Professional Documents

Culture Documents

Dry Transformer Maintenance

Dry Transformer Maintenance

Uploaded by

Fayyaz HeroCopyright:

Available Formats

You might also like

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- EHV KV: Guide For Installation of Oil-Immersed Transformers and AboveDocument18 pagesEHV KV: Guide For Installation of Oil-Immersed Transformers and Aboveruel delacruz100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- A - Buch PL120106Document84 pagesA - Buch PL120106Cristian Piñeros100% (1)

- Volumetric - or Cubic Thermal ExpansionDocument10 pagesVolumetric - or Cubic Thermal ExpansionAs'adNo ratings yet

- Dry Transformer MaintenanceDocument1 pageDry Transformer MaintenanceWangun100% (3)

- Power Transformer MaintenanceDocument27 pagesPower Transformer MaintenanceBIKASH SAHNo ratings yet

- LVDTT Cleaning and Maintenance Tips 1TQC1932E0003 REV.A JUL 2020Document2 pagesLVDTT Cleaning and Maintenance Tips 1TQC1932E0003 REV.A JUL 2020imami.lazuardi2No ratings yet

- Polymeric Insulator Cleaning ProcedureDocument4 pagesPolymeric Insulator Cleaning ProcedureSellappan Muthusamy100% (1)

- Power Transformer Maintenance-R1Document27 pagesPower Transformer Maintenance-R1R4jput ShaileshNo ratings yet

- Technical ReferencesDocument16 pagesTechnical Referencessudhi_786No ratings yet

- Guidelines For Installing TransformersDocument7 pagesGuidelines For Installing Transformersjogiyajee100% (1)

- 2.4 Urgency Handling: 3.1 Brief IntroductionDocument46 pages2.4 Urgency Handling: 3.1 Brief IntroductionClip nhungcaunoihayNo ratings yet

- Transformer Installation - Some Best PracticesDocument5 pagesTransformer Installation - Some Best PracticespctinformationNo ratings yet

- Transformer Dry Type Install Best Practices White Paper WP009003ENDocument8 pagesTransformer Dry Type Install Best Practices White Paper WP009003ENthommyNo ratings yet

- Insulation Resistance and Electrical Testing For HVAC - FlukeDocument4 pagesInsulation Resistance and Electrical Testing For HVAC - FlukeNoel Gregorio SantosNo ratings yet

- Operation and Maintenance Trafo TrafindoDocument12 pagesOperation and Maintenance Trafo TrafindoDwi Cahya SeptiawanNo ratings yet

- Erection Procedure For Power TransformerDocument3 pagesErection Procedure For Power Transformerparuchurivenkat5272No ratings yet

- Erection Procedure For Power TransformerDocument3 pagesErection Procedure For Power TransformerWaqar Ali Sher100% (1)

- GAPS Guidelines: Transformers - SurroundingsDocument5 pagesGAPS Guidelines: Transformers - SurroundingsAsad KhanNo ratings yet

- Extract Pages From HF61G00224S - HTW - D - 0 - UM - GB - R134a - Feag - HIREFDocument8 pagesExtract Pages From HF61G00224S - HTW - D - 0 - UM - GB - R134a - Feag - HIREFHafiz Mehroz KhanNo ratings yet

- Dry Type MiniSub Manual With NGRDocument12 pagesDry Type MiniSub Manual With NGRroni pardamean sijabatNo ratings yet

- Electrical PM Program (By Hanover Risk Solution)Document16 pagesElectrical PM Program (By Hanover Risk Solution)didiekilham100% (2)

- Dry Transformer ManualDocument7 pagesDry Transformer Manualbacuoc.nguyen356100% (1)

- Transformer Galley 10kva 440V/233V: Installation InstructionDocument5 pagesTransformer Galley 10kva 440V/233V: Installation InstructionstargaxxxxNo ratings yet

- Assignment #3: To: Ma'Am Saima AliDocument9 pagesAssignment #3: To: Ma'Am Saima AliEsmatullah BegzadNo ratings yet

- Installation Instructions For Air Cooled Condensing Units: Model Series 1 To 5 TonDocument8 pagesInstallation Instructions For Air Cooled Condensing Units: Model Series 1 To 5 Tonb sherrillNo ratings yet

- Generator MaintenanceDocument2 pagesGenerator MaintenanceArun GouthamNo ratings yet

