Professional Documents

Culture Documents

0110 09 Fordcity

0110 09 Fordcity

Uploaded by

CarlosCopyright:

Available Formats

You might also like

- Checklist Vision Jet SF50 v1.2Document6 pagesChecklist Vision Jet SF50 v1.2José SoaresNo ratings yet

- France-8-Corsica v1 m56577569830522658 PDFDocument34 pagesFrance-8-Corsica v1 m56577569830522658 PDFcdimcea9306No ratings yet

- Chenab Bridge ReportDocument13 pagesChenab Bridge ReportAkash Agrawal75% (4)

- Millau Viaduct Long Span BridgeDocument11 pagesMillau Viaduct Long Span BridgeRohit DigraNo ratings yet

- Chenab Bridge - Cost, Construction, Images, Status, InaugurationDocument7 pagesChenab Bridge - Cost, Construction, Images, Status, InaugurationIndra MishraNo ratings yet

- History of Electric Motorcycles and ScootersDocument5 pagesHistory of Electric Motorcycles and Scooterspaurak100% (1)

- ZFPumpen E 08Document22 pagesZFPumpen E 08help3rNo ratings yet

- MaritimeLaw DeskBookDocument46 pagesMaritimeLaw DeskBookSasidharan Rajendran100% (2)

- Chenab Bridge: P.Anil Kumar 1005-15-741508Document20 pagesChenab Bridge: P.Anil Kumar 1005-15-741508vsballaNo ratings yet

- Greece WebDocument3 pagesGreece Websalisafita1No ratings yet

- Replacement of Bearings in The Golden Horn Bridge PDFDocument3 pagesReplacement of Bearings in The Golden Horn Bridge PDFVCNo ratings yet

- IABSE Final Paper PDFDocument8 pagesIABSE Final Paper PDFAndrew PetryszakNo ratings yet

- Dorman Long TechnologyDocument5 pagesDorman Long Technologyrisang haryoNo ratings yet

- Indian Institute of Tecnology, Roorkee: AUTUMN SEMESTER:-2016-17Document20 pagesIndian Institute of Tecnology, Roorkee: AUTUMN SEMESTER:-2016-17Allyne CristinaNo ratings yet

- Taney Bridge Paper 21-01-03Document35 pagesTaney Bridge Paper 21-01-03Doug WeirNo ratings yet

- Cable Stayed BridgesDocument33 pagesCable Stayed Bridgesmaged salama100% (1)

- C CI Segmental Concrete Bridges Oct 051Document4 pagesC CI Segmental Concrete Bridges Oct 051Varun VermaNo ratings yet

- Case Study 1: Bandra-Worli Sea Link ProjectDocument23 pagesCase Study 1: Bandra-Worli Sea Link ProjectAarushi Arora100% (1)

- Kurilpa Bridge Case StudyDocument4 pagesKurilpa Bridge Case StudyTheomi BunburyNo ratings yet

- Suspension Bridge: Presented By: Ngooi Wan ZheDocument8 pagesSuspension Bridge: Presented By: Ngooi Wan ZheEmily NgooiNo ratings yet

- Can Tho Bridge VietnamDocument2 pagesCan Tho Bridge VietnamIndra Nath MishraNo ratings yet

- VSL (1897) PDFDocument2 pagesVSL (1897) PDFRaed Naim KhammashNo ratings yet

- Tac 2006Document21 pagesTac 2006Chewfy1No ratings yet

- Thesis DraftDocument4 pagesThesis DraftPremchand SahooNo ratings yet

- Final ThesisDocument43 pagesFinal ThesisAnimikh BanerjeeNo ratings yet

- CVH CFST Arch BridgeDocument71 pagesCVH CFST Arch BridgeTùng NguyễnNo ratings yet

- Discover Bridge Over Missouri RiverDocument11 pagesDiscover Bridge Over Missouri RiverEr.Praveen RajNo ratings yet

- CASE STUDY of MQS111 (QH21009)Document5 pagesCASE STUDY of MQS111 (QH21009)Smitesh AhireNo ratings yet

- Bridge ConstructionDocument53 pagesBridge ConstructionRuthNo ratings yet

- 02 Cable Stay Suspension Extradosed Bridges HDocument16 pages02 Cable Stay Suspension Extradosed Bridges HdziktadzikkNo ratings yet

