the risk assessment for an identified hazard is ranked ’Low’ but the regulatory

requirements have not been complied to while establishing and/or implementing controls, the ranking for the assesses risk shall be considered ‘Very High’

Risk Assessment Steps:

Step 1: Identify Hazards Title (e.g. Physical Hazard, Fire Hazard, and Electrical Hazards).

Step 2: List Hazards Details identified (e.g. Tripping Hazard, Flammable Materials stored, Working in Electrical Cabinets).

Step 3: List Causes of Hazard (e.g. Untidy workplace, Hot work, un-isolated electrical supply). Likelihood Descriptor to assist in Qualitative Assessment of Likelihood/ Frequency of Occurrence.

Step 4: List Consequences of Hazard (e.g. Personnel Injury, Fire, electric shock).

Step 5: Determine Likelihood and Consequences to People, Assets, Environment, and Reputation from attached Risk Assessment A Has occurred within port industry worldwide.

Matrix (Page 2) (this should be the most probable outcome without controls and should be listed as 2A, 3D etc.).

Step 6. Calculate the Risk Index using the Qualitative or Semi-Quantitative Risk Assessment Matrix as deemed appropriate. This is a B Has occurred regionally within port industry or judged likely to have occurred.

product of Likelihood and Consequence and should be stated Low, Medium, High or Very High).

Step 7. List Existing Controls. (e.g. Tidy Site Policy, Hot Work Permit, Isolation of Electrical Supply). C Has occurred in port industry within UAE or judged likely to have occurred.

Step 8. List Safety Critical Activities and Additional Controls that may be deemed necessary to reduce risk level to ALARP.

Step 9: Recalculate Likelihood and Consequences to People, Assets, Environment, and Reputation from attached Risk Assessment D

Matrix.

Has occurred in port industry within UAE on an annual basis or judged likely to have occurred.

Step 10. Recalculate the Risk Index. E

Step 11. If residual risk deemed to be High or Very High then risk must be reduced further before proceeding, if risk is medium then May occur in UAE port industry multiple times annually.

note that risk reduction must be planned, monitored and documented, if risk is low then risk is acceptable without required further

action.

* Risk Assessment Matrix – Qualitative LIKELIHOOD

ALARP

Consequences P= People A= Assets E= Environment R= Reputation A B C D E

VERY

5- Catastrophic Multiple fatalities Extensive damage Massive effect International impact

HIGH

Single fatality or

4 - Severe Major damage Major effect National impact HIGH

permanent disability

Major injury or health

3 – Critical Localized effect Localized effect Considerable impact MEDIUM

effects

Minor injury or health

2 – Marginal Minor effect Minor effect Minor impact

effects

Slight injury or health

1 - Negligible Slight effect Slight effect Slight impact LOW

effects

For additional information refer to HSE-COR-PRC-SYS-11 HSE Risks & Opportunities Management

CA-HSSE-HSE-FRM-011-02 (G) Rev. 02/03-Jan-2022

You might also like

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4763% (8)

- Fabrication Procrdure Metering SkidDocument11 pagesFabrication Procrdure Metering SkidgstketutNo ratings yet

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Document5 pagesMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- Pub - Physics For Scientists and Engineers Student Solut - Vol2 PDFDocument498 pagesPub - Physics For Scientists and Engineers Student Solut - Vol2 PDFjoselito67% (3)

- Gramática AwáDocument422 pagesGramática AwáJaghu San100% (1)

- 2900-232 - RA - Anti-Termite WorksDocument7 pages2900-232 - RA - Anti-Termite WorksSundarapandian NeelamegamNo ratings yet

- Jesa-Construction of Chemical Storage Shelter For CPP RegenDocument28 pagesJesa-Construction of Chemical Storage Shelter For CPP RegenResearcherNo ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- Co2 Cylinder House-JesaDocument24 pagesCo2 Cylinder House-JesaResearcherNo ratings yet

- CM Project Risk AssessmentDocument6 pagesCM Project Risk AssessmentangeloNo ratings yet

