Professional Documents

Culture Documents

002-Installation of Insulation of CHWP Above Ground

002-Installation of Insulation of CHWP Above Ground

Uploaded by

Binod DavisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

002-Installation of Insulation of CHWP Above Ground

002-Installation of Insulation of CHWP Above Ground

Uploaded by

Binod DavisCopyright:

Available Formats

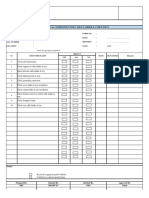

QUALITY MANAGEMENT SYSTEM

MS for Installation of Chilled water

pipe Insulation Works

DOC.No: VKBS/HPCL/HVAC/0002

PROJECT HPGRDC

EMPLOYER HPCL

PMC EIL

CONTRACTOR VK Building Services Pvt Ltd

METHOD STATEMENT FOR INSTALLATION OF

CHILLED WATER PIPE INSULATION WORKS

ABOVE GROUND LEVEL

VKBS EIL

Signature:

Date:

Name: Sahayaraj Binod Davis Mohan

Organization: VKBS VKBS VKBS

HVAC Work Method Statement 1

QUALITY MANAGEMENT SYSTEM

MS for Installation of Chilled water

pipe Insulation Works

DOC.No: VKBS/HPCL/HVAC/0002

INDEX

1. PURPOSE

2. MATERIAL

3. REFERENCES

4. PROCEDURE

4.1. STORAGE

4.2. PREPARATION

4.3. INSULATION APPLICATION

5. RECORDS

HVAC Work Method Statement 2

QUALITY MANAGEMENT SYSTEM

MS for Installation of Chilled water

pipe Insulation Works

DOC.No: VKBS/HPCL/HVAC/0002

INSTALLATION OF PIPE INSULATION USING NITRILE RUBBER (SOR NO. 1.20.2)

1. PURPOSE

Purpose of this method statement is to outline the method of storage, handling,

fabrication and installation of Pipe insulation with Nitrile Rubber.

2. MATERIAL

Nitrile Rubber insulation.

Insulation adhesive, Block tape etc.

3. TOOLS & TACKLES

1. Rigid and flexible measuring tape

2. Compass and marker

3. Cutters and knives

4. Calipers

5. Scissors

6. Brushes of different sizes

4. REFERENCES

Insulation Manufacturer’s catalogues, tender specifications and approved TDS.

Insulation thickness application as per tender schedule.

HVAC Work Method Statement 3

QUALITY MANAGEMENT SYSTEM

MS for Installation of Chilled water

pipe Insulation Works

DOC.No: VKBS/HPCL/HVAC/0002

5. PROCEDURE

A. STORAGE

Insulation material shall be stored in proper storage place and shall be stacked

one above other in neatly manner as per material safety data sheet.

Flammable materials like insulation adhesive (hot bitumen) shall be stored

separately in enclosed cold area as per manufacturer’s recommendations and

shall not be exposed directly to sunlight or hot conditions with proper

barricading and away from flammable materials.

Storage shall have adequate lighting and proper ventilation.

B. PREPARTION

Before starting the works ensure the piping installation is complete and

inspection, pressure testing for the same is completed and approved to start

the insulation works.

Ensure all service clearances are available prior to start and same documents

to be attached for PMC clearance.

All work permits are needs to be obtained from the PMC and client.

Ensure latest revisions of approved and coordinated drawings are available to

execute the work.

All pipes shall be brushed and cleaned properly. All pipes shall be primer

coated before starting the insulation.

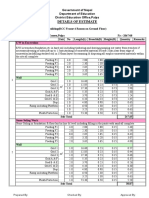

The following approved schedule of insulation thickness to be used in

HVAC Work Method Statement 4

QUALITY MANAGEMENT SYSTEM

MS for Installation of Chilled water

pipe Insulation Works

DOC.No: VKBS/HPCL/HVAC/0002

different sizes.

Description Pipe diameter in mm Insulation thickness in mm

Indoor Chilled Water Piping 25 32

32 to 40 40

50 to 80 45

100 to 250 50

C. INSULATION APPLICATION

Insulation materials sheets are to be pre-cut as per required pipes length on a

flat surface.

A thin film of the adhesive is to be applied on the surface of the insulation

and also on pipe surface.

When the adhesive is tack dry, place the insulation on the pipe surface and

then apply pressure firmly on insulation to achieve good bonding and to avoid

air bubbles.

After installation of insulation on the pipes, seal the transverse and

longitudinal joints as per manufacturer’s recommendations.

After completion of pressure test, insulation sheets to be precut as per pipe

joints with overlap.

HVAC Work Method Statement 5

QUALITY MANAGEMENT SYSTEM

MS for Installation of Chilled water

pipe Insulation Works

DOC.No: VKBS/HPCL/HVAC/0002

All longitudinal and transverse joints shall be sealed by application of

adhesive and Insulation Tape.