- Forging New Generations of EngineersDocument44 pagesForging New Generations of EngineersLe Tuan DungNo ratings yet

- (2010, Biana) A Semi-Integral Composite Bridge of High SkewDocument10 pages(2010, Biana) A Semi-Integral Composite Bridge of High SkewAnderson UrreaNo ratings yet

- Golden Gate BridgeDocument49 pagesGolden Gate BridgeAbhishek Koul100% (1)

- Development and Application of A Flexible Combined Support System For Tunnel Rehabilitation - DSI UndergroundDocument2 pagesDevelopment and Application of A Flexible Combined Support System For Tunnel Rehabilitation - DSI UndergroundLuca BrandiNo ratings yet

- 1.1 General: Chabahil Road in Kathmandu District, BagmatiDocument25 pages1.1 General: Chabahil Road in Kathmandu District, Bagmatienlacer009No ratings yet

- (Josias Lemuel Hernandez) (ID-343 (Professor: Nathan Bright)Document9 pages(Josias Lemuel Hernandez) (ID-343 (Professor: Nathan Bright)Josias HernandezNo ratings yet

- Test Done in Akashi Kaikyo Bridge PDFDocument10 pagesTest Done in Akashi Kaikyo Bridge PDFCris BandaNo ratings yet

- Long Span Reinforced Concrete Arch Bridges in Yunnan, China: Song-Ping BAI, Jian-Ping ZHOU & Bao-Chun CHENDocument8 pagesLong Span Reinforced Concrete Arch Bridges in Yunnan, China: Song-Ping BAI, Jian-Ping ZHOU & Bao-Chun CHENjoseluisyNo ratings yet

- Application For Accord of Administrative Approval For Construction of Bridge 1x40M Trussed Girder Foot BridgeDocument2 pagesApplication For Accord of Administrative Approval For Construction of Bridge 1x40M Trussed Girder Foot Bridgehakim imtiyazNo ratings yet

- B ThesisDocument77 pagesB ThesisshubhadipNo ratings yet

- 2 PartDocument69 pages2 PartshubhadipNo ratings yet

- Case Studies For Steel Bridge Erection Conventional, Lateral Slides and Incremental LaunchingDocument9 pagesCase Studies For Steel Bridge Erection Conventional, Lateral Slides and Incremental LaunchingMiguel PerezNo ratings yet

- Project Report: World's First PC-steel Composite Cable-Stayed Bridge Using Corrugated Steel Plate Webs For PC GirdersDocument6 pagesProject Report: World's First PC-steel Composite Cable-Stayed Bridge Using Corrugated Steel Plate Webs For PC GirdersNehaNo ratings yet

- Modern Practice On Bridge Construction On World RailwaysDocument37 pagesModern Practice On Bridge Construction On World RailwaysA Sattar M El-farraNo ratings yet

- 112 Feature BoyneBridgeDocument2 pages112 Feature BoyneBridgeaaaaahhhhhhhhNo ratings yet

- Kharkopar STN Concept, Material, ServicesDocument6 pagesKharkopar STN Concept, Material, Serviceskomal100% (1)

- Bridges: Sunil Ledwani 19 Nikesh Malhotra 21 Sagesh Nair 30 Prasun Pandey Sagar Vartak Bhavesh MankaniDocument34 pagesBridges: Sunil Ledwani 19 Nikesh Malhotra 21 Sagesh Nair 30 Prasun Pandey Sagar Vartak Bhavesh MankaniBhaveshmankaniNo ratings yet

- Module-V CE23105 BridgesDocument18 pagesModule-V CE23105 BridgesOm PrakashNo ratings yet

- Kurilpa Bridge Case Study PDFDocument4 pagesKurilpa Bridge Case Study PDFkamomartNo ratings yet

- Chapter 2Document8 pagesChapter 2aaryandas86No ratings yet

- June 2017 CI Franklin Avenue Bridge ArticleDocument10 pagesJune 2017 CI Franklin Avenue Bridge ArticleFernando Castillo HerreraNo ratings yet

- Fig: - Integral Members of Steel Truss BridgeDocument5 pagesFig: - Integral Members of Steel Truss Bridgearjun 2008No ratings yet

- 1997v01 High StrengthDocument5 pages1997v01 High StrengthIgnacio Hiram M RoqueNo ratings yet

