Professional Documents

Culture Documents

T&F Journal Ictacem

T&F Journal Ictacem

Uploaded by

Debasish BandyopadhyayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T&F Journal Ictacem

T&F Journal Ictacem

Uploaded by

Debasish BandyopadhyayCopyright:

Available Formats

Numerical Study of the Effect of Shear Connectors

in Insulated Sandwich Panel Building System

Devjit Acharjee Dibya Jyoti Basu Debasish Bandyopadhyay

Dept.of Construction Engineering Dept.of Construction Engineering Dept.of Construction Engineering

Jadavpur University Jadavpur University Jadavpur University

Kolkata, India Kolkata, India Kolkata, India

ORCID: 0000-0002-8454-9038 ORCID: 0000-0002-8454-9038 ORCID: 0000-0003-1968-701X

Abstract— Expanded polystyrene sandwich (EPS) Panels are contributed approximately 28% of the EPS panel's through-

one of the most advanced building systems currently accessible thickness shear strength [5]. The diameter of shear keys was

as an alternate solution for India's urgently needed affordable

housing. The structural stability of these structures, on the other increased to improve the through-thickness shear strength and

hand, is significantly dependent on these shear connectors' stiffness of EPS panels [4, 6, 7].

proper operation. The proposed paper looked into the effect of

spacing and alternative scenarios of shear connector failures, as The purpose of this study is to develop a FE model of an

well as the degradation of the bond between concrete and EPS panel to analyse its mechanical response and the impact

polystyrene core in EPS panels under flexure. It is also of shear keys, adopting static and dynamic analysis steps. The

attempted to perform a parametric study of the wall panel

thickness, reinforcement spacing, and grade of steel. It is panel is subjected to a three-point bending test using dynamic

observed that the structural stability of EPS panels depends on implicit analysis. The panel's through-thickness shear strength

the spacing, diameter and adequacies of the shear connectors. It improves with a higher reinforcing ratio. The use of better

seems that the insulated precast building panel structural

graded materials as shear keys increased its load-bearing

system has a great potential for practical implementation to

achieve the goal of efficient affordable housing. capacity. The typical buckling failure of shear keys is also

examined. The present study promises to evaluate EPS panel’s

Keywords—EPS Panel, Shear Connectors, Serviceability. flexural performance to achieve its safety and durability.

I. INTRODUCTION

II. NUMERICAL MODELLING

The need for energy has increased dramatically as industry

The EPS panel's geometry is represented by a square with

has grown. Residential energy consumption in India has

dimensions of 1000 mm X 1000 mm. The concrete cover is 35

climbed from 55% to over 80% in recent years [16]. The

mm thick and the polystyrene core is 60 mm thick. Fixed-fixed

growing depletion of natural resources for aggregate

boundary conditions are applied to the two opposing sides of

production, combined with rising global temperatures, has

the EPS panel. The concrete cover and polystyrene core are

compelled research into the best green building materials and

discretized using 3D stress brick components, while the

sustainable construction [7]. Expanded polystyrene sandwich

reinforcing steel is discretized using 2D truss elements [14].

(EPS) panels have grown in popularity as a result of its low

The M25 concrete cover, expanded polystyrene core, and FE

heat transmission, mechanical resilience, and long lifespan

500 steel reinforcements of 3 mm diameter are used in the

[3]. Shear keys in the reinforcing mesh control the shearing

primary numerical model of the EPS panel [2]. The

action between the concrete and polystyrene layers, as well as

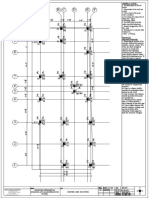

reinforcing mesh embedded in the EPS panel and the FE

composite action in EPS panels [1]. Choi et al [8] investigated

discretization is given respectively in Fig. 1. In both

the effects of changing composite action on stress variations

directions, the transverse shear connectors are kept 100 mm

in EPS panels. Literature [1] discusses various types of shear

apart (c to c). Assuming it as 100%, another FE model with

connectors that can be used to transport shear from the bottom

shear connectors spaced 200 mm apart (c to c) is considered

to the top layers of the composite. The impact of shear

50%. Table 1. shows the material properties for the basic

connectors on composite constructions has been extensively

model. Using the same dynamic step, the influence of material

explored by researchers and scientists [11, 12, 15]. The

mechanical characteristics, shear key diameter is investigated.

