Professional Documents

Culture Documents

Electrodos Convinados Flux

Electrodos Convinados Flux

Uploaded by

luisCopyright:

Available Formats

You might also like

- How to Build Max-Performance Chevy LT1/LT4 EnginesFrom EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesRating: 3 out of 5 stars3/5 (1)

- Boeing 787 Lessons LearntDocument46 pagesBoeing 787 Lessons LearntckleenordamNo ratings yet

- SEVPL BrochureDocument20 pagesSEVPL BrochureNaveen AnandNo ratings yet

- MOD4 Mark II: Ada Mp-1Document5 pagesMOD4 Mark II: Ada Mp-1Andrei PopaNo ratings yet

- W200 Casing Design Day 2 PDFDocument84 pagesW200 Casing Design Day 2 PDFYosef Shaaban100% (1)

- 2015-LMFP-016 Guide For U1-2115 Error and Abnormal Noise SL-M437x 537x SeriesDocument4 pages2015-LMFP-016 Guide For U1-2115 Error and Abnormal Noise SL-M437x 537x SeriesAntonio HerreraNo ratings yet

- Annotated Bibliography 2Document2 pagesAnnotated Bibliography 2nidhivashishtha83No ratings yet

- Comparatii Si Echivalente Branduri Sarma TubularaDocument4 pagesComparatii Si Echivalente Branduri Sarma TubularaAnonymous LpKY4pNo ratings yet

- Tubular Wire Products:: Filler Metals For Demand Critical Seismic ApplicationsDocument1 pageTubular Wire Products:: Filler Metals For Demand Critical Seismic ApplicationsOctavio Ochoa HernadezNo ratings yet

- Gas Turbines SpecsDocument11 pagesGas Turbines SpecsDiêgo MonteiroNo ratings yet

- 2022 12 05#ReleaseNotes - 750 8x0xDocument58 pages2022 12 05#ReleaseNotes - 750 8x0xEJNo ratings yet

- Lista de Equipos 2020Document2 pagesLista de Equipos 2020Renzo Cardenas SalasNo ratings yet

- Xy-Sa-Gpi2304-2 PLDDocument2 pagesXy-Sa-Gpi2304-2 PLDrafaelNo ratings yet

- Engineering Drawings and Spare Parts Lists - Carousel EFC-U-24 G-L - 111390 - R01 - English - K3Document27 pagesEngineering Drawings and Spare Parts Lists - Carousel EFC-U-24 G-L - 111390 - R01 - English - K3ZubairNo ratings yet

- List of The Inverter Brands Compatible With TBB Low-Voltage Lithium Batteries V3.0Document3 pagesList of The Inverter Brands Compatible With TBB Low-Voltage Lithium Batteries V3.0fatou tallNo ratings yet

- Approved BatteryDocument7 pagesApproved BatteryСергій МенжинськийNo ratings yet

- Joyadapter v1 1 Adi04 PartlistDocument1 pageJoyadapter v1 1 Adi04 PartlistHarald DasselNo ratings yet

- VIN, Engine and Transmission Numbers Vehicle Identification NumberDocument4 pagesVIN, Engine and Transmission Numbers Vehicle Identification NumberDoc ImportNo ratings yet

- Vessel InformationDocument241 pagesVessel InformationNayem PoshariNo ratings yet

- HT Cable Voltage Drop CalculationDocument9 pagesHT Cable Voltage Drop CalculationPaul Goh Yngwie100% (1)

- Electrical Part ListDocument5 pagesElectrical Part ListecurrasNo ratings yet

- Corvus DocumentationDocument10 pagesCorvus Documentationwahyudi aji WienarnoNo ratings yet

- Ad 100 VTDocument35 pagesAd 100 VTleonataxxNo ratings yet

- Schaeffler 422 0136 10Document10 pagesSchaeffler 422 0136 10Gabriel JLNo ratings yet

- Service Bulletin Trucks: ICON (Idle Management System)Document26 pagesService Bulletin Trucks: ICON (Idle Management System)Registr RegistrNo ratings yet

