Professional Documents

Culture Documents

30 JET-40 (4 CYL) (90-814676R1) SN US 0C159200 AND UP-BE 9570305 AND UP - Pages.1 10

30 JET-40 (4 CYL) (90-814676R1) SN US 0C159200 AND UP-BE 9570305 AND UP - Pages.1 10

Uploaded by

mendozamontesjoseCopyright:

Available Formats

You might also like

- Mercury Service Manual 40 50 55 60 90 PDFDocument566 pagesMercury Service Manual 40 50 55 60 90 PDFbilly_gfroerer86% (14)

- MERCURY Outboard 40-50-60 4 Stroke Service ManualDocument589 pagesMERCURY Outboard 40-50-60 4 Stroke Service ManualDoug89% (9)

- Mercury 115 Service ManualDocument4 pagesMercury 115 Service ManualPat Balmos18% (11)

- Mercruiser Service Manual GM V6 4.3 CompleteDocument895 pagesMercruiser Service Manual GM V6 4.3 CompletePaul Chuon94% (16)

- Mercury 175xr2 SportJet Service ManualDocument207 pagesMercury 175xr2 SportJet Service ManualMarian Ariciuc100% (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them86% (7)

- 5206582-Instant Download Mercury Mercruiser 5 0l 5 7l 6 2l Service Repair Manual 2001-2006 BoatDocument636 pages5206582-Instant Download Mercury Mercruiser 5 0l 5 7l 6 2l Service Repair Manual 2001-2006 Boatdanlandry1100% (10)

- Mercury 30 - 40hp Service OEM ManualDocument532 pagesMercury 30 - 40hp Service OEM Manualwboerema100% (1)

- Service Manual #29Document537 pagesService Manual #29CharlesWhiteNo ratings yet

- MerCruiser #30 90-863161 09:00 PDFDocument355 pagesMerCruiser #30 90-863161 09:00 PDFRandall Petterson100% (3)

- Merc Service Manual 28 Bravo Stern DrivesDocument596 pagesMerc Service Manual 28 Bravo Stern DrivesHayduke them84% (19)

- Manual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveDocument100 pagesManual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveWallace Ferlim100% (7)

- Mercury Outboard Engine Service ManualDocument149 pagesMercury Outboard Engine Service ManualGlen Lewis100% (2)

- 40-50 Mercury Manual PDFDocument599 pages40-50 Mercury Manual PDFjasleen80% (5)

- 225-225 EFI - 50 EFI-3.0 Litre Marathon-3.0 Litre SeaPro United States-With Serial Numbers 0D280813 and AboveDocument639 pages225-225 EFI - 50 EFI-3.0 Litre Marathon-3.0 Litre SeaPro United States-With Serial Numbers 0D280813 and AboveMomed MdNo ratings yet

- Mercury Mercruiser #25 Service Manual Marine Engines GM v-6 262 CID (4.3L) (PDF, EnG, 9.97 MB)Document755 pagesMercury Mercruiser #25 Service Manual Marine Engines GM v-6 262 CID (4.3L) (PDF, EnG, 9.97 MB)Lucas Oliveira100% (1)

- Mercury Repair ManualDocument638 pagesMercury Repair ManualJames Hicks100% (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- 40 60 PDFDocument547 pages40 60 PDFDiego Arcos67% (3)

- Mercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFDocument364 pagesMercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFVit100% (1)

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- Mercury 40-50-55-60 Service Repair ManualDocument4 pagesMercury 40-50-55-60 Service Repair ManualRyan ActonNo ratings yet

- Verado 200-275 Workshop-1Document90 pagesVerado 200-275 Workshop-1Servicios Luna LSNo ratings yet

- 1992-2000.mercury Mariner Outboard 105-225 Service Manual Sprotetto PDFDocument797 pages1992-2000.mercury Mariner Outboard 105-225 Service Manual Sprotetto PDFRoberto Implatini100% (5)

- Service Manual: Models 45 Jet 50 55 60 45 Jet 50 55 Marathon 55 Seapro 60 60 Big Foot 60 Marathon 60 SeaproDocument565 pagesService Manual: Models 45 Jet 50 55 60 45 Jet 50 55 Marathon 55 Seapro 60 60 Big Foot 60 Marathon 60 SeaproPaul Martin100% (2)

- Mercury 135:150:175:20:225HP XR6 Magnum II EFI Pro Max Super Magnum 90-824052R2 09:97 PDFDocument824 pagesMercury 135:150:175:20:225HP XR6 Magnum II EFI Pro Max Super Magnum 90-824052R2 09:97 PDFRandall Petterson100% (4)

- Mercury Mariner 4, 5, 6 4 Stroke Sevice ManualDocument260 pagesMercury Mariner 4, 5, 6 4 Stroke Sevice ManualDenisovgabNo ratings yet