All valves, fittings, joints, strainers etc. shall be insulated to the same

thickness as specified for the main run of the piping.

Vale bonnet, spindles shall be insulated in such a manner as not to cause

damage to the insulation when the valve is open or close.

All equipment like pumps, expansion tanks shall be insulated as specified

thickness as per approved TDS.

Complete the identification with the direction of flow.

6. RECORDS

Signed off IMIR

Signed off Installation inspection request with installation check list

************************

HVAC Work Method Statement 6

You might also like

- En 1627 - 2011 Pedestrian Doorsets, Windows, Curtain Walling, Grilles and Shutters - Burglar Resistance - Requirements and ClassificationDocument31 pagesEn 1627 - 2011 Pedestrian Doorsets, Windows, Curtain Walling, Grilles and Shutters - Burglar Resistance - Requirements and ClassificationAlineMeirelesNo ratings yet

- CPVC Method StatementDocument2 pagesCPVC Method StatementPrashanth A67% (3)

- Ipc2002 27131Document15 pagesIpc2002 27131faridNo ratings yet

- Pedro Ar Des Preboard 4 Low-Rise Natl Govt OfcDocument5 pagesPedro Ar Des Preboard 4 Low-Rise Natl Govt OfcJeypee De GeeNo ratings yet

- DCBCP I-2 - Volume IIDocument207 pagesDCBCP I-2 - Volume IIEdmond Bautista100% (1)

- Method of Statement MEPDocument4 pagesMethod of Statement MEPMallu JustfornewsNo ratings yet

- Svsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals LimitedDocument52 pagesSvsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals Limitedkrmrps0% (1)

- MOS IMU 1 - Method Statement For DuctworkDocument12 pagesMOS IMU 1 - Method Statement For DuctworkAzwan Awalludin100% (3)

- Method Statement For Installation of FansDocument5 pagesMethod Statement For Installation of FansBinod Davis50% (2)

- Time Variance DPWH Field Engineers Training Participant - SDocument97 pagesTime Variance DPWH Field Engineers Training Participant - SRenz FernandezNo ratings yet

- MC-training Design For Fire Volunteers, Members of Fire Brigades and Fire Safety PractionersDocument5 pagesMC-training Design For Fire Volunteers, Members of Fire Brigades and Fire Safety PractionersMacabebe Fire Station100% (1)

- Method Statement For Installation of Chilled Water Pipe Insulation Works Above Ground LevelDocument6 pagesMethod Statement For Installation of Chilled Water Pipe Insulation Works Above Ground LevelBinod DavisNo ratings yet

- Method Statement For Installation & Insulation of Buried Chilled Water PipingDocument8 pagesMethod Statement For Installation & Insulation of Buried Chilled Water PipingBinod DavisNo ratings yet

- 011-Refrigerant Copper Piping, Insulation, Leak Test, Evacuation and VRF Unit InstallationDocument10 pages011-Refrigerant Copper Piping, Insulation, Leak Test, Evacuation and VRF Unit InstallationBinod DavisNo ratings yet

- 007-Installation of Cooling TowerDocument5 pages007-Installation of Cooling TowerBinod DavisNo ratings yet

- Chilled Water Pipe Insulation Method Statement - Method Statement HQDocument3 pagesChilled Water Pipe Insulation Method Statement - Method Statement HQابوزيد عبد الجوادNo ratings yet

- 003-Installation of Buried Fire Hydrant PipeDocument8 pages003-Installation of Buried Fire Hydrant PipeBinod DavisNo ratings yet

- Usm - Qa Plan AcmvDocument88 pagesUsm - Qa Plan AcmvTAPIZ ACMVNo ratings yet

- HVAC Piping Insulation-Fiberglas InsulationDocument7 pagesHVAC Piping Insulation-Fiberglas Insulationbudi budihardjoNo ratings yet

- R02 - 32SI - Insulation System For Refrigerant Piping PDFDocument12 pagesR02 - 32SI - Insulation System For Refrigerant Piping PDFRatilal M JadavNo ratings yet

- HPCL Electrical Method StatementDocument25 pagesHPCL Electrical Method StatementBinod DavisNo ratings yet

- Especificaciones Aislamiento TuberíaDocument5 pagesEspecificaciones Aislamiento TuberíaolivaresjhonNo ratings yet

- Drying & Cleanning SpecificationDocument5 pagesDrying & Cleanning SpecificationAnant Rubade100% (1)

- 06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkDocument16 pages06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkJhoNo ratings yet

- Method Statement For Conduits WiringDocument8 pagesMethod Statement For Conduits WiringÖmeralp SakNo ratings yet

- MECCOCT18-12292: NACE Paper NoDocument9 pagesMECCOCT18-12292: NACE Paper NoOwais MalikNo ratings yet

