Professional Documents

Culture Documents

Model 1213R: National-Spencer Inc

Model 1213R: National-Spencer Inc

Uploaded by

dial94902Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 1213R: National-Spencer Inc

Model 1213R: National-Spencer Inc

Uploaded by

dial94902Copyright:

Available Formats

National-Spencer Inc.

Questions? Call: 1-800-231-1525 Or visit www.zeeline.com

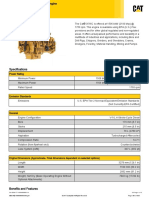

Model 1213R

Pneumatic Pump Description:

The 1213R Greasing System was designed as a

complete solution for dispensing grease from a 120lb.

drum. The 65:1 pneumatic pump is powerful enough to

handle most grease, up to No. 3 NLGI. The 1536A

control handle is capable of boosting the output pres-

sure to 10,000 psi, making it the ideal choice for a

backed up grease fitting.

Product Specifications:

Part # 1213R

Pump Heavy-Duty 65:1 Ratio

Max Grease NLGI No. 3

Max. Delivery 66-oz per minute @ 90PSI

Max. Air PSI 110 PSI

Air Consumption 8.74 CFM @ 100 PSI

Air Inlet 1/4" NPT

Air Hose 1/4" x 4-ft (2004)

Pump Head Dia. 2 1/2"

Head Length 10"

Tube Length 29"

1213RAR Pump Tube Diameter 1 3/16"

Air Line Filter Package 1559A-ASSY

Included Accessories:

Control Handle Drum Cover Follower Plate Drum Dolly

1536A 65385 1524 120-S

“Z” Swivel 6’ Grease Hose 4’ Air Hose Air Regulator

1545 1806 2004 1559A-ASSY

IMPORTANT NOTE STARTING UP

FOR REASONS OF SAFETY Fig. 1 - Fit a tube for

AND PRODUCT INTEGRITY, compressed air to the air

THE OPERATOR MUST intake reduction A of the

air-operated pump, by

RESTRICT HIMSELF TO

means of 1/4" threaded

ORDINARY MAINTENANCE fittings G.

(FILTERS, SILENCERS, The compressed air supply

CLEANING...) WHEREAS must not exceed 8 bar.

FOR ANY INTERVENTIONS

OF EXTRA- ORDINARY GREASE DELIVERY

MAINTENANCE OR TUBE

REPAIR, ALWAYS CON- Fig. 1 - Before connecting

TACT OUR SALES AND the grease delivery tube C

SERVICE CENTRES. (supplied on request), to

the liquid outlet reduction

of the air- operated pump,

operate the pump for

20-30 secs. max. so that

the grease comes out of

TRANSPORT AND HANDLING the same.

The air-operated grease pumps

are supplied packed, assembled

and ready to us. Do not disperse DIFFICULT SUCTION

the container in the environment. If grease delivery is not obtained (formation of

No special attention is needed air pockets) it is advisable to lift the air- operat-

when handling and packing new ed pump (fig. 2) and pour 200-300 cc of SAE 40

air- operated pumps. oil in the suction zone of the same in order to

eliminate the suction of air. This operation is

nearly always necessary when the grease used

is not of the self- levelling type, the diaphragm

is not used and the grease has been hardened

by the cold.

As soon as the grease comes out the pump,

connect tube A (fig. 3) and, at the end of the

tube, gun B supplied on request. Operate the

pump by keeping the delivery gun open until

grease comes out. If the grease fails to come

out, check the tube and gun.

FORCED LUBRICATION

The condensation in compressed air can slow down

and even block the motor cylinder; in order to prevent

this from happening, every now and again operate the

aeropulsometer for a couple of minutes after having let

in, from the air inlet hole, 50 grams of vaseline oil, or in

any case, another very fluid oil. If necessary, repeat this

operation until the motor is perfectly lubricated.

FILTER CLEANING

In the event of poor or slow grease delivery, check the

state of filters A - B - C.

GREASE DIAPHRAGM (fig. 4)

For regular, trouble-free operation, we always recommend application of the grease

diaphragm M, especially when self-levelling greases are not used. The diaphragm, which

is pulled towards the bottom of the drum by suction pressure caused by the air-operated

pump, compresses the grease, preventing the formation of air pockets which could cause

a blockage in delivery. Always keeping the grease clean will preserve its characteristics

and also enable the grease, which without a diaphragm would otherwise remain stuck to

the walls of the drum, to be collected from the bottom and almost totally drawn.