- 75-75 MARATHON-75 SEA PRO-90 - 100-115-125-65-80 JET With Serial Numbers United States - 0D283222 and Above Belgium - 09793577 and Above PDFDocument585 pages75-75 MARATHON-75 SEA PRO-90 - 100-115-125-65-80 JET With Serial Numbers United States - 0D283222 and Above Belgium - 09793577 and Above PDFjay hixNo ratings yet

- Mercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFDocument364 pagesMercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFVitNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- 30 40MDocument333 pages30 40MDouglas Duarte100% (2)

- SM - 3.0L - 4cycl PDFDocument420 pagesSM - 3.0L - 4cycl PDFtableNo ratings yet

- Service Manual Outline: Section 1 - Important InformationDocument420 pagesService Manual Outline: Section 1 - Important InformationAngel Alvarez100% (1)

- Service Manual Outline: Section 1 - Important InformationDocument20 pagesService Manual Outline: Section 1 - Important InformationНиколай АксёновNo ratings yet

- Motor de Popa - IntroducaoDocument337 pagesMotor de Popa - IntroducaoSilveirabmNo ratings yet

- 4.3L-262CID (4.3L) (90-861328-1) .Pages.1 20 PDFDocument20 pages4.3L-262CID (4.3L) (90-861328-1) .Pages.1 20 PDFSerge MichelNo ratings yet

- Service Manual #28Document688 pagesService Manual #28CharlesWhiteNo ratings yet

- 135-150-175-200 With Serial Numbers United States - 0G960500 and AboveDocument638 pages135-150-175-200 With Serial Numbers United States - 0G960500 and AbovePAVLOSNo ratings yet

- 135-175 VeradoDocument3 pages135-175 Verado이영석50% (2)

- Service Manual OutlineDocument20 pagesService Manual OutlineJorge LopesNo ratings yet

- 4.2L (LD) DieselDocument641 pages4.2L (LD) Dieselhcmotores1No ratings yet

- Cover PDFDocument3 pagesCover PDFJim LassNo ratings yet

- Mercury 30hpDocument332 pagesMercury 30hpJorge LopesNo ratings yet

- Service Manual #27 SupplimentDocument271 pagesService Manual #27 SupplimentCharlesWhiteNo ratings yet

- Starting Model Year 2000-200-225 OptiMax-Direct Fuel Injection-Starting Serial Number OG960500Document745 pagesStarting Model Year 2000-200-225 OptiMax-Direct Fuel Injection-Starting Serial Number OG960500myinves00No ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceFrom EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Solution Techniques For Models Yielding Ordinary Differential Equations (ODE)Document67 pagesSolution Techniques For Models Yielding Ordinary Differential Equations (ODE)Nikhil DewalkarNo ratings yet

- 10 Best JobsitesDocument14 pages10 Best JobsitesHemansu PathakNo ratings yet

- Power Electronics: Thyristor Controlled Power For Electric MotorsDocument10 pagesPower Electronics: Thyristor Controlled Power For Electric Motorsshahab moinNo ratings yet

- Experiencing Postsocialist CapitalismDocument251 pagesExperiencing Postsocialist CapitalismjelisNo ratings yet

- OptiMix - Manual - EN - Rev.03.05 (Mixer)Document89 pagesOptiMix - Manual - EN - Rev.03.05 (Mixer)Đức Nguyễn100% (2)

- Latest Volleyball News From The NCAA and NAIADocument3 pagesLatest Volleyball News From The NCAA and NAIAFernan RomeroNo ratings yet

- EC Physical Sciences Grade 11 November 2022 P1 and MemoDocument25 pagesEC Physical Sciences Grade 11 November 2022 P1 and MemokhulntandoNo ratings yet

- Housekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesDocument8 pagesHousekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesMehwish FatimaNo ratings yet

- Paul CooksDocument4 pagesPaul CooksMicNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- B94-6 R1995 E1984Document21 pagesB94-6 R1995 E1984zojoNo ratings yet

- B.inggris-Daily ActivitiesDocument11 pagesB.inggris-Daily ActivitiesDadang SopianNo ratings yet

- Thrift Banks ActDocument25 pagesThrift Banks ActMadelle Pineda100% (1)

- CentrifugationDocument10 pagesCentrifugationBk FNo ratings yet

- OrganoLithium ReagentDocument6 pagesOrganoLithium ReagentizaowsikNo ratings yet

- WRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkDocument2 pagesWRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkFatmah El WardagyNo ratings yet

- Ged Test Accom App AdhdDocument7 pagesGed Test Accom App AdhdJeannette DorfmanNo ratings yet

- Getting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFDocument7 pagesGetting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFoktaNo ratings yet

- Activity Sheets Signal WordsDocument15 pagesActivity Sheets Signal WordsGrace Ann EscabarteNo ratings yet

- 1231.322 323 MSDS Sabroe 1507-100 MSDSDocument6 pages1231.322 323 MSDS Sabroe 1507-100 MSDSzhyhhNo ratings yet