- HvacDocument48 pagesHvacmohamed adelNo ratings yet

- SECTION 23 07 00 Hvac Insulation: Based On DFD Master Specification Dated 11/18/2022Document21 pagesSECTION 23 07 00 Hvac Insulation: Based On DFD Master Specification Dated 11/18/2022Eugene RomillaNo ratings yet

- Jgpd-Isf-t-sh-sa-1302-04-Ms For Placement of Light Weight Concrete For Roof Deck Areas Rev-04Document87 pagesJgpd-Isf-t-sh-sa-1302-04-Ms For Placement of Light Weight Concrete For Roof Deck Areas Rev-04gulzamanNo ratings yet

- The Use of Clad Piping Components For Refinery Applications (51300-97510-SG)Document13 pagesThe Use of Clad Piping Components For Refinery Applications (51300-97510-SG)arnoldbatista55No ratings yet

- MST-Construction and Installation of Manhole, HDPE Pipe and Isolation Gate ValveDocument7 pagesMST-Construction and Installation of Manhole, HDPE Pipe and Isolation Gate Valvearmsarabia01No ratings yet

- JCR-190623-TTSB-F3201-signed For Insulation WorksDocument12 pagesJCR-190623-TTSB-F3201-signed For Insulation WorksFadzil AmalludinNo ratings yet

- 2.9 Qk-Cl-08-00007-Installation of Closed Cell Elastomeric Insulation For Domestic Cold Water, Hot Water and Rain Water Piping SystemDocument1 page2.9 Qk-Cl-08-00007-Installation of Closed Cell Elastomeric Insulation For Domestic Cold Water, Hot Water and Rain Water Piping SystemMoh'd SameerNo ratings yet

- Insulation Systems For Refrigerant PipingDocument10 pagesInsulation Systems For Refrigerant PipingdarthmoodyNo ratings yet

- Insulation Systems For Refrigerant PipingDocument10 pagesInsulation Systems For Refrigerant PipingBryan VertuodasoNo ratings yet

- Elips Product SpecificationsDocument10 pagesElips Product SpecificationsMohammed ShifulNo ratings yet

- Nu Division 22 Combined 20170330Document235 pagesNu Division 22 Combined 20170330Jothimanikkam SomasundaramNo ratings yet

- Method Statement For ChillersDocument8 pagesMethod Statement For ChillersFark Off100% (1)

- 58 Curran FDocument6 pages58 Curran FAmulNo ratings yet

- MOS - Fire FightingDocument23 pagesMOS - Fire FightingMohammad Hadoumi SaldanNo ratings yet

- 2A?Djkhkcu: Insulation & LiningsDocument4 pages2A?Djkhkcu: Insulation & LiningsbenssjNo ratings yet

- 23 0700 - HVAC InsulationDocument38 pages23 0700 - HVAC InsulationMohamedHanyNo ratings yet

- Work Method Statement of PipingDocument13 pagesWork Method Statement of PipingBinod DavisNo ratings yet

- STD Supplementary Specifications S74Document24 pagesSTD Supplementary Specifications S74Bharat MaddulaNo ratings yet

- Best Practice For Inspecting Piping InsulationDocument8 pagesBest Practice For Inspecting Piping InsulationJustice AbbanNo ratings yet

- Masterspec Copper SpecificationDocument10 pagesMasterspec Copper SpecificationNabil RamehNo ratings yet

- PDFMerge 52a7dDocument90 pagesPDFMerge 52a7dabdalla el-saadaneyNo ratings yet

- Thermal InsulationDocument6 pagesThermal Insulationalbaz666666No ratings yet

- Wis4 35 01Document17 pagesWis4 35 01Sarwat Naim SiddiquiNo ratings yet

- 23 07 00 General HVAC Insulation RequirementsDocument5 pages23 07 00 General HVAC Insulation RequirementsolivaresjhonNo ratings yet

- PRES-E-01 Electrical EquipmentDocument2 pagesPRES-E-01 Electrical EquipmentsalamlinNo ratings yet

- Quiet DuctDocument4 pagesQuiet DuctacrisostoNo ratings yet

- Plumbing Piping InsulationDocument9 pagesPlumbing Piping InsulationMY PCNo ratings yet

- Method Statments For Mechanical WorksDocument34 pagesMethod Statments For Mechanical WorksUmar Farooq100% (1)

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Method Statement Refrigerant Copper PipingDocument9 pagesMethod Statement Refrigerant Copper PipingWasim AhmedNo ratings yet

- 0815STFRANCISSCH3SPECv2-WINDOWS NAT. & MEC. VENT 0815 3 SP1006Document1 page0815STFRANCISSCH3SPECv2-WINDOWS NAT. & MEC. VENT 0815 3 SP1006Philip MelemuriyilNo ratings yet