buckling and failure of shear connectors inside the panel, as

well as other mechanical parameters related to the flexural TABLE I. Material properties for the basic model

member's strength and stiffness [10], have all been examined

to develop more efficient shear connector design. Hodicky et

al. [9] looked into the effect of the percentage of reinforcement

on composite structure mechanical strength. With low shear

spacing, the structure was reported to be prone to flexural

cracks and fatal failure of the entire structure [7]. The

concrete-polystyrene bonding action, on the other hand,

XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEE

Information Classification: General

orienting the shear keys and using the appropriate adhesive

substance between the concrete and polystyrene layers.

.

Fig. 1. Reinforcement mesh & 3 point bending assembly

III. RESULTS AND DISCUSSIOINS

Fig. 2.Typical displacement contour of the panel under three-

This section of the study describes the findings of the point bending with 100% shear keys.

computational analysis. The failure pattern of the sandwich

panel under static loading is presented using the three-point

bending test (see Fig. 1). Regardless of the shear key features,

the lower concrete cover is found to be more prone to flexural

cracks. The first crack appears in the structure's shear span and

progresses to the top concrete layer [7]. The panel's flexural Fig. 3.Displacement contour (front view) through the EPS

behaviour is depicted by the displacement contour of the panel panel cross-section without shear keys.

during the three-point bending test, as shown in Fig. 2.

Shear sliding to some extent can be observed in the

composite interfaces. Higher tensile stress is found on the

shear keys; which further induces flexural cracks in the lower

concrete fibre. The first scenario has smaller shear key

spacing, whereas the others have wider spacing, and finally, a

model without shear keys is explored. The displacement

contour (refer to Fig.3) clearly illustrates the effect of critical Fig. 4.Load-deflection curve of sandwich panel with

shear sliding in EPS panels without shear keys. different % of shear keys

The effect of shear keys on the mechanical characteristics

of EPS panels can be seen in the standard load-deflection

curve (as shown in Fig. 4). The numerical evaluations resulted

in decreased load to deflection values with decreasing

reinforcing percentages, implying that the structure's flexural

strength decreases when shear reinforcement is reduced. The

degree of composite action may also have a significant

influence in this case. Without shear keys, the composite

Fig. 5.Load-deflection relation of sandwich panels varying

structure's performance has worsened significantly, as shown the grade of shear keys

in the figures (Fig. 4. & Fig. 5.). The flexural strength of

sandwich panels improves as the grade of reinforcing steel

increases. Better graded reinforcements in an EPS panel may

be able to minimize the thickness of the polystyrene core,

lowering the cost of constructing an EPS panel.

The study concludes with a dynamic explicit analysis step

that examines the composite panel under pure shear. Fixed

boundary conditions are applied (see Fig.1), and Fig. 6.Shear stress contour of the expanded polystyrene

insulated panel under pure shear

displacement-controlled loadings are given along the positive

z-axis. Using the typical shear stress contour of the composite

structure, the numerical result (as shown in Fig.6) of the EPS

panel under pure shear is demonstrated.

The reduction in bond strength between the concrete and

polystyrene interfaces is one of the main factors for the

emergence of flexural cracks in the lower concrete cover. The

shear load-displacement curve helps to explain this Fig. 7.Typical shear load-deflection curve of the insulated

panel under pure shear.

occurrence (refer Fig. 7). This can be solved by properly

Information Classification: General

The shear keys' buckling configuration is shown in Fig. 8. conductivity of expanded polystyrene at different

The cracks will migrate towards the upper face once apparent temperatures and densities.

surface cracks occur. Tension cracks will appear first, and this [4] Tomlinson, D.G., Teixeira, N., Fam, A. 2016. New Shear

might be considered as the first stage of stable crack Connector Design for Insulated Concrete Sandwich

propagation, necessitating the use of retrofitting procedures to Panels Using Basalt Fiber-Reinforced Polymer Bars. J.

restore serviceability. Compos. Constr. 20, 04016003.