- Assignment #3: To: Ma'Am Saima AliDocument9 pagesAssignment #3: To: Ma'Am Saima AliEsmatullah BegzadNo ratings yet

- Installation, Commissioning and Maintenance of Industrial ValvesDocument2 pagesInstallation, Commissioning and Maintenance of Industrial ValvesEmrah BinayNo ratings yet

- PR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkDocument6 pagesPR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkJuan Nacimba NacimbaNo ratings yet

- Mounting Procedure For The Power Transformer.Document3 pagesMounting Procedure For The Power Transformer.Inshrah ZahidNo ratings yet

- LKS Dust Opacity Analyzer D10 2Document19 pagesLKS Dust Opacity Analyzer D10 2KC WangNo ratings yet

- HVPE Operation and MaintenanceDocument116 pagesHVPE Operation and MaintenanceMinerva AbantoNo ratings yet

- Distribution Transformer Instruction ManualDocument14 pagesDistribution Transformer Instruction Manualzafarbajwa11No ratings yet

- 5.1.2 Two-Stage High Pressure Industrial Air CompresorsDocument124 pages5.1.2 Two-Stage High Pressure Industrial Air CompresorsPablo Andres Espin MartinNo ratings yet

- Imee 5Document8 pagesImee 5HirakNo ratings yet

- 3rd Topic ESP Q & ADocument20 pages3rd Topic ESP Q & APrafulla NandaleNo ratings yet

- Testing and Maintenacne of High Voltage Bushings PsmmCHAP-06Document24 pagesTesting and Maintenacne of High Voltage Bushings PsmmCHAP-06protectionwork100% (1)

- Maintenance Procedure For Switchyard Equipment Volume-II (EHV CBS, CTs Etc) PDFDocument39 pagesMaintenance Procedure For Switchyard Equipment Volume-II (EHV CBS, CTs Etc) PDFRAJESH PARIKSYANo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- Meggering Insulation Resistance Testing of Dry-Type Power TransformerDocument3 pagesMeggering Insulation Resistance Testing of Dry-Type Power TransformerSugeng SumarnoNo ratings yet

- IOM - Farr Gold Series GSP 4 UK EnglishDocument32 pagesIOM - Farr Gold Series GSP 4 UK EnglishJulio CNo ratings yet

- LKS Dust & Opacity Analyzer D10Document18 pagesLKS Dust & Opacity Analyzer D10KC WangNo ratings yet

- Half and Full CoatedDocument5 pagesHalf and Full Coatedwaluyo perwalianelektroNo ratings yet

- Installation, Operation and Maintenance Guide: For Indoor/Outdoor Dry-Type TransformersDocument36 pagesInstallation, Operation and Maintenance Guide: For Indoor/Outdoor Dry-Type TransformersClaudio Hernández PobleteNo ratings yet

- Drip Tube SpecDocument1 pageDrip Tube SpecashwinNo ratings yet

- Distribution Transformer Instruction ManualDocument10 pagesDistribution Transformer Instruction ManualmartinpellsNo ratings yet

- Low Voltage Dry-Type ManualDocument5 pagesLow Voltage Dry-Type ManualAjay AbrahamNo ratings yet

- Transformer DictionaryDocument9 pagesTransformer DictionaryChristian Rally Ramos GonzalezNo ratings yet

- IOM14055 DustCollectorIOM GSP1 Mini 1.0 enDocument19 pagesIOM14055 DustCollectorIOM GSP1 Mini 1.0 enEinar MuñizNo ratings yet

- HK OIM 7433659 Rev5.16Document20 pagesHK OIM 7433659 Rev5.16Ingeniería AplicacionesNo ratings yet

- 1414665118314-Ti Mi 0039 PDFDocument15 pages1414665118314-Ti Mi 0039 PDFmithun 46No ratings yet

- Safety Guide and Basic Factors For The Selection, Installation and Maintenance of Hose and Hose AssembliesDocument4 pagesSafety Guide and Basic Factors For The Selection, Installation and Maintenance of Hose and Hose Assembliesphankhoa83-1No ratings yet

- Maintenance of TransformerDocument8 pagesMaintenance of TransformeranilsinghteslaNo ratings yet

- PCT - Is It Time To Change That TransformerDocument3 pagesPCT - Is It Time To Change That TransformerpctinformationNo ratings yet

- Maintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESDocument2 pagesMaintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESVelmar diseño y construccionNo ratings yet

- Sanjay Kar Chowdhury Cbip 2006Document7 pagesSanjay Kar Chowdhury Cbip 2006Gunadevan ChandrasekaranNo ratings yet

- Direct Steam Injection HumidifierDocument41 pagesDirect Steam Injection Humidifierسامح الجاسم100% (1)

- GE Fanuc Automation Computer Numerical CDocument174 pagesGE Fanuc Automation Computer Numerical CFayyaz HeroNo ratings yet

- G3R I-O Datasheet J25I-E-01Document9 pagesG3R I-O Datasheet J25I-E-01Fayyaz HeroNo ratings yet

- Alarm 414 (Digital Servo System Is Abnormal) : PointsDocument12 pagesAlarm 414 (Digital Servo System Is Abnormal) : PointsFayyaz HeroNo ratings yet

- f0 Alm 945Document1 pagef0 Alm 945Fayyaz HeroNo ratings yet

- Straub Couplings Catalog 2017Document24 pagesStraub Couplings Catalog 2017kman548No ratings yet

- Wall Partition (Civil Works)Document1 pageWall Partition (Civil Works)alvin calusaNo ratings yet

- Ariston Spare Part CatalougeDocument19 pagesAriston Spare Part CatalougeNuboogh ErbilNo ratings yet

- 04.Mr - Swaminathan - Second Floor Parapet Wall Projection Ceiling Layout 2Document1 page04.Mr - Swaminathan - Second Floor Parapet Wall Projection Ceiling Layout 2kishore kumarNo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- Impact Response of Elasto-Plastic Granular Chains Containing An Intruder ParticleDocument9 pagesImpact Response of Elasto-Plastic Granular Chains Containing An Intruder ParticleCesar HernandezNo ratings yet

- Hong & Lee - Strut and Tie ModelDocument14 pagesHong & Lee - Strut and Tie ModelWilbert HernandezNo ratings yet

- Publication 3 10700 639Document3 pagesPublication 3 10700 639Yordanos SolomonNo ratings yet

- Flow, Slope &pipe Dia. Calculation Using Manning's FormulaDocument18 pagesFlow, Slope &pipe Dia. Calculation Using Manning's FormulaMohammad Risky NaNo ratings yet

- Tes 1Document2 pagesTes 1jarottsNo ratings yet

- 1 Pendahuluan Fracture Mechanics RWP Gasal 22-23Document15 pages1 Pendahuluan Fracture Mechanics RWP Gasal 22-23RaNo ratings yet

- 2100 2800 Series PDFDocument2 pages2100 2800 Series PDFhendrabudimanNo ratings yet

- Magnetrol-Level Switch PDFDocument16 pagesMagnetrol-Level Switch PDFnatalNo ratings yet

- ADAPT TN220 Waffle Slab DesignDocument6 pagesADAPT TN220 Waffle Slab DesignVinnieTranNo ratings yet

- IndxDocument50 pagesIndxsupriyo1970No ratings yet

- Transpo Eng'g Slides 1 PDFDocument79 pagesTranspo Eng'g Slides 1 PDFEloisa PonceNo ratings yet

- Elbow SupportDocument3 pagesElbow SupportНемања КараклајићNo ratings yet

- Bahay Na BatoDocument32 pagesBahay Na BatokristineNo ratings yet

- Nanofluids As A Coolant in Automobile Radiator: A Review: Chandan KumarDocument6 pagesNanofluids As A Coolant in Automobile Radiator: A Review: Chandan KumarArun KumarNo ratings yet

- 56 - Isijint 2015 231 PDFDocument13 pages56 - Isijint 2015 231 PDFRaphael Mariano de SouzaNo ratings yet

- C CodesStand Schneider Jan11Document3 pagesC CodesStand Schneider Jan11Magdy BakryNo ratings yet

- E155-14 Standard Reference Radiographs For Inspection of Aluminum and Magnesium Castings PDFDocument4 pagesE155-14 Standard Reference Radiographs For Inspection of Aluminum and Magnesium Castings PDFVuong Tran VanNo ratings yet

- 02 Arch - Stru CoordinationDocument70 pages02 Arch - Stru Coordinationarjun 11No ratings yet

