Professional Documents

Culture Documents

PTC 19.3

PTC 19.3

Uploaded by

TATA STEELCopyright:

Available Formats

You might also like

- Homework #3Document31 pagesHomework #3mahrbhojia50% (2)

- Cable CalculationsDocument9 pagesCable CalculationsMohamed Mostafa0% (1)

- Strand7 TutorialDocument219 pagesStrand7 TutorialJay Ryan Santos67% (3)

- HP ProBook 6560b - FoxConn Cure DIS Rev 0Document52 pagesHP ProBook 6560b - FoxConn Cure DIS Rev 0amitintime4uNo ratings yet

- CPLT-V15 (1) Manual Chicago PneumaticDocument178 pagesCPLT-V15 (1) Manual Chicago PneumaticEduardo SainzNo ratings yet

- Protection Scheme 13.8kV SwitchgearDocument69 pagesProtection Scheme 13.8kV Switchgeardaniel.cabasa2577100% (1)

- EMH222 Chapter 12 Assignments Answer SchemeDocument10 pagesEMH222 Chapter 12 Assignments Answer SchemeWeeIng100% (1)

- 1K 2K In-Chassis MaintenanceDocument76 pages1K 2K In-Chassis MaintenanceLiviu Neda100% (1)

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- Steam Control ValveDocument3 pagesSteam Control ValvedpdcpNo ratings yet

- Cem 1212cDocument3 pagesCem 1212cGabriel GranadoNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Ds dpsm690 en inDocument3 pagesDs dpsm690 en inmanojNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- CEM 1203 42 BuzzerDocument5 pagesCEM 1203 42 BuzzerEAKIT SPAINNo ratings yet

- Welding: Nahadin SanatDocument4 pagesWelding: Nahadin Sanatvahid mobiniNo ratings yet

- Cuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingDocument9 pagesCuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingVăn HoàngNo ratings yet

- 30m High Communication Steel PoleDocument19 pages30m High Communication Steel Polelorraine atienzaNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- CBL-VDL BK-14-1231 Ông 140Document3 pagesCBL-VDL BK-14-1231 Ông 140phuongNo ratings yet

- 1000 L-Slurry Receiving Tank - DWGDocument1 page1000 L-Slurry Receiving Tank - DWGaurinkokelloNo ratings yet

- Cl17-011-Dat-El-Sacyr-005a-006 (Ri)Document17 pagesCl17-011-Dat-El-Sacyr-005a-006 (Ri)jorgeNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- VALVULA VAPOR Joseestrada PDFDocument5 pagesVALVULA VAPOR Joseestrada PDFRaulRodriguezNo ratings yet

- CT-1205CL-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncDocument3 pagesCT-1205CL-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncrstramirezNo ratings yet

- D-240, TTC Industrial Area, Near Uran Phata Signal, Nerul, Navi Mumbai - 400 706 Ph. +91 22 66512000Document14 pagesD-240, TTC Industrial Area, Near Uran Phata Signal, Nerul, Navi Mumbai - 400 706 Ph. +91 22 66512000ChandanSinghNo ratings yet

- Megger Sheet New 10k Modified For BasementDocument2 pagesMegger Sheet New 10k Modified For BasementShahadad PNNo ratings yet

- 24x16AWG RAMCRODocument1 page24x16AWG RAMCROederNo ratings yet

- Cable CalculationsDocument9 pagesCable CalculationsFasil ENo ratings yet

- 150w Core ZW42508TCDocument1 page150w Core ZW42508TCErkanNo ratings yet

- TRANSMITTAL OF DOCUMENTATION - Earthing Material Accessories-1Document46 pagesTRANSMITTAL OF DOCUMENTATION - Earthing Material Accessories-1Usama AnsariNo ratings yet

- Elbow 2-9000 SW 90DDocument1 pageElbow 2-9000 SW 90DJovianto PrisilaNo ratings yet

- Radiographic Inspection Report: TNDT-CPP-PIP-RT-1250Document19 pagesRadiographic Inspection Report: TNDT-CPP-PIP-RT-1250Hendra SembiringNo ratings yet