- Agile TestingDocument5 pagesAgile TestingAman YadavNo ratings yet

- Ebook Digital Marketing PDF Full Chapter PDFDocument67 pagesEbook Digital Marketing PDF Full Chapter PDFamy.farley40997% (33)

- Flexural Test of Concrete Beam SpecimenDocument6 pagesFlexural Test of Concrete Beam SpecimenJenevive TumacderNo ratings yet

- Bar Bending Schedule: Title: Commercial BLDG Cutting ListDocument22 pagesBar Bending Schedule: Title: Commercial BLDG Cutting ListJet ArcaNo ratings yet

- 2011 C1 CoMe ORGMIDocument8 pages2011 C1 CoMe ORGMIADJ ADJNo ratings yet

- 4final Examination Prof Ed 10Document7 pages4final Examination Prof Ed 10Danelle EsparteroNo ratings yet

- ScheduleDocument2 pagesScheduleJen NevalgaNo ratings yet

- Different Kinds of Meat ProductsDocument7 pagesDifferent Kinds of Meat ProductsYam MuhiNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet

30 JET-40 (4 CYL) (90-814676R1) SN US 0C159200 AND UP-BE 9570305 AND UP - Pages.1 10

30 JET-40 (4 CYL) (90-814676R1) SN US 0C159200 AND UP-BE 9570305 AND UP - Pages.1 10

Uploaded by

mendozamontesjoseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30 JET-40 (4 CYL) (90-814676R1) SN US 0C159200 AND UP-BE 9570305 AND UP - Pages.1 10

30 JET-40 (4 CYL) (90-814676R1) SN US 0C159200 AND UP-BE 9570305 AND UP - Pages.1 10

Uploaded by

mendozamontesjoseCopyright:

Available Formats

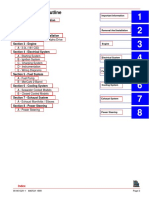

Service Manual Outline

Section 1 - Important Information

Section 2 - Electrical & Ignition

A - Ignition System

Important

Information

1

2

B - Battery, Charging System & Starting System

C - Timing, Synchronizing & Adjustment Electrical & Ignition

D - Wiring Diagrams

Section 3 - Fuel System & Carburetion

Section 4 - Powerhead

Section 5 - Mid-Section

A - Clamp/Swivel Bracket & Drive Shaft Housing

B - Power Trim (Design I)

Fuel System &

Carburetion

3

C - Power Trim (Design II)

D - Power Trim (Design III)

E - Power Trim (Design IV)

F - Manual Tilt System (Design I, II, III)

Powerhead

4

G - Manual Tilt System (Design IV)

Section 6 - Lower Unit

A - Lower Unit

B - Jet Drive

Section 7 - Outboard Motor Installation/Attachments

Mid-Section

5

A - Outboard Motor Installation/Attachments

B - Tiller Handle and Co-Pilot

C - Rewind Starter

Section 8 - Oil Injection System

Lower Unit

6

7

Outboard Motor

Installation/

Attachments

Oil Injection System

8

90-814676R1 DECEMBER 1996 iii

Notice We could not possibly know of and advise the service

trade of all conceivable procedures by which a ser-

Throughout this publication, “Dangers”, “Warnings” vice might be performed and of the possible hazards

and “Cautions” (accompanied by the International and/or results of each method. We have not under-

HAZARD Symbol ) are used to alert the mechanic taken any such wide evaluation. Therefore, anyone

to special instructions concerning a particular service who uses a service procedure and/or tool, which is

or operation that may be hazardous if performed in- not recommended by the manufacturer, first must

correctly or carelessly. OBSERVE THEM CARE- completely satisfy himself that neither his nor the

FULLY! products safety will be endangered by the service

procedure selected.

These “Safety Alerts” alone cannot eliminate the haz-

ards that they signal. Strict compliance to these spe- All information, illustrations and specifications con-

cial instructions when performing the service, plus tained in this manual are based on the latest product

“Common Sense” operation, are major accident pre- information available at the time of publication. As re-

vention measures. quired, revisions to this manual will be sent to all deal-

ers contracted by us to sell and/or service these prod-

DANGER ucts.

DANGER - Immediate hazards which WILL result It should be kept in mind, while working on the prod-

in severe personal injury or death. uct, that the electrical system and ignition system are

capable of violent and damaging short circuits or se-

WARNING vere electrical shocks. When performing any work

where electrical terminals could possibly be

WARNING - Hazards or unsafe practices which grounded or touched by the mechanic, the battery

COULD result in severe personal injury or death. cables should be disconnected at the battery.

CAUTION Any time the intake or exhaust openings are exposed

during service they should be covered to protect

Hazards or unsafe practices which could result against accidental entrance of foreign material which

in minor personal injury or product or property could enter the cylinders and cause extensive inter-

damage. nal damage when the engine is started.

It is important to note, during any maintenance proce-

dure replacement fasteners must have the same

Notice to Users of This measurements and strength as those removed.