- Modelos Disponibles de Laser PickupDocument7 pagesModelos Disponibles de Laser PickupPablo Acapulco GuerreroNo ratings yet

- Num de Parte Shark 50mmDocument2 pagesNum de Parte Shark 50mmRuben Castro QuispeNo ratings yet

- DHBVN MASTER Technical Specifiaction 1Document24 pagesDHBVN MASTER Technical Specifiaction 1Ashish bhattNo ratings yet

- Thomson Roundrail 1DC SpecsheetDocument2 pagesThomson Roundrail 1DC SpecsheetElectromateNo ratings yet

- 1-WPS REGISTER FOR STRUCTURE STTPIP Rev ODocument6 pages1-WPS REGISTER FOR STRUCTURE STTPIP Rev Oxuanthien309No ratings yet

- Information: Product Support BulletinDocument8 pagesInformation: Product Support BulletiningpalacioNo ratings yet

- PS HydroTransDocument2 pagesPS HydroTransababoolNo ratings yet

- Welding Consumables For Pipeline Construction - ENDocument64 pagesWelding Consumables For Pipeline Construction - ENmaheshNo ratings yet

- Lexus Toyota ManualDocument37 pagesLexus Toyota Manualjorge morillo100% (1)

- Welding Electrodes For Petrochemical IndustryG PDFDocument44 pagesWelding Electrodes For Petrochemical IndustryG PDFerogonNo ratings yet

- Catálogo Conectores StäubliDocument0 pagesCatálogo Conectores StäubliFernando TulcánNo ratings yet

- Part List 005Document11 pagesPart List 005Mario AsselNo ratings yet

- Stepping Motor Bypass CableDocument5 pagesStepping Motor Bypass CablePHÁT NGUYỄN THẾ100% (14)

- WH 980/3 Caterpillar Volvo Construction EquipmentDocument4 pagesWH 980/3 Caterpillar Volvo Construction EquipmentJunaid AhmedNo ratings yet

- A21ea R495Document20 pagesA21ea R495Sergio AlbertoNo ratings yet

- Q 117R2Document2 pagesQ 117R22791957No ratings yet

- A21EA Rev50Document20 pagesA21EA Rev50dddotyNo ratings yet

- Rivet TypesDocument37 pagesRivet TypesMani Rathinam RajamaniNo ratings yet

- MIL-B-81934 2C Bearings, Self LubricatingDocument5 pagesMIL-B-81934 2C Bearings, Self LubricatingthomasNo ratings yet

- Army CableTelephoneTM 11 381Document192 pagesArmy CableTelephoneTM 11 381dannoxyzNo ratings yet

- Product Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1Document10 pagesProduct Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1pavanreguNo ratings yet

- VTN80G B.M. Thuot Nodal Design v0.1Document15 pagesVTN80G B.M. Thuot Nodal Design v0.1Đoàn SơnNo ratings yet

- Crane 10 TonDocument24 pagesCrane 10 TonErwin AntoNo ratings yet

- Cat Contra Incêndio ANV - Asa RotativaDocument1 pageCat Contra Incêndio ANV - Asa RotativaTecFogo Segurança Contra IncêndioNo ratings yet

- Tabela de Lubrificantes para Caminh Es DieselDocument1 pageTabela de Lubrificantes para Caminh Es DieselClevio FerreiraNo ratings yet

- FPT F4DFE613M U-R-015-0290Document3 pagesFPT F4DFE613M U-R-015-0290Goran MatovicNo ratings yet

- KX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension CardDocument55 pagesKX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension Cardjuanka_ing_2010No ratings yet

- Gas Flux WeldingDocument78 pagesGas Flux WeldingyendikesumaNo ratings yet

- Check ValvesDocument35 pagesCheck ValvesPrateek KansalNo ratings yet

- Proposal For Crane Access Over Trench Solid SlabDocument31 pagesProposal For Crane Access Over Trench Solid SlabAguirre De Joya RonaldoNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- British Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerFrom EverandBritish Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- T° PrecalentamientoDocument1 pageT° PrecalentamientoluisNo ratings yet