[5] Woltman, G.D., Tomlinson, D.G., Fam, A. 2011. A

comparative study of various FRP shear connectors for

sandwich concrete walls. Adv. FRP Compos. Civ. Eng.

- Proc. 5th Int. Conf. FRP Compos. Civ. Eng. CICE

2010, 237–240.

Buckling of the shear connectors of the expanded

Fig. 8. [6] Jiang, H., Zhang, X., Shao, X., Bao, J. 2018. How do the

polystyrene panel under pure shear industrial structure optimization and urbanization

development affect energy consumption in Zhejiang

In flexure and shear testing, the numerical findings of this

province of China? Sustain.

work reveal the thickness-shear behaviour of composite

panels. Bond degradation is one of the major reasons for [7] Joseph, J. Daniel Ronald, Prabakar, J.,

structure failure, hence it's important to apply adhesive Alagusundaramoorthy, P. 2019. Experimental studies on

adequately between the surfaces. The current study appears to through- thickness shear behaviour of EPS based precast

be useful for predicting global structural responses of EPS concrete sandwich panels with truss shear connectors.

panels for application in real-time construction. Compos. Part B Eng. 166, 446–456.

[8] Choi, K.B., Choi, W.C., Feo, L., Jang, S.J., Yun, H. Do.

IV. CONCLUSIONS 2016. In-plane shear behavior of insulated precast

The numerical results from the present study has revealed concrete sandwich panels reinforced with corrugated

that the lower concrete fibre of the EPS panel is extremely GFRP shear connectors. Compos. Part B Eng. 79, 419-

vulnerable to tensile cracks, which would further propagate up 429.

to the final collapse. Under a pure shear load, the shear load- [9] Hodicky, K., Gopal, G., Rizkalla, S., Hulin, T., Stang, H.

displacement curve for the composite structure is 2015. Experimental and Numerical Investigation of the

approximately tri-linear (refer Fig. 7.); supporting the results FRP Shear Mechanism for Concrete Sandwich Panels. J.

of previous literature [7]. The failure of the shear keys is also Compos. Constr. 19, 04014083.

associated with the buckling of the members; as evident from

[10] Zhang, K., Varma, A.H., Malushte, S.R., Gallocher, S.

the results (refer Fig. 8.). It is found that the serviceability of

2014. Effect of shear connectors on local buckling and

the EPS panels declined with lower percentage of shear

composite action in steel concrete composite walls, Nucl.

reinforcement. Moreover, EPS panels with higher graded

Eng. Des. 269, 231–239.

shear keys achieved better flexural and shear strength. A full-

scale EPS panel wall could be analysed for future study. The [11] Kandil, M.A.E.N., Mahdy, M., Raheem, A.H.A.,

effect of door openings can also be studied along with Tahwia, A.M. 2020. Effect of shear connectors on

modifying material qualities, reinforcement diameter, and strength of structural sandwich panels. SN Appl. Sci. 2.

reinforcement mesh size. The present research seems to be [12] Limão, N. 2016. 국회선진화법’ 에 관한 보론 No Title’.

important for increasing the reliability of modular building

입법학연구 제 13 집 1 호, 31–48.

materials like EPS panels to create sustainable infrastructure.

[13] Ali, R.A., Abdelaziz, M.F. 2021. Simplified Analysis

REFERENCES

Method of 3D Sandwich Composite Panels Subjected to

[1] Christadoss, A., Pazhani, K.C., Sivasankar, S., Hareesh, Flexure 10, 268–272.

C.M. 2020. Numerical study on through thickness shear [14] Hibbitt D, S. P., Karlsson, B. 2001. ABAQUS/CAE

capacity of insulated sandwich panels. Mater. Today User’s Man. 1 and 2, 1–847.

Proc. 27, 1511–1515.

[15] Bush, T.D., Stine, G.L. 1994. Flexural Behavior of

[2] Dey, A., Roy, A., Ali, J.S. 2015. A computational static Composite Precast Concrete Sandwich Panels with

parametric study of a polystyrene sandwiched composite Continuous Truss Connectors. PCI J. 39, 112–121.

structural system. 2nd Int. 17th Natl. Conf. Mach. Mech.

