Professional Documents

Culture Documents

2002 10 It Is A Pump

2002 10 It Is A Pump

Uploaded by

Harshad SolankiCopyright:

Available Formats

You might also like

- Electrical Submersible Pump Handbook PDFDocument67 pagesElectrical Submersible Pump Handbook PDFFernandoEnriqueCalveteGonzález100% (2)

- Drilling Simulator Lab Report FinalDocument18 pagesDrilling Simulator Lab Report Finalnasreldin3100% (1)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- UK MCA 4th Class OralDocument33 pagesUK MCA 4th Class OralRicky Chua Snr100% (4)

- LM Advanced Pumping AFAC Licenced WebDocument160 pagesLM Advanced Pumping AFAC Licenced WebFromOzNo ratings yet

- Rocess Afety Eacon: It's A Bird, It's A Plane, It's A PUMP!Document1 pageRocess Afety Eacon: It's A Bird, It's A Plane, It's A PUMP!Alejandro HernandezNo ratings yet

- The Basics of Pump Startup - 1Document5 pagesThe Basics of Pump Startup - 1FrankNo ratings yet

- 1 - 5 Well Test Equipment 26.03.2015Document49 pages1 - 5 Well Test Equipment 26.03.2015Lakshman Kumar JulapalliNo ratings yet

- 4 PumpsDocument26 pages4 PumpsdhasdjNo ratings yet

- Can A Water Pump ExplodeDocument1 pageCan A Water Pump ExplodeHimanshu ChichraNo ratings yet

- Poppet Valve - Types, Working, Operation, Diagram, Applications, Advantages & DisadvantagesDocument2 pagesPoppet Valve - Types, Working, Operation, Diagram, Applications, Advantages & DisadvantagesAbdul Mohid SheikhNo ratings yet

- How To Synchronize Generators On A ShipDocument115 pagesHow To Synchronize Generators On A Shipandriea03100% (1)

- AMPLDocument15 pagesAMPLAMitNo ratings yet

- Field Testing of A Closed Loop PumpDocument4 pagesField Testing of A Closed Loop Pumpmagarmat1980No ratings yet

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDocument8 pagesTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYNo ratings yet

- The Basics of Pump StartupDocument12 pagesThe Basics of Pump StartupMika JulisaNo ratings yet

- Centrifugal Pump - Project Reportcopy-1Document40 pagesCentrifugal Pump - Project Reportcopy-1DR SHNGM0% (1)

- Hydraulic Ram Pump ThesisDocument8 pagesHydraulic Ram Pump ThesisProfessionalPaperWriterCanada100% (2)

- Case Histories of Pump Explosions While Running Isolated (Giles Lodal 2001)Document5 pagesCase Histories of Pump Explosions While Running Isolated (Giles Lodal 2001)rachitNo ratings yet

- Rotary EvaporatorDocument3 pagesRotary EvaporatorAltaf Ur RehmanNo ratings yet

- Application of Valves 1687106274Document93 pagesApplication of Valves 1687106274Muhammed RaheesNo ratings yet

- Learning For Oil and Gas PlantDocument93 pagesLearning For Oil and Gas Plantlucky yadavNo ratings yet

- 2003 11 Temperature and Pressure RatingsDocument1 page2003 11 Temperature and Pressure RatingsHarshad SolankiNo ratings yet

- Pump Doctor's Surgery: Looking Beyond The ObviousDocument2 pagesPump Doctor's Surgery: Looking Beyond The ObviousIzallmachineNo ratings yet

- PSVDocument38 pagesPSVSajid Raza100% (2)

- Section 7, Introduction To Well Testing EquipmentDocument54 pagesSection 7, Introduction To Well Testing EquipmenthammamiNo ratings yet

- Group-17 FFO 3130502Document16 pagesGroup-17 FFO 3130502Priya TandelNo ratings yet

- LRVP Startup Troubleshooting Oct14Document5 pagesLRVP Startup Troubleshooting Oct14Fergus GardnerNo ratings yet

