Professional Documents

Culture Documents

TS-347 Tientai

TS-347 Tientai

Uploaded by

Oscar JimenezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS-347 Tientai

TS-347 Tientai

Uploaded by

Oscar JimenezCopyright:

Available Formats

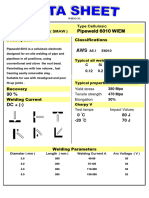

TS-347 AWS A5.

4 E347-16

EN ISO 3581-B ES347-16

JIS Z 3221 ES347-16

Characteristics and Applications:

The product provides good inter-granular corrosion resistance and heat resistance due to its Nb

content. It is suitable for the welding of chemical vessels, steel strip, heat transfer tube, seamless pipe, steel

bar and AISI 347, 321, 304L steel plates.

Notes on usage:

1. Clean up the contaminations on the base metal, groove and pass to pass with stainless steel brush.

2. Maintain short arc length. Moving range should be controlled within 2.5 times of the wire’s dia when you are

welding with weave method.

3. Dry the electrodes at 250~300℃ for 60 minutes before using. Take out consumables for half day

consumption and keep in the environment at 100~150℃ during welding process.

4. Use lower current to prevent from crack and minimize base metal dilution.

Typical chemical composition of weld metal (wt%):

C Mn Si P S Cr Ni Nb

AWS ≦0.08 0.5-2.5 ≦1.00 ≦0.04 ≦0.03 18.0-21.0 9.0-11.0 8xC-1.00

EN ISO ≦0.08 0.5-2.5 ≦1.00 ≦0.04 ≦0.03 18.0-21.0 9.0-11.0 8xC-1.00

Typical value 0.032 1.30 0.50 0.035 0.010 20.00 9.50 0.35

Typical mechanical properties of weld metal:

Tensile strength Elongation

MPa(ksi) %

AWS ≧520(75) ≧30

EN ISO ≧520(75) ≧25

Typical value 600(87) 38

Welding position:

Sizes and recommended current range (AC or DC<+>):

Diameter (mm) 2.6 3.2 4.0 4.8

Length (mm) 300 350 350 350

F 60-90 80-130 130-170 180-210

Amps

V&OH 50-70 70-110 100-130 -

2108

You might also like

- Holland Shielding Catalog-2018 PDFDocument145 pagesHolland Shielding Catalog-2018 PDFdilnair99No ratings yet

- PH-Electric-Rope-Shovel-Components (Splited)Document3 pagesPH-Electric-Rope-Shovel-Components (Splited)Oscar JimenezNo ratings yet

- TFW-347L TientaiDocument1 pageTFW-347L TientaiOscar JimenezNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- CHE421Document1 pageCHE421Eko SuherNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- 04042016000000A Avesta 2205 Covered ElectrodesDocument1 page04042016000000A Avesta 2205 Covered Electrodesmeckup123No ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- L1 34454 en B Boehler Aws E6013 Se en v1Document1 pageL1 34454 en B Boehler Aws E6013 Se en v1brayanNo ratings yet

- Askaynak - As B-248Document1 pageAskaynak - As B-248Faraj KhalikovNo ratings yet

- Hobart 9LDocument1 pageHobart 9LFelipe montanaNo ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- Datasheet BOHLER AWS E7018-1 Stick ElectrodeDocument1 pageDatasheet BOHLER AWS E7018-1 Stick ElectrodeArhamNo ratings yet

- Che507r PDFDocument1 pageChe507r PDFAnonymous AkzeMHNTUyNo ratings yet

- Ama 23ak - enDocument1 pageAma 23ak - enmohamed AdelNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- B Boehler FOX EV 50-A Se en 5Document1 pageB Boehler FOX EV 50-A Se en 5Sun SunNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- CHW 50C6Document1 pageCHW 50C6scribdsonbaNo ratings yet

- AWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Document2 pagesAWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Andre Brama AlvariNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Document8 pagesDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 30crnimo8: Steel GradeDocument2 pages30crnimo8: Steel GradewemersonsrNo ratings yet

- 0218 Ja enDocument1 page0218 Ja enHoque AnamulNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- THERO F-EHCr 65Document1 pageTHERO F-EHCr 65Filipe CordeiroNo ratings yet

- Avesta 316L-SKRDocument1 pageAvesta 316L-SKRIuliu HurducaciNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- T Thermanit GEW 316L-17 Se en 5Document1 pageT Thermanit GEW 316L-17 Se en 5PubcrawlNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Nickel Based ElectrodeDocument1 pageNickel Based Electrodewalter091011No ratings yet

- Special Metal Korea Co., LTDDocument1 pageSpecial Metal Korea Co., LTDWelli E SNo ratings yet

- SM 385Document1 pageSM 385Arizal Nur ArdhiNo ratings yet

- TOKO 1978 Electric Welding Rod Technical Data SheetDocument8 pagesTOKO 1978 Electric Welding Rod Technical Data SheetYurizki LhzNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Böhler Fox Ohv: Rutile-Cellulosic Stick Electrode, UnalloyedDocument1 pageBöhler Fox Ohv: Rutile-Cellulosic Stick Electrode, UnalloyedMiroslav MiladinovićNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- 02112015000000B - Boehler FOX EAS 2-A - CeDocument1 page02112015000000B - Boehler FOX EAS 2-A - CeAHRAKNo ratings yet

- Hardface NM oDocument1 pageHardface NM ojohndupNo ratings yet

- B - Boehler FOX SPE - Se - en - 5Document1 pageB - Boehler FOX SPE - Se - en - 5panait trofinNo ratings yet

- 490N High Tensile Strength Steel_7010Document1 page490N High Tensile Strength Steel_7010Takul ThongyooNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Pipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionDocument1 pagePipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshNo ratings yet

