Professional Documents

Culture Documents

AISI 1018 Steel

AISI 1018 Steel

Uploaded by

sroenschCopyright:

Available Formats

You might also like

- Judd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFDocument60 pagesJudd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFJoão Henrique Ribeiro BarbosaNo ratings yet

- Sailorgirl PatternDocument12 pagesSailorgirl Patterndaniela luevanos100% (5)

- Technical Information Loctite Liofol La 7728/ Loctite Liofol La 6028Document3 pagesTechnical Information Loctite Liofol La 7728/ Loctite Liofol La 6028Mohit100% (1)

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 pagesAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezNo ratings yet

- Aluminio 3105 H16Document2 pagesAluminio 3105 H16Cesar Zarate100% (1)

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- Cold Drawn PDFDocument1 pageCold Drawn PDFAna Emily PrentissNo ratings yet

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanNo ratings yet

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- MaterialData 7754Document2 pagesMaterialData 7754Joko TriwardonoNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- MaterialData 6937Document1 pageMaterialData 6937Cristobal Gutierrez CarrascoNo ratings yet

- Sae 4320 FPDocument2 pagesSae 4320 FPBarron ValentinNo ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument2 pagesAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffNo ratings yet

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- MaterialData AISI-SAE101Document2 pagesMaterialData AISI-SAE101Ian KellyNo ratings yet

- SUS 316 Material Properties PDFDocument1 pageSUS 316 Material Properties PDFYudo ArdianNo ratings yet

- AISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundDocument2 pagesAISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundygfrostNo ratings yet

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDocument1 pageJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNo ratings yet

- 304 Stainless Steel Tecnical DataDocument2 pages304 Stainless Steel Tecnical DataArmando MátalNo ratings yet

- Aluminium A380Document1 pageAluminium A380Ashokkumar VelloreNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- AISI 1050 Carbon Steel Wire AlloyDocument1 pageAISI 1050 Carbon Steel Wire Alloyjuprijupri25No ratings yet

- AISI Type 304L Stainless Steel Material Data - 12676Document1 pageAISI Type 304L Stainless Steel Material Data - 12676Ian Pillay100% (1)

- Sandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyDocument1 pageSandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyLorena Grijalba LeónNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless Steeldaniel enrique romero robayoNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocument2 pagesAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNo ratings yet

- AISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 inDocument2 pagesAISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 indiego AlvarezNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- AISI 1020 Steel, As RolledDocument3 pagesAISI 1020 Steel, As Rollednum fistismNo ratings yet

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadNo ratings yet

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezNo ratings yet

- Acero Inoxidable 405, Recocido, ChapaDocument1 pageAcero Inoxidable 405, Recocido, ChapaLorena Grijalba LeónNo ratings yet

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDocument1 pageAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiNo ratings yet

- AISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundDocument2 pagesAISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundGiancarlo PassalacquaNo ratings yet

- Material - S45C NormalizedDocument1 pageMaterial - S45C NormalizedhanazahrNo ratings yet

- Sae 5160 VBDocument2 pagesSae 5160 VBBarron ValentinNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFbbbNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFMayand DuaNo ratings yet

- Mild Steel PDFDocument3 pagesMild Steel PDFHardikNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFFebrian JhaNo ratings yet

- Aluminum 5052Document6 pagesAluminum 5052lalfredoperezNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- Aluminum 380.0-F Die Casting AlloyDocument2 pagesAluminum 380.0-F Die Casting AlloyLuis BadoffNo ratings yet

- JIS S45C Steel, TemperedDocument2 pagesJIS S45C Steel, TemperedAnonymous kAday2100% (2)

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- Din 1Document1 pageDin 1ttpatelNo ratings yet

- Bronze (Low-Silicon) UNS C65100, OSO35 (Tornillos Maquinas)Document2 pagesBronze (Low-Silicon) UNS C65100, OSO35 (Tornillos Maquinas)Carlos Andres Garcia MuñozNo ratings yet

