Professional Documents

Culture Documents

Momentive Silicone

Momentive Silicone

Uploaded by

bilge0637Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Momentive Silicone

Momentive Silicone

Uploaded by

bilge0637Copyright:

Available Formats

Technical Data Sheet

RTV100 Series

RTV102, RTV103, RTV106, RTV108, RTV109, RTV112, RTV116, RTV118 Adhesive

Sealants

Description

RTV102, RTV103, RTV106, RTV108, RTV109, RTV112, RTV116 and RTV118

one-component, ready-to-use adhesive sealants are extremely versatile. They cure to a

tough, durable, resilient silicone rubber on exposure to atmospheric moisture at room

temperature. Acetic acid vapors are released from the sealant surface as a by-product

of cure.

RTV102, RTV103, RTV108 and RTV109 sealants are standard strength paste

consistency products which can be applied to vertical and overhead surfaces where

pourable/self-leveling sealants are not practical.

RTV112 and RTV118 sealants are self-leveling products which are preferable to paste-

consistency sealants when flow into small crevices and hard-to-reach places is desired.

RTV106 sealant is paste-consistency sealant. RTV116 sealant is a self-leveling

sealant. Both RTV106 and RTV116 sealants are standard strength high-temperature

sealants.

Since all these sealants utilize a moisture cure system, they must not be used in

thicknesses of greater than 6mm (1/4 in.).

Where section depths exceed 6mm (1/4 in.), Momentive Performance Materials one

component, addition cure or two-component silicone rubber compounds are

recommended.

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 1 of 12

RTV100 Series

Key Features and Benefits

One-component products

Capability to cure at room temperature and ambient humidity

Self adhesion properties

Low temperature flexibility

High temperature performance

Excellent weatherability and ozone and chemical resistance

Excellent electrical insulation properties

Typical Physical Properties

RTV102

RTV103 RTV112

Uncured Properties RTV106 RTV116

RTV108 RTV118

RTV109

Self

Consistency Paste Paste Self leveling

leveling

RTV102: White

RTV103: Black RTV112: White

Color Red Red

RTV108: Translucent RTV118: Translucent

RTV109: Aluminum

Viscosity, poises – – 250 200

Application Rate,

400 400 – –

(g/min)

Specific Gravity 1.05 1.07 1.09 1.05

Tack-Free Time,

20 20 30 20

minutes

RTV102

Cured RTV103 RTV112

RTV106 RTV116

Properties(1) RTV108 RTV118

RTV109

Mechanical:

Tensile Strength,

28 (400) 26 (375) 25 (350) 23 (325)

kg/cm2 (lb/in2)

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 2 of 12

RTV100 Series

Elongation, % 450 400 350 325

Hardness, Shore A 30 30 20 25

Tear Strength,

8 (45) 7 (40) – –

kg/cm (lb/in)

Shear Strength,

14 (200) 14 (200) 7 (125) 7 (100)

kg/cm2 (lb/in2)(2)

Peel Strength,

7 (40) 7 (40) 3 (25) 3 (15)

kg/cm (lb/in)(3)

Electrical:

Dielectric

Strength, 20 (500) 20 (500) 16 (400) 16 (400)

kv/mm (v/mil)

Dielectric

Constant 2.8 2.8 2.8 2.8

@ 60 Hz

Dissipation Factor

0.001 0.001 0.001 0.001

@ 60 Hz

Volume

Resistivity, 3x1015 3x1014 2x1014 6x1014

ohm-cm

Thermal:(4)

Brittle Point, °C

-60 (-75) -60 (-75) -60 (-75) -60 (-75)

(°F)

Maximum

continuous

204 (400) 260 (500) 260 (500) 204 (400)

operating

temperature, °C (°F)

Maximum

intermittent

260 (500) 315 (600) 315 (600) 260 (500)

operating

temperature, °C (°F)

Additional

Information:(4)

Linear Shrinkage,

1.0 1.0 1.0 1.0

%

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 3 of 12

RTV100 Series

Thermal

Conductivity, 0.0005 0.0005 0.0005 0.0005

cal/sec/cm2, °C/cm

(Btu/hr/ft2, °F/ft) (0.12) (0.12) (0.12) (0.12)

Coefficient of

Expansion 27x10-5 27x10-5 27x10-5 27x10-5

cm/cm, °C

(in/in, °F) (15x10-5) (15x-5) (15x-5) (15x-5)

(1) Cure time 3 days at 25°C (77°F) / 50% relative humidity.