- Sector Die CatalogueDocument3 pagesSector Die CatalogueAHMED YOUSEF100% (1)

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Load Schedule Calculation Sheet: Electrical Department Project Name: Project No.: Panel Data: Main Feeder DataDocument7 pagesLoad Schedule Calculation Sheet: Electrical Department Project Name: Project No.: Panel Data: Main Feeder DataDardakNo ratings yet

- GRP 86A PipelineDocument1 pageGRP 86A PipelineAli RaheemNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Electric Circuit and Wiring Diagram Customer Project Loadingarm B0030 12" Cilacap PT Pbas, PT - Patra Badak Arun SolusiDocument109 pagesElectric Circuit and Wiring Diagram Customer Project Loadingarm B0030 12" Cilacap PT Pbas, PT - Patra Badak Arun Solusiserge.rinaudoNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- MSRC Cfa - 20230622 - 0001Document3 pagesMSRC Cfa - 20230622 - 0001Saad MuzaffarNo ratings yet

- VN2406LZL1 ON SemiconductorDocument3 pagesVN2406LZL1 ON SemiconductorLucas FloresNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- MODEL: CEP-2242 Description: Piezo Audio Indicator: FeaturesDocument3 pagesMODEL: CEP-2242 Description: Piezo Audio Indicator: FeaturesRishab SinglaNo ratings yet

- Elbow 1,5-6000 SW 90D - OKDocument1 pageElbow 1,5-6000 SW 90D - OKJovianto PrisilaNo ratings yet

- An TororoDocument2 pagesAn Tororokhauka ronaldNo ratings yet

- Untitled. - Complete PDFDocument5 pagesUntitled. - Complete PDFDrMahmoud AbbasNo ratings yet

- MODEL: CMI-1295-0585T Description: Magnetic Buzzer IndicatorDocument4 pagesMODEL: CMI-1295-0585T Description: Magnetic Buzzer IndicatorRishab SinglaNo ratings yet

- Xinjiang Beixin Road & Bridge Group Co. LTD: XBRB - Lab - BDocument13 pagesXinjiang Beixin Road & Bridge Group Co. LTD: XBRB - Lab - BAhmedNo ratings yet

- Example Project Three Line PDFDocument6 pagesExample Project Three Line PDFerfan fatahiNo ratings yet

- Elbow 1-6000 SW 90d - OkDocument1 pageElbow 1-6000 SW 90d - OkJovianto PrisilaNo ratings yet

- 1A Surface Mount Schottky Barrier Rectifier: Top ViewDocument6 pages1A Surface Mount Schottky Barrier Rectifier: Top ViewDavid VasquezNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- c40 4202730541 50 11kv DV Safering XT Manual RmuDocument21 pagesc40 4202730541 50 11kv DV Safering XT Manual Rmubaljeet negiNo ratings yet

- CLC PDFDocument1 pageCLC PDFAnonymous qXdGlWLDMTNo ratings yet

- Sessional 6Document2 pagesSessional 6Ankit VermaNo ratings yet

- Calculation Pipe Header For CompressorDocument4 pagesCalculation Pipe Header For CompressorsyaifullintechNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Zttgroup: ZN ZNDocument10 pagesZttgroup: ZN ZNA&Z cableNo ratings yet

- B-6326-PR-00-0046-002 Rev 6Document15 pagesB-6326-PR-00-0046-002 Rev 6sushilNo ratings yet

- Cables For Intrinsic Safety Loop CalculationDocument5 pagesCables For Intrinsic Safety Loop CalculationTATA STEELNo ratings yet

- Electronic Mosquito RacketDocument1 pageElectronic Mosquito RacketTATA STEELNo ratings yet

- GETPIVOTDATA Function in ExcelDocument6 pagesGETPIVOTDATA Function in ExcelTATA STEELNo ratings yet

- Ti00452g08en07 15Document41 pagesTi00452g08en07 15TATA STEELNo ratings yet

- P&ID-1 TutorialsDocument12 pagesP&ID-1 TutorialsTATA STEELNo ratings yet

- Interview Questions On Temperature MeasurementDocument2 pagesInterview Questions On Temperature MeasurementTATA STEELNo ratings yet

