Professional Documents

Culture Documents

PMI375-T500 Datasheet

PMI375-T500 Datasheet

Uploaded by

rafaleo84Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PMI375-T500 Datasheet

PMI375-T500 Datasheet

Uploaded by

rafaleo84Copyright:

Available Formats

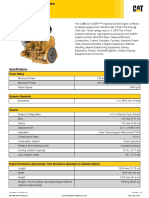

Data Sheet

EM-PMI375-T500

Electric machine, permanent magnet internal

FEATURES

• Synchronous Reluctance assisted Permanent

Magnet (SRPM) technology

• Extremely compact and robust aluminum frame

structure

• Highest efficiency throughout the operation range

on the market (~96 %)

• Liquid cooled with water-glycol mixture

• Low coolant flow required

• Allowed coolant temperature up to +65°C

• IP65 enclosure class to maximize reliability, IP67

available as option

• Multiple mounting possibilities

GENERAL

GENERATOR SPECIFIC FEATURES

The machine is developed especially for demanding

• Standard SAE flange mounting to match the diesel

applications. It is smaller, lighter and more efficient than

engine connection

conventional products on the market.

• Wide selection of speed ratings allowing the

generator to be selected to customer specific

TYPICAL APPLICATIONS

applications with various voltage requirements

• Can also be used as starter motor for the ICE • Generator for diesel-electric/serial hybrid

applications

MOTOR SPECIFIC FEATURES • Traction/propulsion motor

• Generator/Motor for parallel hybrid applications

• Extended speed and torque capabilities compared

to standard PM motors from Danfoss reluctance

assisted permanent magnet motor technology

• Motor structure is designed to be able to produce

high starting torque: EM-PMI motor can produce

instantly full torque to a non-rotating shaft

• Optimized speed range to meet the most common

gear ratios used in heavy mobile machinery

1 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

SPECIFICATIONS

General electrical properties

Nominal voltage (line to line) 500 VAC

Voltage stress IEC 60034-25, Curve A: Without filters for motors up to 500 VAC

Nominal efficiency 96 %

Pole pair number 6

Power supply Inverter fed.

Nominal inverter switching frequency 8 kHz

Minimal inverter switching frequency 4 kHz (with limited speed 1.4 times nominal speed)

Basic information

Machine type Synchronous reluctance assisted permanent magnet

Frame material Aluminum

Mounting direction Can be used in all directions, see user guide for details. Greased for life

bearings required.

Mounting (IEC 60034-7) IM 3009-B5 (flange horizontal),

IM 3019-V1 (flange and D-end down)

Standard flange D-end (SAE J617) SAE 3 transmission housing

Standard axle spline D-end DIN5480 W50x2x24x8f

Standard flange N-end (SAE J617) SAE 4 flywheel housing

Standard rotation direction Clockwise (both directions possible)

Bearing type Standard:

6211-2RS1/C3WT

+BHS option:

6211/C3 (with LGHP2 grease)

+BIN option:

D-end: 6211-2RS1/C3WT

N-end: 6211-2RS1/HC5C3WT

+BIA option:

6211-2RS1/HC5C3WT

+BHS+BIN options:

D-end: 6211/C3 (with LGHP2 grease)

N-end: 6211/HC5C3WT (with LGHP2 grease)

+BHS+BIA options:

6211/HC5C3 (with LGHP2 grease)

Protection class IP65

IP67 available as option +IP67

Duty type (IEC 60034-1) S1/S9

Machine coating Dark grey RAL7024

Mechanical

Total weight 172 kg (no options)

Moment of inertia 0.46 kgm²

Torsional stiffness of shaft drive end 4*10^5 Nm/rad (from middle of the D-end spline to rotor air gap)

Rotating mass 52.5 kg

Maximum static torque range on the shaft, max.

3400 Nm

25000 cycles, R=0 (*

2 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

Maximum dynamic torque range on the shaft,

2500 Nm

max. 1e6 cycles, R=0 (*

Maximum allowed vibratory torque range,

0.3 x nominal torque of machine

1e9...1e10 cycles (*

Maximum deceleration (fault stop) 6000 rad/s2

Dimensions

Length (frame) 368 mm

Diameter (frame) 450 mm

Cooling

Plain water with appropriate corrosive inhibitor (max. 50 % corrosive

Cooling liquid

inhibitor)

Cooling liquid corrosive inhibitor type Ethylene glycol (Glysantin G48 recommended)