(2) At 100% cohesive failure.

(3) At 100% cohesive failure using 1 in. x 8 in. stainless steel screen at 180° pull angle.

(4) Information is provided for customer convenience only. These properties are not

tested on a routine basis.

Potential Applications

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 4 of 12

RTV100 Series

Product Features Potential Applications UL Food Contact

RTV102 (White) General purpose bonding,

RTV103 (Black) sealing, electrical FDA 21 CFR

General

RTV108 insulation, formed- File 177.2600, USDA,

purpose

(Translucent) in-place gaskets. Can be 36952 NSF International

pastes

RTV109 applied to vertical or Std. No. 51

(Aluminum) overhead surfaces.

Sealing heating elements,

gasketing, electrical

insulation, and other FDA 21

High critical bonding and CFR177.2600,

File

RTV106 (Red) temperature sealing applications where USDA,

36952

paste parts must perform at high NSF International

temperatures. Can be Std. No. 51

applied to vertical or

overhead surfaces.

Thin section potting, filling

small surface voids,

self leveling protective FDA 21 CFR

High coating, electrical File 177.2600, USDA,

RTV116 (Red)

temperature insulation 36952 NSF International

where high Std. No. 51

temperature performance

is required.

Electrical insulation, thin

section potting, self

FDA 21 CFR

RTV112 (White) leveling

General File 177.2600, USDA,

RTV118 protective coatings. Will

purpose 36952 NSF International

(Translucent) flow into small crevices

Std. No. 51

and

hard to reach places.

These sealants were not designed for and should not be used for applications intended

for permanent implantation into the human body.

These sealants are not for use in delicate electrical and electronic applications in which

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 5 of 12

RTV100 Series

corrosion of copper, brass or other sensitive metals is undesirable.

Patent Status

Nothing contained herein shall be construed to imply the nonexistence of any relevant

patents or to constitute the permission, inducement or recommendation to practice any

invention covered by any patent, without authority from the owner of the patent.

Product Safety, Handling and Storage

Customers should review the latest Safety Data Sheet (SDS) and label for product

safety information, safe handling instructions, personal protective equipment if

necessary, emergency service contact information, and any special storage conditions

required for safety. Momentive Performance Materials (MPM) maintains an around-

the-clock emergency service for its products. SDS are available at

www.momentive.com or, upon request, from any MPM representative. For product

storage and handling procedures to maintain the product quality within our stated

specifications, please review Certificates of Analysis, which are available in the Order

Center. Use of other materials in conjunction with MPM products (for example, primers)

may require additional precautions. Please review and follow the safety information

provided by the manufacturer of such other materials.

Processing Recommendations

Surface Preparation

RTV102, RTV103, RTV106, RTV108, RTV109, RTV112, RTV116 and RTV118 sealants

will bond to many clean surfaces without the aid of primers. These surfaces typically

include many metals, glass, ceramic, silicone rubber and some rigid plastics. These

adhesive sealant products will also produce fair bonds to organic rubber and to some

flexible plastics not containing fugitive plasticizers (which migrate to the surface,

impairing adhesion). An evaluation should be made to determine bond strength for

each specific application. For difficult-to-bond substrates, use of a primer is suggested.

Primers SS4004, SS4044 and SS4179 are recommended for use with these sealants.

Complete information and usage instructions for these primer products are contained in

a separate product data sheet.

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 6 of 12

RTV100 Series

Where adhesion is required, surfaces should be thoroughly cleaned with a suitable

solvent such as naphtha or methyl ethyl ketone (MEK) to remove dirt, oil and grease.

The surface should be wiped dry before applying the adhesive sealant.

When solvents are used, proper safety precautions must be observed.

Application and Cure Time Cycle

Paste-consistency products may be applied directly to clean or primed substrates.

Where broad surfaces are to be mated, the sealant should be applied in a thin, less

than 6mm (1/4 in.) diameter, bead or ribbon around the edge of the surface to be

bonded.

Flowable products may be applied to clean or primed substrates by pouring directly

from the original container or dipping. These products will self-level on a surface, filling

small crevices and surface voids. Depth of potted sections should not exceed 6mm (1/4

in.).