- 40nicrmo7-3: Steel GradeDocument3 pages40nicrmo7-3: Steel GradeGanesh K CNo ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- D & H 11018ultratherme-M - P15yrcyDocument1 pageD & H 11018ultratherme-M - P15yrcyjubieethegreatNo ratings yet

- Annealed Engineering Steel C45E / 1042 (ASTMDocument2 pagesAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahNo ratings yet

- Chemical Composition of ASTM A516 Grade 70 / ASME SA516 Grade 70Document4 pagesChemical Composition of ASTM A516 Grade 70 / ASME SA516 Grade 70Abdul WahabNo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- 03112015000000B - Boehler FOX SUM - CeDocument1 page03112015000000B - Boehler FOX SUM - Cekapster KannourNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- 2018 Fender Illustrated Product GuideDocument53 pages2018 Fender Illustrated Product GuideOscar Jimenez0% (1)

- DC275 Maxstar 161 Series EnglishDocument4 pagesDC275 Maxstar 161 Series EnglishOscar JimenezNo ratings yet

- Invertec V350-Pro (Ce) : Operator's ManualDocument56 pagesInvertec V350-Pro (Ce) : Operator's ManualOscar JimenezNo ratings yet

- Fender LTD Ed Blackwood P90 Telecaster 0175107721 SM REV A 3-21-17Document6 pagesFender LTD Ed Blackwood P90 Telecaster 0175107721 SM REV A 3-21-17Oscar JimenezNo ratings yet

- POWER WAVE Connection GuideDocument63 pagesPOWER WAVE Connection GuideOscar Jimenez100% (1)

- Mantenimiento y Reparación Esab SoldaduraDocument89 pagesMantenimiento y Reparación Esab SoldaduraOscar JimenezNo ratings yet

- Civil Unit1Document82 pagesCivil Unit1Harshit KothalaNo ratings yet

- ATT-13/96, FORMING MARSHALL SPECIMENS, Field MethodDocument5 pagesATT-13/96, FORMING MARSHALL SPECIMENS, Field MethodCE PassajNo ratings yet

- Riveted Joint - 5Document40 pagesRiveted Joint - 5Nakshatra Patil 4-Year B.Tech. Mechanical EngineeringNo ratings yet

- Gresham's Law: Gresham's Law Is Commonly Stated: "Bad Money Drives Out Good", But Is More Accurately Stated: "Bad MoneyDocument6 pagesGresham's Law: Gresham's Law Is Commonly Stated: "Bad Money Drives Out Good", But Is More Accurately Stated: "Bad MoneyJosé María Bravo LinerosNo ratings yet

- ORD 5700 Parker O-Ring HandbookDocument292 pagesORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- MakuriDocument11 pagesMakuriJhoncastilloNo ratings yet

- Akvola Technologies MicroGas S Technical Specifications - Web PDFDocument2 pagesAkvola Technologies MicroGas S Technical Specifications - Web PDFHardik VavdiyaNo ratings yet

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 pagesDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozNo ratings yet

- Aws B2.1/B2.1M-BMG:2014Document73 pagesAws B2.1/B2.1M-BMG:2014Baguz SaputraNo ratings yet

- SPECIFICATIONDocument25 pagesSPECIFICATIONkingcedsNo ratings yet

- Design & Fabrication of Metal Scrap Bailing PressDocument4 pagesDesign & Fabrication of Metal Scrap Bailing PressReyazul HaqueNo ratings yet

- SSE Product CatalogueDocument8 pagesSSE Product CatalogueKiran GuttiNo ratings yet

- Aluminum Paint: Standard Specification ForDocument2 pagesAluminum Paint: Standard Specification ForEvert RiveraNo ratings yet

- ES 180i Pro, ES 200i Pro: RogueDocument26 pagesES 180i Pro, ES 200i Pro: RogueAUFA JAYA PERKASANo ratings yet

- Steel Structures - (Introduction) - 2Document13 pagesSteel Structures - (Introduction) - 2Ceren ŞirinNo ratings yet

- TopperDocument6 pagesTopperLe site de thierry thierryNo ratings yet

- BS Iso 4990Document23 pagesBS Iso 4990Thomas ValoNo ratings yet

- CheckPoint Product BrochureDocument20 pagesCheckPoint Product BrochureJefril SiruNo ratings yet

- SRI-MPS-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22147R0Document5 pagesSRI-MPS-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22147R0Dito NarendraNo ratings yet

- Guide To Milling Tool InsertsDocument46 pagesGuide To Milling Tool InsertsCristian FuentesNo ratings yet

- Brief Industrial Profile of VISAKHAPATNAM District - DC MsmeDocument26 pagesBrief Industrial Profile of VISAKHAPATNAM District - DC MsmeParas AgarwalNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- VG7 XVS - MDocument1 pageVG7 XVS - Mluis acostaNo ratings yet

- Jewelry I Syllabus Course Description 18-19Document4 pagesJewelry I Syllabus Course Description 18-19api-303422685No ratings yet

- Tle 6 LM Quarter 4Document29 pagesTle 6 LM Quarter 4RjVValdezNo ratings yet

- The Blacksmith in Eighteenth Century WilliamsburgDocument37 pagesThe Blacksmith in Eighteenth Century WilliamsburgCarmela GabrieleNo ratings yet

- 5.3 Code, Standard and RegulationDocument7 pages5.3 Code, Standard and Regulationandrieysyah2525No ratings yet

- Hr+Oxspec+ +Laser+Cut+Screen+SetupsDocument10 pagesHr+Oxspec+ +Laser+Cut+Screen+SetupstibisortNo ratings yet

- Fitter Mechanical Assembly (CSCQ0304)Document7 pagesFitter Mechanical Assembly (CSCQ0304)yudiar djamaldilliahNo ratings yet