Numbers on the heads of the metric bolts and on the

Manual surfaces of metric nuts indicate their strength. Ameri-

This service manual has been written and published can bolts use radial lines for this purpose, while most

by the Service Department of Mercury Marine to aid American nuts do not have strength markings. Mis-

our dealers’ mechanics and company service per- matched or incorrect fasteners can result in damage

sonnel when servicing the products described here- or malfunction, or possibly personal injury. There-

in. fore, fasteners removed should be saved for reuse in

It is assumed that these personnel are familiar with the same locations whenever possible. Where the

the servicing procedures of these products, or like or fasteners are not satisfactory for re-use, care should

similar products manufactured and marketed by be taken to select a replacement that matches the

Mercury Marine, that they have been trained in the original.

recommended servicing procedures of these prod-

ucts which includes the use of mechanics’ common

hand tools and the special Mercury Marine or recom-

mended tools from other suppliers.

90-814676R1 DECEMBER 1996 i

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten thousands of

an inch./mm. When any product component is serv-

iced, care and cleanliness are important. Throughout

this manual, it should be understood that proper

cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is

considered standard shop practice even if not specif-

ically stated.

Whenever components are removed for service,

they should be retained in order. At the time of instal-

lation, they should be installed in the same locations

and with the same mating surfaces as when re-

moved.

Personnel should not work on or under an outboard

which is suspended. Outboards should be attached

to work stands, or lowered to ground as soon as pos-

sible.

We reserve the right to make changes to this manual

without prior notification.

Refer to dealer service bulletins for other pertinent in-

formation concerning the products described in this

manual.

ii 90-814676R1 DECEMBER 1996

IMPORTANT 1

INFORMATION

50332

GENERAL INFORMATION and

SPECIFICATIONS

Table of Contents

Page

Propeller Information . . . . . . . . . . . . . . . . . . . . . . 1-1

How to Use this Manual . . . . . . . . . . . . . . . . . . . . 1-1

General Specifications . . . . . . . . . . . . . . . . . . . . . 1-2

Propeller Selection . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Propeller Installation . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trim “In” Angle Adjustment . . . . . . . . . . . . . . . . . 1-4

Power Trim System (Models with Power

Trim) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General Information . . . . . . . . . . . . . . . . . . . . . 1-4

Checking Trim System Fluid Level . . . . . . . . 1-5

Trimming (Models with Power Trim) . . . . . . . . . . 1-5

Trimming Outboard “Out” (“Up”)

Characteristics . . . . . . . . . . . . . . . . . . . . . . . 1-5

Trimming Outboard “In” (’Down”)

Characteristics . . . . . . . . . . . . . . . . . . . . . . . 1-5

Trim Tab Adjustment . . . . . . . . . . . . . . . . . . . . . . . 1-6

Boat Performance . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Test Instructions . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Boat Test Chart (Example) . . . . . . . . . . . . . . . 1-7

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Ride-Guide Steering Cable and Pivot

Points Lubrication . . . . . . . . . . . . . . . . . . . . 1-9

Gear Housing Lubrication . . . . . . . . . . . . . . . 1-10

Salt Water Corrosion - Gear Housing

Bearing Carrier and Cover Nut . . . . . . . . 1-10

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . 1-11

Flushing Outboard Cooling System . . . . . . . . . 1-11

Following Complete Submersion . . . . . . . . . . . 1-12

Salt Water Submersion (Special

Instructions) . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Submerged While Running (Special

Instructions) . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Submerged Engine (Fresh Water) (Plus

Special Instructions) . . . . . . . . . . . . . . . . . 1-12

Out-of-Season Outboard Storage . . . . . . . . . . 1-13

Out-of-Season Battery Storage . . . . . . . . . . . . 1-13

How Weather Affects Engine

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Conditions Affecting Operation . . . . . . . . . . . . . 1-15

Detonation: Causes and Prevention . . . . . . . . 1-15

Compression Check . . . . . . . . . . . . . . . . . . . . . . 1-16

Painting Procedure . . . . . . . . . . . . . . . . . . . . . . . 1-17

Decal Application . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1-0 - IMPORTANT INFORMATION 90-814676R1 DECEMBER 1996

Propeller Information

For in-depth information on marine propellers and

boat performance - written by marine engineers - see

your Authorized Dealer for the illustrated “What You

Should Know About Quicksilver Propellers and Boat

Performance Information” (Part No. 90-86144).

How to Use this Manual

The manual is divided into SECTIONS (shown, right)

which represents major components and systems.

Some SECTIONS are further divided into PARTS.

Each PART has a title page. A “Table of Contents” for

the particular PART is printed on the back of the title

page.

SECTIONS and PARTS are listed on the “Service

Manual Outline” sheet which immediately follows the

cover of this book.