Ma, X., Wang, M. C., Li. 2020. A summary on research

Ina. 2015 1–9.

of household energy consumption: A bibliometric

[3] Doǧan, B., Tan, H. 2019. The numerical and analysis. Sustain. 12.

experimental investigation of the change of the thermal

Information Classification: General

You might also like

- Landscape Detailing Volume 3 StructuresDocument277 pagesLandscape Detailing Volume 3 Structurest_49No ratings yet

- Magic Circular Vol.50 - 3Document26 pagesMagic Circular Vol.50 - 3FaeGiN100% (1)

- Concrete-Based Constrained Layer DampingDocument12 pagesConcrete-Based Constrained Layer DampingYongliang LiuNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Experimental Evaluation and Analysis of Flexural Response of Sandwich Beam Panels With An Expanded Polystyrene CoreDocument12 pagesExperimental Evaluation and Analysis of Flexural Response of Sandwich Beam Panels With An Expanded Polystyrene CoreSourav ChakrabortyNo ratings yet

- On The Shear Behavior of ECCDocument8 pagesOn The Shear Behavior of ECCShabnam ArabNo ratings yet

- Simplified Modelling of Timber - Framed Walls Under Lateral LoadsDocument10 pagesSimplified Modelling of Timber - Framed Walls Under Lateral LoadsIonFlorentaNo ratings yet

- Engineering Structures: Douglas Tomlinson, Amir FamDocument3 pagesEngineering Structures: Douglas Tomlinson, Amir FamAbdullah AnjumNo ratings yet

- Tesis Mirip 2Document11 pagesTesis Mirip 2Doddy UskonoNo ratings yet

- Flexural and Shear Behaviour of Layered Sandwich BeamsDocument14 pagesFlexural and Shear Behaviour of Layered Sandwich BeamsWahid FerdousNo ratings yet

- Comparative Study On Expanded Polystyrene (EPS) Core Reinforced Concrete Sandwich Panels Based and R.C.C Brick Infill StructureDocument9 pagesComparative Study On Expanded Polystyrene (EPS) Core Reinforced Concrete Sandwich Panels Based and R.C.C Brick Infill StructureIJRASETPublicationsNo ratings yet

- Finite Element Analysis of Thin Precast Concrete Sandwich PanelsDocument6 pagesFinite Element Analysis of Thin Precast Concrete Sandwich PanelsAristotle MedinaNo ratings yet

- Efficient Nonlinear Modeling of Strong Wood Frame Shear Walls For Mid-Rise BuildingsDocument15 pagesEfficient Nonlinear Modeling of Strong Wood Frame Shear Walls For Mid-Rise BuildingsCristian PNo ratings yet

- Axial Compression Behavior of A New Type of PrefabDocument7 pagesAxial Compression Behavior of A New Type of PrefabArunkumar sNo ratings yet

- Cement: Concrete CompositesDocument9 pagesCement: Concrete CompositesAdi PrasetyoNo ratings yet

- The Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneDocument11 pagesThe Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneVinh LENo ratings yet

- Construction and Building MaterialsDocument11 pagesConstruction and Building MaterialsMohammed H ShehadaNo ratings yet

- 1 s2.0 S0143974X19307886 MainDocument19 pages1 s2.0 S0143974X19307886 MainSiva GuruNo ratings yet

- 2017-Experimental and Numerical Investigations Into Seismic Performance of Timber-Steel Hybrid Structure With Supplemental DampersDocument12 pages2017-Experimental and Numerical Investigations Into Seismic Performance of Timber-Steel Hybrid Structure With Supplemental DampersGuillaumeHNONo ratings yet

- Journal of Constructional Steel Research: Z. Li, T. Li, Y. XiaoDocument14 pagesJournal of Constructional Steel Research: Z. Li, T. Li, Y. XiaoSaeed MohebbiNo ratings yet

- Experimental and Numerical Investigations of Steel-Polymer Hybrid Floor Ryu2018Document16 pagesExperimental and Numerical Investigations of Steel-Polymer Hybrid Floor Ryu2018juan diazNo ratings yet

- Analysis of Multi Storey Building by UsiDocument5 pagesAnalysis of Multi Storey Building by UsiHero Djoni SNo ratings yet