- Bridge RetroDocument13 pagesBridge RetroKiller BeeNo ratings yet

- Design of Long Span Concrete Box Girder Bridges: Challenges and SolutionsDocument11 pagesDesign of Long Span Concrete Box Girder Bridges: Challenges and SolutionsRajkamal AroraNo ratings yet

- Michele MeleDocument37 pagesMichele MeleMaria Alejandra Rivas HueteNo ratings yet

- EN18350456 Training PresentationDocument13 pagesEN18350456 Training PresentationThushan De SilvaNo ratings yet

- Cable Stay BridgeDocument42 pagesCable Stay BridgeKartikMandaniNo ratings yet

- Design and Construction of Pre-Tensioned Sutlej Bridge in PunjabDocument16 pagesDesign and Construction of Pre-Tensioned Sutlej Bridge in PunjabYogesh GhuleNo ratings yet

- RaviabstractDocument21 pagesRaviabstractSunil Kumar IndiaNo ratings yet

- Donghai Bridge - The First Super Long Open Sea Crossing in ChinaDocument6 pagesDonghai Bridge - The First Super Long Open Sea Crossing in ChinaHossein DoudiNo ratings yet

- SDR 473Document19 pagesSDR 473Ralitsa OlevaNo ratings yet

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Scaffolding - Sa Gi 8 - 001Document91 pagesScaffolding - Sa Gi 8 - 001noel beloyNo ratings yet

- 121GW EEVBlog Circuit Diagram PDFDocument1 page121GW EEVBlog Circuit Diagram PDFAnonymous yHeaKj9bqNo ratings yet

- Compound Wall EstimatesDocument132 pagesCompound Wall EstimatesLearn & teachNo ratings yet

- 0 All 1)Document125 pages0 All 1)RAMITHPNo ratings yet

- 2014-12-08-NS Web Version Catalogue Va-04Document1 page2014-12-08-NS Web Version Catalogue Va-04東栄大出No ratings yet

- Hyperloop: Presented By: Meshel AlkorbiDocument16 pagesHyperloop: Presented By: Meshel AlkorbiMeshel AlkorbiNo ratings yet

- Curriculum Vitae: Application FormDocument3 pagesCurriculum Vitae: Application FormNicka Ashley Jarabe-AcostaNo ratings yet

- Unit 8 Tourism Lesson 2 A Closer Look 1Document16 pagesUnit 8 Tourism Lesson 2 A Closer Look 1Nga NguyenNo ratings yet

- Seconds From Disaster. Aircrash InvestigationDocument8 pagesSeconds From Disaster. Aircrash InvestigationgauravmktNo ratings yet

- Technical Publication GeneralDocument16 pagesTechnical Publication Generalsabbir RafitNo ratings yet

- Draft Contract GLIIT-BMI GAR 5500-5300Document12 pagesDraft Contract GLIIT-BMI GAR 5500-5300Julian Nico100% (1)

- Advisory Circular 147 02 Approved Part 147 Training OrganisationsDocument114 pagesAdvisory Circular 147 02 Approved Part 147 Training OrganisationsVỸ TRẦNNo ratings yet

- 2011 Volvo S60 Owners ManualDocument342 pages2011 Volvo S60 Owners ManualRadu PNo ratings yet

- FM2PN1DDocument2 pagesFM2PN1DAlana Christie JeffryNo ratings yet

- Model DBRDocument77 pagesModel DBRArnab SurNo ratings yet

- Letran de Davao, IncDocument3 pagesLetran de Davao, IncPatricia DianeNo ratings yet

- Bridge Railing & Deck DesignDocument28 pagesBridge Railing & Deck Designmedhat145No ratings yet

- TSRTC Bus PassDocument2 pagesTSRTC Bus Passkaushikkadari321No ratings yet

- Bascos V Court of Appeals, 221 SCRA 318 (DIGEST) - KRVDocument2 pagesBascos V Court of Appeals, 221 SCRA 318 (DIGEST) - KRVKhenlie VillaceranNo ratings yet

- Alstom Manual Volume 1 PDFDocument24 pagesAlstom Manual Volume 1 PDFSahil Kumar100% (1)

- Trans-Atlantic Slave TradeDocument2 pagesTrans-Atlantic Slave TradeDarien BurrellNo ratings yet