Section Section Heading

1 Important Information

2 Electrical and Ignition

3 Fuel System and Carburetion

4 Powerhead

5 Mid-Section

6 Lower Unit

7 Outboard Installation/Attachments

8 Oil Injection System

90-814676R1 DECEMBER 1996 IMPORTANT INFORMATION - 1-1

General Specifications

Model 40

Horsepower 40

Engine Type 4 Cylinder, In-Line, Two-Stroke

Full Throttle RPM Range 5000-5500

Idle RPM Range (in Forward Gear) 600-700

Piston Displacement 44 cu. in. (721cc)

Cylinder Bore Standard 2.565 in. (65.151mm)

Stroke 2.125 in. (53.975mm)

Ignition Type Thunderbolt Capacitor Discharge

Firing Order 1-3-2-4

Recommended Spark Plug NGK BUHW-2

Gear Selection Forward - Neutral - Reverse

Gear Ratio 2:1

Gear Housing Lubricant Capacity 12.5 fl. oz. (370ml)

Outboard Weight (ELPTO) 192 lbs. (87kg)

Carburetion 2 Carburetors, Center Bowl

Recommended Gasoline Any leaded or unleaded (lead-free) gasoline, with

a minimum posted octane rating of 86

(research octane number 90)

Remote Fuel Tank

Capacity:

- U.S. Gallons 6.6

- Imperial Gallons 5.5

- Liters 25

Recommended Oil Quicksilver 2-Cycle Outboard Oil

Gasoline/Oil Ratio 50:1

Oil Tank Capacity* 0.935 gal. (3.54 Liters)

Maximum Operation at Full Throttle* 7 Hours

Oil Remaining when Warning Buzzer Sounds* 7.5 fl. oz.

Approximate Running Time Remaining at Wide 30 Minutes

Open Throttle when Buzzer Sounds*

Recommended Battery Rating Minimum Reserve Capacity rating of 100 Minutes

and Cold Cranking Amperage of 350 Amperes

*Specification for Oil Injected Model

1-2 - IMPORTANT INFORMATION 90-814676R1 DECEMBER 1996

Propeller Selection Coat the propeller shaft with Quicksilver Anti-Corro-

sion Grease or 2-4-C Marine Lubricant with Teflon.

1. Select a propeller that will allow the engine to op-

erate at or near the top of the recommended full IMPORTANT: To prevent the propeller hub from

throttle RPM range (listed in “Specifications,” corroding and seizing to the propeller shaft, es-

preceding) with a normal load. Maximum engine pecially in salt water, always apply a coat of the

speed (RPM) for propeller selection exists when recommended lubricant to the entire propeller

boat speed is maximum and trim is minimum for shaft at the recommended maintenance intervals

that speed. (High RPM, caused by an excessive and also each time the propeller is removed.

trim angle, should not be used in determining cor- Flo-Torq I Drive Hub Propellers

rect propeller.) Normally, there is a 150-350 RPM

change between propeller pitches. c b

2. If full throttle operation is below the recom-

mended range, the propeller MUST BE changed

to a lower pitch to prevent loss of performance

and possible engine damage.

3. For better acceleration, such as is needed in wa- a

ter skiing, propping up to 500 RPM above the rec-

ommended range is advised. Continuous opera-

a - Forward Thrust Hub

tion above the recommended maximum RPM, b - Propeller Nut Retainer

however, is not permissible. c - Propeller Nut

4. After initial propeller installation, the following Flo-Torq II Drive Hub Propellers

common conditions may require that the propel- c

ler be changed to a lower pitch: e d

a. Warmer weather and great humidity will

cause an RPM loss.

b. Operating in a higher elevation causes an

RPM loss.

c. Operating with a damaged propeller or a dirty b a

boat bottom or gear housing will cause an

RPM loss. a - Forward Thrust Hub

b - Replaceable Drive Sleeve

d. Operation with an increased load (additional c - Rear Thrust Hub

passengers, equipment, pulling skiers, etc.). d - Propeller Nut Retainer

e - Propeller Nut

1. Tighten propeller nut to 55 lb.ft. (75 N·m). Bend

Propeller Installation tabs against nut.

WARNING a

If the propeller shaft is rotated while the engine

is in gear, there is the possibility that the engine

b

b

will crank over and start. To prevent this type of

accidental engine starting and possible serious

injury caused from being struck by a rotating pro-

peller, always shift outboard to neutral position

and remove spark plug leads when you are serv- a - Propeller Nut - Torque To 55 lb. ft. (75 N·m)

b - Bend Tabs Against Nut

icing the propeller.

90-814676R1 DECEMBER 1996 IMPORTANT INFORMATION - 1-3

Trim “In” Angle Adjustment Power Trim System (Models

WARNING with Power Trim)

Operating some boats with outboard trimmed to General Information

the full “in” trim angle [not using trim adjustment

bolt (a)] at planing speed will cause undesirable The power trim system is filled at the manufacturer

and/or unsafe steering conditions. Each boat and is ready for use.

must be water tested for handling characteristics Trim outboard through entire trailering range several

after outboard installation and after any trim ad- times to remove any air from the system.

justments.