- Experimental Study On The Ferrocement PanelsDocument8 pagesExperimental Study On The Ferrocement PanelsIJRASETPublicationsNo ratings yet

- Numerical Simulation of Prestressed Precast Concrete Bridge Deck Panels Using Damage Plasticity ModelDocument10 pagesNumerical Simulation of Prestressed Precast Concrete Bridge Deck Panels Using Damage Plasticity ModelAnand RajNo ratings yet

- Colombo 2015Document11 pagesColombo 2015Daania RasoolNo ratings yet

- Construction and Building MaterialsDocument12 pagesConstruction and Building MaterialsSURIYA A (RA2012001010008)No ratings yet

- Axial Behavior of Reinforced Concrete Column With Ultra-High Performance Concrete Stay-In-Place FormworkDocument14 pagesAxial Behavior of Reinforced Concrete Column With Ultra-High Performance Concrete Stay-In-Place Formworknagham tariqNo ratings yet

- 119TOBCTJDocument8 pages119TOBCTJকিশলয়No ratings yet

- Literature Review: 1 General 1.1 Infill WallDocument23 pagesLiterature Review: 1 General 1.1 Infill WallhiveNo ratings yet

- Sun 2020Document10 pagesSun 2020shijumon8055No ratings yet

- Engineering Structures: Ehsan Nasiri, Yi LiuDocument14 pagesEngineering Structures: Ehsan Nasiri, Yi LiuMaruthish KvNo ratings yet

- Engineering Structures: Mohamed A. Shaheen, Konstantinos Daniel Tsavdaridis, Emad SalemDocument13 pagesEngineering Structures: Mohamed A. Shaheen, Konstantinos Daniel Tsavdaridis, Emad SalemprasanthNo ratings yet

- 1 s2.0 S0950061819328272 MainDocument14 pages1 s2.0 S0950061819328272 MainPraveen DevarajanNo ratings yet

- Flexural Behavior of Composite Reinforced Concrete Slurry-Infiltrated Mat Concrete (SIMCON) MembersDocument10 pagesFlexural Behavior of Composite Reinforced Concrete Slurry-Infiltrated Mat Concrete (SIMCON) MemberspicottNo ratings yet

- Literature ReviewDocument8 pagesLiterature ReviewAkhil RajagopalNo ratings yet

- Engineered Cementitious Composites For Structural ApplicationsDocument20 pagesEngineered Cementitious Composites For Structural ApplicationsPODNo ratings yet

- ZhangDocument14 pagesZhangConstanza CornejoNo ratings yet

- Experimental and Numerical Evaluation of MechanicaDocument5 pagesExperimental and Numerical Evaluation of Mechanicabeatrice santosNo ratings yet

- Seismic Behavior of Steel-Concrete Composite Structures: December 2019Document7 pagesSeismic Behavior of Steel-Concrete Composite Structures: December 2019Usha EngineeringNo ratings yet

- 14WCEE Paper SubmittedDocument8 pages14WCEE Paper SubmittedBtwo yousunkmybattleshipNo ratings yet

- Civil Project ReportDocument12 pagesCivil Project ReportAravindan KrishnamoorthyNo ratings yet

- Nonlinear Analysis Methods For Reinforced Concrete Buildings With Shear WallsDocument8 pagesNonlinear Analysis Methods For Reinforced Concrete Buildings With Shear Wallsakif-benzer-6764No ratings yet

- Flexural Response of Textile-Reinforced Sandwich Slab With Modified Polymeric CoreDocument12 pagesFlexural Response of Textile-Reinforced Sandwich Slab With Modified Polymeric Corehiraiimopoi29No ratings yet

- Engineering Structures: Bruno Dal Lago, Milot Muhaxheri, Liberato FerraraDocument19 pagesEngineering Structures: Bruno Dal Lago, Milot Muhaxheri, Liberato FerraraMohammad AkbarNo ratings yet

- $RSO3PEJDocument16 pages$RSO3PEJMaruthish KvNo ratings yet

- $% Bài Quan Trọng%Energy Absorption and in-plane Crushing Behavior of Aluminium ReinforcedDocument6 pages$% Bài Quan Trọng%Energy Absorption and in-plane Crushing Behavior of Aluminium ReinforcedNhanNo ratings yet