Cooling method (IEC 60034-6) IC 71 W

Minimum cooling liquid flow 20 l/min

Coolant circuit capacity 1.4 l

Maximum operating pressure 3 bar

Pressure loss 0.4 bar with 20 l/min (+25°C coolant)

Nominal cooling liquid temperature +65°C (derating required if exceeded), +40°C with +CL option

Minimum cooling liquid temperature -20°C

Maximum cooling liquid temperature +70°C

Temperature rating

Insulation class (IEC 60034-1) H (+180°C)

Temperature rise (IEC 60034-1) +85°C (F) / +110°C (H)

Maximum winding temperature +175°C

Nominal ambient temperature +65°C / +40°C with +CL option

Min. ambient temperature -40°C

Nominal altitude (IEC 60034-1) 1000 m

Vibration & Shock tolerance

5.9 GRMS

ISO 16750-3

Test VII – Commercial vehicle, sprung masses – Table 12

Mechanical vibration Notes:

Test duration 8h axis (two axes tested; radial and axial)

Total spectral acceleration 5.91 GRMS

Test done with EM-PMI375-T800 (with flange mounting)

50 G

ISO 16750-3

4.2.2 Test for devices on rigid points on the body and on the frame

Notes:

Mechanical shock

⎯acceleration: 500 m/s2;

⎯duration: 6 ms;

⎯number of shocks: 10 per test direction

Test done with EM-PMI375-T800 (with flange mounting)

3 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

Connections

Coolant connection 2 x G3/4 bore (see dimension drawing for details)

Cable direction Standard cable direction towards D-end

3 x 70 mm2 max. (SINGLE winding model)

HV cables

2 x 3 x 70 mm2 max. (DUAL winding model)

HV cable glands Pflitsch blueglobe TRI bg 225ms tri

HUBER+SUHNER Radox Elastomer S, screened, single core, automotive

HV cable recommended type cable (FHLR4GC13X)

www.hubersuhner.com

HV cable lug size 35-8, 50-8, 70-8

35 mm2: Druseidt with narrow flange 03901

50 mm2: Druseidt with narrow flange 03903

Recommended cable lug

70 mm2: Druseidt with narrow flange 03906

www.druseidt.de

1 x 3 phase box (SINGLE winding model)

HV connection boxes

2 x 3 phase box (DUAL winding model)

47 pin DEUTSCH HD34-24-47PE for resolver and temperature

LV connector measurement

https://www.te.com

LV connector type DEUTSCH HD34-24-47PE

LV connector pin type Gold plated

LV mating connector type DEUTSCH HD36-24-47SE or DEUTSCH HD36-24-47SE-059 (**

DEUTSCH 0462-201-1631

DEUTSCH 0462-005-2031

LV mating connector pin type

Plug: DEUTSCH 0413-204-2005 (size 20)

Plug: DEUTSCH 0413-003-1605 (size 16)

LV connector pin configuration See Table 1

Connection box with 2 x M25 cable glands (reserve 2 x plugged M16

LV connections (+LVB1 option)

threads available) and terminal block for LV connections. See Table 2

Anti-condensation heater (+HEAT1 option) 65 W 230 VAC single phase heater resistor

Hummel art no. 7651 0 51 01 D (combination of housing 7651 0 00 00 0,

Heater connector (+HEAT1 option) insert 7084 9 51 10 1, crimp pins 7010 9 42 01 1)

https://www.hummel.com

Hummel art no. 7550 6 51 02 D (combination of housing 7550 6 00 00 0,

Heater mating connector

insert 7084951102 and crimp socket 7010 9 42 00 2)

Heater connector pin type Hummel 7010 9 42 01 1

Heater connector pin configuration See Table 3

Bearing temp. measurement connector type 4-pin M12 A coded male

Bearing temp. measurement mating type 4-pin M12 A coded female

Bearing temp. measurement connector pin

SeeTable 4

configuration

(* The values are based on structural analysis and they are not applicable to any marine class rules or requirements.

(** Connector IP-rating of IP67 is reached only when connector mating part is installed and all unused pin holes are plugged in

the connector mating part with the following plugs, depending on the hole size: DEUTSCH 0413-003-1605 (size 16) or DEUTSCH

0413-204-2005 (size 20). For further information, contact the connector manufacturer TE connectivity directly.