- Valvula de BolaDocument14 pagesValvula de BolaluisNo ratings yet

- Astm F2620-20 - Astm F2620-20Document11 pagesAstm F2620-20 - Astm F2620-20luisNo ratings yet

- Astm D2657 07 2023Document5 pagesAstm D2657 07 2023luisNo ratings yet

- 00 Caserones IOM - PO 121274Document86 pages00 Caserones IOM - PO 121274luisNo ratings yet

- Spy de LieDocument62 pagesSpy de LieluisNo ratings yet

- Barcol Impressor ManualDocument1 pageBarcol Impressor ManualluisNo ratings yet

- A SMEDocument4 pagesA SMEFranqui FernandesNo ratings yet

- DD Robinson Dumaguete: 1.00 General RequirementsDocument44 pagesDD Robinson Dumaguete: 1.00 General RequirementsAizon SusulanNo ratings yet

- Types of Mining: Stripping Ratio Mass of Burden/mass of MineralDocument6 pagesTypes of Mining: Stripping Ratio Mass of Burden/mass of MineralHILLARY FRANCIS SHENJERENo ratings yet

- 15 05 025 - Modification and Refurbishment ReportDocument9 pages15 05 025 - Modification and Refurbishment ReportEngineersEDGE CoimbatoreNo ratings yet

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocument10 pagesDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhNo ratings yet

- Al Alloys For BIWDocument10 pagesAl Alloys For BIWAnshuman RoyNo ratings yet

- OSNA10 Sheathing MTL Group EN 2019Document6 pagesOSNA10 Sheathing MTL Group EN 2019David RobsonNo ratings yet

- Chemical Filter Cartridge A2B2E2K2 P3Document3 pagesChemical Filter Cartridge A2B2E2K2 P3Zeina FarhatNo ratings yet

- Shanz - Vermeer 1996 - Angles of Friction and Dilatancy of SandDocument7 pagesShanz - Vermeer 1996 - Angles of Friction and Dilatancy of Sandjorge.jimenezNo ratings yet

- Electrical Conductivity Using Relative Lux Levels: Presented by Group 3 of 1CPE-1BDocument11 pagesElectrical Conductivity Using Relative Lux Levels: Presented by Group 3 of 1CPE-1BharveyvanellopeNo ratings yet

- Faarfield: FAARFIELD V 1.42 - Airport Pavement DesignDocument2 pagesFaarfield: FAARFIELD V 1.42 - Airport Pavement DesignRahul RanaNo ratings yet

- Semstone 110: Selection & Specification DataDocument3 pagesSemstone 110: Selection & Specification DataskNo ratings yet

- Floor Cleaner MSDSDocument2 pagesFloor Cleaner MSDSBob hamiltonNo ratings yet

- Final Internship ReportDocument39 pagesFinal Internship ReportKirubel AyeleNo ratings yet

- PHD Thesis. Cyclic Behavior of Steel Fiber Reinforced Concrete: From Material To Seismic ColumnsDocument24 pagesPHD Thesis. Cyclic Behavior of Steel Fiber Reinforced Concrete: From Material To Seismic ColumnsZarr AkshNo ratings yet

- Water Softening 2Document15 pagesWater Softening 2M Ihsan DanishNo ratings yet

- DM Conc DRB Rev2aDocument7 pagesDM Conc DRB Rev2aJonniel De GuzmanNo ratings yet

- Water Storage TanksDocument4 pagesWater Storage TanksMomo-Princess Peanut-buttercupNo ratings yet

- Disinfection Sterilization 2Document15 pagesDisinfection Sterilization 2Ãbdi TefNo ratings yet

- Catalog Mech - (Y-STRAINER)Document1 pageCatalog Mech - (Y-STRAINER)sourav samadderNo ratings yet

- 2018 Hazardous Chemical ListDocument5 pages2018 Hazardous Chemical ListAnonymous eqE9SkTNo ratings yet

- 12 ChemistryDocument38 pages12 ChemistryyoNo ratings yet

- 15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryDocument20 pages15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryAdemilson JuniorNo ratings yet