- Nasa STD 5001a Approved 2008-08-05Document20 pagesNasa STD 5001a Approved 2008-08-05sroenschNo ratings yet

- Eurosurv 27 26 1Document6 pagesEurosurv 27 26 1sroenschNo ratings yet

- Ansibifma x5 12011 Office ChairsDocument4 pagesAnsibifma x5 12011 Office ChairssroenschNo ratings yet

- Purdue ME 452 Machine Design II Hw5csol - sp12Document9 pagesPurdue ME 452 Machine Design II Hw5csol - sp12sroenschNo ratings yet

- ANSYS Hyperelastic MaterialsDocument188 pagesANSYS Hyperelastic MaterialssroenschNo ratings yet

- Roensch - The Finite Element MethodDocument8 pagesRoensch - The Finite Element MethodsroenschNo ratings yet

- Torque Data ChartDocument2 pagesTorque Data ChartAscenderBSP100% (1)

- Roensch - The Finite Element Method - A Four-Article SeriesDocument8 pagesRoensch - The Finite Element Method - A Four-Article SeriessroenschNo ratings yet

- BIFMA Chair Standards PDFDocument2 pagesBIFMA Chair Standards PDFsroenschNo ratings yet

- Torque Data ChartDocument2 pagesTorque Data ChartAscenderBSP100% (1)

- Product Data Sheet: Socket Head Cap ScrewsDocument2 pagesProduct Data Sheet: Socket Head Cap ScrewssroenschNo ratings yet

- Metric Hex Bolts ISO 4014Document2 pagesMetric Hex Bolts ISO 4014sroenschNo ratings yet

- Reinforcement Detailing in Concrete StructuresDocument6 pagesReinforcement Detailing in Concrete StructurescherogonyaNo ratings yet

- Culverts, Trafficsigns, FoundationDocument308 pagesCulverts, Trafficsigns, FoundationsrinivasparasaNo ratings yet

- Cavity Plug XEOA - Full - en - Us - LetterDocument1 pageCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNo ratings yet

- Presentation Dr. Fahmida Gulshan 1Document30 pagesPresentation Dr. Fahmida Gulshan 1Vishal SharmaNo ratings yet

- 339 Handloom TechDocument52 pages339 Handloom TechO P Siddharth PerumalNo ratings yet

- Hearts PDFDocument2 pagesHearts PDFShmitnheheNo ratings yet

- STD-24. Iso-20567-3-2012Document9 pagesSTD-24. Iso-20567-3-2012Seda ErsoyNo ratings yet

- Performance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDocument4 pagesPerformance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDarwin DarmawanNo ratings yet

- Astm A 240 A 240M C05Document12 pagesAstm A 240 A 240M C05cvazquez999No ratings yet

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 pagesWear Resistant Steel: Material Data Sheet, Edition April 2016Zoltán PálfyNo ratings yet

- Masonry Block Fence Wall SystemDocument6 pagesMasonry Block Fence Wall SystemRenzNo ratings yet

- Dureza Total Con Titulador DigitalDocument8 pagesDureza Total Con Titulador DigitalJESSICA VANESSA ARISMENDI AVILEZNo ratings yet

- Technology and Livelihood Education 6: Industrial ArtsDocument13 pagesTechnology and Livelihood Education 6: Industrial ArtsCorazon Diong Sugabo-TaculodNo ratings yet

- X Cbe 26770 Key 140003254976 200907311028Document3 pagesX Cbe 26770 Key 140003254976 200907311028namalNo ratings yet

- f73999416 ERECTION PROGRESS REPORT GWC-QAFDocument4 pagesf73999416 ERECTION PROGRESS REPORT GWC-QAFAbdulrahman AlkilaniNo ratings yet

- 16 Mechanical Saddles CATALOGUE 2021Document16 pages16 Mechanical Saddles CATALOGUE 2021Bryan Daumett Valdespino FriasNo ratings yet