- Sproperty Unit Test Standard G 100 P: Mechanical PropertiesDocument3 pagesSproperty Unit Test Standard G 100 P: Mechanical PropertiesAnonymous MAQrYFQDzVNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Document8790922772No ratings yet

- Concrete Technology NotesDocument5 pagesConcrete Technology NotesawasarevinayakNo ratings yet

- Load and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationDocument5 pagesLoad and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationBRAYAN GERARDO AREVALO MENDOZANo ratings yet

- Bolts: Cap ScrewsDocument8 pagesBolts: Cap Screwsjairo F. Arroyo MNo ratings yet

Dry Transformer Maintenance

Dry Transformer Maintenance

Uploaded by

Fayyaz HeroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Transformer Maintenance

Dry Transformer Maintenance

Uploaded by

Fayyaz HeroCopyright:

Available Formats

DRY TYPE TRANSFORMER MAINTENANCE

Maximize your transformer’s life-expectancy

CAUTION: Always de-energize a transformer and and should be applied at a relatively low pressure (not

ground its case before entering or working on the over 25 lbs/in2). Lead supports, tap changers and terminal

transformer. Connect the ground to all transformer boards, bushings, and other major insulating surfaces

terminals. Remove these connections before reenergizing should be brushed or wiped with a dry lint-free cloth. The

the transformer. use of liquid cleaners is undesirable because some have a

deteriorating effect on insulating materials.

The life of your dry type transformers can be improved

with proper maintenance. An inspection and maintenance The insulation resistance test is used to determine the

schedule should be established to maximize the life of this moisture content of a transformer’s insulation material.

equipment. Evidence of rusting, corrosion, and The insulation resistance test should be made before

deterioration of the insulation, varnish or paint should be conducting an applied voltage test. The test data should

checked, and corrective measures taken. Auxiliary be recorded with the ambient temperature and humidity at

devices should be inspected and serviced during these the time of measurement.

inspections.

If a dry type transformer’s insulation resistance readings

Windings should be inspected for contaminants, do not meet the minimum values in Table 1 below, it

especially on insulating surfaces or where they could should be dried before the applied voltage test is

restrict air flow. Check for loose connections, condition performed or before the transformer is placed in service.

of tap changers, terminal boards and for the general Contact Alfa for more information.

condition of the transformer. Check for signs of

overheating and tracking or carbonization marks.

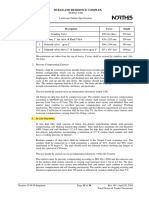

The intervals at which ventilated dry type transformers MINIMUM INSULATION RESISTANCE TABLE

should be inspected depends on operating conditions. For WINDING CLASS INSULATION RESISTANCE

clean, dry locations, an annual inspection may be KV MΩ

sufficient. For harsher environments where there is dust, 1.2 600

metallic particles or chemical fumes, a more frequent

2.5 1000

inspection may be required. Usually after a few

inspections, a schedule can be established based on the 5.0 1500

existing conditions. 8.7 2000

15.0 3000

Dust, dirt or residues on windings or insulators should be

TABLE 1

removed to permit free circulation of air and to reduce the

possibility of insulation breakdowns. Particular attention

should be given to cleaning windings and vents. ALFA TRANSFORMER

6107 South Zero Street • Fort Smith AR 72903

The windings may be cleaned with a vacuum cleaner, a Ph 479-646-1668 • Fax 479-646-4101

www.alfatransformer.com

blower, or with compressed air. The use of a vacuum

cleaner is preferred, followed by compressed air or

nitrogen. Maintain adequate ventilation during cleaning.

The compressed air or nitrogen should be clean and dry 9/21/2023 c:\xampp743\htdocs\alfa_new_site\Word\

You might also like

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- EHV KV: Guide For Installation of Oil-Immersed Transformers and AboveDocument18 pagesEHV KV: Guide For Installation of Oil-Immersed Transformers and Aboveruel delacruz100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- A - Buch PL120106Document84 pagesA - Buch PL120106Cristian Piñeros100% (1)

- Volumetric - or Cubic Thermal ExpansionDocument10 pagesVolumetric - or Cubic Thermal ExpansionAs'adNo ratings yet

- Dry Transformer MaintenanceDocument1 pageDry Transformer MaintenanceWangun100% (3)

- Power Transformer MaintenanceDocument27 pagesPower Transformer MaintenanceBIKASH SAHNo ratings yet

- LVDTT Cleaning and Maintenance Tips 1TQC1932E0003 REV.A JUL 2020Document2 pagesLVDTT Cleaning and Maintenance Tips 1TQC1932E0003 REV.A JUL 2020imami.lazuardi2No ratings yet

- Polymeric Insulator Cleaning ProcedureDocument4 pagesPolymeric Insulator Cleaning ProcedureSellappan Muthusamy100% (1)

- Power Transformer Maintenance-R1Document27 pagesPower Transformer Maintenance-R1R4jput ShaileshNo ratings yet

- Technical ReferencesDocument16 pagesTechnical Referencessudhi_786No ratings yet

- Guidelines For Installing TransformersDocument7 pagesGuidelines For Installing Transformersjogiyajee100% (1)

- 2.4 Urgency Handling: 3.1 Brief IntroductionDocument46 pages2.4 Urgency Handling: 3.1 Brief IntroductionClip nhungcaunoihayNo ratings yet

- Transformer Installation - Some Best PracticesDocument5 pagesTransformer Installation - Some Best PracticespctinformationNo ratings yet

- Transformer Dry Type Install Best Practices White Paper WP009003ENDocument8 pagesTransformer Dry Type Install Best Practices White Paper WP009003ENthommyNo ratings yet

- Insulation Resistance and Electrical Testing For HVAC - FlukeDocument4 pagesInsulation Resistance and Electrical Testing For HVAC - FlukeNoel Gregorio SantosNo ratings yet

- Operation and Maintenance Trafo TrafindoDocument12 pagesOperation and Maintenance Trafo TrafindoDwi Cahya SeptiawanNo ratings yet

- Erection Procedure For Power TransformerDocument3 pagesErection Procedure For Power Transformerparuchurivenkat5272No ratings yet

- Erection Procedure For Power TransformerDocument3 pagesErection Procedure For Power TransformerWaqar Ali Sher100% (1)

- GAPS Guidelines: Transformers - SurroundingsDocument5 pagesGAPS Guidelines: Transformers - SurroundingsAsad KhanNo ratings yet

- Extract Pages From HF61G00224S - HTW - D - 0 - UM - GB - R134a - Feag - HIREFDocument8 pagesExtract Pages From HF61G00224S - HTW - D - 0 - UM - GB - R134a - Feag - HIREFHafiz Mehroz KhanNo ratings yet

- Dry Type MiniSub Manual With NGRDocument12 pagesDry Type MiniSub Manual With NGRroni pardamean sijabatNo ratings yet

- Electrical PM Program (By Hanover Risk Solution)Document16 pagesElectrical PM Program (By Hanover Risk Solution)didiekilham100% (2)

- Dry Transformer ManualDocument7 pagesDry Transformer Manualbacuoc.nguyen356100% (1)

- Transformer Galley 10kva 440V/233V: Installation InstructionDocument5 pagesTransformer Galley 10kva 440V/233V: Installation InstructionstargaxxxxNo ratings yet

- Assignment #3: To: Ma'Am Saima AliDocument9 pagesAssignment #3: To: Ma'Am Saima AliEsmatullah BegzadNo ratings yet

- Installation Instructions For Air Cooled Condensing Units: Model Series 1 To 5 TonDocument8 pagesInstallation Instructions For Air Cooled Condensing Units: Model Series 1 To 5 Tonb sherrillNo ratings yet

- Generator MaintenanceDocument2 pagesGenerator MaintenanceArun GouthamNo ratings yet

- Assignment #3: To: Ma'Am Saima AliDocument9 pagesAssignment #3: To: Ma'Am Saima AliEsmatullah BegzadNo ratings yet

- Installation, Commissioning and Maintenance of Industrial ValvesDocument2 pagesInstallation, Commissioning and Maintenance of Industrial ValvesEmrah BinayNo ratings yet

- PR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkDocument6 pagesPR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkJuan Nacimba NacimbaNo ratings yet

- Mounting Procedure For The Power Transformer.Document3 pagesMounting Procedure For The Power Transformer.Inshrah ZahidNo ratings yet

- LKS Dust Opacity Analyzer D10 2Document19 pagesLKS Dust Opacity Analyzer D10 2KC WangNo ratings yet