- Factor Influencing On Purchase Decision of Two Wheeler-Bilal LuharDocument76 pagesFactor Influencing On Purchase Decision of Two Wheeler-Bilal LuharVishal Patel100% (1)

- MMD Airman Air Compressor PDS185S 6E1Document2 pagesMMD Airman Air Compressor PDS185S 6E1Eka setyaNo ratings yet

- Specificatie Tehnica BOPPDocument2 pagesSpecificatie Tehnica BOPPkrys780% (1)

- Starke County Indiana TimelineDocument51 pagesStarke County Indiana TimelineallenmoNo ratings yet

0110 09 Fordcity

0110 09 Fordcity

Uploaded by

CarlosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0110 09 Fordcity

0110 09 Fordcity

Uploaded by

CarlosCopyright:

Available Formats

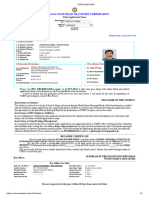

STEEL BRIDGE A

NAL LLI

TIO AN

NA C

merit award: LONG SPAN E

Ford City Veterans Bridge

Ford City, PA

T

he Ford City Veterans Bridge in Armstrong County at Ford

City, PA is a three-span continuous curved steel plate girder

bridge with a total length of 323m (1060’), carrying S.R. 0128

over the Allegheny River and the Pittsburgh and Shawmut

Railroad . The structure showcases Pennsylvania’s longest

curved girder to date and PennDOT’s first use of grade 485W (70 ksi) high

performance steel.

Construction

The project was awarded on April 15, 1998, and traffic was placed on the new bridge on July 31, 2000. The bridge was

completed in time for the dedication and naming ceremony on July 28, 2000, but many unique construction challenges had

to be overcome in order to accomplish this.

Modern Steel Construction / October 2001

of the first projects in Pennsylvania to

use “partnering” in the design phase to

provide local input directly into the de-

sign of the new bridge. By implement-

ing partnering during the design phase

and working with the local community,

PennDOT and its “stakeholders” were

able to expedite the design schedule

and deliver the best project possible to

meet the community’s needs.

Significant Project Features

• 3-span, steel curved girder bridge

with a main span length of 127.0m

(416.67’).

• Total bridge length of 323.0m

(1059.71’).

• The structure stands 29.2m (95.8’)

above water at the west pier.

• First use of high performance steel

in Pennsylvania and one of the

largest applications in the nation.

• Currently, Pennsylvania’s longest

curved girder with a length of

102.0m (334.87’).

• The curved girder had an extremely

tight radius of 155m (509’).

• Construction of the new bridge

used 9531 cubic meters (12,466 cubic

yards) of concrete, 5 million pounds

of structural steel and 1 million

pounds of reinforcing bars.

• Built in 1914, the existing bridge

was demolished in August of 2000.

Owner

Pennsylvania Department of Transportation,

Indiana, PA

Structural Engineer

Michael Baker Jr., Inc., Coraopolis, PA

Steel Fabricator

PDM Bridge, Eau Claire, WI (AISC member)

Steel Detailer

Candraft Detailing, Inc., Port Coquitlam, BC

Canada (NISD member)

The first significant challenge was Project Success

the transportation of the 4.3m (14’) The completion of the project

Steel Erector

deep girders to the project site by water marked two very significant accom-

Abate Irwin, Inc., Eighty Four, PA

and train. The girders were fabricated plishments for the industry. First, by

(NEA member)

by PDM Bridge, of Eau Claire, WI. It using one of the largest applications of

took an enormous amount of man- curved high performance weathering

General Contractor

power, equipment and coordination to steel in the nation to date, the project

Trumbull Corporation, Pittsburgh, PA

accomplish this task. Another difficult has paved-the-way for the construction

challenge was the fabrication and erec- industry to utilize this new material.

tion of these same large girders. This Eventually, this will greatly reduce con- Software

task was also difficult because of the struction costs as the new steel be- Some in-house

tight radius of 155m (509’) in the comes increasingly more popular and

curved section of the bridge. available. Second, this project was one

October 2001 / Modern Steel Construction

You might also like

- Checklist Vision Jet SF50 v1.2Document6 pagesChecklist Vision Jet SF50 v1.2José SoaresNo ratings yet

- France-8-Corsica v1 m56577569830522658 PDFDocument34 pagesFrance-8-Corsica v1 m56577569830522658 PDFcdimcea9306No ratings yet