- PT NAH Technology Presentation 27 DecDocument22 pagesPT NAH Technology Presentation 27 DecBayu FirdausNo ratings yet

- BNPB DED Studio BNPB TVDocument43 pagesBNPB DED Studio BNPB TVAndrew Halim RamadanNo ratings yet

- KOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingDocument7 pagesKOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingMosul SpaceNo ratings yet

- Fire Performance of Mass TimberDocument5 pagesFire Performance of Mass TimberciviliiiNo ratings yet

- 2F-1 Kinetic Modelling of Biomass Gasification and CombustionDocument20 pages2F-1 Kinetic Modelling of Biomass Gasification and Combustionizzet1969No ratings yet

- Petronas Structure SystemDocument11 pagesPetronas Structure SystemRim ZreikaNo ratings yet

Electrodos Convinados Flux

Electrodos Convinados Flux

Uploaded by

luisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrodos Convinados Flux

Electrodos Convinados Flux

Uploaded by

luisCopyright:

Available Formats

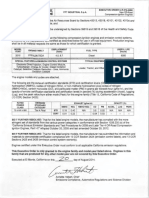

Electrodes and Flux-Electrode Combinations

Last update: November 25, 2008

The following electrodes and electrode-flux combinations have been approved for use on TxDOT projects until the expiration dates noted.

To request that a product be added to this list or to renew an expired approval, the contractor or fabricator must submit certified copies of all tests required by

the applicable AWS A5 specification in accordance with the applicable welding code (AWS D1.5 or D1.1) to Texas Department of Transportation, Construction

Division, Materials & Pavements Section/Steel Bridge Fabrication Branch (CP-51), 125 E. 11th St., Austin, TX 78701-2483. It is the responsibility of

consumable users to ensure that updated documents are submitted. Approval will expire a year after the test date.

For more information contact Heather Gilmer at 512/506-5921 or hgilmer@dot.state.tx.us