National-Spencer Inc. 1213RAR Operating Guide

You might also like

- Workshop Manual: Dpa Fuel Injection Pump DDNX116A (EN)Document114 pagesWorkshop Manual: Dpa Fuel Injection Pump DDNX116A (EN)Carl Anthony Chamberlain94% (16)

- XA400S - XR400S Illustrated Parts Catalog - MASTERDocument531 pagesXA400S - XR400S Illustrated Parts Catalog - MASTERCorrado Sirianni100% (5)

- Manual Compresora Sullair 425Document2 pagesManual Compresora Sullair 425Franz JW Monteza100% (1)

- WPCE Electric Line Pressure Control Equipment String BDocument2 pagesWPCE Electric Line Pressure Control Equipment String BLuis Quiñel100% (1)

- AB Series: Triplex Plunger Pump, AgricultureDocument4 pagesAB Series: Triplex Plunger Pump, AgricultureSaadNo ratings yet

- Standard P&ID Symbols Legend - Industry Standardized P&ID SymbolsDocument4 pagesStandard P&ID Symbols Legend - Industry Standardized P&ID SymbolsGhulam Khairul IlhamNo ratings yet

- Catalog 2010 PDFDocument3 pagesCatalog 2010 PDFArpit VermaNo ratings yet

- Enerpac PA Series CatalogDocument3 pagesEnerpac PA Series CatalogTitanplyNo ratings yet

- HY10 1630US 5 2012-Accumulator AccessoriesDocument12 pagesHY10 1630US 5 2012-Accumulator AccessoriesFelipe DiazNo ratings yet

- Suntec TA3 Pump SpecificationDocument2 pagesSuntec TA3 Pump Specificationsayda MaowiaNo ratings yet

- Vane Pumps Single, Double & Triple T6 Mobile ApplicationDocument12 pagesVane Pumps Single, Double & Triple T6 Mobile Applicationdelhi hydraulics100% (1)

- ESN2013S PumpDocument4 pagesESN2013S PumpHeber LeyvaNo ratings yet

- Ficha-Tecnica-10500 10502 10504 All PMDocument1 pageFicha-Tecnica-10500 10502 10504 All PMJorge Luis Sánchez MuñozNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- 2PE. Catalogue ES.-catalaogoDocument40 pages2PE. Catalogue ES.-catalaogodkniskyNo ratings yet

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDocument2 pagesLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaNo ratings yet

- NM6-110E Data SheetDocument3 pagesNM6-110E Data SheetDedi WahyudiNo ratings yet

- DP-40 Aln Manual (MM10 R3)Document10 pagesDP-40 Aln Manual (MM10 R3)Amit ChourasiaNo ratings yet

- Parker (T6, T6CC) Hydraulic Vane PumpsDocument12 pagesParker (T6, T6CC) Hydraulic Vane PumpsEduardo Valladares DuranNo ratings yet

- BD ModelDocument11 pagesBD ModelSameh AbdelazizNo ratings yet

- Vincke Gear Pumps CatDocument48 pagesVincke Gear Pumps CatVelibor KaranovicNo ratings yet

- CBGA Full en Us A4Document2 pagesCBGA Full en Us A4Epul HaqNo ratings yet

- 1.5PE - Technical CatalogueDocument26 pages1.5PE - Technical CatalogueOmar Ricardo De La Garza NavarroNo ratings yet

- BGRP GP BacktbackDocument2 pagesBGRP GP Backtbackinder24242No ratings yet

- Apollo Ambient Air Pump: The CALIPSO Single Operator ModelDocument1 pageApollo Ambient Air Pump: The CALIPSO Single Operator ModelCarlos ArteagaNo ratings yet

- Model DP-Series 5 6 G P M 6 0 0 P S I: Hydrostatic Test Pumps Post Hole DiggersDocument1 pageModel DP-Series 5 6 G P M 6 0 0 P S I: Hydrostatic Test Pumps Post Hole DiggersbabjihanumanthuNo ratings yet

- 3PE Technical Catalogue BombaDocument32 pages3PE Technical Catalogue BombaTavo VergaraNo ratings yet