- Lab Work: Turbine Technologies, LTD., 410 Phillips Street, Chetek, WI, 54728 USADocument19 pagesLab Work: Turbine Technologies, LTD., 410 Phillips Street, Chetek, WI, 54728 USAcorey6No ratings yet

- How Often Should You Test Your Fire Pump?Document3 pagesHow Often Should You Test Your Fire Pump?dwisunuNo ratings yet

- H V P, I .: The Molecular SieveDocument3 pagesH V P, I .: The Molecular SieveganeshNo ratings yet

- Mechanical MaintDocument9 pagesMechanical MainthmnnhgczdmNo ratings yet

- Vacuum Purging and Processing Tips - Skunk Pharm Research LLC PDFDocument46 pagesVacuum Purging and Processing Tips - Skunk Pharm Research LLC PDFAllery100% (1)

- ESP HandBookDocument67 pagesESP HandBookJose FloresNo ratings yet

- 2 FfoDocument15 pages2 FfoPriya TandelNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-19Document2 pages01.hazards of Trapped Pressure & Vacuum-19rahulNo ratings yet

- User Manual GK Compact - EN - V4.3 - 2018-02Document20 pagesUser Manual GK Compact - EN - V4.3 - 2018-02Heidi De VliegherNo ratings yet

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaNo ratings yet

- Hydromax-UserDocument28 pagesHydromax-UserKeone SemanaNo ratings yet

- Well Control EquiptDocument115 pagesWell Control EquiptGhavban David100% (3)

- Why We Need To Close TheDocument2 pagesWhy We Need To Close TheAli AlilouNo ratings yet

- Safety Concerns: Relief Valves, Corrosion, and Safety TripsDocument12 pagesSafety Concerns: Relief Valves, Corrosion, and Safety TripsAbhimanyu SharmaNo ratings yet

- L 5 and L 10 Troubleshooting GuideDocument8 pagesL 5 and L 10 Troubleshooting GuideJohn DawsonNo ratings yet

- AP-TRANSFER PlumbpumpDocument8 pagesAP-TRANSFER PlumbpumpWilson wayerNo ratings yet

- 15 - FRAMO Portable Cargo PumpDocument6 pages15 - FRAMO Portable Cargo PumpMomchil DimitrovNo ratings yet

- Pumps Operation & ControlDocument57 pagesPumps Operation & ControlAli HegaigNo ratings yet

- NidojapixikelewDocument2 pagesNidojapixikelewAli KiaNo ratings yet

- THIS Medical BDocument18 pagesTHIS Medical BEmilia May AguinaldoNo ratings yet

- Lab Rotary EvaporatorDocument7 pagesLab Rotary EvaporatorAnna Yunita SitompulNo ratings yet

- 5 15FSvcDocument8 pages5 15FSvcDavinaNo ratings yet

- Self Priming PumpsDocument4 pagesSelf Priming PumpsMohamad Mostafa AhmedNo ratings yet

- Fix A Fouled FractionatorDocument3 pagesFix A Fouled Fractionatorfawmer61No ratings yet

- Troubleshooting Guide: Back NextDocument1 pageTroubleshooting Guide: Back NextAkonSayagyiNo ratings yet

- Piper Alpha Background & ShortcomingsDocument4 pagesPiper Alpha Background & Shortcomingsfashwin0% (1)

- Beacon EnglishDocument1 pageBeacon EnglishALI ASGHAR SOOMRONo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- 2009 05 Mechanical IntegrityDocument1 page2009 05 Mechanical IntegrityHarshad SolankiNo ratings yet

- 2008 02 How Can You Use The BeaconDocument1 page2008 02 How Can You Use The BeaconHarshad SolankiNo ratings yet

- 2008 09 Plant SecurityDocument1 page2008 09 Plant SecurityHarshad SolankiNo ratings yet

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDocument1 page2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiNo ratings yet

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDocument1 page2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiNo ratings yet