4 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

PIN Description

47 Temperature 1, PT100 (P), windings

46 Temperature 1, PT100 (N), windings

33 Temperature 2, PT100 (P), windings

32 Temperature 2, PT100 (N), windings

45 Temperature 3, PT100 (P), windings

31 Temperature 3, PT100 (N), windings

30 Temperature 4, PT100 (P), windings (+TEMP4 option)

29 Temperature 4, PT100 (N), windings (+TEMP4 option)

44 Temperature 5, PT100 (P), windings (+TEMP4 option)

43 Temperature 5, PT100 (N), windings (+TEMP4 option)

28 Temperature 6, PT100 (P), windings (+TEMP4 option)

16 Temperature 6, PT100 (N), windings (+TEMP4 option)

42 Temperature 7, PT100 (P), windings (+TEMP5 option)

27 Temperature 7, PT100 (N), windings (+TEMP5 option)

15 Temperature 8, PT100, (P) windings (+TEMP5 option)

14 Temperature 8, PT100 (N), windings (+TEMP5 option)

40 Temperature 9, PT100 (P), windings (+TEMP5 option)

26 Temperature 9, PT100 (N), windings (+TEMP5 option)

41 Temperature 10, PT100 (P), windings (+TEMP5 option)

13 Temperature 10, PT100 (N), windings (+TEMP5 option)

39 Temperature 11, PT100 (P), windings (+TEMP5 option)

38 Temperature 11, PT100 (N), windings (+TEMP5 option)

25 Temperature 12, PT100 (P), windings (+TEMP5 option)

12 Temperature 12, PT100 (N), windings (+TEMP5 option)

35 Resolver, RES_COS_N, in-built non-contacting

20 Resolver, RES_COS_P, in-built non-contacting

36 Resolver, RES_SIN_N, in-built non-contacting

21 Resolver, RES_SIN_P, in-built non-contacting

22 Resolver, EXCN, in-built non-contacting

10 Resolver, EXCP, in-built non-contacting

34 Resolver, SHIELD/GROUND, in-built non-contacting

37 Resolver, RES_COS_N, in-built non-contacting (additional resolver with +RES2 option)

24 Resolver, RES_COS_P, in-built non-contacting (additional resolver with +RES2 option)

23 Resolver, RES_SIN_N, in-built non-contacting (additional resolver with +RES2 option)

11 Resolver, RES_SIN_P, in-built non-contacting (additional resolver with +RES2 option)

9 Resolver, EXCN, in-built non-contacting (additional resolver with +RES2 option)

8 Resolver, EXCP, in-built non-contacting (additional resolver with +RES2 option)

4 Resolver, SHIELD/GROUND, in-built non-contacting (additional resolver with +RES2 option)

Table 1 Pin configuration of LV-connector

5 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

PIN Description

1 Temperature 1, PT100 (P), windings

2 Temperature 1, PT100 (N), windings

3 Temperature 2, PT100 (P), windings

4 Temperature 2, PT100 (N), windings

5 Temperature 3, PT100 (P), windings

6 Temperature 3, PT100 (N), windings

7 Temperature 4, PT100 (P), windings (+TEMP4 option)

8 Temperature 4, PT100 (N), windings (+TEMP4 option)

9 Temperature 5, PT100 (P), windings (+TEMP4 option)

10 Temperature 5, PT100 (N), windings (+TEMP4 option)

11 Temperature 6, PT100 (P), windings (+TEMP4 option)

12 Temperature 6, PT100 (N), windings (+TEMP4 option)

16 Heater, phase, 230 VAC

17 Heater, neutral

Heater, ground / protective earth, M4 screw inside connection box

General shielding, ground / protective earth, M4 screw inside connection box

18 Resolver, RES_COS_N, in-built non-contacting

19 Resolver, RES_COS_P, in-built non-contacting

20 Resolver, RES_SIN_N, in-built non-contacting

21 Resolver, RES_SIN_P, in-built non-contacting

22 Resolver, EXCN, in-built non-contacting

23 Resolver, EXCP, in-built non-contacting

24 Temperature, PT100 (P), bearings N-end (+BTMP1 option)

25 Temperature, PT100 (N), bearings N-end (+BTMP1 option)

NA D-end bearing temperature sensor with separate connector (+BTMP1 option), see table below

Table 2 Pin configuration of LV connections (+LVB1 option)

PIN Description

1 Phase, 230 VAC

2 Neutral

Ground / protective earth

4 Reserve

5 Reserve

Table 3 Pin configuration of heater with connector

PIN Description

1

PT100

2

3

PT100_GND

4

Table 4 Pin configuration of bearing temperature sensor connector (one sensor)