- 15 SmacnaDocument9 pages15 Smacnaarln_605551822No ratings yet

- HE-GS-Blueskin WP 200-Waterproof-E5 CSI 07 11 13Document5 pagesHE-GS-Blueskin WP 200-Waterproof-E5 CSI 07 11 13bernardo.vidalNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Method Statement For Installation & Insulation of Buried Chilled Water PipingDocument8 pagesMethod Statement For Installation & Insulation of Buried Chilled Water PipingBinod DavisNo ratings yet

- Method Statement For Installation of Chilled Water Pipe Insulation Works Above Ground LevelDocument6 pagesMethod Statement For Installation of Chilled Water Pipe Insulation Works Above Ground LevelBinod DavisNo ratings yet

- Installation of Fire Hydrant SystemDocument19 pagesInstallation of Fire Hydrant SystemBinod Davis67% (3)

- Method Statement For Air Handling UnitDocument7 pagesMethod Statement For Air Handling UnitBinod DavisNo ratings yet

- Work Method Statement of PipingDocument13 pagesWork Method Statement of PipingBinod DavisNo ratings yet

- Method Statement of ChillersDocument5 pagesMethod Statement of ChillersBinod DavisNo ratings yet

- LYT0026 - 2020-09-04 - L1P0W1 - Installation Manual - Roofing and Walling - WEB PDFDocument64 pagesLYT0026 - 2020-09-04 - L1P0W1 - Installation Manual - Roofing and Walling - WEB PDFjunaid76No ratings yet

- Welding Cable 35 MM2Document2 pagesWelding Cable 35 MM2Itachi UchihaNo ratings yet

- Boral Partiwall and Fire Wall Class 1aDocument28 pagesBoral Partiwall and Fire Wall Class 1aRaja RajanNo ratings yet

- Shapes of The NailDocument23 pagesShapes of The NailJESSICA B. SUMILLERNo ratings yet

- Consultant ListDocument9 pagesConsultant ListFitsum DojuNo ratings yet

- Earthquake Hazard Maps of Turkey EnglishDocument9 pagesEarthquake Hazard Maps of Turkey Englishcarlos torresNo ratings yet

- WP1 - UTCB TypologyDocument26 pagesWP1 - UTCB Typologynenad lazicNo ratings yet

- Nawa Khola Vented Causeway EstimatesDocument8 pagesNawa Khola Vented Causeway Estimateshimal kafleNo ratings yet

- Case 2 Decision Making 2Document4 pagesCase 2 Decision Making 2Izie BellaNo ratings yet

- Study of Transparent Concrete: Presented ByDocument17 pagesStudy of Transparent Concrete: Presented ByGaurav JainNo ratings yet

- Abdulpk@ciitsahiwal Edu PKDocument8 pagesAbdulpk@ciitsahiwal Edu PKAhmadrazatahirNo ratings yet

- 23 Case Studies For Falling From HeightsDocument65 pages23 Case Studies For Falling From HeightsAejaz MujawarNo ratings yet

- Role of Technology in Affordable Housing Programme 28th Feb 2019Document28 pagesRole of Technology in Affordable Housing Programme 28th Feb 2019Carol KamothoNo ratings yet

- 12 Saes-Q-009.Document5 pages12 Saes-Q-009.engr.sulaiman0016No ratings yet

- Red Book Firestopping PDFDocument170 pagesRed Book Firestopping PDFbigmac2No ratings yet

- Electrical Completion Check List-Rev DDocument4 pagesElectrical Completion Check List-Rev DArmando BiringkanaeNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Document22 pagesBK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Panneer SelvamNo ratings yet

- Detail Estimate-4 Room BuildingDocument32 pagesDetail Estimate-4 Room BuildingKisna Bhurtel50% (6)

- Joseph Allen SteinDocument22 pagesJoseph Allen Steinleniya leniyaNo ratings yet

- Texter CatalogueDocument12 pagesTexter CataloguedileepaNo ratings yet

- North Eastern Hill University: Department of ArchitectureDocument9 pagesNorth Eastern Hill University: Department of ArchitectureManas pratim DasNo ratings yet

- Laboratory Evaluation On Performance of Diatomite and Glass Fiber Compound Modified Asphalt MixtureDocument9 pagesLaboratory Evaluation On Performance of Diatomite and Glass Fiber Compound Modified Asphalt MixtureYara MounaNo ratings yet

- Shosi 1Document2 pagesShosi 1MOHAMMED SAZZAD HOSSAINNo ratings yet

- Building Information ModellingDocument9 pagesBuilding Information ModellingKaran SDNo ratings yet

- Architectural - Sheet Metal - CollieDocument42 pagesArchitectural - Sheet Metal - CollieWissam AlameddineNo ratings yet