The trim system is pressurized and is not externally

IMPORTANT: Some boat/outboard combina- vented.

tions, that do not use the trim adjustment pin (a)

and are trimmed to the full “in” trim angle, will not The outboard can be raised or lowered manually by

experience any undesirable and/or unsafe steer- loosening the manual release valve 2 to 3 turns coun-

ing conditions during planing speed. Thus, not terclockwise.

using trim adjustment pin may be desired. How- The trim “out” angle of this outboard is not adjustable.

ever, some boats with outboard trimmed to the The trim system has an internal valve which will auto-

full “In” trim angle at planing speeds will cause matically stop the outward trim travel at 200 when en-

undesirable and/or unsafe steering conditions. If gine RPM is approximately 2000 RPM or higher; out-

these steering conditions are experienced, un- board also has to be in water and in gear.

der no circumstances should the outboard be

The outboard can be operated beyond the 200 trim

operated without the trim adjustment pin and

limit for operating outboard in shallow water if engine

without the pin adjusted in the proper holes to

RPM is kept below approximately 2000 RPM.

prevent unsafe handling characteristics.

Water test the boat not using the trim adjustment pin.

If undesirable and/or unsafe steering conditions are

experienced (boat runs with nose down), install trim

adjustment pin in proper hole to prevent unsafe han-

dling characteristics.

50158

50157 50146

a - Fill Screw (System is Pressurized, DO NOT Open Unless

Outboard is Tilted to Full Up Position)

b - Manual Tilt Release Valve Location

1-4 - IMPORTANT INFORMATION 90-814676R1 DECEMBER 1996

Checking Trim System Fluid Level Trimming (Models with

IMPORTANT: This trim system is pressurized. Power Trim)

Remove fill screw when outboard is trimmed to

the full “up” position. Retighten fill screw secure- NOTE: Because varying hull designs react differently

ly. in various degrees of rough water, it is recommended

to experiment with trim positions to determine wheth-

1. Trim outboard to full “up” position. Engage tilt lock er trimming up or down will improve the ride in rough

level (a). Trim system fluid can only be checked water.

when outboard is in this position.

When trimming your outboard from a mid-trim posi-

tion (trim tab in neutral straight fore-and-aft position),

you can expect the following results:

Trimming Outboard “Out” (“Up”)

Characteristics

WARNING

Excessive trim “out” also may reduce the stabil-

ity of some high speed hulls. To correct instabili-

ty at high speed, reduce the power GRADUALLY

and trim the outboard “In” slightly before resum-

ing high speed operation. (Rapid reduction in

power will cause a sudden change of steering

torque and may cause additional momentary

50157 boat instability.)

2. Remove fill screw and check fluid level. Fluid lev- 1. Will lift bow of boat, generally increasing top

el should be to bottom of threads in fill hole (b). speed.

3. If necessary, add Quicksilver Power Trim & 2. Transfers steering torque harder to left on stan-

Steering Fluid or; Automatic Transmission Fluid dard or slightly elevated transom installation

(ATF) Type F, FA or Dexron 11 fluid to trim (single outboard).

system. 3. Increases clearance over submerged objects.

4. Reinstall fill screw. 4. In excess, can cause porpoising and/or ventila-

tion.

5. If trimmed out beyond the water pickup, reduced

water supply can cause serious overheating.

b Trimming Outboard “In” (“Down”)

Characteristics

WARNING

Excessive speed at minimum trim “in” may

cause undesirable and/or unsafe steering condi-

tions. Each boat should be tested for handling

characteristics after any adjustment is made to

the trim angle (trim adjustment pin relocation).

1. Will help planing off, particularly with a heavy

load.

2. Usually improves ride in choppy water.

90-814676R1 DECEMBER 1996 IMPORTANT INFORMATION - 1-5

You might also like

- Mercury Service Manual 40 50 55 60 90 PDFDocument566 pagesMercury Service Manual 40 50 55 60 90 PDFbilly_gfroerer86% (14)

- MERCURY Outboard 40-50-60 4 Stroke Service ManualDocument589 pagesMERCURY Outboard 40-50-60 4 Stroke Service ManualDoug89% (9)

- Mercury 115 Service ManualDocument4 pagesMercury 115 Service ManualPat Balmos18% (11)

- Mercruiser Service Manual GM V6 4.3 CompleteDocument895 pagesMercruiser Service Manual GM V6 4.3 CompletePaul Chuon94% (16)

- Mercury 175xr2 SportJet Service ManualDocument207 pagesMercury 175xr2 SportJet Service ManualMarian Ariciuc100% (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them86% (7)

- 5206582-Instant Download Mercury Mercruiser 5 0l 5 7l 6 2l Service Repair Manual 2001-2006 BoatDocument636 pages5206582-Instant Download Mercury Mercruiser 5 0l 5 7l 6 2l Service Repair Manual 2001-2006 Boatdanlandry1100% (10)