6 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

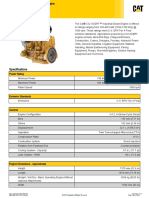

PRESSURE LOSS VS COOLANT FLOW

1

Pressure loss [bar]

0,8

0,6

0,4

0,2

0

0 5 10 15 20 25 30 35

Volume flow [l/min]

Picture 1 Pressure loss vs coolant flow

MOTORS (temperature class F, maximum winding temperature +150°C, with +CL option)

Coolant temperature +65°C Coolant temperature +40°C Coolant temperature +40 / +65°C

Cont. Cont. Nom. Cont. Cont. Nom. Nom. Max. Peak

Type Peak

Torque Power Torque Power speed torque

Current Current speed torque

[rpm] DUAL

[Nm] [kW] [A] [Nm] [kW] [A] [rpm] SINGLE (*

(*** (**

EM-PMI375-T500-1100 526 61 77 573 66 86 1100 2200 1490 -

EM-PMI375-T500-1300 520 71 95 575 78 110 1300 2600 1480 -

EM-PMI375-T500-1600 515 86 111 575 96 127 1600 3200 1450 -

EM-PMI375-T500-1800 511 96 121 560 106 132 1800 3600 1400 -

EM-PMI375-T500-2000 502 105 136 550 115 149 2000 4000 1200 -

EM-PMI375-T500-2300 497 120 156 543 125 168 2300 4000 1170 1450

EM-PMI375-T500-2700 472 133 170 530 150 192 2700 4000 895 1194

EM-PMI375-T500-3200 442 148 192 484 162 208 3200 4000 736 1038

(* Peak torque achieved with one 350A inverter

(** Peak torque achieved with two 350A inverters

(*** Mechanical maximum speed

GENERATORS (temperature class F, maximum winding temperature +150°C, with +CL option)

Coolant temperature

Coolant temperature +65°C Coolant temperature +40°C

+40 / +65°C

Volt/

Type Apparent Cont. Nom. Apparent Cont. Nom. Nom. speed

Nom.

power power Power power Power Power ratio

Current Current speed Freq.

factor factor

[kVA] [kW] [A] [kVA] [kW] [A] [rpm] [Hz] [VAC

/rpm] (*

EM-PMI375-T500-1100 67 57 77 0.95 76 72 86 0.95 1200 120 0.470

EM-PMI375-T500-1300 82 77 94 0.90 95 83 109 0.87 1400 140 0.403

EM-PMI375-T500-1600 96 88 110 0.94 110 100 126 0.91 1700 170 0.336

EM-PMI375-T500-1800 104 97 120 0.97 113 110 131 0.97 1900 190 0.302

EM-PMI375-T500-2000 116 105 135 0.93 129 120 148 0.93 2100 210 0.280

EM-PMI375-T500-2300 133 120 153 0.93 144 131 165 0.91 2400 240 0.245

EM-PMI375-T500-2700 145 145 169 0.94 164 155 191 0.94 2800 280 0.210

EM-PMI375-T500-3200 164 148 190 0.94 177 166 205 0.94 3300 330 0.175

(* Back EMF for cold (+20°C) generator

7 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

MOTORS (temperature class F, maximum winding temperature +150°C, with nominal voltage 400 VAC)

Coolant temperature +40 °C

Type Cont. Torque Cont. Power Nom. Current Nom. Speed Max. Speed Peak Torque

[Nm] [kW] [A] [rpm] [rpm] (* [Nm]

EM-PMI375-T500-1100 634 53 88 800 2200 1490

EM-PMI375-T500-1300 625 65 108 1000 2600 1480

EM-PMI375-T500-1600 590 74 127 1200 3200 1450

EM-PMI375-T500-1800 592 81 136 1300 3600 1400

EM-PMI375-T500-2000 586 92 156 1500 4000 1200

EM-PMI375-T500-2300 590 105 181 1700 4000 1170

EM-PMI375-T500-2700 555 116 196 2000 4000 895

EM-PMI375-T500-3200 541 136 228 2400 4000 736

(* Mechanical maximum speed

MOTORS (temperature class H, maximum winding temperature +175°C)

Coolant temperature +65°C Coolant temperature +40°C Coolant temperature +40 / +65°C