- 2007 09 Hot Work PermitsDocument1 page2007 09 Hot Work PermitsHarshad SolankiNo ratings yet

- 2007 07 Hose Repaired With Duct TapeDocument1 page2007 07 Hose Repaired With Duct TapeHarshad SolankiNo ratings yet

- 2007 01 2006 Beacon ReviewDocument1 page2007 01 2006 Beacon ReviewHarshad SolankiNo ratings yet

- 2007 05 Great Boston Molasses FloodDocument1 page2007 05 Great Boston Molasses FloodHarshad Solanki100% (1)

- 2007 04 MR Potato Head Is DownDocument1 page2007 04 MR Potato Head Is DownHarshad SolankiNo ratings yet

- 2006 10 Store CylindersDocument1 page2006 10 Store CylindersHarshad SolankiNo ratings yet

2002 10 It Is A Pump

2002 10 It Is A Pump

Uploaded by

Harshad SolankiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2002 10 It Is A Pump

2002 10 It Is A Pump

Uploaded by

Harshad SolankiCopyright:

Available Formats

CCPS

An AIChE Industry Technology Alliance

Process Safety Beacon

Messages for Manufacturing Personnel

October 2002

Sponsored by CWRT

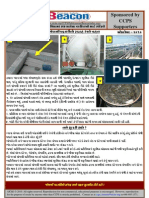

Its a bird, its a plane, itsA PUMP!

The Incident

A 75 HP centrifugal pump was operated with both suction and discharge valves closed for about 45 minutes. It was believed to be completely full of liquid. As mechanical energy from the motor was transferred to heat, the liquid in the pump slowly increased in temperature and pressure until finally the pump failed catastrophically. One fragment weighing 5 pounds was found over 400 feet away. Luckily, no one was in the area so there were no injuries.

Why would events such as this happen?

This situation is different than operating a pump deadheaded where the suction valve is open but there is no flow through the pump. Here, pressure relief occurs back through the pump suction line. In the past, this event likely would have ended with a seal failure - seal leakage would have been sufficient to relieve the pressure. New seal designs are significantly improved. This older relief system can no longer be counted upon. As processes have become more automated it is now much easier to accidentally start a pump or operate the wrong valve. Spare pump arrangements can also be a problem if the incorrect pump is started. For example, the north pump has valves aligned for operation but the south pump is started.

What can I do?

If you discover a blocked in pump in operation, use extreme caution. Shut the pump down remotely; keep people FAR away until it has cooled. Use care when starting pumps. Communication about which pump is valved for operation must be very clear. Some plants try to have an individual near the pump when it is started. This may not be possible in all situations, but it can eliminate many problems. If possible, open the casing drain on a pump that will be out of service for an extended period. But, check to make sure you are not creating another problem (environmental, cost, etc) by doing so! And, a routine tour of a manufacturing area can identify many things a blocked in pump operation is just one of them!

Pumps move liquids for us everyday, but they can also generate heat a significant hazard if it has no place to go!

AIChE 2002. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps@aiche.org or 212-591-7319. http://www.aiche.org/ccps/safetybeacon.htm

You might also like

- Electrical Submersible Pump Handbook PDFDocument67 pagesElectrical Submersible Pump Handbook PDFFernandoEnriqueCalveteGonzález100% (2)

- Drilling Simulator Lab Report FinalDocument18 pagesDrilling Simulator Lab Report Finalnasreldin3100% (1)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- UK MCA 4th Class OralDocument33 pagesUK MCA 4th Class OralRicky Chua Snr100% (4)

- LM Advanced Pumping AFAC Licenced WebDocument160 pagesLM Advanced Pumping AFAC Licenced WebFromOzNo ratings yet

- Rocess Afety Eacon: It's A Bird, It's A Plane, It's A PUMP!Document1 pageRocess Afety Eacon: It's A Bird, It's A Plane, It's A PUMP!Alejandro HernandezNo ratings yet