- G7 Science Q1 - Week 6-Unsaturated and Saturated SolutionDocument14 pagesG7 Science Q1 - Week 6-Unsaturated and Saturated SolutionJessa-Bhel AlmueteNo ratings yet

- Karl Fischer (Water Determination)Document4 pagesKarl Fischer (Water Determination)Alfonso Dominguez Gonzalez100% (1)

- Cycom-977-3 CM en PDFDocument5 pagesCycom-977-3 CM en PDFSeçkin MartinNo ratings yet

- Loctite Ea 9396 AeroDocument4 pagesLoctite Ea 9396 AerobenNo ratings yet

- CHM413 Exp 3Document5 pagesCHM413 Exp 3Anis NasuhaNo ratings yet

- ATS 3 Retarding Admixtures PDFDocument4 pagesATS 3 Retarding Admixtures PDFvinay rodeNo ratings yet

- Effect of Metal Coupling On Rusting of IronDocument12 pagesEffect of Metal Coupling On Rusting of IronAnkit Choudhary52% (23)

- New Dimensions of SoftnessDocument9 pagesNew Dimensions of SoftnessEugene PaiNo ratings yet

- Chemical BondingDocument4 pagesChemical Bondingbooksale SiNo ratings yet

- Rubber Water BlastDocument12 pagesRubber Water BlastEng Mostafa ElsayedNo ratings yet

- 1.2 FS Pipeline PDFDocument233 pages1.2 FS Pipeline PDFmaheshdabli0% (1)

AISI 1018 Steel

AISI 1018 Steel

Uploaded by

sroenschCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISI 1018 Steel

AISI 1018 Steel

Uploaded by

sroenschCopyright:

Available Formats

5/17/22, 10:13 PM AISI 1018 Steel, cold drawn

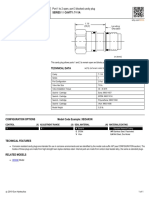

AISI 1018 Steel, cold drawn

Categories: Metal; Ferrous Metal; Carbon Steel; AISI 1000 Series Steel; Low Carbon Steel

Material Medium low-carbon steel, has good weldability and slightly better machinability than the lower carbon steels.

Notes:

Key Words: carbon steels, AMS 5069, ASTM A108, UNS G10180, AS 1442 K1018 (Australia), AS 1443 K1018, CSN 12020

(Czech), CSN 12022, AFNOR NF A33-101 AF42C20, DIN 1.0453, DIN C16.8, DGN B-301 1018 (Mexico),

COPANT 331 1018 (Pan America), COPANT 333 1018, MST.T (Russia), ST.20A, ST.3, ST.3T, GOST M18S,

GOST 23570 18ps, GOST 23570 18sp, GOST 5520 18K, GOST 5521 S, NBN 629 D37-2 (Belgium), NBN 630

E37-1, NBN 630 E37-2, NBN A21-221 C17KD, BDS 9801 S (Bulgaria), GB 715 ML3 (China), TS 302 Fe35.2

(Turkey), TS 346 Fe35, BS 970 080A17, DEF STAN95-1-1 C1018

Vendors: No vendors are listed for this material. Please click here if you are a supplier and would like information on how

to add your listing to this material.