- Mercury 30 - 40hp Service OEM ManualDocument532 pagesMercury 30 - 40hp Service OEM Manualwboerema100% (1)

- Service Manual #29Document537 pagesService Manual #29CharlesWhiteNo ratings yet

- MerCruiser #30 90-863161 09:00 PDFDocument355 pagesMerCruiser #30 90-863161 09:00 PDFRandall Petterson100% (3)

- Merc Service Manual 28 Bravo Stern DrivesDocument596 pagesMerc Service Manual 28 Bravo Stern DrivesHayduke them84% (19)

- Manual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveDocument100 pagesManual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveWallace Ferlim100% (7)

- Mercury Outboard Engine Service ManualDocument149 pagesMercury Outboard Engine Service ManualGlen Lewis100% (2)

- 40-50 Mercury Manual PDFDocument599 pages40-50 Mercury Manual PDFjasleen80% (5)

- 225-225 EFI - 50 EFI-3.0 Litre Marathon-3.0 Litre SeaPro United States-With Serial Numbers 0D280813 and AboveDocument639 pages225-225 EFI - 50 EFI-3.0 Litre Marathon-3.0 Litre SeaPro United States-With Serial Numbers 0D280813 and AboveMomed MdNo ratings yet

- Mercury Mercruiser #25 Service Manual Marine Engines GM v-6 262 CID (4.3L) (PDF, EnG, 9.97 MB)Document755 pagesMercury Mercruiser #25 Service Manual Marine Engines GM v-6 262 CID (4.3L) (PDF, EnG, 9.97 MB)Lucas Oliveira100% (1)

- Mercury Repair ManualDocument638 pagesMercury Repair ManualJames Hicks100% (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- 40 60 PDFDocument547 pages40 60 PDFDiego Arcos67% (3)

- Mercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFDocument364 pagesMercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFVit100% (1)

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- Mercury 40-50-55-60 Service Repair ManualDocument4 pagesMercury 40-50-55-60 Service Repair ManualRyan ActonNo ratings yet

- Verado 200-275 Workshop-1Document90 pagesVerado 200-275 Workshop-1Servicios Luna LSNo ratings yet

- 1992-2000.mercury Mariner Outboard 105-225 Service Manual Sprotetto PDFDocument797 pages1992-2000.mercury Mariner Outboard 105-225 Service Manual Sprotetto PDFRoberto Implatini100% (5)

- Service Manual: Models 45 Jet 50 55 60 45 Jet 50 55 Marathon 55 Seapro 60 60 Big Foot 60 Marathon 60 SeaproDocument565 pagesService Manual: Models 45 Jet 50 55 60 45 Jet 50 55 Marathon 55 Seapro 60 60 Big Foot 60 Marathon 60 SeaproPaul Martin100% (2)

- Mercury 135:150:175:20:225HP XR6 Magnum II EFI Pro Max Super Magnum 90-824052R2 09:97 PDFDocument824 pagesMercury 135:150:175:20:225HP XR6 Magnum II EFI Pro Max Super Magnum 90-824052R2 09:97 PDFRandall Petterson100% (4)

- Mercury Mariner 4, 5, 6 4 Stroke Sevice ManualDocument260 pagesMercury Mariner 4, 5, 6 4 Stroke Sevice ManualDenisovgabNo ratings yet

- 75-75 MARATHON-75 SEA PRO-90 - 100-115-125-65-80 JET With Serial Numbers United States - 0D283222 and Above Belgium - 09793577 and Above PDFDocument585 pages75-75 MARATHON-75 SEA PRO-90 - 100-115-125-65-80 JET With Serial Numbers United States - 0D283222 and Above Belgium - 09793577 and Above PDFjay hixNo ratings yet

- Mercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFDocument364 pagesMercury 200 OptiMax Jet Drive Service Manual (Since 2001) (PDF, ENG, 16.3 MB) PDFVitNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- 30 40MDocument333 pages30 40MDouglas Duarte100% (2)

- SM - 3.0L - 4cycl PDFDocument420 pagesSM - 3.0L - 4cycl PDFtableNo ratings yet

- Service Manual Outline: Section 1 - Important InformationDocument420 pagesService Manual Outline: Section 1 - Important InformationAngel Alvarez100% (1)

- Service Manual Outline: Section 1 - Important InformationDocument20 pagesService Manual Outline: Section 1 - Important InformationНиколай АксёновNo ratings yet

- Motor de Popa - IntroducaoDocument337 pagesMotor de Popa - IntroducaoSilveirabmNo ratings yet

- 4.3L-262CID (4.3L) (90-861328-1) .Pages.1 20 PDFDocument20 pages4.3L-262CID (4.3L) (90-861328-1) .Pages.1 20 PDFSerge MichelNo ratings yet

- Service Manual #28Document688 pagesService Manual #28CharlesWhiteNo ratings yet