- P&ID-2 TutorialsDocument19 pagesP&ID-2 TutorialsTATA STEELNo ratings yet

- 6 Rules To Be CharismaticDocument7 pages6 Rules To Be CharismaticTATA STEELNo ratings yet

- Instrument Turndown RatioDocument2 pagesInstrument Turndown RatioTATA STEELNo ratings yet

- Troubleshooting Overheating or Thermal Issues On IntelDocument2 pagesTroubleshooting Overheating or Thermal Issues On IntelTATA STEELNo ratings yet

- Thumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb RulesDocument12 pagesThumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb RulesTATA STEELNo ratings yet

- Plumbing Drainage Guidelines - Plumbing Sanitary Drainage WorkDocument3 pagesPlumbing Drainage Guidelines - Plumbing Sanitary Drainage WorkTATA STEELNo ratings yet

- Assignment 3Document1 pageAssignment 3TATA STEELNo ratings yet

- Electrical Work Charges Labour and Material 2023 - Quotation For Electrical Work With MaterialDocument2 pagesElectrical Work Charges Labour and Material 2023 - Quotation For Electrical Work With MaterialTATA STEELNo ratings yet

- Issues With TilesDocument2 pagesIssues With TilesTATA STEELNo ratings yet

- 5kW Solar Systems Price in India - Waaree EnergiesDocument3 pages5kW Solar Systems Price in India - Waaree EnergiesTATA STEELNo ratings yet

- Standard Kitchen Size and Dimensions - Modular Kitchen Dimension - 12 Perfect Kitchen DimensionsDocument5 pagesStandard Kitchen Size and Dimensions - Modular Kitchen Dimension - 12 Perfect Kitchen DimensionsTATA STEELNo ratings yet

- 12 Life Lessons People Learn Too LateDocument4 pages12 Life Lessons People Learn Too LateTATA STEELNo ratings yet

- Inst Electrical InterfaceDocument46 pagesInst Electrical InterfaceTATA STEELNo ratings yet

- My Sleep Diary 2Document8 pagesMy Sleep Diary 2TATA STEELNo ratings yet

- Calculate Flowmeter ParametersDocument3 pagesCalculate Flowmeter ParametersTATA STEELNo ratings yet

- Salt in Crude Analyzer SchematicDocument1 pageSalt in Crude Analyzer SchematicTATA STEELNo ratings yet

- 5 Ways To Never Get AngryDocument6 pages5 Ways To Never Get AngryTATA STEELNo ratings yet

- Hershey ChocolatesDocument2 pagesHershey ChocolatesTATA STEELNo ratings yet

- Chap 1 Coordinate SystemDocument8 pagesChap 1 Coordinate SystemTATA STEELNo ratings yet

- For Good LifeDocument4 pagesFor Good LifeTATA STEELNo ratings yet

- Gate Branch Wise Cut Off - Gate Last Year Cut Off - IIT Cut OffDocument7 pagesGate Branch Wise Cut Off - Gate Last Year Cut Off - IIT Cut OffTATA STEELNo ratings yet

- Changing MindsetDocument4 pagesChanging MindsetTATA STEELNo ratings yet

- GATE PreparationDocument1 pageGATE PreparationTATA STEELNo ratings yet

- Displacer Level Transmitter Dry Calibration With WeightsDocument7 pagesDisplacer Level Transmitter Dry Calibration With WeightsTATA STEELNo ratings yet

- Material Case StudyDocument8 pagesMaterial Case StudyI'NhonqMinnie100% (1)

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument31 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- 2D Finite Element Analysis of Rubber Pad Forming Process: October 2016Document11 pages2D Finite Element Analysis of Rubber Pad Forming Process: October 2016Rui MatiasNo ratings yet

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDocument33 pages(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- FCVL 10 - 520 P 020220 enDocument2 pagesFCVL 10 - 520 P 020220 enAnonymous Xz3PgZR8100% (1)

- Air Conditioning 2Document20 pagesAir Conditioning 2Cornel IordacheNo ratings yet

