Professional Documents

Culture Documents

DEV 22452 Delphi Interiors

DEV 22452 Delphi Interiors

Uploaded by

Bspatz1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DEV 22452 Delphi Interiors

DEV 22452 Delphi Interiors

Uploaded by

Bspatz1Copyright:

Available Formats

SD 3-26-99

DEV 22452 samples for EAR 15728 completed 3-26-99

Delphi Interiors. Steering column compressive energy absorber.

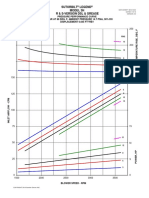

Compression / Recovery test

Customer specifications: (SS mesh cylinder)

dimensions: OD = 4.0 in, ID = 1.5 in, Height = 4.0 in

performance: 50% reduction in height before spike in stiffness occurs. From supplied graph,

the "spike" appears to be when the force reaches 1,000 to 1,500 lb.

function: compressive energy absorption in an automotive steering column.

compression force (lb) force (lb) compression force (lb) force (lb)

(in) compression recovery (in) compression recovery

0.1 15 0 1.4 415 0

0.2 35 0 1.5 450 0

0.3 55 0 1.6 490 0

0.4 80 0 1.7 525 0

0.5 105 0 1.8 560 10

0.6 130 0 1.9 600 20

0.7 160 0 2.0 630 35

0.8 185 0 2.1 675 50

0.9 215 0 2.2 720 75

1.0 250 0 2.3 770 110

1.1 290 0 2.4 830 160

1.2 340 0 2.5 905 280

1.3 375 0 2.6 1000 1,000

NOTES:

1) EAR 15728 samples are very preliminary parts, intended to allow the customer to perform

their own testing in order to get an idea of the general characteristics of knitted wire mesh.

Factors such as housing dimensions and compression speed will affect performance.

The non-linear compression / recovery characteristics of wire mesh is expected to be suitable for

their application.

2) Compression tests performed using a test fixture (similar to a hollow round die) with a 4.0 in ID

barrel and a 1.5 in OD pin. Crosshead speed = 1.0 in/min.

3) Samples for EAR 15728 were made using 4 pieces of crimped mesh (crimped length =13.75 in each)

from 56-0510-0990 / Honda 25176001. This mesh is 4.5 in wide after crimping.

The mesh pieces were wound on a 1.5 in diameter mandrel (end to end as if they were 1

continuous piece of mesh), and the outside 3 layers (wraps) of mesh were welded in 2 places.

These samples were not pressed, only wound and welded.

(Samples were fabricated from production mesh, which Metex had in stock.)

4) EAR 15728 samples (quantity = 2): OD: snug fit into a 4.0 in ID housing.

DEV 22452

ID: snug fit onto a 1.5 in OD pin.

HT = 4.5 in Wgt = 11.782, 12.160 oz

5) To meet the customer HT specification mesh width must be reduced to approximately 4.5

inches, in order to achieve a 4.0 in width after crimping. (use crimper from 56-0510-0990)

6) To reduce cost while still providing more than adequate corrosion resistance, the wire may

be changed from 316A to 304A. The effect on compression / recovery must be determined.

7) Future samples should be made with 1 continuous piece of mesh.

8) Contact: Rale Wolf, Delphi Interiors, 250 Northwood Blvd, Vandalia, OH 45377-5057

mail code110. 937-356-2248, fax 937-356-2303

You might also like

- 4 Stroke Shift Kit Installation InstructionsDocument15 pages4 Stroke Shift Kit Installation InstructionsJ. RussellNo ratings yet

- Unique Drum Assembly - Sheet 1 of 2: B - 22 SD-100D TFDocument2 pagesUnique Drum Assembly - Sheet 1 of 2: B - 22 SD-100D TFRICHARD BURBANONo ratings yet

- Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument2 pagesWorldwide Fastener Standard: Printed Copies Are UncontrolledRasatja Yongskulrote100% (1)

- Lapp Cable Size ListDocument1 pageLapp Cable Size ListVISHAL MODINo ratings yet

- Fact Sheet - Diesel Motor Mechanic - Mobile PlantDocument5 pagesFact Sheet - Diesel Motor Mechanic - Mobile PlantVikranth Reddy100% (3)

- AS7510 Joint System - DS100-62 - LRDocument2 pagesAS7510 Joint System - DS100-62 - LRScaricatore92No ratings yet

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document26 pagesAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98No ratings yet

- Power Cable Intern ReportDocument34 pagesPower Cable Intern ReportParteek KansalNo ratings yet

- SUPREME-flexible Cable PDFDocument12 pagesSUPREME-flexible Cable PDFRobert BudiwijayaNo ratings yet

- BS-5467 1Document2 pagesBS-5467 1Yazhar MuhammedNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- Cable THW 90 CeperDocument2 pagesCable THW 90 CeperManuel PelaesNo ratings yet

- Aerial Bundle Conductor Abc CableDocument1 pageAerial Bundle Conductor Abc CableBrianNo ratings yet

- Anchor BoltDocument18 pagesAnchor BoltDa WongNo ratings yet

- Interlocked Armor Power Cable, 5000 VOLTSDocument1 pageInterlocked Armor Power Cable, 5000 VOLTSpedro perezNo ratings yet

- Single Core Cables - 600/1000 V: Dimensions & WeightsDocument5 pagesSingle Core Cables - 600/1000 V: Dimensions & WeightsMohan KNo ratings yet

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- June 19, 2012Document9 pagesJune 19, 2012ahmed.abdelmegeed78No ratings yet

- CableDocument2 pagesCablejay shahNo ratings yet

- Data Sheet: Equipment Wire Equipment Wire Equipment Wire Equipment WireDocument3 pagesData Sheet: Equipment Wire Equipment Wire Equipment Wire Equipment Wireamro emadNo ratings yet

- FITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDocument9 pagesFITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDênis DáyolNo ratings yet

- Section 2 - Thread - BasicsDocument27 pagesSection 2 - Thread - BasicsChris MedeirosNo ratings yet

- Check Valve Keystone F85Document4 pagesCheck Valve Keystone F85Robi KeiNo ratings yet

- Valvula de Retencao PortinholaDocument1 pageValvula de Retencao PortinholaDeivid MiquelinoNo ratings yet

- Tutorial 1Document12 pagesTutorial 1MAHLATSE MULALANo ratings yet

- Cti PDFDocument5 pagesCti PDFFarhan ShahNo ratings yet

- DS Ipex Pipe SCH40 & SCH80Document3 pagesDS Ipex Pipe SCH40 & SCH80KPHMXNo ratings yet

- 480-LSOH Installation WiresDocument2 pages480-LSOH Installation WiresJoseph PoplingerNo ratings yet

- Wire Size SpecificationsDocument2 pagesWire Size Specificationsjaveeed0401No ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- FT Sifer 950iDocument2 pagesFT Sifer 950iAshik M RasheedNo ratings yet

- Solar Cable 2023Document5 pagesSolar Cable 2023H. NurzeinNo ratings yet

- Anchor Bolt: Steel Structures in IndustryDocument15 pagesAnchor Bolt: Steel Structures in Industryvenugopal BedadakotaNo ratings yet

- Size of CB Protecting of MotorDocument4 pagesSize of CB Protecting of MotorjigarNo ratings yet

- Stainless Steel Flexible Hose AssembliesDocument10 pagesStainless Steel Flexible Hose AssembliesDkdkkdNo ratings yet

- Centricast CL 2030 Data SheetDocument6 pagesCentricast CL 2030 Data SheetOlmer Romero MendezNo ratings yet

- 2006 National Standard Plumbing Code ILLUSTRATED 255 PDFDocument1 page2006 National Standard Plumbing Code ILLUSTRATED 255 PDFAhmed Mohamed GadoNo ratings yet

- Draka PVCDocument4 pagesDraka PVCapi-3803155No ratings yet

- HT Xlpe PDFDocument3 pagesHT Xlpe PDFrengaramanujanNo ratings yet

- Data-Sheet Slip JointDocument4 pagesData-Sheet Slip Jointamit02mechNo ratings yet

- 33Kv Cables MV Cable SpecificationDocument3 pages33Kv Cables MV Cable SpecificationelsayedNo ratings yet

- 840 Series Hygienic Pump: Watson-Marlow PumpsDocument2 pages840 Series Hygienic Pump: Watson-Marlow PumpsCesar Armando Hernandez ViteNo ratings yet

- Appendix E PARTICLE SIZE-U.S. SIEVE SIZEDocument3 pagesAppendix E PARTICLE SIZE-U.S. SIEVE SIZEVeronica CorreaNo ratings yet

- Fittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898Document40 pagesFittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898nidhinNo ratings yet

- LT PVC Catalogue PDFDocument14 pagesLT PVC Catalogue PDFkapilNo ratings yet

- 11 - OSS - O-Rings - Low - ResDocument52 pages11 - OSS - O-Rings - Low - ResOsvaldo Cansigno PeláezNo ratings yet

- Model 7041-A Flange-Ansi Class 125/150Document2 pagesModel 7041-A Flange-Ansi Class 125/150Zaira LorenaNo ratings yet

- BS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsDocument3 pagesBS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsBhagoo HatheyNo ratings yet

- 085 PsigDocument1 page085 PsigpinkeshNo ratings yet

- Single Core (IS 694) Current RatingDocument1 pageSingle Core (IS 694) Current RatingGuru RajNo ratings yet

- Extrana Product CatalogDocument78 pagesExtrana Product CatalogBaswara SadewaNo ratings yet

- Multitrack SNW RangeDocument2 pagesMultitrack SNW RangeSergejjjNo ratings yet

- Appendix 5. Standard Screen Scales PDFDocument3 pagesAppendix 5. Standard Screen Scales PDFJorell PaguioNo ratings yet

- D-01 Model 7041 Flange Adapter-Ansi Class 125150Document4 pagesD-01 Model 7041 Flange Adapter-Ansi Class 125150Daniel SanNo ratings yet

- PVC Insulated Heavy Duty Cables: Wiring The WorldDocument23 pagesPVC Insulated Heavy Duty Cables: Wiring The WorldPritam SinghNo ratings yet

- Question 4Document2 pagesQuestion 4jalalNo ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- Flexible Joint TWFDocument5 pagesFlexible Joint TWFAhmad FauziNo ratings yet

- 1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveDocument4 pages1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveabrahamNo ratings yet

- HRL12500W Feb 2006 PDFDocument2 pagesHRL12500W Feb 2006 PDFenzoNo ratings yet

- Electrical Calculation Sheet - EcsDocument47 pagesElectrical Calculation Sheet - EcsPradeesh Vijayan (v.prathi)No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Service LetterDocument10 pagesService LettercocoisolisgmailcomNo ratings yet

- 车种 车型 发动机型式 Denso IridiumDocument1 page车种 车型 发动机型式 Denso IridiumMutasem RedaNo ratings yet

- 2016 Heavy Duty BrochureDocument52 pages2016 Heavy Duty BrochureedilfreddyzNo ratings yet

- The FIAT Case: A Therapeutical CrisisDocument27 pagesThe FIAT Case: A Therapeutical CrisisShan E Azeem100% (1)

- Asset: Tesla Is A Story Stock. Aswath Damodaran, A: DefinesDocument2 pagesAsset: Tesla Is A Story Stock. Aswath Damodaran, A: Definesronaldo mendozaNo ratings yet

- PIP048 DataSht FlangeRepairRing-2Document1 pagePIP048 DataSht FlangeRepairRing-2Juan VillarroelNo ratings yet

- Sutorbilt Legend Model 3H R & S-Version DSL & GreaseDocument1 pageSutorbilt Legend Model 3H R & S-Version DSL & GreaseJosue UrgilésNo ratings yet

- Sew Part List R97 - enDocument3 pagesSew Part List R97 - enkittiponglertsattakarnNo ratings yet

- Handbook of Driver Assistance Systems - Parking Assistance (2016)Document16 pagesHandbook of Driver Assistance Systems - Parking Assistance (2016)gpvnayakNo ratings yet

- Massey Ferguson 4260 TRACTORS ( - K37009) Service Parts Catalogue Manual (Part Number 819919)Document17 pagesMassey Ferguson 4260 TRACTORS ( - K37009) Service Parts Catalogue Manual (Part Number 819919)bvk2980022100% (1)

- Model: USF-36: Universal Single Width BlowerDocument2 pagesModel: USF-36: Universal Single Width BlowerJoseph DavidNo ratings yet

- How A Car WorksDocument2 pagesHow A Car WorksZeroNo ratings yet

- 2000 2.7 Engine WiringDocument8 pages2000 2.7 Engine WiringJorge EspinoNo ratings yet

- History of Automotive TechnologyDocument10 pagesHistory of Automotive TechnologyAieree Jim AguilarNo ratings yet

- Power+Graph+BFA+306+ +55PS+Plug+and+PlayDocument1 pagePower+Graph+BFA+306+ +55PS+Plug+and+PlayHady SundayanaNo ratings yet

- Engine Core Arr GPDocument3 pagesEngine Core Arr GPERIC ERICNo ratings yet

- When That Engine Needs Service... : DiacomDocument7 pagesWhen That Engine Needs Service... : DiacomTânia RodriguesNo ratings yet

- Utilization of Electric PowerDocument8 pagesUtilization of Electric Powerits RoddurNo ratings yet

- TPR Piston Rings Catalogue For Japanese Vehicles Vol17 TP Vol17 3Document168 pagesTPR Piston Rings Catalogue For Japanese Vehicles Vol17 TP Vol17 3Hassan BelahcenNo ratings yet

- GMK6250 E-Gas Compact Pin ArrangementDocument1 pageGMK6250 E-Gas Compact Pin ArrangementВиталий РогожинскийNo ratings yet

- Lista 2Document9 pagesLista 2Amaris MedinaNo ratings yet

- 2 Format For Project Phase - Ii - Second ReviewDocument17 pages2 Format For Project Phase - Ii - Second ReviewNostalgic MediatorNo ratings yet

- Reto 8 - ForcesDocument2 pagesReto 8 - ForcesJuliana cabrera corellaNo ratings yet

- PC Hio 390 A1a PDFDocument66 pagesPC Hio 390 A1a PDFwendyrunawaywmeNo ratings yet

- Manual SAPDocument356 pagesManual SAPErick Domínguez100% (1)

- Ss163505e - JB 14k-Scissor-Lift WEB - 0Document2 pagesSs163505e - JB 14k-Scissor-Lift WEB - 0Kleiver CarpioNo ratings yet

- Auto Electrician Vacancy 2024Document1 pageAuto Electrician Vacancy 2024tamupfavayiNo ratings yet