Professional Documents

Culture Documents

Apr14 - Prevent Gasket Blowout - What's Most Important

Apr14 - Prevent Gasket Blowout - What's Most Important

Uploaded by

Karen ChaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apr14 - Prevent Gasket Blowout - What's Most Important

Apr14 - Prevent Gasket Blowout - What's Most Important

Uploaded by

Karen ChaiCopyright:

Available Formats

SPECIAL REPORT

Prevent Gasket Blowout—

What’s Most Important? SEALING SENSE

First of Two Parts

By FSA member Randy Wacker, P.E.

G asket blowout is the most catastrophic of gasket failures.

It usually occurs with no discernable warning and

causes a sudden and significant release of internal pressure,

which they are dependent. Equation 2 provides greater

detail to draw attention to these components.

usually accompanied with loud popping sound or whistle. Equation 2

Depending on the process being contained and/or the (FGten) + (FBtot) - (FGrelax) ± (Fhyd) ± ( Fother) = FBlowout

amount of stored energy at the time, the result can be fatal.

Part One of this two-part Sealing Sense series brings FClamping has been subdivided into four components. These

attention to the balance of forces present at the potential components are defined as follows:

moment of gasket blowout and provides guidance on how

to protect against this type of gasket failure. Equations are FBtot = The total initial force on the gasket created

provided to assist with evaluating these forces and results are from tightening the fasteners to a prescribed

presented to show that to protect against blowout, clamp- target torque

ing force can be significantly more important than gasket FGrelax = Loss of compressive gasket stress because of

tensile strength. time, temperature and load effects

FHyd = Force resulting from hydraulic load being

BLOWOUT FORCES contained

For the purpose of this article, Figure 1 identifies the gen- FOther = General collection of other effects that reduce

eral condition of potential blowout. It shows an axial “cut” or increase the clamping force

across the thickness of the gasket and the three general forces

affecting blowout. Equation 1 provides the force balance in Fhyd and FOther, though normally negative, can be positive

the radial direction. The potential condition of blowout and help prevent blowout.

is taken when the sum of these forces is equally balanced.

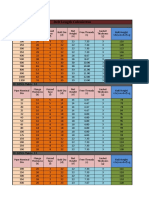

That is, the forces holding the gasket in place and together is Table 1 lists common conditions that should be consid-

equal to the outward force trying to dislodge or damage it. ered when evaluating each force. The reader is cautioned

that this is only a partial listing. The intent is to bring atten-

Equation 1 tion to the type and number of factors that can affect the

FGten + FClamping = FBlowout force balance.

Equation 3 provides a further redefinition and rearrange-

These are defined as follows: ment of terms that allow the potential blowout pressure

FGten = Force supplied by the (resisting) tensile to be evaluated directly. Example values are supplied for a

strength of gasket

FClamping = Frictional force on gasket from combined

axial forces

FBlowout = Outward radial force trying to separate gasket

from flanges

These three forces give a general descriptive condition Figure 1. Forces on a gasket

of blowout, but do little to identify the components upon

80 April 2014 www.pump-zone.com PUMPS & SYSTEMS

Sealing Technologies

2-inch, Class 150, ASME B16.21 ring gasket.

Equation 3

[σ • A + μ • (FBtotal – σgRF • Ag – FOther)]

PBO = tg blowout

(

π • t • Di +

μ • π • Di2

4 )

The added terms are defined as follows:

σtg = Tensile strength of gasket, 2,700 pound-force per square inch

(lbf/in2)

Ablowout = 2 x gasket width x gasket thickness in compressed condition, in2

μ = Friction factor, gasket on flange face, 0.2

FBtotal = Total bolt load at original tightening torque, 32,914 pound force

(lbf )

σgRF = Loss of gasket stress to time, temperature and loading history,

2,050 lbf/in2

Ag = Axial area of gasket, 5.84 in2

Di = Inner diameter of gasket, 2.38 inches

t = Thickness of gasket in compressed condition (0.0625 inch)

FOther = as above, 10,000 lbf

PBO = Blowout pressure, lbf/in2

ANALYSIS OF BLOWOUT FACTORS

A way to trial different values to inspect their potential effect on PBO is avail-

able. It will be used to test the general belief that gasket tensile strength is

always a major factor in preventing gasket blowout. To investigate, two series

of calculations are evaluated to the resulting value of PBO.