AWS

Electrode or Flux-Electrode Spec Welding Position Expiration

Producer Combination AWS Classification(s) (note a) (note b) Current Notes Date

ESAB Dual Shield II 71 Ultra E71T-1C,12C A5.20 H,F,VU,OH DCEP e 3/12/2009

ESAB Dual Shield II 80 Ni1H4 E81T1-Ni1MH4 A5.29 H,F,VU,OH DCEP f 3/7/2009

ESAB Spoolarc 86-A1 ER70S-6H4 A5.18 H,F e 1/21/2009

Hobart FabCOR 86R E70C-6M-H4 A5.18 H,F DCEP f 6/16/2009

Hobart TM-770 E71T-1M,12MJH8 A5.20 H,F,VU,OH DCEP f 6/16/2009

Hobart TM RX7 1/16 60 CL E70T1,9 A5.20 H,F DCEP e 6/16/2009

Hobart Verti-Cor 81Ni2 E81T1-Ni2C-H8,M-H8 A5.29 DCEP 7/28/2009

Hobart Verti-Cor IINi1 E81T1-Ni21CJ-H8,MJ-H8 A5.29 DCEP 7/28/2009

Lincoln Excalibur 7028 E7028-H8 A5.1 F, H-fillet AC or DCEP r 2/26/2009

Lincoln Excalibur 8018-C3 MR E8018-C3(H4R) A5.5 AC or DCEP g 2/1/2009

Lincoln Jetweld LH-70 E7018(H4R) A5.1 F,VU,OH, H-fillet DCEP g 1/16/2009

Lincoln Lincolnweld AXXX10/L-61 F7A4-EM12K-Ni1-H8 A5.23 6/25/2009

Lincoln Lincolnweld 780/L-61 F7A2-EM12K-H8 A5.17 i 12/10/2008

Lincoln Lincolnweld 860/L-61 F7A4-EM12K-H8 A5.17 8/20/2009

Lincoln Lincolnweld 860/LA-75 F7A2-ENi1K-Ni1-H8 A5.23 m 6/16/2009

Lincoln Lincolnweld 960/L-61 F7A2-EM12K-H8 A5.17 6/5/2009

Lincoln Lincolnweld 960/LA-75 F8A2-ENi1K-Ni1-H8 A5.23 m 8/21/2009

Lincoln Lincolnweld 980/LA-75 F7A2-ENi1K-Ni1-H8 A5.23 m 5/7/2009

Lincoln Lincolnweld MIL800-HPNi/LA-85 F9A4-ENi5-G-H2 A5.23 j,m 2/14/2009

Lincoln Outershield 71M E71T-1,9C(-H16) A5.20 H,F,VU,OH DCEP e 7/17/2009

Lincoln SuperArc L-50 ER70S-3 A5.18 8/28/2009

Lincoln SuperArc L-56 ER70S-6 A5.18 H,F 1/29/2009

Lincoln UltraCore 71A85 E71T-1MH8,9MH8 A5.20 H,F,VU,OH DCEP f 8/18/2009

Lincoln UltraCore 71C E71T-1CH8,9CH8 A5.20 H,F,VU,OH DCEP e 7/17/2009

Lincoln UltraCore 81Ni1C-H E81T1-Ni1C-H4 A5.29 H,F,VU,OH DCEP e 12/6/2008

National Standard NS-115 ER70S-6 A5.18 e 8/18/2009

Select-Arc Select 70C-6 E70C-6M A5.18 H,F DCEP f 3/14/2009

Select-Arc Select 727 E71T-1C, 9C, 12C A5.20 H,F,VU,OH DCEP e 2/13/2009

Notes:

a) For SMAW, see Table A3 of AWS A5.1 or Table A2 of AWS A5.5 for typical amperage ranges. Only SMAW (AWS A5.1 or A5.5) and FCAW (AWS A5.20

b) H=horizontal, F=flat, V=vertical, VU=vertical up, VD=vertical down, OH=overhead. For SMAW (AWS A5.1 & A5.5), V & OH for 5/32 in. and under only.

c) Not approved for welding of bridge structural members. See the appropriate AWS specification (D1.1 or D1.4) and TxDOT Standard Specification Item 448,

d) Not approved for structural field welding. See TxDOT Standard Specification Item 448, Table 1.

e) External shielding CO2

f) External shielding 75-80% Ar, remainder CO2 (“M” classification)

g) Low-hydrogen electrode (see Table 4.7 of AWS D1.5 for permissible atmospheric exposure)

h) Active flux. If multiple passes are welded, limit plate thickness to 1 in. and voltage to 35V

i) Single-pass welding only

j) Approved for welding HPS70W steel with reduced preheat.

k) Aluminum electrode. Consult the appropriate AWS A5 spec.

l) Stainless steel electrode. 3/16 in. and larger not recommended for all positions. See AWS D1.6 for appropriate base metals.

m) Weathering electrode: particularly suited for matching of color and properties of weathering steel

n) To be used only for field welding of root passes that are 100% removed

o) 5/32" only

p) not approved for 3/32" electrode

r) 1/4" size not approved

s) 3/32" size does not have R designation

t) 3/16" and 1/4" sizes not approved

u) Only 1/8" size approved.

v) 5/64" & 3/32": F&H only

w) 1/8" size does not have H4R designation

x) H designation not valid for sizes less than 1/4"

You might also like

- How to Build Max-Performance Chevy LT1/LT4 EnginesFrom EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesRating: 3 out of 5 stars3/5 (1)

- Boeing 787 Lessons LearntDocument46 pagesBoeing 787 Lessons LearntckleenordamNo ratings yet

- SEVPL BrochureDocument20 pagesSEVPL BrochureNaveen AnandNo ratings yet

- MOD4 Mark II: Ada Mp-1Document5 pagesMOD4 Mark II: Ada Mp-1Andrei PopaNo ratings yet

- W200 Casing Design Day 2 PDFDocument84 pagesW200 Casing Design Day 2 PDFYosef Shaaban100% (1)

- 2015-LMFP-016 Guide For U1-2115 Error and Abnormal Noise SL-M437x 537x SeriesDocument4 pages2015-LMFP-016 Guide For U1-2115 Error and Abnormal Noise SL-M437x 537x SeriesAntonio HerreraNo ratings yet