- Chenab Bridge ReportDocument13 pagesChenab Bridge ReportAkash Agrawal75% (4)

- Millau Viaduct Long Span BridgeDocument11 pagesMillau Viaduct Long Span BridgeRohit DigraNo ratings yet

- Chenab Bridge - Cost, Construction, Images, Status, InaugurationDocument7 pagesChenab Bridge - Cost, Construction, Images, Status, InaugurationIndra MishraNo ratings yet

- History of Electric Motorcycles and ScootersDocument5 pagesHistory of Electric Motorcycles and Scooterspaurak100% (1)

- ZFPumpen E 08Document22 pagesZFPumpen E 08help3rNo ratings yet

- MaritimeLaw DeskBookDocument46 pagesMaritimeLaw DeskBookSasidharan Rajendran100% (2)

- Chenab Bridge: P.Anil Kumar 1005-15-741508Document20 pagesChenab Bridge: P.Anil Kumar 1005-15-741508vsballaNo ratings yet

- Greece WebDocument3 pagesGreece Websalisafita1No ratings yet

- Replacement of Bearings in The Golden Horn Bridge PDFDocument3 pagesReplacement of Bearings in The Golden Horn Bridge PDFVCNo ratings yet

- IABSE Final Paper PDFDocument8 pagesIABSE Final Paper PDFAndrew PetryszakNo ratings yet

- Dorman Long TechnologyDocument5 pagesDorman Long Technologyrisang haryoNo ratings yet

- Indian Institute of Tecnology, Roorkee: AUTUMN SEMESTER:-2016-17Document20 pagesIndian Institute of Tecnology, Roorkee: AUTUMN SEMESTER:-2016-17Allyne CristinaNo ratings yet

- Taney Bridge Paper 21-01-03Document35 pagesTaney Bridge Paper 21-01-03Doug WeirNo ratings yet

- Cable Stayed BridgesDocument33 pagesCable Stayed Bridgesmaged salama100% (1)

- C CI Segmental Concrete Bridges Oct 051Document4 pagesC CI Segmental Concrete Bridges Oct 051Varun VermaNo ratings yet

- Case Study 1: Bandra-Worli Sea Link ProjectDocument23 pagesCase Study 1: Bandra-Worli Sea Link ProjectAarushi Arora100% (1)

- Kurilpa Bridge Case StudyDocument4 pagesKurilpa Bridge Case StudyTheomi BunburyNo ratings yet

- Suspension Bridge: Presented By: Ngooi Wan ZheDocument8 pagesSuspension Bridge: Presented By: Ngooi Wan ZheEmily NgooiNo ratings yet

- Can Tho Bridge VietnamDocument2 pagesCan Tho Bridge VietnamIndra Nath MishraNo ratings yet

- VSL (1897) PDFDocument2 pagesVSL (1897) PDFRaed Naim KhammashNo ratings yet

- Tac 2006Document21 pagesTac 2006Chewfy1No ratings yet

- Thesis DraftDocument4 pagesThesis DraftPremchand SahooNo ratings yet

- Final ThesisDocument43 pagesFinal ThesisAnimikh BanerjeeNo ratings yet

- CVH CFST Arch BridgeDocument71 pagesCVH CFST Arch BridgeTùng NguyễnNo ratings yet

- Discover Bridge Over Missouri RiverDocument11 pagesDiscover Bridge Over Missouri RiverEr.Praveen RajNo ratings yet

- CASE STUDY of MQS111 (QH21009)Document5 pagesCASE STUDY of MQS111 (QH21009)Smitesh AhireNo ratings yet

- Bridge ConstructionDocument53 pagesBridge ConstructionRuthNo ratings yet

- 02 Cable Stay Suspension Extradosed Bridges HDocument16 pages02 Cable Stay Suspension Extradosed Bridges HdziktadzikkNo ratings yet

- Forging New Generations of EngineersDocument44 pagesForging New Generations of EngineersLe Tuan DungNo ratings yet

- (2010, Biana) A Semi-Integral Composite Bridge of High SkewDocument10 pages(2010, Biana) A Semi-Integral Composite Bridge of High SkewAnderson UrreaNo ratings yet

- Golden Gate BridgeDocument49 pagesGolden Gate BridgeAbhishek Koul100% (1)