The cure process begins with the formation of a skin on the exposed surface of the

sealant and progresses inward through the material. At 25°C (77°F) and 50% relative

humidity, RTV102, RTV103, RTV106, RTV108, RTV109, RTV112 and RTV116 sealants

will form a surface skin which is tack-free to the touch in 15 to 30 minutes. Once the

tack-free skin has begun to form, further tooling of the adhesive sealant is not

advisable.

Higher temperatures and humidity will accelerate the cure process low temperatures

and low humidity will slow the cure rate.

As the adhesive sealant cures, acetic acid vapors are released from the sealant

surface. The odor of acetic acid will completely disappear when curing is completed.

A 3mm (1/8 in.) section of adhesive sealant will cure through in approximately 24 hours

at 25°C (77°F) and 50% R.H. Since cure time increases with thickness, use of these

adhesive sealants should be limited to section thicknesses of 6mm (1/4 in.) or less.

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 7 of 12

RTV100 Series

Bond Strength Development

In addition to the effects of temperature and relative humidity, development of

maximum bond strength will depend on joint configuration, degree of confinement,

sealant thickness and substrate porosity. Normally, sufficient bond strength will develop

in 12 to 24 hours to permit handling of parts. Minimum stress should be applied to the

bonded joint until full adhesive strength is developed. Eventually the adhesive strength

of the bond will exceed the cohesive strength of the silicone rubber sealant itself.

Always allow maximum cure time available for best results.

PACKAGING AND DISPENSING

RTV adhesive sealants from Momentive Performance Materials are supplied ready-

to-use in collapsible aluminum squeeze tubes, caulking cartridges and in bulk

containers.

Collapsible aluminum tubes may be squeezed by hand or with the aid of mechanical

wringers which allow more complete removal of material from the tube. Air-operated

dispensing guns may also be used with aluminum tubes and offer the advantages of

improved control and faster application for production line use. The sealant may be

dispensed from caulking cartridges by using simple mechanical caulking guns or

air-operated guns. Air-operated guns will allow greater control and application speed.

Both tubes and cartridges are easy to use, can be put into production quickly and

require minimal capital investment.

Note: Do not exceed 45 psig when used in air-powered caulking guns.

Bulk containers require a larger initial investment in dispensing equipment, but offer the

most economical packaging for volume production. Bulk dispensing systems are

air-operated extrusion pumps coupled to hand or automated dispensing units. Pumps

which are specifically designed for pumping one-component RTV silicone rubber have

TEFLON® seals, packings and lined hoses to prevent moisture permeation and pump

cure problems.

CLEAN UP AND REMOVAL

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 8 of 12

RTV100 Series

Before curing, solvent systems such as naphtha or methyl ethyl ketone (MEK) are most

effective. Refer to solvent use warnings in the section on surface preparation.

After cure, selected chemical strippers which will remove the silicone rubber are

available from other manufacturers. Specific product information may be obtained on

request.

Limitations

Customers must evaluate Momentive Performance Materials products and make their

own determination as to fitness of use in their particular applications.

Specifications

FDA STATUS

RTV102, RTV103, RTV106, RTV108, RTV109, RTV112, RTV116 and RTV118

sealants are compositionally compliant with the requirements of 21 CFR 177.2600 –

Rubber articles intended for repeated use and have been found, through testing of a

representative sample, to meet the extractives limitations in 21 CFR 177.2600(e)

and/or (f).

Note: It is the responsibility of the user to determine that the final product complies with

the extractive limitations and other requirements of 21 CFR 177.2600 under their

specific manufacturing procedures.

BIOCOMPATABILITY STATUS

A representative sample of RTV 108 has passed USP Class VI (United States

Pharmacopoeia USP 23, National Formulary 18, 1995).

A representative sample of RTV 118 has passed USP Class VI (United States

Pharmacopoeia USP 23, National Formulary 18, 1995).

USDA STATUS

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 9 of 12

RTV100 Series

RTV102, RTV103, RTV106, RTV108, RTV109, RTV112, RTV116 and RTV118 sealants

may be used on equipment which may contact edible products in official

establishments operating under the Federal meat and poultry products inspection

program. See USDA letter of Authorization.

NSF INTERNATIONAL STATUS

NSF International lists RTV102, RTV103, RTV106, RTV108, RTV109, RTV112,

RTV116 and RTV118 sealants under NSF International Standard No. 51 (Plastic

Materials and Components for Use in Food Equipment), as satisfactory for use on food

contact surfaces.

UL STATUS

RTV102, RTV103, RTV106, RTV108, RTV109, RTV112, RTV116 and RTV118 silicone

rubber adhesive sealants are recognized by Underwriters Laboratories, Inc., under their

Component Recognition Program (UL File No. E-36952).

MILITARY SPECIFICATION

MIL-A-46106

Group I Type I General Purpose Paste: RTV102, RTV103, RTV108, RTV109

Type II General Purpose Flowable: RTV112, RTV118

Group III Type I High Temperature Paste: RTV106

Type II High Temperature Flowable: RTV116

Testing for referenced MIL Spec is performed in accordance with current Momentive

Performance Materials quality test methods, laboratory conditions, and procedures,

frequency and sampling, which are not necessarily identical with the methods,

conditions, procedures, frequency and sampling stated or referenced in the listed

specification. Any certification will be limited to listed properties and will not imply or

state conformity to any other aspect of the referenced specification, including but not

limited to marking, packaging, bar coding, testing, or sampling. Contact Momentive

Performance Materials for a comparison review.

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 10 of 12

RTV100 Series

Contact Information

Email

commercial.services@momentive.com

Telephone

Americas Latin America EMEAI- Europe, Middle ASIA PACIFIC

East, Africa & India

+1 800 295 2392 Brazil Europe China

Toll free* +55 11 4534 9650 +390510924300 800 820 0202

+704 805 6946 Direct Number Direct number Toll free

Direct Number +86 21 3860 4892

Direct number

*All American Mexico India, Middle East & Japan

countries +52 55 2169 7670 Africa +81 3 5544 3111

Direct Number + 91 44 71212207 Direct number

Direct number*

*All Middle Eastern Korea

countries, Africa, India, +82 2 6201 4600

For literature and technical assistance, visit our website at: www.momentive.com

DISCLAIMER:

THE MATERIALS, PRODUCTS AND SERVICES OF MOMENTIVE PERFORMANCE

MATERIALS INC. AND ITS SUBSIDIARIES AND AFFILIATES (COLLECTIVELY

“SUPPLIER”), ARE SOLD SUBJECT TO SUPPLIER’S STANDARD CONDITIONS

OF SALE, WHICH ARE INCLUDED IN THE APPLICABLE DISTRIBUTOR OR

OTHER SALES AGREEMENT, PRINTED ON THE BACK OF ORDER

ACKNOWLEDGMENTS AND INVOICES, AND AVAILABLE UPON REQUEST.

ALTHOUGH ANY INFORMATION, RECOMMENDATIONS, OR ADVICE CONTAINED

HEREIN IS GIVEN IN GOOD FAITH, SUPPLIER MAKES NO WARRANTY OR

GUARANTEE, EXPRESS OR IMPLIED, (i) THAT THE RESULTS DESCRIBED

HEREIN WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE

EFFECTIVENESS OR SAFETY OF ANY DESIGN INCORPORATING ITS

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 11 of 12

RTV100 Series

PRODUCTS, MATERIALS, SERVICES, RECOMMENDATIONS OR ADVICE.

EXCEPT AS PROVIDED IN SUPPLIER’S STANDARD CONDITIONS OF SALE,

SUPPLIER AND ITS REPRESENTATIVES SHALL IN NO EVENT BE RESPONSIBLE

FOR ANY LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS

OR SERVICES DESCRIBED HEREIN. Each user bears full responsibility for making

its own determination as to the suitability of Supplier’s materials, services,

recommendations, or advice for its own particular use. Each user must identify and

perform all tests and analyses necessary to assure that its finished parts incorporating

Supplier’s products, materials, or services will be safe and suitable for use under

end-use conditions. Nothing in this or any other document, nor any oral

recommendation or advice, shall be deemed to alter, vary, supersede, or waive any

provision of Supplier’s standard Conditions of Sale or this Disclaimer, unless any such

modification is specifically agreed to in a writing signed by Supplier. No statement

contained herein concerning a possible or suggested use of any material, product,

service or design is intended, or should be construed, to grant any license under any

patent or other intellectual property right of Supplier covering such use or design, or as

a recommendation for the use of such material, product, service or design in the

infringement of any patent or other intellectual property right.