- Annotated Bibliography 2Document2 pagesAnnotated Bibliography 2nidhivashishtha83No ratings yet

- Comparatii Si Echivalente Branduri Sarma TubularaDocument4 pagesComparatii Si Echivalente Branduri Sarma TubularaAnonymous LpKY4pNo ratings yet

- Tubular Wire Products:: Filler Metals For Demand Critical Seismic ApplicationsDocument1 pageTubular Wire Products:: Filler Metals For Demand Critical Seismic ApplicationsOctavio Ochoa HernadezNo ratings yet

- Gas Turbines SpecsDocument11 pagesGas Turbines SpecsDiêgo MonteiroNo ratings yet

- 2022 12 05#ReleaseNotes - 750 8x0xDocument58 pages2022 12 05#ReleaseNotes - 750 8x0xEJNo ratings yet

- Lista de Equipos 2020Document2 pagesLista de Equipos 2020Renzo Cardenas SalasNo ratings yet

- Xy-Sa-Gpi2304-2 PLDDocument2 pagesXy-Sa-Gpi2304-2 PLDrafaelNo ratings yet

- Engineering Drawings and Spare Parts Lists - Carousel EFC-U-24 G-L - 111390 - R01 - English - K3Document27 pagesEngineering Drawings and Spare Parts Lists - Carousel EFC-U-24 G-L - 111390 - R01 - English - K3ZubairNo ratings yet

- List of The Inverter Brands Compatible With TBB Low-Voltage Lithium Batteries V3.0Document3 pagesList of The Inverter Brands Compatible With TBB Low-Voltage Lithium Batteries V3.0fatou tallNo ratings yet

- Approved BatteryDocument7 pagesApproved BatteryСергій МенжинськийNo ratings yet

- Joyadapter v1 1 Adi04 PartlistDocument1 pageJoyadapter v1 1 Adi04 PartlistHarald DasselNo ratings yet

- VIN, Engine and Transmission Numbers Vehicle Identification NumberDocument4 pagesVIN, Engine and Transmission Numbers Vehicle Identification NumberDoc ImportNo ratings yet

- Vessel InformationDocument241 pagesVessel InformationNayem PoshariNo ratings yet

- HT Cable Voltage Drop CalculationDocument9 pagesHT Cable Voltage Drop CalculationPaul Goh Yngwie100% (1)

- Electrical Part ListDocument5 pagesElectrical Part ListecurrasNo ratings yet

- Corvus DocumentationDocument10 pagesCorvus Documentationwahyudi aji WienarnoNo ratings yet

- Ad 100 VTDocument35 pagesAd 100 VTleonataxxNo ratings yet

- Schaeffler 422 0136 10Document10 pagesSchaeffler 422 0136 10Gabriel JLNo ratings yet

- Service Bulletin Trucks: ICON (Idle Management System)Document26 pagesService Bulletin Trucks: ICON (Idle Management System)Registr RegistrNo ratings yet

- Modelos Disponibles de Laser PickupDocument7 pagesModelos Disponibles de Laser PickupPablo Acapulco GuerreroNo ratings yet

- Num de Parte Shark 50mmDocument2 pagesNum de Parte Shark 50mmRuben Castro QuispeNo ratings yet

- DHBVN MASTER Technical Specifiaction 1Document24 pagesDHBVN MASTER Technical Specifiaction 1Ashish bhattNo ratings yet

- Thomson Roundrail 1DC SpecsheetDocument2 pagesThomson Roundrail 1DC SpecsheetElectromateNo ratings yet

- 1-WPS REGISTER FOR STRUCTURE STTPIP Rev ODocument6 pages1-WPS REGISTER FOR STRUCTURE STTPIP Rev Oxuanthien309No ratings yet

- Information: Product Support BulletinDocument8 pagesInformation: Product Support BulletiningpalacioNo ratings yet

- PS HydroTransDocument2 pagesPS HydroTransababoolNo ratings yet

- Welding Consumables For Pipeline Construction - ENDocument64 pagesWelding Consumables For Pipeline Construction - ENmaheshNo ratings yet