- Development and Application of A Flexible Combined Support System For Tunnel Rehabilitation - DSI UndergroundDocument2 pagesDevelopment and Application of A Flexible Combined Support System For Tunnel Rehabilitation - DSI UndergroundLuca BrandiNo ratings yet

- 1.1 General: Chabahil Road in Kathmandu District, BagmatiDocument25 pages1.1 General: Chabahil Road in Kathmandu District, Bagmatienlacer009No ratings yet

- (Josias Lemuel Hernandez) (ID-343 (Professor: Nathan Bright)Document9 pages(Josias Lemuel Hernandez) (ID-343 (Professor: Nathan Bright)Josias HernandezNo ratings yet

- Test Done in Akashi Kaikyo Bridge PDFDocument10 pagesTest Done in Akashi Kaikyo Bridge PDFCris BandaNo ratings yet

- Long Span Reinforced Concrete Arch Bridges in Yunnan, China: Song-Ping BAI, Jian-Ping ZHOU & Bao-Chun CHENDocument8 pagesLong Span Reinforced Concrete Arch Bridges in Yunnan, China: Song-Ping BAI, Jian-Ping ZHOU & Bao-Chun CHENjoseluisyNo ratings yet

- Application For Accord of Administrative Approval For Construction of Bridge 1x40M Trussed Girder Foot BridgeDocument2 pagesApplication For Accord of Administrative Approval For Construction of Bridge 1x40M Trussed Girder Foot Bridgehakim imtiyazNo ratings yet

- B ThesisDocument77 pagesB ThesisshubhadipNo ratings yet

- 2 PartDocument69 pages2 PartshubhadipNo ratings yet

- Case Studies For Steel Bridge Erection Conventional, Lateral Slides and Incremental LaunchingDocument9 pagesCase Studies For Steel Bridge Erection Conventional, Lateral Slides and Incremental LaunchingMiguel PerezNo ratings yet

- Project Report: World's First PC-steel Composite Cable-Stayed Bridge Using Corrugated Steel Plate Webs For PC GirdersDocument6 pagesProject Report: World's First PC-steel Composite Cable-Stayed Bridge Using Corrugated Steel Plate Webs For PC GirdersNehaNo ratings yet

- Modern Practice On Bridge Construction On World RailwaysDocument37 pagesModern Practice On Bridge Construction On World RailwaysA Sattar M El-farraNo ratings yet

- 112 Feature BoyneBridgeDocument2 pages112 Feature BoyneBridgeaaaaahhhhhhhhNo ratings yet

- Kharkopar STN Concept, Material, ServicesDocument6 pagesKharkopar STN Concept, Material, Serviceskomal100% (1)

- Bridges: Sunil Ledwani 19 Nikesh Malhotra 21 Sagesh Nair 30 Prasun Pandey Sagar Vartak Bhavesh MankaniDocument34 pagesBridges: Sunil Ledwani 19 Nikesh Malhotra 21 Sagesh Nair 30 Prasun Pandey Sagar Vartak Bhavesh MankaniBhaveshmankaniNo ratings yet

- Module-V CE23105 BridgesDocument18 pagesModule-V CE23105 BridgesOm PrakashNo ratings yet

- Kurilpa Bridge Case Study PDFDocument4 pagesKurilpa Bridge Case Study PDFkamomartNo ratings yet

- Chapter 2Document8 pagesChapter 2aaryandas86No ratings yet

- June 2017 CI Franklin Avenue Bridge ArticleDocument10 pagesJune 2017 CI Franklin Avenue Bridge ArticleFernando Castillo HerreraNo ratings yet

- Fig: - Integral Members of Steel Truss BridgeDocument5 pagesFig: - Integral Members of Steel Truss Bridgearjun 2008No ratings yet

- 1997v01 High StrengthDocument5 pages1997v01 High StrengthIgnacio Hiram M RoqueNo ratings yet

- Bridge RetroDocument13 pagesBridge RetroKiller BeeNo ratings yet

- Design of Long Span Concrete Box Girder Bridges: Challenges and SolutionsDocument11 pagesDesign of Long Span Concrete Box Girder Bridges: Challenges and SolutionsRajkamal AroraNo ratings yet

- Michele MeleDocument37 pagesMichele MeleMaria Alejandra Rivas HueteNo ratings yet

- EN18350456 Training PresentationDocument13 pagesEN18350456 Training PresentationThushan De SilvaNo ratings yet