The use of the “™” symbol designates registered or unregistered trademarks of Momentive Performance Materials Inc. or its

affiliated companies. Momentive and the Momentive logo are trademarks of Momentive Performance Materials Inc.

HCD-RTV100 Series (Rev. 2021-05-05 1:44 PM) Page 12 of 12

You might also like

- Proof of Cash ProblemDocument3 pagesProof of Cash ProblemKathleen Frondozo71% (7)

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- DSG 18 21 Parts Manual 33 PgsDocument33 pagesDSG 18 21 Parts Manual 33 PgskacemNo ratings yet

- Multiplication Table 1 To 60Document8 pagesMultiplication Table 1 To 60Matilda Duncan100% (1)

- Rtv1xx Tech Data SheetDocument6 pagesRtv1xx Tech Data SheetAnonymous VNu3ODGavNo ratings yet

- RTV160, RTV162 and RTV167 Electronic Grade Silicone Adhesive SealantsDocument4 pagesRTV160, RTV162 and RTV167 Electronic Grade Silicone Adhesive SealantspokleNo ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- Thermosolo GS: Description and Scope of ApplicationDocument2 pagesThermosolo GS: Description and Scope of ApplicationCatalin FilipNo ratings yet

- 1.16 Supresor de Picos Titan E120X120Document2 pages1.16 Supresor de Picos Titan E120X120SEBASTIAN PAEZ VALENCIANo ratings yet

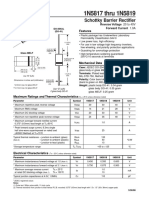

- 1N5817 Thru 1N5819: Schottky Barrier RectifierDocument2 pages1N5817 Thru 1N5819: Schottky Barrier Rectifierjohn9999_502754No ratings yet

- Fluon® ETFE Film - Advanced Fluoropolymer Film-V0.1Document10 pagesFluon® ETFE Film - Advanced Fluoropolymer Film-V0.1White_rabbit2885764No ratings yet

- Topcable Powerflex RV-K enDocument2 pagesTopcable Powerflex RV-K enreivin27No ratings yet

- Conector Encoder FrezadoraDocument23 pagesConector Encoder FrezadoragilbertoNo ratings yet

- D25XB40 ........ D25XB100 25 Amp. Glass Passivated Single Phase in Line Bridge RectifierDocument4 pagesD25XB40 ........ D25XB100 25 Amp. Glass Passivated Single Phase in Line Bridge RectifierAlejandro RomeroNo ratings yet

- WAGO 750-600enDocument6 pagesWAGO 750-600enFirmanNo ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesFirman TopNo ratings yet

- Tecsun Duo (PV) Tecsun Duo (PV) S: Twin Cables For PhotovoltaicsDocument8 pagesTecsun Duo (PV) Tecsun Duo (PV) S: Twin Cables For PhotovoltaicsAdrian Martin BarrionuevoNo ratings yet

- Technical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Document5 pagesTechnical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Sami LAHMIDINo ratings yet

- ILED Aquarius Perimeter Light Specification Sheet 1Document4 pagesILED Aquarius Perimeter Light Specification Sheet 1bakien-canNo ratings yet

- Semi-Rotary Drive DFPD-20-RP-90-RD-F04: Data SheetDocument4 pagesSemi-Rotary Drive DFPD-20-RP-90-RD-F04: Data SheetŁukasz OlszewskiNo ratings yet

- MATERIAL SPECIFICATION DuranexDocument7 pagesMATERIAL SPECIFICATION Duranexhamdany danyNo ratings yet

- Datasheet MomentiveDocument5 pagesDatasheet Momentivehuynh thi y viNo ratings yet

- 1 Watt Glass Case Zener Diodes: 1N3016B-1 - 1N3045B-1Document5 pages1 Watt Glass Case Zener Diodes: 1N3016B-1 - 1N3045B-1StuxnetNo ratings yet

- White High Efficiency HD IP67: AdonisDocument6 pagesWhite High Efficiency HD IP67: AdonisShoeb UndreNo ratings yet

- En Iso Mattex Geomatt TB - I-25!08!2013Document1 pageEn Iso Mattex Geomatt TB - I-25!08!2013FarhatNo ratings yet

- 1 Watt Glass Case Zener Diodes: 1N3016B-1 - 1N3045B-1Document5 pages1 Watt Glass Case Zener Diodes: 1N3016B-1 - 1N3045B-1Otto AndradeNo ratings yet

- Sikafloor 235 Esd ENGDocument5 pagesSikafloor 235 Esd ENGvalentin.hernandezNo ratings yet

- Specialty Plastics: Polyvinylfluoride (PVF)Document14 pagesSpecialty Plastics: Polyvinylfluoride (PVF)Akash YadavNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- DMW FL PDFDocument2 pagesDMW FL PDFjose luisNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- Transformer Manufacturer EnquiryDocument26 pagesTransformer Manufacturer EnquiryblaagicaNo ratings yet

- Vishay Dale ResistorsDocument8 pagesVishay Dale Resistorsalko123No ratings yet

- RGP10A, RGP10B, RGP10D, RGP10G, RGP10J, RGP10K, RGP10M: Vishay General SemiconductorDocument4 pagesRGP10A, RGP10B, RGP10D, RGP10G, RGP10J, RGP10K, RGP10M: Vishay General SemiconductorDelos Santos JojoNo ratings yet

- IMT Aquarius Perimeter Light ELPZ5AP0E243 Catalogo DatasheetDocument4 pagesIMT Aquarius Perimeter Light ELPZ5AP0E243 Catalogo Datasheetshahrol effendy rodziNo ratings yet

- Product Specifications Product Specifications: HWXX HWXX - 6516DS - VTM VTM 6515DS 6515DSDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS - VTM VTM 6515DS 6515DSИван КадигробNo ratings yet

- Repsol Alcudia PE046Document1 pageRepsol Alcudia PE046armandoestavanquitoNo ratings yet

- Product Specifications Product Specifications: HWXX HWXX - 6516DS1 6516DS1 - VTM VTMDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS1 6516DS1 - VTM VTMBenjamin GilNo ratings yet

- Item Conductive Tile Static-Disiipative TileDocument3 pagesItem Conductive Tile Static-Disiipative Tilebheemannadora sappaNo ratings yet

- Tech Data Sheet Siltech 100HV: Typical PropertiesDocument2 pagesTech Data Sheet Siltech 100HV: Typical PropertiesVictor Rocha ZavaletaNo ratings yet

- Rgp02-Xxe: Vishay General SemiconductorDocument4 pagesRgp02-Xxe: Vishay General SemiconductorTuan ThanhNo ratings yet

- Product CAT RSTI SA - DatasheetDocument9 pagesProduct CAT RSTI SA - Datasheetvikivarma147No ratings yet

- Elettrotek Kabel GAALFLEXDocument2 pagesElettrotek Kabel GAALFLEXIvan NikodijevicNo ratings yet

- VG1000Document57 pagesVG1000Yralba PalaNo ratings yet

- NCS-30 Jet LubeDocument1 pageNCS-30 Jet LubemichNo ratings yet

- FSD350PP DatasheetDocument3 pagesFSD350PP DatasheetDale XiaoNo ratings yet

- Exact 8201Document2 pagesExact 8201Kashif MuhammadNo ratings yet

- Sikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetDocument3 pagesSikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetKhin Sandi KoNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- D 4 SBDocument4 pagesD 4 SBinmortaljcNo ratings yet

- Data Sheet: 4x2x0,22snDocument2 pagesData Sheet: 4x2x0,22snSerhiy ShvaykaNo ratings yet

- Product Specifications Product Specifications: HWXX HWXX - 6516DS 6516DS - VTM VTMDocument2 pagesProduct Specifications Product Specifications: HWXX HWXX - 6516DS 6516DS - VTM VTMЕвгений ГрязевNo ratings yet

- DBXLH 9090C VTMDocument3 pagesDBXLH 9090C VTMMuhammad MumtazNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Prefabricated Vertical Drain For Soft Ground Improvement: Verti-Drain Is DAEHAN's Registered TrademarkDocument6 pagesPrefabricated Vertical Drain For Soft Ground Improvement: Verti-Drain Is DAEHAN's Registered Trademark김경모No ratings yet