Physical Properties Metric English Comments

Density 7.87 g/cc 0.284 lb/in³

Mechanical Properties Metric English Comments

Hardness, Brinell 126 126

Hardness, Knoop 145 145 Converted from Brinell

Hardness, Rockwell B 71 71 Converted from Brinell

Hardness, Vickers 131 131 Converted from Brinell

Tensile Strength, Ultimate 440 MPa 63800 psi

Tensile Strength, Yield 370 MPa 53700 psi

Elongation at Break 15 % 15 % In 50 mm

Reduction of Area 40 % 40 %

Modulus of Elasticity 200 GPa 29000 ksi

Bulk Modulus 159 GPa 23100 ksi Estimated from elastic modulus

Poissons Ratio 0.29 0.29 Typical for steel

Machinability 70 % 70 % Based on AISI 1212 steel = 100%

Shear Modulus 78.0 GPa 11300 ksi Estimated from elastic modulus

Electrical Properties Metric English Comments

Electrical Resistivity 0.0000159 ohm-cm 0.0000159 ohm-cm annealed condition

@Temperature 0.000 °C @Temperature 32.0 °F

0.0000219 ohm-cm 0.0000219 ohm-cm annealed condition

@Temperature 100 °C @Temperature 212 °F

0.0000293 ohm-cm 0.0000293 ohm-cm annealed condition

@Temperature 200 °C @Temperature 392 °F

Thermal Properties Metric English Comments

Specific Heat Capacity 0.486 J/g-°C 0.116 BTU/lb-°F annealed

@Temperature >=100 °C @Temperature >=212 °F

Thermal Conductivity 51.9 W/m-K 360 BTU-in/hr-ft²-°F estimated based on similar materials

Component Elements Metric English Comments

Properties

Carbon, C 0.14 - 0.20 % 0.14 - 0.20 %

Iron, Fe 98.81 - 99.26 % 98.81 - 99.26 % As remainder

Manganese, Mn 0.60 - 0.90 % 0.60 - 0.90 %

Phosphorus, P <= 0.040 % <= 0.040 %

Sulfur, S <= 0.050 % <= 0.050 %

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format. Users

requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent

units. We advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you refer to

MatWeb's terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

https://www.matweb.com/search/datasheet_print.aspx?matguid=3a9cc570fbb24d119f08db22a53e2421 1/1

You might also like

- Judd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFDocument60 pagesJudd Foundation Guidelines - For The Care and Handling of Judd Works in Metal PDFJoão Henrique Ribeiro BarbosaNo ratings yet

- Sailorgirl PatternDocument12 pagesSailorgirl Patterndaniela luevanos100% (5)

- Technical Information Loctite Liofol La 7728/ Loctite Liofol La 6028Document3 pagesTechnical Information Loctite Liofol La 7728/ Loctite Liofol La 6028Mohit100% (1)

- AISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDocument2 pagesAISI 4140 Steel, Oil Quenched, 650°C (1200°F) Temper, 25 MM (1 in PDFDiegoAlvarezHuguezNo ratings yet

- Aluminio 3105 H16Document2 pagesAluminio 3105 H16Cesar Zarate100% (1)

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- Cold Drawn PDFDocument1 pageCold Drawn PDFAna Emily PrentissNo ratings yet

- AISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument3 pagesAISI 1015 Steel, Cold Drawn: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelAleesha RehanNo ratings yet

- AISI 1035 SteelDocument2 pagesAISI 1035 SteelCarlos Andres Garcia MuñozNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- MaterialData 7754Document2 pagesMaterialData 7754Joko TriwardonoNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- MaterialData 6937Document1 pageMaterialData 6937Cristobal Gutierrez CarrascoNo ratings yet

- Sae 4320 FPDocument2 pagesSae 4320 FPBarron ValentinNo ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument2 pagesAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffNo ratings yet

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- MaterialData AISI-SAE101Document2 pagesMaterialData AISI-SAE101Ian KellyNo ratings yet

- SUS 316 Material Properties PDFDocument1 pageSUS 316 Material Properties PDFYudo ArdianNo ratings yet

- AISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundDocument2 pagesAISI 1022 Steel, Heat Treated, Quenched From Pot, 13.7 MM RoundygfrostNo ratings yet

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDocument1 pageJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNo ratings yet

- 304 Stainless Steel Tecnical DataDocument2 pages304 Stainless Steel Tecnical DataArmando MátalNo ratings yet

- Aluminium A380Document1 pageAluminium A380Ashokkumar VelloreNo ratings yet

- 304Document2 pages304julianmorantesNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- AISI 1050 Carbon Steel Wire AlloyDocument1 pageAISI 1050 Carbon Steel Wire Alloyjuprijupri25No ratings yet

- AISI Type 304L Stainless Steel Material Data - 12676Document1 pageAISI Type 304L Stainless Steel Material Data - 12676Ian Pillay100% (1)

- Sandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyDocument1 pageSandvik Cuprothal 10 Resistance Wire: Metal Nonferrous Metal Copper AlloyLorena Grijalba LeónNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless Steeldaniel enrique romero robayoNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocument2 pagesAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNo ratings yet

- AISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 inDocument2 pagesAISI 4340 Steel, Oil Quenched 800°C (1470°F), 540°C (1000°F) Temper, 50 MM (2 indiego AlvarezNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- AISI 1020 Steel, As RolledDocument3 pagesAISI 1020 Steel, As Rollednum fistismNo ratings yet

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadNo ratings yet

- AISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1Document2 pagesAISI 1045 Steel, Hot Rolled, 19-32 MM (0.75-1diego AlvarezNo ratings yet

- Acero Inoxidable 405, Recocido, ChapaDocument1 pageAcero Inoxidable 405, Recocido, ChapaLorena Grijalba LeónNo ratings yet

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDocument1 pageAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiNo ratings yet

- AISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundDocument2 pagesAISI 4140 Steel, Normalized at 870°C (1600°F), Air Cooled, 25 MM (1 In.) RoundGiancarlo PassalacquaNo ratings yet

- Material - S45C NormalizedDocument1 pageMaterial - S45C NormalizedhanazahrNo ratings yet

- Sae 5160 VBDocument2 pagesSae 5160 VBBarron ValentinNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFbbbNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFMayand DuaNo ratings yet

- Mild Steel PDFDocument3 pagesMild Steel PDFHardikNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFFebrian JhaNo ratings yet

- Aluminum 5052Document6 pagesAluminum 5052lalfredoperezNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- Aluminum 380.0-F Die Casting AlloyDocument2 pagesAluminum 380.0-F Die Casting AlloyLuis BadoffNo ratings yet

- JIS S45C Steel, TemperedDocument2 pagesJIS S45C Steel, TemperedAnonymous kAday2100% (2)

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- Din 1Document1 pageDin 1ttpatelNo ratings yet

- Bronze (Low-Silicon) UNS C65100, OSO35 (Tornillos Maquinas)Document2 pagesBronze (Low-Silicon) UNS C65100, OSO35 (Tornillos Maquinas)Carlos Andres Garcia MuñozNo ratings yet

- Nasa STD 5001a Approved 2008-08-05Document20 pagesNasa STD 5001a Approved 2008-08-05sroenschNo ratings yet

- Eurosurv 27 26 1Document6 pagesEurosurv 27 26 1sroenschNo ratings yet

- Ansibifma x5 12011 Office ChairsDocument4 pagesAnsibifma x5 12011 Office ChairssroenschNo ratings yet

- Purdue ME 452 Machine Design II Hw5csol - sp12Document9 pagesPurdue ME 452 Machine Design II Hw5csol - sp12sroenschNo ratings yet

- ANSYS Hyperelastic MaterialsDocument188 pagesANSYS Hyperelastic MaterialssroenschNo ratings yet

- Roensch - The Finite Element MethodDocument8 pagesRoensch - The Finite Element MethodsroenschNo ratings yet

- Torque Data ChartDocument2 pagesTorque Data ChartAscenderBSP100% (1)

- Roensch - The Finite Element Method - A Four-Article SeriesDocument8 pagesRoensch - The Finite Element Method - A Four-Article SeriessroenschNo ratings yet

- BIFMA Chair Standards PDFDocument2 pagesBIFMA Chair Standards PDFsroenschNo ratings yet

- Torque Data ChartDocument2 pagesTorque Data ChartAscenderBSP100% (1)

- Product Data Sheet: Socket Head Cap ScrewsDocument2 pagesProduct Data Sheet: Socket Head Cap ScrewssroenschNo ratings yet