- Cable Stay BridgeDocument42 pagesCable Stay BridgeKartikMandaniNo ratings yet

- Design and Construction of Pre-Tensioned Sutlej Bridge in PunjabDocument16 pagesDesign and Construction of Pre-Tensioned Sutlej Bridge in PunjabYogesh GhuleNo ratings yet

- RaviabstractDocument21 pagesRaviabstractSunil Kumar IndiaNo ratings yet

- Donghai Bridge - The First Super Long Open Sea Crossing in ChinaDocument6 pagesDonghai Bridge - The First Super Long Open Sea Crossing in ChinaHossein DoudiNo ratings yet

- SDR 473Document19 pagesSDR 473Ralitsa OlevaNo ratings yet

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Scaffolding - Sa Gi 8 - 001Document91 pagesScaffolding - Sa Gi 8 - 001noel beloyNo ratings yet

- 121GW EEVBlog Circuit Diagram PDFDocument1 page121GW EEVBlog Circuit Diagram PDFAnonymous yHeaKj9bqNo ratings yet

- Compound Wall EstimatesDocument132 pagesCompound Wall EstimatesLearn & teachNo ratings yet

- 0 All 1)Document125 pages0 All 1)RAMITHPNo ratings yet

- 2014-12-08-NS Web Version Catalogue Va-04Document1 page2014-12-08-NS Web Version Catalogue Va-04東栄大出No ratings yet

- Hyperloop: Presented By: Meshel AlkorbiDocument16 pagesHyperloop: Presented By: Meshel AlkorbiMeshel AlkorbiNo ratings yet

- Curriculum Vitae: Application FormDocument3 pagesCurriculum Vitae: Application FormNicka Ashley Jarabe-AcostaNo ratings yet

- Unit 8 Tourism Lesson 2 A Closer Look 1Document16 pagesUnit 8 Tourism Lesson 2 A Closer Look 1Nga NguyenNo ratings yet

- Seconds From Disaster. Aircrash InvestigationDocument8 pagesSeconds From Disaster. Aircrash InvestigationgauravmktNo ratings yet

- Technical Publication GeneralDocument16 pagesTechnical Publication Generalsabbir RafitNo ratings yet

- Draft Contract GLIIT-BMI GAR 5500-5300Document12 pagesDraft Contract GLIIT-BMI GAR 5500-5300Julian Nico100% (1)

- Advisory Circular 147 02 Approved Part 147 Training OrganisationsDocument114 pagesAdvisory Circular 147 02 Approved Part 147 Training OrganisationsVỸ TRẦNNo ratings yet

- 2011 Volvo S60 Owners ManualDocument342 pages2011 Volvo S60 Owners ManualRadu PNo ratings yet

- FM2PN1DDocument2 pagesFM2PN1DAlana Christie JeffryNo ratings yet

- Model DBRDocument77 pagesModel DBRArnab SurNo ratings yet

- Letran de Davao, IncDocument3 pagesLetran de Davao, IncPatricia DianeNo ratings yet

- Bridge Railing & Deck DesignDocument28 pagesBridge Railing & Deck Designmedhat145No ratings yet

- TSRTC Bus PassDocument2 pagesTSRTC Bus Passkaushikkadari321No ratings yet

- Bascos V Court of Appeals, 221 SCRA 318 (DIGEST) - KRVDocument2 pagesBascos V Court of Appeals, 221 SCRA 318 (DIGEST) - KRVKhenlie VillaceranNo ratings yet

- Alstom Manual Volume 1 PDFDocument24 pagesAlstom Manual Volume 1 PDFSahil Kumar100% (1)

- Trans-Atlantic Slave TradeDocument2 pagesTrans-Atlantic Slave TradeDarien BurrellNo ratings yet

- Factor Influencing On Purchase Decision of Two Wheeler-Bilal LuharDocument76 pagesFactor Influencing On Purchase Decision of Two Wheeler-Bilal LuharVishal Patel100% (1)

- MMD Airman Air Compressor PDS185S 6E1Document2 pagesMMD Airman Air Compressor PDS185S 6E1Eka setyaNo ratings yet

- Specificatie Tehnica BOPPDocument2 pagesSpecificatie Tehnica BOPPkrys780% (1)

- Starke County Indiana TimelineDocument51 pagesStarke County Indiana TimelineallenmoNo ratings yet