- The Basics of Pump Startup - 1Document5 pagesThe Basics of Pump Startup - 1FrankNo ratings yet

- 1 - 5 Well Test Equipment 26.03.2015Document49 pages1 - 5 Well Test Equipment 26.03.2015Lakshman Kumar JulapalliNo ratings yet

- 4 PumpsDocument26 pages4 PumpsdhasdjNo ratings yet

- Can A Water Pump ExplodeDocument1 pageCan A Water Pump ExplodeHimanshu ChichraNo ratings yet

- Poppet Valve - Types, Working, Operation, Diagram, Applications, Advantages & DisadvantagesDocument2 pagesPoppet Valve - Types, Working, Operation, Diagram, Applications, Advantages & DisadvantagesAbdul Mohid SheikhNo ratings yet

- How To Synchronize Generators On A ShipDocument115 pagesHow To Synchronize Generators On A Shipandriea03100% (1)

- AMPLDocument15 pagesAMPLAMitNo ratings yet

- Field Testing of A Closed Loop PumpDocument4 pagesField Testing of A Closed Loop Pumpmagarmat1980No ratings yet

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDocument8 pagesTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYNo ratings yet

- The Basics of Pump StartupDocument12 pagesThe Basics of Pump StartupMika JulisaNo ratings yet

- Centrifugal Pump - Project Reportcopy-1Document40 pagesCentrifugal Pump - Project Reportcopy-1DR SHNGM0% (1)

- Hydraulic Ram Pump ThesisDocument8 pagesHydraulic Ram Pump ThesisProfessionalPaperWriterCanada100% (2)

- Case Histories of Pump Explosions While Running Isolated (Giles Lodal 2001)Document5 pagesCase Histories of Pump Explosions While Running Isolated (Giles Lodal 2001)rachitNo ratings yet

- Rotary EvaporatorDocument3 pagesRotary EvaporatorAltaf Ur RehmanNo ratings yet

- Application of Valves 1687106274Document93 pagesApplication of Valves 1687106274Muhammed RaheesNo ratings yet

- Learning For Oil and Gas PlantDocument93 pagesLearning For Oil and Gas Plantlucky yadavNo ratings yet

- 2003 11 Temperature and Pressure RatingsDocument1 page2003 11 Temperature and Pressure RatingsHarshad SolankiNo ratings yet

- Pump Doctor's Surgery: Looking Beyond The ObviousDocument2 pagesPump Doctor's Surgery: Looking Beyond The ObviousIzallmachineNo ratings yet

- PSVDocument38 pagesPSVSajid Raza100% (2)

- Section 7, Introduction To Well Testing EquipmentDocument54 pagesSection 7, Introduction To Well Testing EquipmenthammamiNo ratings yet

- Group-17 FFO 3130502Document16 pagesGroup-17 FFO 3130502Priya TandelNo ratings yet

- LRVP Startup Troubleshooting Oct14Document5 pagesLRVP Startup Troubleshooting Oct14Fergus GardnerNo ratings yet

- Lab Work: Turbine Technologies, LTD., 410 Phillips Street, Chetek, WI, 54728 USADocument19 pagesLab Work: Turbine Technologies, LTD., 410 Phillips Street, Chetek, WI, 54728 USAcorey6No ratings yet

- How Often Should You Test Your Fire Pump?Document3 pagesHow Often Should You Test Your Fire Pump?dwisunuNo ratings yet

- H V P, I .: The Molecular SieveDocument3 pagesH V P, I .: The Molecular SieveganeshNo ratings yet

- Mechanical MaintDocument9 pagesMechanical MainthmnnhgczdmNo ratings yet

- Vacuum Purging and Processing Tips - Skunk Pharm Research LLC PDFDocument46 pagesVacuum Purging and Processing Tips - Skunk Pharm Research LLC PDFAllery100% (1)