- (General Scaffolding JRADocument7 pages(General Scaffolding JRA891629No ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- Silo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment FormDocument9 pagesSilo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment Form891629100% (1)

- JRA No 10-110 Grading, Leveling and Cleaning of ROW For Zam-4 Flow LineDocument6 pagesJRA No 10-110 Grading, Leveling and Cleaning of ROW For Zam-4 Flow LineAijaz AhmedNo ratings yet

- 3 - JSA Loading Off LoadingDocument5 pages3 - JSA Loading Off LoadingAijaz AhmedNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Earth Work Risk AssessmentDocument5 pagesEarth Work Risk Assessmentabdelghafour megaacheNo ratings yet

- Job Risk Assessment JRA No: CE/QTLM/SCF/IS/0522/074Document8 pagesJob Risk Assessment JRA No: CE/QTLM/SCF/IS/0522/074891629No ratings yet

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- JRA 10-009 Concrete of Foundation FEC Switch RoomDocument5 pagesJRA 10-009 Concrete of Foundation FEC Switch RoomAijaz AhmedNo ratings yet

- JSA Format Internal ReactorDocument13 pagesJSA Format Internal Reactorsakthi venkatNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Safety: AnalysisDocument23 pagesSafety: AnalysisshahbazchafekarNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- JRA No 10-107 Installation of Nitrogen ReceiverDocument7 pagesJRA No 10-107 Installation of Nitrogen ReceiverAijaz AhmedNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- 2 RA 1410 Earth WorksDocument5 pages2 RA 1410 Earth WorksMuhammad Shahid Iqbal50% (2)

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- Jsa Cooling TowerDocument5 pagesJsa Cooling TowerRavi thokalNo ratings yet

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- Ra ChsDocument12 pagesRa ChsResearcherNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- RA Construction For Sub-Base & Road Base WorksDocument17 pagesRA Construction For Sub-Base & Road Base WorksBleep NewsNo ratings yet

- JHA For Maintenance of Floating Type Heat Exchanger 1Document10 pagesJHA For Maintenance of Floating Type Heat Exchanger 1imranrehman85No ratings yet

- JSA - Thrust BoringDocument17 pagesJSA - Thrust BoringAhmed AbdulfatahNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- JSA LandFill KHPT-BBB JODocument1 pageJSA LandFill KHPT-BBB JOICEDA HumNo ratings yet

- Daily JSA - Back Filling, Levelling and ComapactionDocument3 pagesDaily JSA - Back Filling, Levelling and Comapactionshoaib akhtarNo ratings yet

- JRA No 10-106 Installation of Dry Air Receiver VesselDocument6 pagesJRA No 10-106 Installation of Dry Air Receiver VesselAijaz AhmedNo ratings yet

- Construction of New Telecom BuildingDocument6 pagesConstruction of New Telecom BuildingZubair Ahmed KhaskheliNo ratings yet

- Risk Assessment - T&C For Medium Voltage SwitchgearDocument8 pagesRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad Irfan0% (1)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- 43 Equipment Erection (Static and Rotary)Document5 pages43 Equipment Erection (Static and Rotary)Hamza Dhariwal100% (1)

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- JRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampDocument4 pagesJRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampAijaz AhmedNo ratings yet

- JRA No 10-105 Installation of Distribution Panels at FEC AREADocument7 pagesJRA No 10-105 Installation of Distribution Panels at FEC AREAAijaz AhmedNo ratings yet

- Common JSA-Job Safety Analysis - 2024Document7 pagesCommon JSA-Job Safety Analysis - 2024Shovon khanNo ratings yet

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- New 2.hirac Matrix For ExerciseDocument9 pagesNew 2.hirac Matrix For Exercisejrchshn26No ratings yet

- Precast Lifting Risk Assessment (0075) - Rev-01Document8 pagesPrecast Lifting Risk Assessment (0075) - Rev-01Muhammad OsamaNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- JRA 10-001 Devlopment of Barrow AreaDocument5 pagesJRA 10-001 Devlopment of Barrow AreaAijaz AhmedNo ratings yet