- Referat BuzoDocument11 pagesReferat BuzoAnaNo ratings yet

- Hydratec BlainDocument6 pagesHydratec Blaincoco MPNo ratings yet

- Honeywell T200 M Sensor DatasheetDocument2 pagesHoneywell T200 M Sensor DatasheetShane ChagparNo ratings yet

- Series and Parallel Pump ExperimentDocument17 pagesSeries and Parallel Pump ExperimentCourse OnlyNo ratings yet

- Mesin Pencacah Rumput (DWG)Document1 pageMesin Pencacah Rumput (DWG)Muhamad HudaNo ratings yet

- R01-X01 Rev 1 Jun 2016 Instrumentation SPI Datasheet TemplatesDocument66 pagesR01-X01 Rev 1 Jun 2016 Instrumentation SPI Datasheet TemplatesSALMANNo ratings yet

- Piping Class - AC11Document2 pagesPiping Class - AC11Дмитрий РыбаковNo ratings yet

- Manual Motores Estacionarios Complete-DHGDocument244 pagesManual Motores Estacionarios Complete-DHGYanio Ballesteros MezaNo ratings yet

- P 1289 PDFDocument171 pagesP 1289 PDFbmccune7187No ratings yet

- CV3013 - Tutorials 1 To 3 (2015) PDFDocument3 pagesCV3013 - Tutorials 1 To 3 (2015) PDFlevanviet0410100% (1)

- 0192 Design Optimization of Eot Crane BridgeDocument9 pages0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- CB 8100 Series UGDocument34 pagesCB 8100 Series UGksenthil09No ratings yet

- 793C Off-Highway Truck: Tool ListDocument18 pages793C Off-Highway Truck: Tool ListPaola Uriol CerquinNo ratings yet

- Mechanical Course - PipingDocument65 pagesMechanical Course - PipingMahathir Che Ap100% (1)

- What Causes Hydraulic Movement at All in A Used New Holland l785Document5 pagesWhat Causes Hydraulic Movement at All in A Used New Holland l785JohnnyLarsonNo ratings yet

- FCAR Diagnostic List: Function System System SystemDocument8 pagesFCAR Diagnostic List: Function System System SystemSergey VladimirovNo ratings yet

- Locomotion Methods of Pipe Climbing Robots: A ReviewDocument13 pagesLocomotion Methods of Pipe Climbing Robots: A ReviewIoan DorofteiNo ratings yet

- LGH RX5 E - SpecDocument2 pagesLGH RX5 E - SpecpradungNo ratings yet

PTC 19.3

PTC 19.3

Uploaded by

TATA STEELCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC 19.3

PTC 19.3

Uploaded by

TATA STEELCopyright:

Available Formats

WIKA Instruments India Pvt. Ltd.

Customer: Name of Customer Name: Name

WIKA Instruments India Pvt. Ltd.

Plot no. 40, Gat No. 94 + 100

Project: Name of Project Date: Date

High Cliff Industrial Estate

Village Kesnand, Wagholi

Pune - 412 207

Ref. -No.: Reference

phone: +91 20 66293200

fax: +91 20 66293325

Calculation email: sales@wika.co.in

Tag-No.: sample

result:

failed web: http://www.wika.co.in

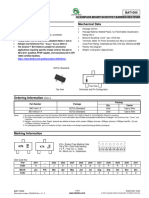

Thermowell Calculation Program v2.3

Results to ASME PTC 19.3 TW - 2010

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

Description Description

WIKA / ASME WIKA / ASME

Result: Process data: 0

Result Eval. failed Temperature T 310.00 °C

Frequency ratio r 0.45 fw/fnc Pressure P 157.89 bar

Ratio limit fw/fnc rmax_ 0.40 inline? Max.velocity v 12.05 m/s

Safety fatigue dyn 2.34 / Med.density rho 636.26 kg/m3

Safety bending stat 8.21 / Kin.viscosity ny mm2/s

Safety pressure Sp 1.99 /

Reduced length (rmax) Ured / Lred 220.0 mm

Note code / R

Pipe data:

Inner diameter Di mm

Shielded length SL / Lo mm

Usable nozzle length *) UNL / mm

Nozzle inner diameter *) NID / mm

*) for support collar

Thermowell sketch

Thermowell data:

WIKA model TW10 Name

Connection flanged

Shape tapered Name

Insertion length U/L 249.000 mm

New insertion length Unew / mm

Reduced length Ured / mm

Stepped length US / Ls 0.000 mm

Step radius RS / rB 0.000 mm

Root radius RQ / rA 2.000 mm

4c wm tapered TW10

Bore diameter B / db 6.600 mm

Root diameter Q/B 30.000 mm

Tip diameter V/A 16.000 mm

Tip thickness Tt / Tt 5.000 mm

Material data:

Grade mat 1.4571 Name

Spec. weight D(T) 7.999 kg/dm3

Youngs modul E(T) 174.9 GPa

Factor for temp. FT 0.890 /

Fatigue strength Sf(T) 55.8 MPa

Max.all.stress 1.5S(T) 129.1 MPa

Press. strength S(T) 86.0 MPa

Fatigue class class B

WIKA has made every reasonable attempt to validate the calculation procedure contained in this spread sheet, however, responsibility for validation rests solely with the user.

This WIKA ASME PTC 19.3 TW 2010 spread sheet copyright © 2010 (compatible with Excel 2007/2010) is intended to assist the experienced designer of thermowells and should

not be considered as a replacement for professional engineering.The end user is responsible to assure that the calculation method is compatible to the process conditions.

For further information see Operation Instruction.

You might also like

- Homework #3Document31 pagesHomework #3mahrbhojia50% (2)

- Cable CalculationsDocument9 pagesCable CalculationsMohamed Mostafa0% (1)

- Strand7 TutorialDocument219 pagesStrand7 TutorialJay Ryan Santos67% (3)

- HP ProBook 6560b - FoxConn Cure DIS Rev 0Document52 pagesHP ProBook 6560b - FoxConn Cure DIS Rev 0amitintime4uNo ratings yet

- CPLT-V15 (1) Manual Chicago PneumaticDocument178 pagesCPLT-V15 (1) Manual Chicago PneumaticEduardo SainzNo ratings yet

- Protection Scheme 13.8kV SwitchgearDocument69 pagesProtection Scheme 13.8kV Switchgeardaniel.cabasa2577100% (1)

- EMH222 Chapter 12 Assignments Answer SchemeDocument10 pagesEMH222 Chapter 12 Assignments Answer SchemeWeeIng100% (1)

- 1K 2K In-Chassis MaintenanceDocument76 pages1K 2K In-Chassis MaintenanceLiviu Neda100% (1)

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- Steam Control ValveDocument3 pagesSteam Control ValvedpdcpNo ratings yet

- Cem 1212cDocument3 pagesCem 1212cGabriel GranadoNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Ds dpsm690 en inDocument3 pagesDs dpsm690 en inmanojNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- CEM 1203 42 BuzzerDocument5 pagesCEM 1203 42 BuzzerEAKIT SPAINNo ratings yet

- Welding: Nahadin SanatDocument4 pagesWelding: Nahadin Sanatvahid mobiniNo ratings yet

- Cuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingDocument9 pagesCuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingVăn HoàngNo ratings yet

- 30m High Communication Steel PoleDocument19 pages30m High Communication Steel Polelorraine atienzaNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- CBL-VDL BK-14-1231 Ông 140Document3 pagesCBL-VDL BK-14-1231 Ông 140phuongNo ratings yet

- 1000 L-Slurry Receiving Tank - DWGDocument1 page1000 L-Slurry Receiving Tank - DWGaurinkokelloNo ratings yet

- Cl17-011-Dat-El-Sacyr-005a-006 (Ri)Document17 pagesCl17-011-Dat-El-Sacyr-005a-006 (Ri)jorgeNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- VALVULA VAPOR Joseestrada PDFDocument5 pagesVALVULA VAPOR Joseestrada PDFRaulRodriguezNo ratings yet