FGten FBtot FGrelax FHyd FOther

Gasket tensile Nut factor Softening Internal Differential

strength of gasket pressure being thermal

modulus contained expansion of

at design (positive or components

temperature negative) (bolt, flange,

gasket)

Coefficient of Flange Cyclic Piping/

friction, gasket misalignment temperature equipment

on flange loading of loads

gasket

circle 140 on card or go to psfreeinfo.com

Tightening Cyclic pressure Vibration

procedure loading of

gasket

Flange Flange rotation

analysis

Torque wrench Relative

precision stiffness

of flange

components

Bolt condition

Table 1. Common conditions to evaluate

PUMPS & SYSTEMS www.pump-zone.com April 2014 81

SPECIAL REPORT

The first series is performed by holding all

values fixed, except σtg. Its value is progressively

reduced in 5 percent increments. In the second

series, all values are held fixed except, FOther. This

shows the potential effect of an axial piping

load or axial flange misalignment that tends to

separate the flanges. Its value is progressively

increased in 5 percent increments. The results

are plotted in Figure 2.

The plot of gasket tensile strength is relatively

flat. This shows PBO to have a low sensitivity to

changes in gasket tensile strength. On the other

hand, PBO shows a significant sensitivity to the

effect of the change in axial piping load. During

the range considered, the overall change in PBO

for tensile strength and the piping load are approx-

imately 4 percent and 41 percent, respectively. In Figure 2. Effect of piping load and gasket tensile strength on blowout pressure

fact, a 5 percent drop in clamping force produces

larger drop in blowout pressure than a 50 percent

drop in tensile strength. Clearly, the clamping force can play a CONCLUSION

much larger role in protecting against blowout. This is equally In this example, the total value of clamping force was

true for any effect that reduces the clamping force. adjusted by considering a single factor such as piping load

or flange misalignment. In reality, the

ultimate value of clamping force will

be the result of the combined effects

of several factors. Unless the value of

gasket tensile strength is very high, the

clamping force will be most responsi-

ble for protecting against blowout.

A review of Table 1 shows a signifi-

cant number of conditions that can

negatively impact blowout pressure.

Developing values for these factors

can often be a challenge. Next month,

Part Two of this Sealing Sense series

will investigate two strategies to help

make this challenge manageable. P&S

NEXT MONTH:

Part Two: Prevent Gasket Blowout—

What’s Most Important?

We invite your suggestions for article topics as

well as questions on sealing issues so we can

better respond to the needs of the industry. Please

direct your suggestions and questions to

sealingsensequestions@fluidsealing.com.

circle 149 on card or go to psfreeinfo.com

82 April 2014 www.pump-zone.com PUMPS & SYSTEMS

You might also like

- Engine V9X NavaraDocument394 pagesEngine V9X Navaramichiganangola92% (12)

- Assembly: Engine (Engine - 2.0L Ecoboost (177Kw/240Ps) - Mi4)Document20 pagesAssembly: Engine (Engine - 2.0L Ecoboost (177Kw/240Ps) - Mi4)Bartłomiej StępieńNo ratings yet

- Manual LT 20-30Document74 pagesManual LT 20-30Juan Carlos Juarez50% (2)

- Weichai Engine WP10Document135 pagesWeichai Engine WP10nksiavash100% (2)

- Daewoo Doosan DB58 Diesel Engine Service Repair ManualDocument20 pagesDaewoo Doosan DB58 Diesel Engine Service Repair ManualRyan Darilag67% (3)

- Torque Method For AFC Plug TypeDocument7 pagesTorque Method For AFC Plug TypePranpath NarupantawartNo ratings yet

- Installation, Operation, Maintenance Instructions For Severn Glocon Control & Choke ValvesDocument4 pagesInstallation, Operation, Maintenance Instructions For Severn Glocon Control & Choke ValvesEderson Santos67% (3)

- Catalog - Velan Memory Seal - Vel BV WebDocument44 pagesCatalog - Velan Memory Seal - Vel BV Webadil_farooq_6No ratings yet

- Primary Flange Forces Part1Document2 pagesPrimary Flange Forces Part1Haftamu HilufNo ratings yet

- Gaskets-The Weakest Link - Article From Chemical Engineering June-2005Document3 pagesGaskets-The Weakest Link - Article From Chemical Engineering June-2005kumar_chemicalNo ratings yet

- Bolt Torque DeterminationDocument11 pagesBolt Torque DeterminationRatna Giridhar Kavali100% (1)

- Initial Gasket Compression Is Key To Safe, Reliable Flange JointsDocument3 pagesInitial Gasket Compression Is Key To Safe, Reliable Flange Jointscmms88No ratings yet

- Tn6540en00 2 MKDocument4 pagesTn6540en00 2 MKAdi SaputraNo ratings yet

- Optimal Prestressing of Bolted FlangesDocument10 pagesOptimal Prestressing of Bolted FlangesRoberto CamposNo ratings yet

- Torque PDFDocument3 pagesTorque PDFicetesterNo ratings yet

- Chapter 3 - Tension Members: A Beginner's Guide To The Steel Construction ManualDocument4 pagesChapter 3 - Tension Members: A Beginner's Guide To The Steel Construction Manualedn_mj1645No ratings yet

- How Do I Determine Bolt Torque For Flanged Connections - GasketsDocument4 pagesHow Do I Determine Bolt Torque For Flanged Connections - GasketsNataraj MohanNo ratings yet

- Nonmandatory Appendix S Design Considerations For Bolted Flange ConnectionsDocument4 pagesNonmandatory Appendix S Design Considerations For Bolted Flange ConnectionstizioNo ratings yet

- How Do I Determine Bolt Torque For Flanged ConnectionsDocument6 pagesHow Do I Determine Bolt Torque For Flanged Connectionsloq100% (1)

- Chapter 1 Lecture Note + TutorialDocument20 pagesChapter 1 Lecture Note + TutorialGuo JingNo ratings yet

- Tension MembersDocument12 pagesTension MembersJay-r MiñozaNo ratings yet

- Low Pressure Soot Blowing TechnologyDocument18 pagesLow Pressure Soot Blowing TechnologyavgpaulNo ratings yet

- Bolted Flange Joint AssembliesDocument1 pageBolted Flange Joint AssembliesBramJanssen76No ratings yet

- Shear StrengthDocument8 pagesShear StrengthpotsuNo ratings yet

- Bolt Design Calc SheetDocument19 pagesBolt Design Calc SheetMarshalNo ratings yet

- Gaskets: Standard Definitions of Terms Relating ToDocument2 pagesGaskets: Standard Definitions of Terms Relating ToAhmad Zubair RasulyNo ratings yet

- Preloaded Joint Analysis Methodology For Space Flight SystemsDocument29 pagesPreloaded Joint Analysis Methodology For Space Flight SystemsDaniel88036No ratings yet

- Wu2005 PDFDocument10 pagesWu2005 PDFChikh YassineNo ratings yet

- Bolt Prestress Force FatigueDocument4 pagesBolt Prestress Force FatigueYadava JaffaNo ratings yet

- Shortening Estimate of Post Tensioned Floors TN458Document16 pagesShortening Estimate of Post Tensioned Floors TN458Anonymous x9STa9No ratings yet

- Technical Notes: Safety Investigation of An Unbonded Floor System With Restraint CracksDocument11 pagesTechnical Notes: Safety Investigation of An Unbonded Floor System With Restraint CracksephremNo ratings yet

- Axial and Pressure Thrust Stiffness of Metal Bellows For Vibration IsolatorsDocument5 pagesAxial and Pressure Thrust Stiffness of Metal Bellows For Vibration IsolatorsHazimNo ratings yet

- Checks For CompactnessDocument15 pagesChecks For CompactnessjologscresenciaNo ratings yet

- Baffies: Mechanical Design CriteriaDocument1 pageBaffies: Mechanical Design CriteriaprateekmuleNo ratings yet

- Analysis of Stress Concentration Factor in Bolted Joint Using Finite Element MethodDocument9 pagesAnalysis of Stress Concentration Factor in Bolted Joint Using Finite Element Methodvj2011100% (1)

- Fukuoka 1992Document6 pagesFukuoka 1992Suissi AnisNo ratings yet

- Coupling Stiffness DiscussionDocument28 pagesCoupling Stiffness Discussionfuzhi2016No ratings yet

- LECTURE 3 - Shear Stress & Allowable StressDocument15 pagesLECTURE 3 - Shear Stress & Allowable StressIhab OmarNo ratings yet

- Dry Gas Seal Centrifugal CompressorDocument23 pagesDry Gas Seal Centrifugal CompressorSomen Mukherjee100% (1)

- Pernos Con Tuerca FatigaDocument7 pagesPernos Con Tuerca FatigaBernardo Mullers FriedebornNo ratings yet

- New Approach Prerequisites: 3 R D M RDocument1 pageNew Approach Prerequisites: 3 R D M RTiHoRNo ratings yet

- Jim Meyer LPG Expansion Joints White PaperDocument7 pagesJim Meyer LPG Expansion Joints White PaperJoshi DhvanitNo ratings yet

- Module3 Design of Tension MembersDocument33 pagesModule3 Design of Tension MembersPrem KumarNo ratings yet

- Adhesion in Extrusion Coating Will Decrease With Diminishing Coating ThicknessDocument33 pagesAdhesion in Extrusion Coating Will Decrease With Diminishing Coating ThicknessLê Lâm BìnhNo ratings yet

- Sec 8 D 2 App 4Document57 pagesSec 8 D 2 App 4Patrick CARVALHONo ratings yet

- Pages From Design of Welded StructureDocument3 pagesPages From Design of Welded Structuremaris_sasecNo ratings yet

- Evaluating Flat-Faced Gasketed Joint Assemblies: Standard Practice ForDocument3 pagesEvaluating Flat-Faced Gasketed Joint Assemblies: Standard Practice ForChulaka PitigalaNo ratings yet

- Static Capacity Plate GirderDocument10 pagesStatic Capacity Plate GirderKarya BangunanNo ratings yet

- 2 Bolts: Table 2.1 Basic Mechanical Properties of Structural BoltsDocument11 pages2 Bolts: Table 2.1 Basic Mechanical Properties of Structural BoltsSafrul EfendiNo ratings yet

- AD 143 - Prying in Bolted ConnectionsDocument2 pagesAD 143 - Prying in Bolted ConnectionsKennedy OnojetaNo ratings yet

- Cold Form PDFDocument30 pagesCold Form PDFNitesh Kumar PatelNo ratings yet

- OPENSTAAD Crash CourseDocument4 pagesOPENSTAAD Crash Courseanon_338686498No ratings yet

- Determination of Leakage Gap and Leakage Mass Flow of Flanged JointsDocument5 pagesDetermination of Leakage Gap and Leakage Mass Flow of Flanged Jointslcm3270% (1)

- GasketsDocument34 pagesGasketsAslam AsiffNo ratings yet

- Deep Rolling Process Simulation - Impact of Kinematic Hardening On Residual StressesDocument5 pagesDeep Rolling Process Simulation - Impact of Kinematic Hardening On Residual Stressesesteban vasquezNo ratings yet

- Chapter 23 Piping Systems - 2001 - Elsevier Ocean Engineering SeriesDocument7 pagesChapter 23 Piping Systems - 2001 - Elsevier Ocean Engineering SeriesJosept RevueltaNo ratings yet

- BHMY 887 Flexflo IOM 31683C 0920 EnglishDocument16 pagesBHMY 887 Flexflo IOM 31683C 0920 EnglishSajjad MehdiNo ratings yet

- Calc PierHeadDocument22 pagesCalc PierHeaddinal031No ratings yet

- TENSION MEMBERS Yielding Shear LagDocument28 pagesTENSION MEMBERS Yielding Shear LagEhsan WasimNo ratings yet

- Safe Aviation: Tungsten Carbide Coatings On Jet Engine ComponentsDocument4 pagesSafe Aviation: Tungsten Carbide Coatings On Jet Engine ComponentsDeviprasad MNo ratings yet

- 1 s2.0 S1738573321000620 MainDocument14 pages1 s2.0 S1738573321000620 MainCricri CriNo ratings yet

- NSC1907-Member Buckling With Tension Flange RestraintDocument3 pagesNSC1907-Member Buckling With Tension Flange Restraintpatricklim1982No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Vibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingFrom EverandVibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingNo ratings yet

- General FlywheelDocument8 pagesGeneral FlywheelRegina FrisbeeNo ratings yet

- G9190 MOTOR GRADER PARTS CATALOG (Updated 16-7-14) 8G190052010600 (D9016867, D9016868, D9019781, D9019782, D9020023-D9089999) PDFDocument393 pagesG9190 MOTOR GRADER PARTS CATALOG (Updated 16-7-14) 8G190052010600 (D9016867, D9016868, D9019781, D9019782, D9020023-D9089999) PDFမင္း သီဟ100% (5)

- 3208 Marine 75v1-Up 01z1-UpDocument52 pages3208 Marine 75v1-Up 01z1-UpCristobal Campos100% (3)

- Fdez. Jove - Valvula 3 Vías - (SFERACO)Document12 pagesFdez. Jove - Valvula 3 Vías - (SFERACO)Pedro VarelaNo ratings yet

- A-A-59326a (1) AcoplamentoDocument15 pagesA-A-59326a (1) AcoplamentogilsonNo ratings yet

- PVC Pipe Gasketed JointsDocument1 pagePVC Pipe Gasketed JointsUnibellNo ratings yet

- Oisd 134Document37 pagesOisd 134skgbondNo ratings yet

- TNC PDFDocument12 pagesTNC PDFketab_doostNo ratings yet

- Pressure Relief Valve Efficiency CalculationsDocument16 pagesPressure Relief Valve Efficiency CalculationsahmedNo ratings yet

- Dynatech T56 Spares ListDocument109 pagesDynatech T56 Spares ListrizkyNo ratings yet

- Technologies: Trenchless Cured-in-Place PipeDocument12 pagesTechnologies: Trenchless Cured-in-Place PipeDaphne BoydNo ratings yet

- MS & RA CombinedDocument49 pagesMS & RA Combinedanishdev6100% (1)

- Bolt Length Calculation: IS 6392-Table 11Document3 pagesBolt Length Calculation: IS 6392-Table 11sumit_b123No ratings yet

- Remove & Install Supplemental Steering PumpDocument9 pagesRemove & Install Supplemental Steering PumpMehdi ChakrouneNo ratings yet

- GHX Industrial, LLC: A United Distribution Group CompanyDocument8 pagesGHX Industrial, LLC: A United Distribution Group CompanyJesus PicaluaNo ratings yet

- Valve StandardsDocument20 pagesValve StandardsCosimoNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Garlock Style 9900 Spec Sheet - (NA) 2021-09 ENDocument1 pageGarlock Style 9900 Spec Sheet - (NA) 2021-09 ENDrojanle MezbraNo ratings yet

- BS en 1514-1-1997 PDFDocument22 pagesBS en 1514-1-1997 PDFuzzy2No ratings yet

- Generator BasicsDocument69 pagesGenerator Basicssujiv_sujiv1278No ratings yet

- MNT Design 2520of 2520equipmentsDocument32 pagesMNT Design 2520of 2520equipmentsshamsabbasNo ratings yet

- Cutes CVP SeriesDocument28 pagesCutes CVP SeriesGabenkNo ratings yet

- Exxonmobil - Serpentina H2S Management Project: Material Requisition For H2S Absorbent Modular SkidDocument21 pagesExxonmobil - Serpentina H2S Management Project: Material Requisition For H2S Absorbent Modular SkidPrakash RajNo ratings yet