Cont. Cont. Nom. Cont. Cont. Nom. Nom. Peak

Type Max. Peak

Torque Power Torque Power torque

Current Current speed speed torque

DUAL

[Nm] [kW] [A] [Nm] [kW] [A] [rpm] [rpm] (*** SINGLE (*

(**

EM-PMI375-T500-1100 572 66 86 617 71 94 1100 2200 1490 -

EM-PMI375-T500-1300 560 76 103 607 83 114 1300 2600 1480 -

EM-PMI375-T500-1600 558 93 122 615 103 136 1600 3200 1450 -

EM-PMI375-T500-1800 552 104 131 616 116 146 1800 3600 1400 -

EM-PMI375-T500-2000 550 115 150 596 125 164 2000 4000 1200 -

EM-PMI375-T500-2300 538 130 169 578 139 184 2300 4000 1170 1450

EM-PMI375-T500-2700 524 148 190 585 165 215 2700 4000 895 1194

EM-PMI375-T500-3200 473 158 207 539 181 233 3200 4000 736 1038

(* Peak torque achieved with one 350A inverter

(** Peak torque achieved with two 350A inverters

(*** Mechanical maximum speed

The maximum allowed peak torque duration at stator winding starting temperature +90°C is 1.5 minutes. The given values

indicate typical duration and are not verified. In case more accurate values are required, cyclic dimensions are needed.

GENERATORS (temperature class H, maximum winding temperature +175°C)

Coolant temperature

Coolant temperature +65°C Coolant temperature +40°C

+40 / +65°C

Volt/

Type Apparent Cont. Nom. Apparent Cont. Nom. Nom. speed

Nom.

power power Power power Power Power ratio

Current Current speed Freq.

factor factor

[kVA] [kW] [A] [kVA] [kW] [A] [rpm] [Hz] [VAC /rpm]

(*

EM-PMI375-T500-1100 76 72 85 0.93 84 78 94 0.94 1200 120 0.470

EM-PMI375-T500-1300 90 83 102 0.93 100 90 113 0.89 1500 150 0.403

EM-PMI375-T500-1600 107 102 121 0.95 117 112 133 0.95 1800 180 0.336

EM-PMI375-T500-1800 113 110 130 0.97 126 124 145 0.98 2000 200 0.302

EM-PMI375-T500-2000 129 123 148 0.95 141 131 163 0.93 2100 210 0.280

EM-PMI375-T500-2300 144 134 166 0.93 158 146 181 0.93 2400 240 0.245

EM-PMI375-T500-2700 163 153 189 0.94 186 173 213 0.93 2800 280 0.210

EM-PMI375-T500-3200 177 166 204 0.94 199 185 230 0.93 3300 330 0.175

(* Back EMF for cold (+20°C) generator

8 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

PRODUCT CODE AND OPTIONS

Use product code including all needed options for ordering. Standard options are not given with the code as they are selected by

default if a non-standard option is not selected. Standard options are indicated by a star (*).

Product name Description

EM-PMI375-T500-1100 Standard 1100 rpm unit with standard options

EM-PMI375-T500-1100+BIN+RES1 Standard unit otherwise but with insulated bearing in N-end and resolver

Table 5 Product code examples

Variant Code Description Additional information

High voltage connections One connection box containing one 3 phase system

* One 3 phase system

with one M25 cable gland per phase

Two galvanically isolated 3 Two connection boxes each containing one 3 phase

-DUAL

phase systems system with one M25 cable gland per phase

Low voltage connections Low voltage connections done DEUTSCH HD34-24-47PE connector for LV

*

with connector connections

Low voltage connections done Connection box with 2x M25 cable glands (reserve

+LVB1 with connection box and 2x plugged M16 threads available) and terminal

terminal strip block for LV connections

N-end attachment * Flange SAE 4 flywheel housing

+NE2 Male shaft + Flange DIN5480 W50x2x24x8f + SAE 4 flywheel housing

Bearing lubrication and Deep groove ball bearing, contact seal on both

mounting direction * Greased for life sides, any mounting direction (see user guide for

details)

Deep groove ball bearing, open design, horizontal

+BHS Grease lubricated

mounting direction (see user guide for details)

Bearing insulation * Non-insulated bearings Non-insulated bearings

+BIN Insulated bearing in N-end Insulated bearing in N-end

+BIA Insulated bearing in both ends Insulated bearing in both ends

Shaft grounding * None

+SG1 D-end shaft grounding In-built grounding ring

Protection class * Standard protection class IP65 protection class

IP67 protection class, not available with +BHS

+IP67 IP67 protection class

option

Cable direction * Cable direction fixed Cable direction towards D-end

+CNE Cable direction towards N-end Cable direction towards N-end

Rotation sensor * None No resolver

+RES1 Resolver In-built non contacting resolver, 6-pole pair

+RES2 Double resolver 2 x In-built non contacting resolver, 6-pole pair

Side mounting No side mounting holes available. In case side

* None mounting holes are present, they are plugged by

default.

12 x side mounting threaded holes M10x1.5.

+SM1 Side mounting Plugged by default with M10x10, DIN 913, (ISO

4026), SET SCREW

Winding temperature * Temperature surveillance 3 x PT100 (two wire) in windings

sensors (**

Redundant temperature 6 x PT100 (two wire) in windings

+TEMP4

surveillance

Redundant temperature 12 x PT100 (two wire) in windings (not available

+TEMP5

surveillance with +LVB1 option)

9 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

Data Sheet

EM-PMI375-T500

Bearing temperature sensors * None

+BTMP1 PT100 in bearings Plug-in connector

Anti-condensation heaters * None

+HEAT1 One anti-condensation heater 230 VAC / 65 W (see user guide for more information)

Marine classification * No marine classification

+CL1 ABS American Bureau of Shipping

+CL2 BV Bureau Veritas

+CL3 DNV

+CL4 LR Lloyd’s Register

+CL5 RINA

+CL6 CCS China Classification Society

(* Standard option

(** Winding temperature sensors are for stator winding. The selection of high voltage connections does not have an influence on the quantity of PT100

elements.

Table 6 Option list

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in

specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are

trademarks of Danfoss A/S. All rights reserved.

10 | © Danfoss | December 2023 AI269157472701en -000201

Classified as Business

You might also like

- D2866 PDFDocument4 pagesD2866 PDFMuhammad rizkiNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- CCU Basic Operations CourseDocument116 pagesCCU Basic Operations CourseRene GutierrezNo ratings yet

- AI269158260707en 000201Document7 pagesAI269158260707en 000201sebastian.vegaNo ratings yet

- EM-PME375-T200: Electric Machine, Permanent Magnet ExternalDocument5 pagesEM-PME375-T200: Electric Machine, Permanent Magnet ExternalÖzgür AkayNo ratings yet

- Em Pmi375 T800 PDFDocument6 pagesEm Pmi375 T800 PDFmaaathanNo ratings yet

- IAI DD - Motor - CJ0199-1A-UST-1-1013Document8 pagesIAI DD - Motor - CJ0199-1A-UST-1-1013ElectromateNo ratings yet

- IAI Direct Drive Motor SpecsheetDocument7 pagesIAI Direct Drive Motor SpecsheetElectromateNo ratings yet

- h25 Incremental Encoder2.3413Document2 pagesh25 Incremental Encoder2.3413PIDNo ratings yet

- HS25 Incremental EncoderDocument4 pagesHS25 Incremental Encoderoswaldo58No ratings yet

- Ie3 Pa Pe SeriesDocument16 pagesIe3 Pa Pe SeriesshakibNo ratings yet

- KP D28PDocument5 pagesKP D28PDerek ChenNo ratings yet

- KP D30SDocument5 pagesKP D30SDerek ChenNo ratings yet

- SS 9022056 18330406 000Document7 pagesSS 9022056 18330406 000Shahid Raza SayedNo ratings yet

- Hayward Tyler Canned Motor Pumps BrochureDocument20 pagesHayward Tyler Canned Motor Pumps Brochuretosh321No ratings yet

- SS-8588179-18397814-018 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18397814-006 PDFDocument6 pagesSS-8588179-18397814-018 SS Page 1 of 6: Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS-IND-18397814-006 PDFJulio César Ccapcha PumaNo ratings yet

- SS 7154026 18397814 001Document6 pagesSS 7154026 18397814 001Amr Abd ElrahmanNo ratings yet

- Man d2842 630 730 KvaDocument4 pagesMan d2842 630 730 KvaSatria TrianaNo ratings yet

- Man D2842 (630 - 730 Kva)Document4 pagesMan D2842 (630 - 730 Kva)eriscano169% (13)

- C400N5C - A042j404 Cummins Gta38Document5 pagesC400N5C - A042j404 Cummins Gta38Maximiliano SanchezNo ratings yet

- Diesel Generator Sets For The Ag Market: Specification SheetDocument4 pagesDiesel Generator Sets For The Ag Market: Specification SheetTheronNo ratings yet

- DC Motor Type DMRDocument44 pagesDC Motor Type DMRmass72No ratings yet

- G.E. 250 KW - WPG275-86Document3 pagesG.E. 250 KW - WPG275-86Ali Yamilé Camizan CuniasNo ratings yet

- Big Blue 600 ProDocument8 pagesBig Blue 600 ProGabrielPacovilcaArhuataNo ratings yet

- Stepping Motors 3 PhasesDocument12 pagesStepping Motors 3 PhasesTamas RaduNo ratings yet

- Cat CB59 eDocument2 pagesCat CB59 ecreativenggNo ratings yet

- C800D6Document4 pagesC800D6Gestión del Talento Humano GEMRANo ratings yet

- Cat Engine c32Document5 pagesCat Engine c32wuub wuugfgNo ratings yet

- Catalogo ServoDocument9 pagesCatalogo ServoOMAR DAVID BERNAL CUASPANo ratings yet

- Generator LogDocument4 pagesGenerator LogFELIXENGIPLASCOMNo ratings yet

- Offer For 4 Units Small Weight Boom Miner Type SM 100,: João Idelfonso BorgesDocument29 pagesOffer For 4 Units Small Weight Boom Miner Type SM 100,: João Idelfonso BorgesCarlos Andres Ramos MejiaNo ratings yet

- SS-8003897-1000006023-001 SS Page 1 of 6Document6 pagesSS-8003897-1000006023-001 SS Page 1 of 6Emanuel CondeNo ratings yet

- WEG 132kW SpecificationDocument8 pagesWEG 132kW Specificationbonginkosi mathunjwaNo ratings yet

- SS15 CPGKDocument4 pagesSS15 CPGKDenzo RyugaNo ratings yet

- Specifications:: 1. Traveling Block (YG-150)Document6 pagesSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisNo ratings yet

- Diesel Generator Set QSK23 Series Engine: 750 kVA - 820 kVA 50 HZ Data Center ContinuousDocument4 pagesDiesel Generator Set QSK23 Series Engine: 750 kVA - 820 kVA 50 HZ Data Center ContinuousTDH OfficialNo ratings yet

- SS12 CPGK DC50 PDFDocument4 pagesSS12 CPGK DC50 PDFTDH OfficialNo ratings yet

- CM20200320 39552 31fa9Document4 pagesCM20200320 39552 31fa9johnward19951995No ratings yet

- Catálogo Adh-Maqchin-Mhb500-3200Document10 pagesCatálogo Adh-Maqchin-Mhb500-3200Multi MaqNo ratings yet

- Nas 6124 en PDFDocument5 pagesNas 6124 en PDFFrankDeviePaculguenQueridoNo ratings yet

- KP-9P-1 (KM385BD) Generating Set Technical Data Sheet: Fuzhou GFF Keypower Equipment Co., LTDDocument5 pagesKP-9P-1 (KM385BD) Generating Set Technical Data Sheet: Fuzhou GFF Keypower Equipment Co., LTDKEYPOWER GENERATOR & LOAD BANKNo ratings yet

- السعدء2Document6 pagesالسعدء2mubarakNo ratings yet

- ACUTRONIC iMPULSE Series-Catalogue Web Rev.B 2022Document9 pagesACUTRONIC iMPULSE Series-Catalogue Web Rev.B 2022masnishinoNo ratings yet

- MTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670Document2 pagesMTU Series 2000 Mining Engines 12V2000Cx6 3235061 1505796670jamal molana100% (1)

- C32acert Ind18 1125Document5 pagesC32acert Ind18 1125Jennifer JonesNo ratings yet

- KP D50PDocument5 pagesKP D50PDerek ChenNo ratings yet

- KPX K12PDocument5 pagesKPX K12PDerek ChenNo ratings yet

- KPX K20PDocument5 pagesKPX K20Pczz6723No ratings yet

- Main Features: Power Generator FDF 365 SDocument4 pagesMain Features: Power Generator FDF 365 SThomas VeldinkNo ratings yet

- Lehe1126 01Document2 pagesLehe1126 01Matías MocilnikarNo ratings yet

- Lehe1126 01Document2 pagesLehe1126 01Matías MocilnikarNo ratings yet

- C1500D6Document4 pagesC1500D6Gestión del Talento Humano GEMRANo ratings yet

- Rental Power 2000 KW: Specification SheetDocument4 pagesRental Power 2000 KW: Specification SheetPauline LunaNo ratings yet

- KPX K25PDocument5 pagesKPX K25Pczz6723No ratings yet

- SS9 CPGKDocument4 pagesSS9 CPGKYahya SaifanNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Final Broucher 11-4 NewDocument3 pagesFinal Broucher 11-4 Newmilan07No ratings yet

- ATS Broussard User ManualDocument33 pagesATS Broussard User ManualMarv d'ar saoutNo ratings yet

- Sheik Md. Maadul Hoque (ID 150201010035)Document49 pagesSheik Md. Maadul Hoque (ID 150201010035)Mizanur RahmanNo ratings yet

- Conclusion and Future EnhancementDocument2 pagesConclusion and Future EnhancementHelloprojectNo ratings yet

- 5.1079 Compromise Agreement (Arwin) v1.1Document3 pages5.1079 Compromise Agreement (Arwin) v1.1Aldrin LeynesNo ratings yet

- Malinta PDFDocument8 pagesMalinta PDFAngelina CruzNo ratings yet

- trắc nghiệm và short answer IHRMDocument16 pagestrắc nghiệm và short answer IHRM2154010201haNo ratings yet

- Employees Compensation CalculationDocument40 pagesEmployees Compensation CalculationRahulDubeyNo ratings yet

- The 60 MM Diameter Solid Shaft Is Subjected To The... PDFDocument3 pagesThe 60 MM Diameter Solid Shaft Is Subjected To The... PDFxy2h5bjs27No ratings yet

- Institute of Cost and Management Accountants of Pakistan: Employment Application FormDocument2 pagesInstitute of Cost and Management Accountants of Pakistan: Employment Application FormRashidAliNo ratings yet

- Operating System (5th Semester) : Prepared by Sanjit Kumar Barik (Asst Prof, Cse) Module-IiiDocument41 pagesOperating System (5th Semester) : Prepared by Sanjit Kumar Barik (Asst Prof, Cse) Module-IiiJeevanantham KannanNo ratings yet

- Analysing Mouse and Pen Flick GesturesDocument6 pagesAnalysing Mouse and Pen Flick GesturesHarini RaoNo ratings yet

- Pdms List Error CaptureDocument4 pagesPdms List Error Capturehnguyen_698971No ratings yet

- Example of Research Paper About Science and TechnologyDocument6 pagesExample of Research Paper About Science and Technologygz8aqe8wNo ratings yet

- Braille Actuator Report MAJORDocument32 pagesBraille Actuator Report MAJORSwapnil BeheraNo ratings yet

- Music and Me Instructions 2021Document3 pagesMusic and Me Instructions 2021api-497020000No ratings yet

- Competency Based LearningDocument9 pagesCompetency Based Learningkarapetyanines08No ratings yet

- SPP ADC Flightplan UnderstandingDocument25 pagesSPP ADC Flightplan UnderstandingYesid BarraganNo ratings yet

- Nguyễn Triệu Anh: Education And Degree Work ExperiencesDocument1 pageNguyễn Triệu Anh: Education And Degree Work ExperiencesQuach Manh ThuongNo ratings yet

- Formulas To LearnDocument3 pagesFormulas To LearnHuệ LêNo ratings yet

- Full Name: Work Experience Career SynopsisDocument2 pagesFull Name: Work Experience Career SynopsisYelchuri Kumar PhanindraNo ratings yet

- Notice of Meeting-1st MDC Ldip Alignment Meeting & WsDocument5 pagesNotice of Meeting-1st MDC Ldip Alignment Meeting & WsByaheng CawayanNo ratings yet

- Installation Guide Andalay Solar ModulesDocument60 pagesInstallation Guide Andalay Solar ModulesdarkleonzNo ratings yet

- Essentials of Marketing Research 4th Edition Hair Test Bank DownloadDocument22 pagesEssentials of Marketing Research 4th Edition Hair Test Bank Downloademmanuelmabelnjt7nn100% (35)

- Criteria For Master Teacher: (With Additional Proposed Documents and The Specific Points As Support To Other Criteria)Document19 pagesCriteria For Master Teacher: (With Additional Proposed Documents and The Specific Points As Support To Other Criteria)Dennis ReyesNo ratings yet

- Wbcviii PDFDocument1,192 pagesWbcviii PDFDaniel PinheiroNo ratings yet

- How To Conduct An OR Study?Document2 pagesHow To Conduct An OR Study?Brylle James BigorniaNo ratings yet

- UHN - Careers at UHN - Job Application PDFDocument4 pagesUHN - Careers at UHN - Job Application PDFKARTHIKEYAN ARTISTNo ratings yet

- Shah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfDocument311 pagesShah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfTri4alNo ratings yet