- HVPE Operation and MaintenanceDocument116 pagesHVPE Operation and MaintenanceMinerva AbantoNo ratings yet

- Distribution Transformer Instruction ManualDocument14 pagesDistribution Transformer Instruction Manualzafarbajwa11No ratings yet

- 5.1.2 Two-Stage High Pressure Industrial Air CompresorsDocument124 pages5.1.2 Two-Stage High Pressure Industrial Air CompresorsPablo Andres Espin MartinNo ratings yet

- Imee 5Document8 pagesImee 5HirakNo ratings yet

- 3rd Topic ESP Q & ADocument20 pages3rd Topic ESP Q & APrafulla NandaleNo ratings yet

- Testing and Maintenacne of High Voltage Bushings PsmmCHAP-06Document24 pagesTesting and Maintenacne of High Voltage Bushings PsmmCHAP-06protectionwork100% (1)

- Maintenance Procedure For Switchyard Equipment Volume-II (EHV CBS, CTs Etc) PDFDocument39 pagesMaintenance Procedure For Switchyard Equipment Volume-II (EHV CBS, CTs Etc) PDFRAJESH PARIKSYANo ratings yet

- Solid Gas Separation1Document48 pagesSolid Gas Separation1krizel100% (1)

- Meggering Insulation Resistance Testing of Dry-Type Power TransformerDocument3 pagesMeggering Insulation Resistance Testing of Dry-Type Power TransformerSugeng SumarnoNo ratings yet

- IOM - Farr Gold Series GSP 4 UK EnglishDocument32 pagesIOM - Farr Gold Series GSP 4 UK EnglishJulio CNo ratings yet

- LKS Dust & Opacity Analyzer D10Document18 pagesLKS Dust & Opacity Analyzer D10KC WangNo ratings yet

- Half and Full CoatedDocument5 pagesHalf and Full Coatedwaluyo perwalianelektroNo ratings yet

- Installation, Operation and Maintenance Guide: For Indoor/Outdoor Dry-Type TransformersDocument36 pagesInstallation, Operation and Maintenance Guide: For Indoor/Outdoor Dry-Type TransformersClaudio Hernández PobleteNo ratings yet

- Drip Tube SpecDocument1 pageDrip Tube SpecashwinNo ratings yet

- Distribution Transformer Instruction ManualDocument10 pagesDistribution Transformer Instruction ManualmartinpellsNo ratings yet

- Low Voltage Dry-Type ManualDocument5 pagesLow Voltage Dry-Type ManualAjay AbrahamNo ratings yet

- Transformer DictionaryDocument9 pagesTransformer DictionaryChristian Rally Ramos GonzalezNo ratings yet

- IOM14055 DustCollectorIOM GSP1 Mini 1.0 enDocument19 pagesIOM14055 DustCollectorIOM GSP1 Mini 1.0 enEinar MuñizNo ratings yet

- HK OIM 7433659 Rev5.16Document20 pagesHK OIM 7433659 Rev5.16Ingeniería AplicacionesNo ratings yet

- 1414665118314-Ti Mi 0039 PDFDocument15 pages1414665118314-Ti Mi 0039 PDFmithun 46No ratings yet

- Safety Guide and Basic Factors For The Selection, Installation and Maintenance of Hose and Hose AssembliesDocument4 pagesSafety Guide and Basic Factors For The Selection, Installation and Maintenance of Hose and Hose Assembliesphankhoa83-1No ratings yet

- Maintenance of TransformerDocument8 pagesMaintenance of TransformeranilsinghteslaNo ratings yet

- PCT - Is It Time To Change That TransformerDocument3 pagesPCT - Is It Time To Change That TransformerpctinformationNo ratings yet

- Maintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESDocument2 pagesMaintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESVelmar diseño y construccionNo ratings yet

- Sanjay Kar Chowdhury Cbip 2006Document7 pagesSanjay Kar Chowdhury Cbip 2006Gunadevan ChandrasekaranNo ratings yet

- Direct Steam Injection HumidifierDocument41 pagesDirect Steam Injection Humidifierسامح الجاسم100% (1)

- GE Fanuc Automation Computer Numerical CDocument174 pagesGE Fanuc Automation Computer Numerical CFayyaz HeroNo ratings yet