- CT-1205CL-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncDocument3 pagesCT-1205CL-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncrstramirezNo ratings yet

- D-240, TTC Industrial Area, Near Uran Phata Signal, Nerul, Navi Mumbai - 400 706 Ph. +91 22 66512000Document14 pagesD-240, TTC Industrial Area, Near Uran Phata Signal, Nerul, Navi Mumbai - 400 706 Ph. +91 22 66512000ChandanSinghNo ratings yet

- Megger Sheet New 10k Modified For BasementDocument2 pagesMegger Sheet New 10k Modified For BasementShahadad PNNo ratings yet

- 24x16AWG RAMCRODocument1 page24x16AWG RAMCROederNo ratings yet

- Cable CalculationsDocument9 pagesCable CalculationsFasil ENo ratings yet

- 150w Core ZW42508TCDocument1 page150w Core ZW42508TCErkanNo ratings yet

- TRANSMITTAL OF DOCUMENTATION - Earthing Material Accessories-1Document46 pagesTRANSMITTAL OF DOCUMENTATION - Earthing Material Accessories-1Usama AnsariNo ratings yet

- Elbow 2-9000 SW 90DDocument1 pageElbow 2-9000 SW 90DJovianto PrisilaNo ratings yet

- Radiographic Inspection Report: TNDT-CPP-PIP-RT-1250Document19 pagesRadiographic Inspection Report: TNDT-CPP-PIP-RT-1250Hendra SembiringNo ratings yet

- Sector Die CatalogueDocument3 pagesSector Die CatalogueAHMED YOUSEF100% (1)

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Load Schedule Calculation Sheet: Electrical Department Project Name: Project No.: Panel Data: Main Feeder DataDocument7 pagesLoad Schedule Calculation Sheet: Electrical Department Project Name: Project No.: Panel Data: Main Feeder DataDardakNo ratings yet

- GRP 86A PipelineDocument1 pageGRP 86A PipelineAli RaheemNo ratings yet

- PSP TCDocument7 pagesPSP TCPSP kanpurdehatNo ratings yet

- Electric Circuit and Wiring Diagram Customer Project Loadingarm B0030 12" Cilacap PT Pbas, PT - Patra Badak Arun SolusiDocument109 pagesElectric Circuit and Wiring Diagram Customer Project Loadingarm B0030 12" Cilacap PT Pbas, PT - Patra Badak Arun Solusiserge.rinaudoNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- MSRC Cfa - 20230622 - 0001Document3 pagesMSRC Cfa - 20230622 - 0001Saad MuzaffarNo ratings yet

- VN2406LZL1 ON SemiconductorDocument3 pagesVN2406LZL1 ON SemiconductorLucas FloresNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- MODEL: CEP-2242 Description: Piezo Audio Indicator: FeaturesDocument3 pagesMODEL: CEP-2242 Description: Piezo Audio Indicator: FeaturesRishab SinglaNo ratings yet

- Elbow 1,5-6000 SW 90D - OKDocument1 pageElbow 1,5-6000 SW 90D - OKJovianto PrisilaNo ratings yet

- An TororoDocument2 pagesAn Tororokhauka ronaldNo ratings yet

- Untitled. - Complete PDFDocument5 pagesUntitled. - Complete PDFDrMahmoud AbbasNo ratings yet

- MODEL: CMI-1295-0585T Description: Magnetic Buzzer IndicatorDocument4 pagesMODEL: CMI-1295-0585T Description: Magnetic Buzzer IndicatorRishab SinglaNo ratings yet

- Xinjiang Beixin Road & Bridge Group Co. LTD: XBRB - Lab - BDocument13 pagesXinjiang Beixin Road & Bridge Group Co. LTD: XBRB - Lab - BAhmedNo ratings yet

- Example Project Three Line PDFDocument6 pagesExample Project Three Line PDFerfan fatahiNo ratings yet

- Elbow 1-6000 SW 90d - OkDocument1 pageElbow 1-6000 SW 90d - OkJovianto PrisilaNo ratings yet