- Oil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetDocument4 pagesOil Pump Type RSA Size 28, 40, 60, 95, 125: Data SheetJhonNo ratings yet

- Two-Stage Engine Driven BrochureDocument8 pagesTwo-Stage Engine Driven BrochurejohnNo ratings yet

- ET1505E34H PumpDocument4 pagesET1505E34H PumpSanti Jonas LopezNo ratings yet

- Parker (T6, T6D) Hydraulic Vane PumpsDocument12 pagesParker (T6, T6D) Hydraulic Vane PumpsMortumDamaNo ratings yet

- PT Nitrogen Pumper 180000Document1 pagePT Nitrogen Pumper 180000Mind Nasrin KadirNo ratings yet

- CAIGLGN Full en Us A4Document2 pagesCAIGLGN Full en Us A4david mendozaNo ratings yet

- 2PE - Technical CatalogueDocument42 pages2PE - Technical CatalogueandrewgeorgecherianNo ratings yet

- 231-6284 Filter CartDocument2 pages231-6284 Filter CartDAnielNo ratings yet

- Valvula Contrabalance CBGA LIN HCLDocument2 pagesValvula Contrabalance CBGA LIN HCLcarlos pachecoNo ratings yet

- Primatic LH SeriesDocument2 pagesPrimatic LH Seriessatya.unitamaNo ratings yet

- A Polyhydron Group Company: DescriptionDocument3 pagesA Polyhydron Group Company: DescriptionHorea CordunianuNo ratings yet

- Hoses English Imperial E329Document2 pagesHoses English Imperial E329MSc Kostic MilosNo ratings yet

- Вакумный насос - N816-3KDocument3 pagesВакумный насос - N816-3KgusmagicpifNo ratings yet

- 4VacuumPumps Gauges10-11Document2 pages4VacuumPumps Gauges10-11ISKT-IsıtmaSogutmaKlimaTesisatNo ratings yet

- 1040 Cu. in - Nitrogen Pilot Cylinder With Pressure SwitchDocument2 pages1040 Cu. in - Nitrogen Pilot Cylinder With Pressure SwitchVikash Kumar SinghNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Data Sheet TRAP BreatherDocument2 pagesData Sheet TRAP BreatherMAMI RAKOTOMAHANINANo ratings yet

- 2 Pumps and Compressors 2Document104 pages2 Pumps and Compressors 2Mannel matuidiNo ratings yet

- The Best of Both Worlds: Atlas Copco PETPACKDocument16 pagesThe Best of Both Worlds: Atlas Copco PETPACKMateus BanuthNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidNo ratings yet

- All Prices IR-SULLAIR-ETCDocument6 pagesAll Prices IR-SULLAIR-ETCJeff LNo ratings yet

- Primatic HH SeriesDocument2 pagesPrimatic HH Seriessatya.unitamaNo ratings yet

- GB500DDocument16 pagesGB500DMiguel BrocaNo ratings yet

- On Vehicle InspectionDocument3 pagesOn Vehicle InspectionEdson CRNo ratings yet

- Casestudy Report On Air Compressors PDFDocument47 pagesCasestudy Report On Air Compressors PDFAbhishek JainNo ratings yet

- Aerzen USA G5 Hybrid Brochure 2015Document8 pagesAerzen USA G5 Hybrid Brochure 2015Eduardo rodriguez gonzalezNo ratings yet

- Suntec Fuel Oil PumpDocument2 pagesSuntec Fuel Oil PumpkmthongNo ratings yet

- Vacuum Pump, KNF, N 820 3FT.18 Data SheetDocument2 pagesVacuum Pump, KNF, N 820 3FT.18 Data Sheetmostafa ahmedNo ratings yet

- Enerpac PTA Series CatalogDocument2 pagesEnerpac PTA Series CatalogTitanplyNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- PVR6 Service Manual 265664 REV 04 19Document8 pagesPVR6 Service Manual 265664 REV 04 19Partagon PowNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- SV80-100 Eng Data1-1996Document9 pagesSV80-100 Eng Data1-1996Bala Krishnan NataNo ratings yet

- Cabezotes Gardner DenverDocument8 pagesCabezotes Gardner DenverChristian CardenasNo ratings yet

- Model Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18ADocument2 pagesModel Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18AErasmo LimaNo ratings yet