- G3R I-O Datasheet J25I-E-01Document9 pagesG3R I-O Datasheet J25I-E-01Fayyaz HeroNo ratings yet

- Alarm 414 (Digital Servo System Is Abnormal) : PointsDocument12 pagesAlarm 414 (Digital Servo System Is Abnormal) : PointsFayyaz HeroNo ratings yet

- f0 Alm 945Document1 pagef0 Alm 945Fayyaz HeroNo ratings yet

- Straub Couplings Catalog 2017Document24 pagesStraub Couplings Catalog 2017kman548No ratings yet

- Wall Partition (Civil Works)Document1 pageWall Partition (Civil Works)alvin calusaNo ratings yet

- Ariston Spare Part CatalougeDocument19 pagesAriston Spare Part CatalougeNuboogh ErbilNo ratings yet

- 04.Mr - Swaminathan - Second Floor Parapet Wall Projection Ceiling Layout 2Document1 page04.Mr - Swaminathan - Second Floor Parapet Wall Projection Ceiling Layout 2kishore kumarNo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- Impact Response of Elasto-Plastic Granular Chains Containing An Intruder ParticleDocument9 pagesImpact Response of Elasto-Plastic Granular Chains Containing An Intruder ParticleCesar HernandezNo ratings yet

- Hong & Lee - Strut and Tie ModelDocument14 pagesHong & Lee - Strut and Tie ModelWilbert HernandezNo ratings yet

- Publication 3 10700 639Document3 pagesPublication 3 10700 639Yordanos SolomonNo ratings yet

- Flow, Slope &pipe Dia. Calculation Using Manning's FormulaDocument18 pagesFlow, Slope &pipe Dia. Calculation Using Manning's FormulaMohammad Risky NaNo ratings yet

- Tes 1Document2 pagesTes 1jarottsNo ratings yet

- 1 Pendahuluan Fracture Mechanics RWP Gasal 22-23Document15 pages1 Pendahuluan Fracture Mechanics RWP Gasal 22-23RaNo ratings yet

- 2100 2800 Series PDFDocument2 pages2100 2800 Series PDFhendrabudimanNo ratings yet

- Magnetrol-Level Switch PDFDocument16 pagesMagnetrol-Level Switch PDFnatalNo ratings yet

- ADAPT TN220 Waffle Slab DesignDocument6 pagesADAPT TN220 Waffle Slab DesignVinnieTranNo ratings yet

- IndxDocument50 pagesIndxsupriyo1970No ratings yet

- Transpo Eng'g Slides 1 PDFDocument79 pagesTranspo Eng'g Slides 1 PDFEloisa PonceNo ratings yet

- Elbow SupportDocument3 pagesElbow SupportНемања КараклајићNo ratings yet

- Bahay Na BatoDocument32 pagesBahay Na BatokristineNo ratings yet

- Nanofluids As A Coolant in Automobile Radiator: A Review: Chandan KumarDocument6 pagesNanofluids As A Coolant in Automobile Radiator: A Review: Chandan KumarArun KumarNo ratings yet

- 56 - Isijint 2015 231 PDFDocument13 pages56 - Isijint 2015 231 PDFRaphael Mariano de SouzaNo ratings yet

- C CodesStand Schneider Jan11Document3 pagesC CodesStand Schneider Jan11Magdy BakryNo ratings yet

- E155-14 Standard Reference Radiographs For Inspection of Aluminum and Magnesium Castings PDFDocument4 pagesE155-14 Standard Reference Radiographs For Inspection of Aluminum and Magnesium Castings PDFVuong Tran VanNo ratings yet

- 02 Arch - Stru CoordinationDocument70 pages02 Arch - Stru Coordinationarjun 11No ratings yet

- Sproperty Unit Test Standard G 100 P: Mechanical PropertiesDocument3 pagesSproperty Unit Test Standard G 100 P: Mechanical PropertiesAnonymous MAQrYFQDzVNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Document8790922772No ratings yet

- Concrete Technology NotesDocument5 pagesConcrete Technology NotesawasarevinayakNo ratings yet

- Load and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationDocument5 pagesLoad and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationBRAYAN GERARDO AREVALO MENDOZANo ratings yet

- Bolts: Cap ScrewsDocument8 pagesBolts: Cap Screwsjairo F. Arroyo MNo ratings yet