- 1A Surface Mount Schottky Barrier Rectifier: Top ViewDocument6 pages1A Surface Mount Schottky Barrier Rectifier: Top ViewDavid VasquezNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- c40 4202730541 50 11kv DV Safering XT Manual RmuDocument21 pagesc40 4202730541 50 11kv DV Safering XT Manual Rmubaljeet negiNo ratings yet

- CLC PDFDocument1 pageCLC PDFAnonymous qXdGlWLDMTNo ratings yet

- Sessional 6Document2 pagesSessional 6Ankit VermaNo ratings yet

- Calculation Pipe Header For CompressorDocument4 pagesCalculation Pipe Header For CompressorsyaifullintechNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Zttgroup: ZN ZNDocument10 pagesZttgroup: ZN ZNA&Z cableNo ratings yet

- B-6326-PR-00-0046-002 Rev 6Document15 pagesB-6326-PR-00-0046-002 Rev 6sushilNo ratings yet

- Cables For Intrinsic Safety Loop CalculationDocument5 pagesCables For Intrinsic Safety Loop CalculationTATA STEELNo ratings yet

- Electronic Mosquito RacketDocument1 pageElectronic Mosquito RacketTATA STEELNo ratings yet

- GETPIVOTDATA Function in ExcelDocument6 pagesGETPIVOTDATA Function in ExcelTATA STEELNo ratings yet

- Ti00452g08en07 15Document41 pagesTi00452g08en07 15TATA STEELNo ratings yet

- P&ID-1 TutorialsDocument12 pagesP&ID-1 TutorialsTATA STEELNo ratings yet

- Interview Questions On Temperature MeasurementDocument2 pagesInterview Questions On Temperature MeasurementTATA STEELNo ratings yet

- P&ID-2 TutorialsDocument19 pagesP&ID-2 TutorialsTATA STEELNo ratings yet

- 6 Rules To Be CharismaticDocument7 pages6 Rules To Be CharismaticTATA STEELNo ratings yet

- Instrument Turndown RatioDocument2 pagesInstrument Turndown RatioTATA STEELNo ratings yet

- Troubleshooting Overheating or Thermal Issues On IntelDocument2 pagesTroubleshooting Overheating or Thermal Issues On IntelTATA STEELNo ratings yet

- Thumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb RulesDocument12 pagesThumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb RulesTATA STEELNo ratings yet

- Plumbing Drainage Guidelines - Plumbing Sanitary Drainage WorkDocument3 pagesPlumbing Drainage Guidelines - Plumbing Sanitary Drainage WorkTATA STEELNo ratings yet

- Assignment 3Document1 pageAssignment 3TATA STEELNo ratings yet

- Electrical Work Charges Labour and Material 2023 - Quotation For Electrical Work With MaterialDocument2 pagesElectrical Work Charges Labour and Material 2023 - Quotation For Electrical Work With MaterialTATA STEELNo ratings yet

- Issues With TilesDocument2 pagesIssues With TilesTATA STEELNo ratings yet

- 5kW Solar Systems Price in India - Waaree EnergiesDocument3 pages5kW Solar Systems Price in India - Waaree EnergiesTATA STEELNo ratings yet

- Standard Kitchen Size and Dimensions - Modular Kitchen Dimension - 12 Perfect Kitchen DimensionsDocument5 pagesStandard Kitchen Size and Dimensions - Modular Kitchen Dimension - 12 Perfect Kitchen DimensionsTATA STEELNo ratings yet

- 12 Life Lessons People Learn Too LateDocument4 pages12 Life Lessons People Learn Too LateTATA STEELNo ratings yet

- Inst Electrical InterfaceDocument46 pagesInst Electrical InterfaceTATA STEELNo ratings yet

- My Sleep Diary 2Document8 pagesMy Sleep Diary 2TATA STEELNo ratings yet

- Calculate Flowmeter ParametersDocument3 pagesCalculate Flowmeter ParametersTATA STEELNo ratings yet

- Salt in Crude Analyzer SchematicDocument1 pageSalt in Crude Analyzer SchematicTATA STEELNo ratings yet

- 5 Ways To Never Get AngryDocument6 pages5 Ways To Never Get AngryTATA STEELNo ratings yet