- CICM 2015 JAHER WASIM Full Paper Infill Wall Seismic ResponseDocument9 pagesCICM 2015 JAHER WASIM Full Paper Infill Wall Seismic ResponseZobair RabbaniNo ratings yet

- Monotonic Simulation of Fastener-Based Cold-Formed Steel Shear WallsDocument7 pagesMonotonic Simulation of Fastener-Based Cold-Formed Steel Shear WallsAB YADAVNo ratings yet

- On Engineered Cementitious Composites (ECC)Document16 pagesOn Engineered Cementitious Composites (ECC)BanNo ratings yet

- ASSIGNMENT - Retrofitting of Concrete Structures With Fiber-Reinforced Polymers (FRP) - Haikal Harith - 2023437158Document17 pagesASSIGNMENT - Retrofitting of Concrete Structures With Fiber-Reinforced Polymers (FRP) - Haikal Harith - 2023437158haikal harithNo ratings yet

- 1 s2.0 S0141029622002814 MainDocument13 pages1 s2.0 S0141029622002814 Main会爆炸的小米NoteNo ratings yet

- Flexural Behavior of Hollow RC Beam Using Glass FiberDocument10 pagesFlexural Behavior of Hollow RC Beam Using Glass FiberIJSTENo ratings yet

- PRELIMINARY FINDINGS ON SIZE EFFECT IN ECC Structural Members in FlexureDocument10 pagesPRELIMINARY FINDINGS ON SIZE EFFECT IN ECC Structural Members in FlexuresardarumersialNo ratings yet

- 1 s2.0 S095006182400432X MainDocument18 pages1 s2.0 S095006182400432X Mainanunciano GuterresNo ratings yet

- Finite Element Analysis of RC Beams With Externally Bonded Simcon Laminates by Using ANSYSDocument8 pagesFinite Element Analysis of RC Beams With Externally Bonded Simcon Laminates by Using ANSYSInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Effect of Material Used For Infill Wall and Its Shape On The Seismic Performance of RC FrameDocument11 pagesEffect of Material Used For Infill Wall and Its Shape On The Seismic Performance of RC FrameIJRASETPublicationsNo ratings yet

- Analytical Model For Seismic Simulation of Reinforced Concrete Coupled Shear WallsDocument19 pagesAnalytical Model For Seismic Simulation of Reinforced Concrete Coupled Shear WallsJorgeIngenieroNo ratings yet

- Composite Structures: Jiangdong Deng, Zhongguo John Ma, Airong Liu, Tianmin Zhou, Chao YouDocument12 pagesComposite Structures: Jiangdong Deng, Zhongguo John Ma, Airong Liu, Tianmin Zhou, Chao YouvardhangargNo ratings yet

- 7 VII July 2019Document11 pages7 VII July 2019Ivan RubioNo ratings yet

- Evaluate Performance of Precast Concrete Wall To Wall ConnectionDocument6 pagesEvaluate Performance of Precast Concrete Wall To Wall ConnectionRohan ReddyNo ratings yet

- Biomimetic Principles and Design of Advanced Engineering MaterialsFrom EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNo ratings yet

- Masters Thesis by Partha Roy - 001410602001-FinalDocument137 pagesMasters Thesis by Partha Roy - 001410602001-FinalDebasish BandyopadhyayNo ratings yet

- Iccms Sa PaperDocument1 pageIccms Sa PaperDebasish BandyopadhyayNo ratings yet

- JMMF 05Document15 pagesJMMF 05Debasish BandyopadhyayNo ratings yet

- Asis Dutta - Springer - 2022Document6 pagesAsis Dutta - Springer - 2022Debasish BandyopadhyayNo ratings yet

- GEGE 1st PAPER PRINTDocument12 pagesGEGE 1st PAPER PRINTDebasish BandyopadhyayNo ratings yet

- Dutta2021 Chapter StaticAnalysisOfThinRectangulaDocument11 pagesDutta2021 Chapter StaticAnalysisOfThinRectangulaDebasish BandyopadhyayNo ratings yet

- Dutta2021 Article AnalysisOfBeamsOnPasternakFounDocument12 pagesDutta2021 Article AnalysisOfBeamsOnPasternakFounDebasish BandyopadhyayNo ratings yet