- Generic RiskDocument15 pagesGeneric RiskSujith B100% (2)

- OET SpeakingDocument92 pagesOET SpeakingAnwaarNo ratings yet

- Developing On AwsDocument7 pagesDeveloping On Awsalton032No ratings yet

- Apache Kafka Quick Start GuideDocument180 pagesApache Kafka Quick Start GuidesleepercodeNo ratings yet

- Comprobante SantanderDocument26 pagesComprobante SantanderCristinaNo ratings yet

- Inventory TheoryDocument18 pagesInventory TheoryIsaac LeeNo ratings yet

- TrashDocument106 pagesTrashMakBuckNo ratings yet

- Incident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsDocument4 pagesIncident Investigation Report - Fire Incedent - 04-11-2018 Swati InteriorsMobin Thomas AbrahamNo ratings yet

- Phelps Corporation Received A Charter Granting The Right To IssueDocument3 pagesPhelps Corporation Received A Charter Granting The Right To IssueJalaj GuptaNo ratings yet

- Writing Task 11Document2 pagesWriting Task 11julee georgeNo ratings yet

- Ethio Lense CollegeDocument9 pagesEthio Lense CollegeAster AbrahaNo ratings yet

- OP AMPS HughesDocument8 pagesOP AMPS Hughesmarkos_mylonas4152No ratings yet

- M4164-C 06-15 - Etrinsa Technical Manual - MN031r2hq PDFDocument142 pagesM4164-C 06-15 - Etrinsa Technical Manual - MN031r2hq PDFMaria Lavinia IordacheNo ratings yet

- CL336: Advanced Transport Phenomena: Written Quiz - 1Document2 pagesCL336: Advanced Transport Phenomena: Written Quiz - 1LikhithNo ratings yet

- Superbrain Yoga: Impact On The Reading Comprehension and Behavior of Slow ReadersDocument8 pagesSuperbrain Yoga: Impact On The Reading Comprehension and Behavior of Slow ReadersPsychology and Education: A Multidisciplinary JournalNo ratings yet

- 801号房Document57 pages801号房Ludmila MironNo ratings yet

- Lexical Semantic Problems in TranslationDocument13 pagesLexical Semantic Problems in Translationvargas199511100% (2)

- Invenia ABUS 2.0 Release Notes - UM - 4700-0044-00 - 4Document24 pagesInvenia ABUS 2.0 Release Notes - UM - 4700-0044-00 - 4Jawad SandhuNo ratings yet

- Stat Fax 3300 Chemistry AnalyzerDocument2 pagesStat Fax 3300 Chemistry AnalyzermohamedNo ratings yet

- Encoder Serie Ria-40Document6 pagesEncoder Serie Ria-40Carlos NigmannNo ratings yet

- SOC FlyerDocument2 pagesSOC Flyersammer1985No ratings yet

- Multi-Threading Processes: The ConceptDocument5 pagesMulti-Threading Processes: The ConceptNenad KiticNo ratings yet

- Sistemi Embedded AA 2012/2013: SOPC Design FlowDocument9 pagesSistemi Embedded AA 2012/2013: SOPC Design Flowmeseret sisayNo ratings yet

- India Email IdsDocument3,365 pagesIndia Email IdsGandhi ManadalapuNo ratings yet

- Polarized Light MicrosDocument59 pagesPolarized Light MicrosAnonymous Ukn4LwNo ratings yet

- SolidCAM 2015 IMachining FAQDocument55 pagesSolidCAM 2015 IMachining FAQhed_panNo ratings yet

- Delcam - PowerINSPECT 2017 WhatsNew CNC RU - 2016Document40 pagesDelcam - PowerINSPECT 2017 WhatsNew CNC RU - 2016phạm minh hùngNo ratings yet

- Inv - 1124003027 - Po - 407097662 - VR - 407097662 - (Top Synthetic Rubber)Document1 pageInv - 1124003027 - Po - 407097662 - VR - 407097662 - (Top Synthetic Rubber)shamirah98No ratings yet