- Lexus Toyota ManualDocument37 pagesLexus Toyota Manualjorge morillo100% (1)

- Welding Electrodes For Petrochemical IndustryG PDFDocument44 pagesWelding Electrodes For Petrochemical IndustryG PDFerogonNo ratings yet

- Catálogo Conectores StäubliDocument0 pagesCatálogo Conectores StäubliFernando TulcánNo ratings yet

- Part List 005Document11 pagesPart List 005Mario AsselNo ratings yet

- Stepping Motor Bypass CableDocument5 pagesStepping Motor Bypass CablePHÁT NGUYỄN THẾ100% (14)

- WH 980/3 Caterpillar Volvo Construction EquipmentDocument4 pagesWH 980/3 Caterpillar Volvo Construction EquipmentJunaid AhmedNo ratings yet

- A21ea R495Document20 pagesA21ea R495Sergio AlbertoNo ratings yet

- Q 117R2Document2 pagesQ 117R22791957No ratings yet

- A21EA Rev50Document20 pagesA21EA Rev50dddotyNo ratings yet

- Rivet TypesDocument37 pagesRivet TypesMani Rathinam RajamaniNo ratings yet

- MIL-B-81934 2C Bearings, Self LubricatingDocument5 pagesMIL-B-81934 2C Bearings, Self LubricatingthomasNo ratings yet

- Army CableTelephoneTM 11 381Document192 pagesArmy CableTelephoneTM 11 381dannoxyzNo ratings yet

- Product Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1Document10 pagesProduct Information Packet: 20HP, 1765RPM, 3PH, 60HZ, 256T, 0952M, TEFC, F1pavanreguNo ratings yet

- VTN80G B.M. Thuot Nodal Design v0.1Document15 pagesVTN80G B.M. Thuot Nodal Design v0.1Đoàn SơnNo ratings yet

- Crane 10 TonDocument24 pagesCrane 10 TonErwin AntoNo ratings yet

- Cat Contra Incêndio ANV - Asa RotativaDocument1 pageCat Contra Incêndio ANV - Asa RotativaTecFogo Segurança Contra IncêndioNo ratings yet

- Tabela de Lubrificantes para Caminh Es DieselDocument1 pageTabela de Lubrificantes para Caminh Es DieselClevio FerreiraNo ratings yet

- FPT F4DFE613M U-R-015-0290Document3 pagesFPT F4DFE613M U-R-015-0290Goran MatovicNo ratings yet

- KX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension CardDocument55 pagesKX-TDA0174XJ KX-TDA0174X: 16port Single Line Telephone Extension Cardjuanka_ing_2010No ratings yet

- Gas Flux WeldingDocument78 pagesGas Flux WeldingyendikesumaNo ratings yet

- Check ValvesDocument35 pagesCheck ValvesPrateek KansalNo ratings yet

- Proposal For Crane Access Over Trench Solid SlabDocument31 pagesProposal For Crane Access Over Trench Solid SlabAguirre De Joya RonaldoNo ratings yet

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- British Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerFrom EverandBritish Aerospace Hawk: Armed Light Attack and Multi-Combat Fighter TrainerNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- T° PrecalentamientoDocument1 pageT° PrecalentamientoluisNo ratings yet

- Valvula de BolaDocument14 pagesValvula de BolaluisNo ratings yet

- Astm F2620-20 - Astm F2620-20Document11 pagesAstm F2620-20 - Astm F2620-20luisNo ratings yet

- Astm D2657 07 2023Document5 pagesAstm D2657 07 2023luisNo ratings yet

- 00 Caserones IOM - PO 121274Document86 pages00 Caserones IOM - PO 121274luisNo ratings yet

- Spy de LieDocument62 pagesSpy de LieluisNo ratings yet

- Barcol Impressor ManualDocument1 pageBarcol Impressor ManualluisNo ratings yet

- A SMEDocument4 pagesA SMEFranqui FernandesNo ratings yet

- DD Robinson Dumaguete: 1.00 General RequirementsDocument44 pagesDD Robinson Dumaguete: 1.00 General RequirementsAizon SusulanNo ratings yet