- MOMRA ClassificationsDocument2 pagesMOMRA Classificationsahmed.atwanNo ratings yet

- Material and Construction CA1Document20 pagesMaterial and Construction CA1Amit DharaNo ratings yet

- Structural Excavation and BackfillDocument3 pagesStructural Excavation and BackfillBillal BhuttaNo ratings yet

- Boq 197761Document7 pagesBoq 197761soykhan999No ratings yet

- Case Study Preston Bus Station: Group 06: Anusha - Jithin - Nuthana AD-V Preetham - VaishnaviDocument19 pagesCase Study Preston Bus Station: Group 06: Anusha - Jithin - Nuthana AD-V Preetham - VaishnaviNuthana DNo ratings yet

- Print 012346789Document1 pagePrint 012346789REVIEW 360No ratings yet

- 04 01 Vlookup Exact Match 1Document7 pages04 01 Vlookup Exact Match 1Deepak SinghNo ratings yet

- Modern Architecture ResearchDocument5 pagesModern Architecture ResearchALAWI SSEKUBUNGANo ratings yet

- Method Statement For HVAC Ductwork Insulation and Acoustic LiningDocument3 pagesMethod Statement For HVAC Ductwork Insulation and Acoustic LiningDong VanraNo ratings yet

- PDS - Hydrotite CJ 0725 - 2018.04.02Document5 pagesPDS - Hydrotite CJ 0725 - 2018.04.02SBW ReportingNo ratings yet

- CIDB Guidelines On Handling, Transportation, Stacking and Installation of Precast ConcreteDocument58 pagesCIDB Guidelines On Handling, Transportation, Stacking and Installation of Precast ConcreteEVONNENo ratings yet

- Bored Micropile InstallationDocument24 pagesBored Micropile Installationbaoya sinoNo ratings yet

- Expose Diagrids RevDocument34 pagesExpose Diagrids RevÆon Teseract100% (2)

- Liberty Data Sheet 0717Document1 pageLiberty Data Sheet 0717Denisse Gasco Zegarra100% (1)

- Waterproofing of ToiletsDocument10 pagesWaterproofing of ToiletsRi SovannaphumiNo ratings yet

- Comparative Analysis of Concrete Strength Made From Selected Brands of Cement in Anambra State, NigeriaDocument11 pagesComparative Analysis of Concrete Strength Made From Selected Brands of Cement in Anambra State, NigeriaSulaimon DolapoNo ratings yet

- The Sinister Secret of Saltmarsh - Ghosts of SaltDocument6 pagesThe Sinister Secret of Saltmarsh - Ghosts of SaltberryNo ratings yet

- Bailey Bridge Field Manual No. 5-277 1986Document373 pagesBailey Bridge Field Manual No. 5-277 1986mengkheang31071999No ratings yet

- PDD-CT-93 Standard Design of Colony GateDocument1 pagePDD-CT-93 Standard Design of Colony Gateihsan ul haqNo ratings yet

- BGN 273 Climate ChangesDocument2 pagesBGN 273 Climate ChangesChe Wan Nur SyazlyanaNo ratings yet

- ARCH 719 Concrete Beam Design Project Assignment - InstructionsDocument2 pagesARCH 719 Concrete Beam Design Project Assignment - InstructionsKhushali ChaliawalaNo ratings yet

- Top of Roof Beam Ceiling Line LineDocument1 pageTop of Roof Beam Ceiling Line Linedominguez margieNo ratings yet

- Miter JointDocument2 pagesMiter JointSreekar ParimiNo ratings yet

- الصوت في المتاحفDocument12 pagesالصوت في المتاحفالمعماري ايمن عامرNo ratings yet

- Classification of BridgesDocument10 pagesClassification of BridgesABHISHEK NAVGIRENo ratings yet

- Architectural Style BangladeshDocument61 pagesArchitectural Style BangladeshJaber AbdullahNo ratings yet

- QAP VSE 11. IS Code List From MoRT&HDocument16 pagesQAP VSE 11. IS Code List From MoRT&HRayudu VVSNo ratings yet

- Center Line DrawingDocument1 pageCenter Line Drawingahmad anasNo ratings yet