- Hershey ChocolatesDocument2 pagesHershey ChocolatesTATA STEELNo ratings yet

- Chap 1 Coordinate SystemDocument8 pagesChap 1 Coordinate SystemTATA STEELNo ratings yet

- For Good LifeDocument4 pagesFor Good LifeTATA STEELNo ratings yet

- Gate Branch Wise Cut Off - Gate Last Year Cut Off - IIT Cut OffDocument7 pagesGate Branch Wise Cut Off - Gate Last Year Cut Off - IIT Cut OffTATA STEELNo ratings yet

- Changing MindsetDocument4 pagesChanging MindsetTATA STEELNo ratings yet

- GATE PreparationDocument1 pageGATE PreparationTATA STEELNo ratings yet

- Displacer Level Transmitter Dry Calibration With WeightsDocument7 pagesDisplacer Level Transmitter Dry Calibration With WeightsTATA STEELNo ratings yet

- Material Case StudyDocument8 pagesMaterial Case StudyI'NhonqMinnie100% (1)

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument31 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- 2D Finite Element Analysis of Rubber Pad Forming Process: October 2016Document11 pages2D Finite Element Analysis of Rubber Pad Forming Process: October 2016Rui MatiasNo ratings yet

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDocument33 pages(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- FCVL 10 - 520 P 020220 enDocument2 pagesFCVL 10 - 520 P 020220 enAnonymous Xz3PgZR8100% (1)

- Air Conditioning 2Document20 pagesAir Conditioning 2Cornel IordacheNo ratings yet

- Referat BuzoDocument11 pagesReferat BuzoAnaNo ratings yet

- Hydratec BlainDocument6 pagesHydratec Blaincoco MPNo ratings yet

- Honeywell T200 M Sensor DatasheetDocument2 pagesHoneywell T200 M Sensor DatasheetShane ChagparNo ratings yet

- Series and Parallel Pump ExperimentDocument17 pagesSeries and Parallel Pump ExperimentCourse OnlyNo ratings yet

- Mesin Pencacah Rumput (DWG)Document1 pageMesin Pencacah Rumput (DWG)Muhamad HudaNo ratings yet

- R01-X01 Rev 1 Jun 2016 Instrumentation SPI Datasheet TemplatesDocument66 pagesR01-X01 Rev 1 Jun 2016 Instrumentation SPI Datasheet TemplatesSALMANNo ratings yet

- Piping Class - AC11Document2 pagesPiping Class - AC11Дмитрий РыбаковNo ratings yet

- Manual Motores Estacionarios Complete-DHGDocument244 pagesManual Motores Estacionarios Complete-DHGYanio Ballesteros MezaNo ratings yet

- P 1289 PDFDocument171 pagesP 1289 PDFbmccune7187No ratings yet

- CV3013 - Tutorials 1 To 3 (2015) PDFDocument3 pagesCV3013 - Tutorials 1 To 3 (2015) PDFlevanviet0410100% (1)

- 0192 Design Optimization of Eot Crane BridgeDocument9 pages0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- CB 8100 Series UGDocument34 pagesCB 8100 Series UGksenthil09No ratings yet

- 793C Off-Highway Truck: Tool ListDocument18 pages793C Off-Highway Truck: Tool ListPaola Uriol CerquinNo ratings yet

- Mechanical Course - PipingDocument65 pagesMechanical Course - PipingMahathir Che Ap100% (1)

- What Causes Hydraulic Movement at All in A Used New Holland l785Document5 pagesWhat Causes Hydraulic Movement at All in A Used New Holland l785JohnnyLarsonNo ratings yet

- FCAR Diagnostic List: Function System System SystemDocument8 pagesFCAR Diagnostic List: Function System System SystemSergey VladimirovNo ratings yet

- Locomotion Methods of Pipe Climbing Robots: A ReviewDocument13 pagesLocomotion Methods of Pipe Climbing Robots: A ReviewIoan DorofteiNo ratings yet

- LGH RX5 E - SpecDocument2 pagesLGH RX5 E - SpecpradungNo ratings yet