- Types of Mining: Stripping Ratio Mass of Burden/mass of MineralDocument6 pagesTypes of Mining: Stripping Ratio Mass of Burden/mass of MineralHILLARY FRANCIS SHENJERENo ratings yet

- 15 05 025 - Modification and Refurbishment ReportDocument9 pages15 05 025 - Modification and Refurbishment ReportEngineersEDGE CoimbatoreNo ratings yet

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocument10 pagesDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhNo ratings yet

- Al Alloys For BIWDocument10 pagesAl Alloys For BIWAnshuman RoyNo ratings yet

- OSNA10 Sheathing MTL Group EN 2019Document6 pagesOSNA10 Sheathing MTL Group EN 2019David RobsonNo ratings yet

- Chemical Filter Cartridge A2B2E2K2 P3Document3 pagesChemical Filter Cartridge A2B2E2K2 P3Zeina FarhatNo ratings yet

- Shanz - Vermeer 1996 - Angles of Friction and Dilatancy of SandDocument7 pagesShanz - Vermeer 1996 - Angles of Friction and Dilatancy of Sandjorge.jimenezNo ratings yet

- Electrical Conductivity Using Relative Lux Levels: Presented by Group 3 of 1CPE-1BDocument11 pagesElectrical Conductivity Using Relative Lux Levels: Presented by Group 3 of 1CPE-1BharveyvanellopeNo ratings yet

- Faarfield: FAARFIELD V 1.42 - Airport Pavement DesignDocument2 pagesFaarfield: FAARFIELD V 1.42 - Airport Pavement DesignRahul RanaNo ratings yet

- Semstone 110: Selection & Specification DataDocument3 pagesSemstone 110: Selection & Specification DataskNo ratings yet

- Floor Cleaner MSDSDocument2 pagesFloor Cleaner MSDSBob hamiltonNo ratings yet

- Final Internship ReportDocument39 pagesFinal Internship ReportKirubel AyeleNo ratings yet

- PHD Thesis. Cyclic Behavior of Steel Fiber Reinforced Concrete: From Material To Seismic ColumnsDocument24 pagesPHD Thesis. Cyclic Behavior of Steel Fiber Reinforced Concrete: From Material To Seismic ColumnsZarr AkshNo ratings yet

- Water Softening 2Document15 pagesWater Softening 2M Ihsan DanishNo ratings yet

- DM Conc DRB Rev2aDocument7 pagesDM Conc DRB Rev2aJonniel De GuzmanNo ratings yet

- Water Storage TanksDocument4 pagesWater Storage TanksMomo-Princess Peanut-buttercupNo ratings yet

- Disinfection Sterilization 2Document15 pagesDisinfection Sterilization 2Ãbdi TefNo ratings yet

- Catalog Mech - (Y-STRAINER)Document1 pageCatalog Mech - (Y-STRAINER)sourav samadderNo ratings yet

- 2018 Hazardous Chemical ListDocument5 pages2018 Hazardous Chemical ListAnonymous eqE9SkTNo ratings yet

- 12 ChemistryDocument38 pages12 ChemistryyoNo ratings yet

- 15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryDocument20 pages15 - GEST 92 171 Edition 6 - Personal Protective Equipment in The Chlorine IndustryAdemilson JuniorNo ratings yet

- PT NAH Technology Presentation 27 DecDocument22 pagesPT NAH Technology Presentation 27 DecBayu FirdausNo ratings yet

- BNPB DED Studio BNPB TVDocument43 pagesBNPB DED Studio BNPB TVAndrew Halim RamadanNo ratings yet

- KOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingDocument7 pagesKOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingMosul SpaceNo ratings yet

- Fire Performance of Mass TimberDocument5 pagesFire Performance of Mass TimberciviliiiNo ratings yet

- 2F-1 Kinetic Modelling of Biomass Gasification and CombustionDocument20 pages2F-1 Kinetic Modelling of Biomass Gasification and Combustionizzet1969No ratings yet

- Petronas Structure SystemDocument11 pagesPetronas Structure SystemRim ZreikaNo ratings yet