- ZALUX Datasheet ACQUEX 301020Document2 pagesZALUX Datasheet ACQUEX 301020Charlie MendozaNo ratings yet

- A5HF-D Product SpecificationsDocument4 pagesA5HF-D Product SpecificationsRobert MurphyNo ratings yet

- Filmtec BW30-2540Document3 pagesFilmtec BW30-2540PT Deltapuro IndonesiaNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Blacktown Boys Ext 1 Trial 2020Document22 pagesBlacktown Boys Ext 1 Trial 2020Kevin FineNo ratings yet

- Mental Health & Wellbeing For Children & Young People - Part TwoDocument24 pagesMental Health & Wellbeing For Children & Young People - Part Twomariya khanNo ratings yet

- The Spirit of Cimm GroupDocument26 pagesThe Spirit of Cimm GroupMuhammad Riaz, 0092-3138432432No ratings yet

- Relé AZ820-2C-5DE (Ring)Document2 pagesRelé AZ820-2C-5DE (Ring)Diego OliveiraNo ratings yet

- DD 1 3 PracticeDocument3 pagesDD 1 3 PracticeJessica IreneNo ratings yet

- Childhood SchizophreniaDocument14 pagesChildhood SchizophreniaAnalia WriterNo ratings yet

- Activity2-3 (Tan Rosalinda G.-BS-ARCH2A)Document4 pagesActivity2-3 (Tan Rosalinda G.-BS-ARCH2A)Rosalinda TanNo ratings yet

- 6.7 NotesDocument9 pages6.7 NoteszufaroaaNo ratings yet

- Baeng 102Document7 pagesBaeng 102Chinni ChinniNo ratings yet

- Digital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Document236 pagesDigital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Paolo Fasselli100% (1)

- Instant Download Mri in Practice 4th Edition Ebook PDF PDF FREEDocument15 pagesInstant Download Mri in Practice 4th Edition Ebook PDF PDF FREEronald.dancy562100% (52)

- 3rdquarter SummativeDocument6 pages3rdquarter SummativeJig Pael FaburadaNo ratings yet

- Literary Analysis Final DraftDocument4 pagesLiterary Analysis Final Draftapi-645801422No ratings yet

- PriyankaDocument2 pagesPriyankaPriyanka AmazonNo ratings yet

- HUAWEI IdeaHub S2 Datasheet (Simplified Edition) - For PrintingDocument10 pagesHUAWEI IdeaHub S2 Datasheet (Simplified Edition) - For PrintingJuan Francisco AriasNo ratings yet

- Basic Naval Architecture Instructors Guide and Problem Set PDFDocument415 pagesBasic Naval Architecture Instructors Guide and Problem Set PDFnauval.arch100% (1)

- Urooj CV For TeachingDocument1 pageUrooj CV For TeachingUrooj ShamsNo ratings yet

- Amot - Safety Shutdown Device - Model 2800DDocument8 pagesAmot - Safety Shutdown Device - Model 2800DSamet KarabayNo ratings yet

- Kinder-New-DLL Week31 - Day1Document4 pagesKinder-New-DLL Week31 - Day1Glaiza BadenasNo ratings yet

- Resilient Marketing Ebook FDocument20 pagesResilient Marketing Ebook Fmaneesh mittalNo ratings yet

- Vessel InformationDocument241 pagesVessel InformationNayem PoshariNo ratings yet

- People StrategyDocument2 pagesPeople StrategyRiddhi SinghalNo ratings yet

- Corrosion Prediction and Material Selection For Sulfuric Acid Alkylation UnitsDocument4 pagesCorrosion Prediction and Material Selection For Sulfuric Acid Alkylation Unitssandrine guerinNo ratings yet

- What Is ABM Strand?: Acquire Basic Industry SkillsDocument6 pagesWhat Is ABM Strand?: Acquire Basic Industry SkillsAngelaNo ratings yet

- EDAG0007Document5 pagesEDAG0007krunalNo ratings yet

- Heating Vent Lighting SE7542Document48 pagesHeating Vent Lighting SE7542sairajNo ratings yet

- Agilent Dual Directional Coupler 778D 100 To 2000 MHZ: Data SheetDocument4 pagesAgilent Dual Directional Coupler 778D 100 To 2000 MHZ: Data Sheetdanilo espinozaNo ratings yet