- 7366 - 30 99 24 1607 - 1Document21 pages7366 - 30 99 24 1607 - 1Syed Qasim AbbasNo ratings yet

- Aircraft Hydraulic SystemDocument23 pagesAircraft Hydraulic SystemmaruliNo ratings yet

- DESPIECE SACABOCADO HIDRAULICO 1-2 - 4.pdf 3 PDFDocument10 pagesDESPIECE SACABOCADO HIDRAULICO 1-2 - 4.pdf 3 PDFAlan FloresNo ratings yet

- Fuel Rail Pressure, CheckingDocument3 pagesFuel Rail Pressure, Checkinghanafi yusuf100% (1)

- Positive Displacement CompressorDocument30 pagesPositive Displacement CompressorchaitanyaNo ratings yet

- M-084 Main Diesel Generator Engine-LnstallaionDocument125 pagesM-084 Main Diesel Generator Engine-LnstallaionВасиль ГудзьNo ratings yet

- Leverage Air CompressorDocument9 pagesLeverage Air CompressorJanice WilliamsNo ratings yet

- Two Stage High/Low Hydraulic Pumps: Concentric ABDocument8 pagesTwo Stage High/Low Hydraulic Pumps: Concentric ABZakNo ratings yet

- CG Pumps: Product CatalogueDocument88 pagesCG Pumps: Product CatalogueAnimesh SahaNo ratings yet

- Centrifugal Pump 2020Document21 pagesCentrifugal Pump 2020Justin VargheseNo ratings yet

- Swing-Out Valve GuideDocument18 pagesSwing-Out Valve Guidejuan david restrepo aguilarNo ratings yet

- SECTION 5.25: Cooling SystemDocument74 pagesSECTION 5.25: Cooling SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Type Certificate Data Sheet No. 1E4Document12 pagesType Certificate Data Sheet No. 1E4flyingemuNo ratings yet

- Transmision CaseDocument70 pagesTransmision CaseFrancisco Hernandez100% (2)

- (TDB) VRF Idu Duct For La (Drain Pump Integrated, R410a, 50 - 60hz, HP - HR) - Ver.1.1 Slim DuctDocument59 pages(TDB) VRF Idu Duct For La (Drain Pump Integrated, R410a, 50 - 60hz, HP - HR) - Ver.1.1 Slim DuctJaime A. AlvarezNo ratings yet

- Direct Condensation of Hydrocarbon VaporsDocument10 pagesDirect Condensation of Hydrocarbon VaporsManju Lata Kapur100% (1)

- EC290B LC Hidrolik Service ManualDocument96 pagesEC290B LC Hidrolik Service ManualMilanNo ratings yet

- SDLGG g9138 Motor GraderDocument5 pagesSDLGG g9138 Motor GraderYacoub ErebihNo ratings yet

- SSP 080 20-16-12 Litre Diesel Engines With Common RailDocument44 pagesSSP 080 20-16-12 Litre Diesel Engines With Common RailNhuong Hoang DinhNo ratings yet

- Modeling and Stress Analysis of Pump PipingDocument15 pagesModeling and Stress Analysis of Pump PipingViệt Hoàng100% (1)

- ACQ580 Catalog 3AUA0000194172 RevH en LowresDocument72 pagesACQ580 Catalog 3AUA0000194172 RevH en Lowresrafa.roeschNo ratings yet

- MackDocument6 pagesMackjonatan arangoNo ratings yet

- Mobatec Modeller Intorduction Course Tutorial IDocument10 pagesMobatec Modeller Intorduction Course Tutorial IMohammad Yasser RamzanNo ratings yet

- 3516C - 2100hp at 1750 Tier 2Document5 pages3516C - 2100hp at 1750 Tier 2woodyjumpsNo ratings yet

- Ra92060 2006-12 PDFDocument36 pagesRa92060 2006-12 PDFabdelrhmangbr86No ratings yet

- Model: JC Size: 4X6-14 Group: 3J 60Hz RPM: 870 Stages: 1: Operating Conditions Pump PerformanceDocument2 pagesModel: JC Size: 4X6-14 Group: 3J 60Hz RPM: 870 Stages: 1: Operating Conditions Pump PerformanceMiguel IgnacioNo ratings yet

- Goulds 7200CB Bulletin PDFDocument12 pagesGoulds 7200CB Bulletin PDFManuel CarreñoNo ratings yet