- ESP HandBookDocument67 pagesESP HandBookJose FloresNo ratings yet

- 2 FfoDocument15 pages2 FfoPriya TandelNo ratings yet

- 01.hazards of Trapped Pressure & Vacuum-19Document2 pages01.hazards of Trapped Pressure & Vacuum-19rahulNo ratings yet

- User Manual GK Compact - EN - V4.3 - 2018-02Document20 pagesUser Manual GK Compact - EN - V4.3 - 2018-02Heidi De VliegherNo ratings yet

- Process Safety BeaconDocument1 pageProcess Safety BeaconRaul tejadaNo ratings yet

- Hydromax-UserDocument28 pagesHydromax-UserKeone SemanaNo ratings yet

- Well Control EquiptDocument115 pagesWell Control EquiptGhavban David100% (3)

- Why We Need To Close TheDocument2 pagesWhy We Need To Close TheAli AlilouNo ratings yet

- Safety Concerns: Relief Valves, Corrosion, and Safety TripsDocument12 pagesSafety Concerns: Relief Valves, Corrosion, and Safety TripsAbhimanyu SharmaNo ratings yet

- L 5 and L 10 Troubleshooting GuideDocument8 pagesL 5 and L 10 Troubleshooting GuideJohn DawsonNo ratings yet

- AP-TRANSFER PlumbpumpDocument8 pagesAP-TRANSFER PlumbpumpWilson wayerNo ratings yet

- 15 - FRAMO Portable Cargo PumpDocument6 pages15 - FRAMO Portable Cargo PumpMomchil DimitrovNo ratings yet

- Pumps Operation & ControlDocument57 pagesPumps Operation & ControlAli HegaigNo ratings yet

- NidojapixikelewDocument2 pagesNidojapixikelewAli KiaNo ratings yet

- THIS Medical BDocument18 pagesTHIS Medical BEmilia May AguinaldoNo ratings yet

- Lab Rotary EvaporatorDocument7 pagesLab Rotary EvaporatorAnna Yunita SitompulNo ratings yet

- 5 15FSvcDocument8 pages5 15FSvcDavinaNo ratings yet

- Self Priming PumpsDocument4 pagesSelf Priming PumpsMohamad Mostafa AhmedNo ratings yet

- Fix A Fouled FractionatorDocument3 pagesFix A Fouled Fractionatorfawmer61No ratings yet

- Troubleshooting Guide: Back NextDocument1 pageTroubleshooting Guide: Back NextAkonSayagyiNo ratings yet

- Piper Alpha Background & ShortcomingsDocument4 pagesPiper Alpha Background & Shortcomingsfashwin0% (1)

- Beacon EnglishDocument1 pageBeacon EnglishALI ASGHAR SOOMRONo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- 2009 05 Mechanical IntegrityDocument1 page2009 05 Mechanical IntegrityHarshad SolankiNo ratings yet

- 2008 02 How Can You Use The BeaconDocument1 page2008 02 How Can You Use The BeaconHarshad SolankiNo ratings yet

- 2008 09 Plant SecurityDocument1 page2008 09 Plant SecurityHarshad SolankiNo ratings yet

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDocument1 page2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiNo ratings yet

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDocument1 page2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiNo ratings yet

- 2007 09 Hot Work PermitsDocument1 page2007 09 Hot Work PermitsHarshad SolankiNo ratings yet

- 2007 07 Hose Repaired With Duct TapeDocument1 page2007 07 Hose Repaired With Duct TapeHarshad SolankiNo ratings yet

- 2007 01 2006 Beacon ReviewDocument1 page2007 01 2006 Beacon ReviewHarshad SolankiNo ratings yet

- 2007 05 Great Boston Molasses FloodDocument1 page2007 05 Great Boston Molasses FloodHarshad Solanki100% (1)

- 2007 04 MR Potato Head Is DownDocument1 page2007 04 MR Potato Head Is DownHarshad SolankiNo ratings yet

- 2006 10 Store CylindersDocument1 page2006 10 Store CylindersHarshad SolankiNo ratings yet