- Metric Hex Bolts ISO 4014Document2 pagesMetric Hex Bolts ISO 4014sroenschNo ratings yet

- Reinforcement Detailing in Concrete StructuresDocument6 pagesReinforcement Detailing in Concrete StructurescherogonyaNo ratings yet

- Culverts, Trafficsigns, FoundationDocument308 pagesCulverts, Trafficsigns, FoundationsrinivasparasaNo ratings yet

- Cavity Plug XEOA - Full - en - Us - LetterDocument1 pageCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNo ratings yet

- Presentation Dr. Fahmida Gulshan 1Document30 pagesPresentation Dr. Fahmida Gulshan 1Vishal SharmaNo ratings yet

- 339 Handloom TechDocument52 pages339 Handloom TechO P Siddharth PerumalNo ratings yet

- Hearts PDFDocument2 pagesHearts PDFShmitnheheNo ratings yet

- STD-24. Iso-20567-3-2012Document9 pagesSTD-24. Iso-20567-3-2012Seda ErsoyNo ratings yet

- Performance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDocument4 pagesPerformance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDarwin DarmawanNo ratings yet

- Astm A 240 A 240M C05Document12 pagesAstm A 240 A 240M C05cvazquez999No ratings yet

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 pagesWear Resistant Steel: Material Data Sheet, Edition April 2016Zoltán PálfyNo ratings yet

- Masonry Block Fence Wall SystemDocument6 pagesMasonry Block Fence Wall SystemRenzNo ratings yet

- Dureza Total Con Titulador DigitalDocument8 pagesDureza Total Con Titulador DigitalJESSICA VANESSA ARISMENDI AVILEZNo ratings yet

- Technology and Livelihood Education 6: Industrial ArtsDocument13 pagesTechnology and Livelihood Education 6: Industrial ArtsCorazon Diong Sugabo-TaculodNo ratings yet

- X Cbe 26770 Key 140003254976 200907311028Document3 pagesX Cbe 26770 Key 140003254976 200907311028namalNo ratings yet

- f73999416 ERECTION PROGRESS REPORT GWC-QAFDocument4 pagesf73999416 ERECTION PROGRESS REPORT GWC-QAFAbdulrahman AlkilaniNo ratings yet

- 16 Mechanical Saddles CATALOGUE 2021Document16 pages16 Mechanical Saddles CATALOGUE 2021Bryan Daumett Valdespino FriasNo ratings yet

- G7 Science Q1 - Week 6-Unsaturated and Saturated SolutionDocument14 pagesG7 Science Q1 - Week 6-Unsaturated and Saturated SolutionJessa-Bhel AlmueteNo ratings yet

- Karl Fischer (Water Determination)Document4 pagesKarl Fischer (Water Determination)Alfonso Dominguez Gonzalez100% (1)

- Cycom-977-3 CM en PDFDocument5 pagesCycom-977-3 CM en PDFSeçkin MartinNo ratings yet

- Loctite Ea 9396 AeroDocument4 pagesLoctite Ea 9396 AerobenNo ratings yet

- CHM413 Exp 3Document5 pagesCHM413 Exp 3Anis NasuhaNo ratings yet

- ATS 3 Retarding Admixtures PDFDocument4 pagesATS 3 Retarding Admixtures PDFvinay rodeNo ratings yet

- Effect of Metal Coupling On Rusting of IronDocument12 pagesEffect of Metal Coupling On Rusting of IronAnkit Choudhary52% (23)

- New Dimensions of SoftnessDocument9 pagesNew Dimensions of SoftnessEugene PaiNo ratings yet

- Chemical BondingDocument4 pagesChemical Bondingbooksale SiNo ratings yet

- Rubber Water BlastDocument12 pagesRubber Water BlastEng Mostafa ElsayedNo ratings yet

- 1.2 FS Pipeline PDFDocument233 pages1.2 FS Pipeline PDFmaheshdabli0% (1)