- 135-150-175-200 With Serial Numbers United States - 0G960500 and AboveDocument638 pages135-150-175-200 With Serial Numbers United States - 0G960500 and AbovePAVLOSNo ratings yet

- 135-175 VeradoDocument3 pages135-175 Verado이영석50% (2)

- Service Manual OutlineDocument20 pagesService Manual OutlineJorge LopesNo ratings yet

- 4.2L (LD) DieselDocument641 pages4.2L (LD) Dieselhcmotores1No ratings yet

- Cover PDFDocument3 pagesCover PDFJim LassNo ratings yet

- Mercury 30hpDocument332 pagesMercury 30hpJorge LopesNo ratings yet

- Service Manual #27 SupplimentDocument271 pagesService Manual #27 SupplimentCharlesWhiteNo ratings yet

- Starting Model Year 2000-200-225 OptiMax-Direct Fuel Injection-Starting Serial Number OG960500Document745 pagesStarting Model Year 2000-200-225 OptiMax-Direct Fuel Injection-Starting Serial Number OG960500myinves00No ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceFrom EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Solution Techniques For Models Yielding Ordinary Differential Equations (ODE)Document67 pagesSolution Techniques For Models Yielding Ordinary Differential Equations (ODE)Nikhil DewalkarNo ratings yet

- 10 Best JobsitesDocument14 pages10 Best JobsitesHemansu PathakNo ratings yet

- Power Electronics: Thyristor Controlled Power For Electric MotorsDocument10 pagesPower Electronics: Thyristor Controlled Power For Electric Motorsshahab moinNo ratings yet

- Experiencing Postsocialist CapitalismDocument251 pagesExperiencing Postsocialist CapitalismjelisNo ratings yet

- OptiMix - Manual - EN - Rev.03.05 (Mixer)Document89 pagesOptiMix - Manual - EN - Rev.03.05 (Mixer)Đức Nguyễn100% (2)

- Latest Volleyball News From The NCAA and NAIADocument3 pagesLatest Volleyball News From The NCAA and NAIAFernan RomeroNo ratings yet

- EC Physical Sciences Grade 11 November 2022 P1 and MemoDocument25 pagesEC Physical Sciences Grade 11 November 2022 P1 and MemokhulntandoNo ratings yet

- Housekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesDocument8 pagesHousekeeping Management Practices and Standards of Selected Hotels and Restaurants of Ilocos Sur, PhilippinesMehwish FatimaNo ratings yet

- Paul CooksDocument4 pagesPaul CooksMicNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- B94-6 R1995 E1984Document21 pagesB94-6 R1995 E1984zojoNo ratings yet

- B.inggris-Daily ActivitiesDocument11 pagesB.inggris-Daily ActivitiesDadang SopianNo ratings yet

- Thrift Banks ActDocument25 pagesThrift Banks ActMadelle Pineda100% (1)

- CentrifugationDocument10 pagesCentrifugationBk FNo ratings yet

- OrganoLithium ReagentDocument6 pagesOrganoLithium ReagentizaowsikNo ratings yet

- WRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkDocument2 pagesWRAP - Case Study - Aggregates - The Channel Tunnel Rail LinkFatmah El WardagyNo ratings yet

- Ged Test Accom App AdhdDocument7 pagesGed Test Accom App AdhdJeannette DorfmanNo ratings yet

- Getting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFDocument7 pagesGetting Started With Nuvoton NUC140 32-Bit ARM Cortex-M0 Microcontroller PDFoktaNo ratings yet

- Activity Sheets Signal WordsDocument15 pagesActivity Sheets Signal WordsGrace Ann EscabarteNo ratings yet

- 1231.322 323 MSDS Sabroe 1507-100 MSDSDocument6 pages1231.322 323 MSDS Sabroe 1507-100 MSDSzhyhhNo ratings yet

- Agile TestingDocument5 pagesAgile TestingAman YadavNo ratings yet

- Ebook Digital Marketing PDF Full Chapter PDFDocument67 pagesEbook Digital Marketing PDF Full Chapter PDFamy.farley40997% (33)

- Flexural Test of Concrete Beam SpecimenDocument6 pagesFlexural Test of Concrete Beam SpecimenJenevive TumacderNo ratings yet

- Bar Bending Schedule: Title: Commercial BLDG Cutting ListDocument22 pagesBar Bending Schedule: Title: Commercial BLDG Cutting ListJet ArcaNo ratings yet

- 2011 C1 CoMe ORGMIDocument8 pages2011 C1 CoMe ORGMIADJ ADJNo ratings yet

- 4final Examination Prof Ed 10Document7 pages4final Examination Prof Ed 10Danelle EsparteroNo ratings yet

- ScheduleDocument2 pagesScheduleJen NevalgaNo ratings yet

- Different Kinds of Meat ProductsDocument7 pagesDifferent Kinds of Meat ProductsYam MuhiNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet