Professional Documents

Culture Documents

E5-Shepl Sample Design Calculation With Fea Validation Report For FRP Storage Tanks

E5-Shepl Sample Design Calculation With Fea Validation Report For FRP Storage Tanks

Uploaded by

MAYANK CHAUHANCopyright:

Available Formats

You might also like

- Solutions Manual Brief Course in Mathematical Statistics 1st Edition TanisDocument3 pagesSolutions Manual Brief Course in Mathematical Statistics 1st Edition Tanisstephensimon3297No ratings yet

- Examen FinalDocument16 pagesExamen FinalMario MerinoNo ratings yet

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDocument23 pagesFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidNo ratings yet

- Dentsply GAC - CatalogDocument336 pagesDentsply GAC - Catalogsorc50% (2)

- Degalan 64/12 N: Binder For Concrete Coatings and Metal CoatingsDocument2 pagesDegalan 64/12 N: Binder For Concrete Coatings and Metal Coatingssriatul2006No ratings yet

- INSPECTION Procedure For GalvanizingDocument14 pagesINSPECTION Procedure For Galvanizingjasminnee100% (1)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- TDS047-02 (GT-F-09C SUMPRO) New StandardDocument7 pagesTDS047-02 (GT-F-09C SUMPRO) New Standardprismatama.kreasindoNo ratings yet

- TDS462-14 (PI6 (5) GY SUMPRO) New StandardDocument6 pagesTDS462-14 (PI6 (5) GY SUMPRO) New Standardprismatama.kreasindoNo ratings yet

- Orion WB2 Propeller Polishing ReportDocument5 pagesOrion WB2 Propeller Polishing Reportjoel jeffery SarkarNo ratings yet

- EnglishDocument57 pagesEnglishnivasssvNo ratings yet

- International GTA220: Thinners & SolventsDocument2 pagesInternational GTA220: Thinners & SolventsAndri AjaNo ratings yet

- Docking Report of Orion wb2Document7 pagesDocking Report of Orion wb2joel jeffery SarkarNo ratings yet

- Kester 977 Soldering Flux en 17feb21 TBDocument4 pagesKester 977 Soldering Flux en 17feb21 TBhugoavchavezNo ratings yet

- Test 123Document11 pagesTest 123herlinaNo ratings yet

- Company Profile Piling PipeDocument52 pagesCompany Profile Piling PipeMargaretta WijayantiNo ratings yet

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDocument23 pagesFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidNo ratings yet

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDocument23 pagesFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidNo ratings yet

- C2C Case StudyDocument6 pagesC2C Case StudyMathan FlufyNo ratings yet

- TDS587-17-P (PL6 BK) - SUMPRO New Standard WaDocument5 pagesTDS587-17-P (PL6 BK) - SUMPRO New Standard Waprismatama.kreasindoNo ratings yet

- Jushi-Glass Fiber-MSDSDocument9 pagesJushi-Glass Fiber-MSDSTarek BenNo ratings yet

- Provisional Product Data Sheet: Sumitomo PolypropyleneDocument2 pagesProvisional Product Data Sheet: Sumitomo PolypropyleneortizmauricioNo ratings yet

- Company Profile: PT Mitra Agung SejatiDocument12 pagesCompany Profile: PT Mitra Agung SejatiDimas Theo PNo ratings yet

- PG770Document2 pagesPG770akankshas06No ratings yet

- GL-ST-500WA Data SheetDocument3 pagesGL-ST-500WA Data SheetAntónio RamosNo ratings yet

- SOFTAK1637Document3 pagesSOFTAK1637Marco JuarezNo ratings yet

- Copy Training Report 2Document21 pagesCopy Training Report 2sachinsinghal199270% (10)

- It - 100 20c TdsDocument2 pagesIt - 100 20c TdsNagaraju PanguluriNo ratings yet

- TDI Alcomer 80 Vers 10 2015Document2 pagesTDI Alcomer 80 Vers 10 2015PrototypeNo ratings yet

- Alsons PresentationDocument19 pagesAlsons PresentationAditya VuthaNo ratings yet

- A Project Report Unsaturated Polyester Resin at Daman: Technologies Technical Know-How - A Gateway To ProsperityDocument49 pagesA Project Report Unsaturated Polyester Resin at Daman: Technologies Technical Know-How - A Gateway To Prosperityrajesh kothariNo ratings yet

- Project Report - SunriseDocument15 pagesProject Report - SunriserajuNo ratings yet

- Tds Britex-95 inDocument1 pageTds Britex-95 inLaboratorio Inkctech0% (1)

- Jushi MSDSDocument12 pagesJushi MSDSOlaniyan SamsonNo ratings yet

- TDS - 985M Soldering FluxDocument2 pagesTDS - 985M Soldering FluxChoice OrganoNo ratings yet

- Cristal 121 - FinalDocument1 pageCristal 121 - FinalSajukurian7No ratings yet

- Mantash Quatation PDFDocument4 pagesMantash Quatation PDFshoaib khanNo ratings yet

- TDS Polyvest MA 75Document3 pagesTDS Polyvest MA 75Fairmont Ind Quality DivisionNo ratings yet

- Company Profile WQCDocument5 pagesCompany Profile WQCharigroupphilippinesNo ratings yet

- Portable Economical Conductivity MeterDocument4 pagesPortable Economical Conductivity Metersaurabh_acmasNo ratings yet

- Company Profile of ROKEE+BREE Lighting-2021Document78 pagesCompany Profile of ROKEE+BREE Lighting-2021Yu AmandaNo ratings yet

- SBN Corp Profile - 2 PDFDocument33 pagesSBN Corp Profile - 2 PDFSyafiq KamaluddinNo ratings yet

- Gypsum RatioDocument3 pagesGypsum RatioAthena MontefalcoNo ratings yet

- Summer Training ReportDocument44 pagesSummer Training ReportMayank GargNo ratings yet

- News Letter April 18Document16 pagesNews Letter April 18HamzaNoumanNo ratings yet

- Mosil Sam - 2825: Heavy Duty GreaseDocument2 pagesMosil Sam - 2825: Heavy Duty GreaseUdit JainNo ratings yet

- Mar Painting 2Document24 pagesMar Painting 2Teguh IndrawanNo ratings yet

- Product Data Sheet AV161 ASTM 20130121Document2 pagesProduct Data Sheet AV161 ASTM 20130121Yuli NugraheniNo ratings yet

- Calguard Anti-Spatter Spray TDS enDocument2 pagesCalguard Anti-Spatter Spray TDS enJeremy OngNo ratings yet

- Litech Company Profile 2020Document12 pagesLitech Company Profile 2020Ven KabNo ratings yet

- Sinopec Super Grease NLGI 2Document2 pagesSinopec Super Grease NLGI 2Yoong TanNo ratings yet

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- Gasket Remover (DS) 125-03017Document2 pagesGasket Remover (DS) 125-03017Teguh RiswantoNo ratings yet

- Protank T11 Chemical TanksDocument4 pagesProtank T11 Chemical TanksMariana HusainNo ratings yet

- Spectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Document6 pagesSpectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Dtl DiagNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- 2015 Shurjoint General Catalog v3Document217 pages2015 Shurjoint General Catalog v3Jesus Javier100% (1)

- ADD: 2 #18 Building Xihainan RD Liwan District Guangzhou China Tel:+86 2034097637Document18 pagesADD: 2 #18 Building Xihainan RD Liwan District Guangzhou China Tel:+86 2034097637raulNo ratings yet

- 186 Soldering Flux: Mildly Activated Rosin Liquid FluxDocument4 pages186 Soldering Flux: Mildly Activated Rosin Liquid FluxAmirNo ratings yet

- E-010814-A-Wuxi Deep-091019Document7 pagesE-010814-A-Wuxi Deep-091019PT. Sahabat Karib IndonesiaNo ratings yet

- TDS PP 500 Bi5.0ga 02Document2 pagesTDS PP 500 Bi5.0ga 02Adrianto GNo ratings yet

- Math 11 - Stat Prob - Q3Wk 1 2 Key.v. 02282021Document17 pagesMath 11 - Stat Prob - Q3Wk 1 2 Key.v. 02282021Cynthia LiaresNo ratings yet

- Uc Boyutlu Baglanma Stilleri Olcegi ToadDocument21 pagesUc Boyutlu Baglanma Stilleri Olcegi Toad4sq8vnbsv2No ratings yet

- 22ESC141 - SyllabusDocument4 pages22ESC141 - SyllabusW03 AKASHNo ratings yet

- MSDS - RacuminDocument6 pagesMSDS - RacuminRizka NataashaNo ratings yet

- Guided Writing (Informal Letter)Document11 pagesGuided Writing (Informal Letter)gnolaz100% (1)

- 3MS - All Sequences 1-2-3 in One - by Teacher Precious Rose 2018Document62 pages3MS - All Sequences 1-2-3 in One - by Teacher Precious Rose 2018Maman Randa Et AzizNo ratings yet

- RCPA Strategic PlanDocument16 pagesRCPA Strategic PlanAleka SevilleNo ratings yet

- K550X Sputter Coater Instruction ManualDocument32 pagesK550X Sputter Coater Instruction ManualCHARLES MICHAEL ALBERT -No ratings yet

- English - Academic Cultur of Universitas AirlanggaDocument27 pagesEnglish - Academic Cultur of Universitas AirlanggaImalinda RadyanisaNo ratings yet

- Policy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21Document9 pagesPolicy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21oreoolepNo ratings yet

- Criteria For Good Research-9Document19 pagesCriteria For Good Research-9vinnu kalyanNo ratings yet

- Travel Africa EditionDocument166 pagesTravel Africa EditionLuis Falcão100% (1)

- PythonDocument4 pagesPythonTrinh Tan Quang Bao K17 DNNo ratings yet

- Sadomasochism Accor Sadomasochism According To Freud's Psychosexual Stages of Chosexual Stages of Development TheoryDocument10 pagesSadomasochism Accor Sadomasochism According To Freud's Psychosexual Stages of Chosexual Stages of Development TheoryDolce BbNo ratings yet

- The Inner Universe Theoryof Dark Energy InterpretationDocument17 pagesThe Inner Universe Theoryof Dark Energy InterpretationCiprian Bitca100% (1)

- Cultural Marxism in The Works of BurroughsDocument1 pageCultural Marxism in The Works of BurroughsChandrapal S BhaskerNo ratings yet

- AbstractsDocument107 pagesAbstractsAnna KorompeliNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/04 February/March 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/04 February/March 2022jesuNo ratings yet

- DUAL ZONE System Reduces False Alarms, Making Outdoor Use More Reliable !Document2 pagesDUAL ZONE System Reduces False Alarms, Making Outdoor Use More Reliable !mcombaleNo ratings yet

- Option d1 PagesDocument9 pagesOption d1 PagesMohammad SuliemanNo ratings yet

- Schaffer HouseDocument39 pagesSchaffer HouseFrancisca CerdaNo ratings yet

- Sheeting Structure Verification Input DataDocument35 pagesSheeting Structure Verification Input DataanonimusazNo ratings yet

- Animal Behavior: Notes by Ali RashdiDocument8 pagesAnimal Behavior: Notes by Ali Rashdinatasha RajperNo ratings yet

- (5.3) Shear and Moment in BeamsDocument62 pages(5.3) Shear and Moment in BeamsIan Arnold FamiNo ratings yet

- Method For Producing Isopropanol by Acetone Hydrogenation: Download PDF Find Prior Art SimilarDocument8 pagesMethod For Producing Isopropanol by Acetone Hydrogenation: Download PDF Find Prior Art SimilaracetilenaNo ratings yet

- BEEE Unit 1.3Document16 pagesBEEE Unit 1.3senthil kumar rasappanNo ratings yet

- OOP ReviewDocument23 pagesOOP ReviewDuy AnhNo ratings yet

- Isaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4Document6 pagesIsaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4isaacNo ratings yet

E5-Shepl Sample Design Calculation With Fea Validation Report For FRP Storage Tanks

E5-Shepl Sample Design Calculation With Fea Validation Report For FRP Storage Tanks

Uploaded by

MAYANK CHAUHANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E5-Shepl Sample Design Calculation With Fea Validation Report For FRP Storage Tanks

E5-Shepl Sample Design Calculation With Fea Validation Report For FRP Storage Tanks

Uploaded by

MAYANK CHAUHANCopyright:

Available Formats

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

276TK1A/B/C/D/E/F/G/H/I/J/K/L/M/N/O - HYDROCHLORIC

ACID STORAGE TANK

SECTION 1

TECHNICAL SPECIFICATIONS

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 1 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

HYDROCHLORIC ACID STORAGE TANK

Tag No.: 276TK1A/B/C/D/E/F/G/H/I/J/K/L/M/N/O

Design Code: BS EN 13121-3 & GEP

Nozzle Drilling Standard: ASME B 16.5 #150

Process Fluid: HCl Solution 30-33% wt, H2SO4 max 7% wt

Fluid Density: 1140-1200 kg/m3

Design Pressure: +0,010 / -0,010 Bar(G)

Design Temperature: 70°C

Operating Pressure: ATM

Operating Temperature: AMB (-15 / +50) °C

Total Volume: 100 KL (Filled)

Liquid Level Maximum: 85%

Hydro Test: Full of Water

Manufacturing Process: Hand Lay Up

Type: Vertical Cylindrical / Torispherical Top and Flat Bottom

MOC: GRP (Vinyl ester Derakane Momentum 411-350 Resin)

Quantity: 15 Nos.

Empty Weight: Approx. 10800 kg

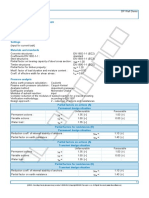

SI. No. Specifications Measurement

1. Diameter of Shell 4000 mm

2. Total Height of Tank 8000 mm

Torispherical Top 5 mm Corrosion Barrier With 30 GSM Carbon Veil + 25 mm Structural Layer +

3.

Thickness 1 mm Outer Layer with UV inhibitors.

5 mm Corrosion Barrier With 30 GSM Carbon Veil + 25 mm Structural Layer +

4. Shell Thickness

1 mm Outer Layer with UV inhibitors.

5 mm Corrosion Barrier With 30 GSM Carbon Veil + 25 mm Structural Layer +

5. Flat Bottom Thickness

1 mm Outer Layer with UV inhibitors.

6. Lifting Trunnion 04 Nos. IS 2062 GRADE A + GRP

7. Fasteners S.S.316L

8. Gasket E-PTFE

9. Name Plate GRP

10. Valves Provided for inbreathing / outbreathing

Access Ladder with

11. Safety Cage & Hand M.S. + GRP Coated

Railing

Nozzle Details – As per Process Specifications & Client Requirements

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 2 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Nozzle Table

Item Nr. Size, ND Rating, Location Service

N1 1 3'' 150#FF ROOF HCl ACID SOLUTION INLET

N2 1 2'' 150#FF ROOF MIXED ACID SOLUTION INLET

N3 1 3'' 150#FF ROOF VENT

N4 1 2'' (Note 5) 150#FF ROOF LEVEL INSTRUMENT CONNECTION (RADAR)

N5 1 2'' (Note 5) 150#FF ROOF LEVEL INSTRUMENT CONNECTION (RADAR)

N6 1 Note 6 Note 6 ROOF INBREATHING/OUTBREATHING VALVE

N7 1 3'' 150#FF SIDE (Note 7) DRAIN

N8 1 3'' 150#FF SIDE HCl / MIXED ACID SOLUTION OUTLET

N9 1 3'' 150#FF SIDE OVERFLOW

N10 1 2'' (Note 5) 150#FF SIDE TI CONNECTION

M1 1 24'' As per DWG. SIDE MANHOLE

M2 1 24'' As per DWG. ROOF MANHOLE

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 3 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

276TK1A/B/C/D/E/F/G/H/I/J/K/L/M/N/O - HYDROCHLORIC

ACID STORAGE TANK

SECTION 2

MECHANICAL CALCULATIONS

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 4 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

TITLE:-

Dia. 4000 x Height 8000 - Design Pressure: +0,010 / -0,010 Bar(G) - HYDROCHLORIC ACID STORAGE TANK

PROJECT No.:- 22423 PROJECT Date 03-02-2023

REF. DRAWING No.: 22423 - I - 001

REVISION:- 0

DESIGN INPUT DATA

Sr. No. Description Unit Input

1 Tank Diameter mm 4000

2 Tank Height mm 8000

3 Cone angle degrees NA

4 Internal Pressure Pi N/mm2 0

5 Vacuum Pv N/mm2 0.000980681

6 External Pressure Pe N/mm2 0

7 Design Temprature Dt °C 70

8 Heat Destortion temprature of Resin HDt °C 105

9 Fluid Specific Gravity ρ - 1.2

10 No of CSM 450 in Chemical barrier Nos. 5

Factor of safety k - 8.1675

k1 - relating to method of manufacturing - 1.5

k2 - for chemical environment and associated strength loss - 1.2

11

k3 - relating to temrature - 1.25

k4 - relating to cyclic loading - 1.1

k5 - relating to curing temprature - 1.1

Basic Wind Speed Vb m/sec 50

c1 - risk coefficient - 1

12

c2 - terrain height and structure size factor - 1

c3 - topography factor - 1

13 Design Wind Speed Vz = c1 x c2 x c3 x Vb m/sec 50

Design Wind Pressure Pw

14 N/mm2 0.0015

Pw = 0.6 x Vz2 / 106

Horizontal Earthquake Co efficient αH - 0.08

Basic Horizontal sesmic co effiecient α0 - 0.08

15

Importance Factor I - 1

Co efficient for soil Foundation β - 1

16 Per square meter weight of chopped strand mat - 450

17 Per square meter weight of woven rowing mat - 610

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 5 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

DESIGN OF DISHED TOP

Sr. No. Description Unit Input

1 Radius of Head Ri mm 4000

2 Knuckle Radius ri mm 400

3 Height of the Dome hi mm 800

Inward Pressure Pin

4 N / mm2 0.000980681

Pin = Pv + Pe

Outward Pressure Po

5 N / mm2 0

Po = Pi + Pf ( Pf = 0 in case of top cover)

6 Weight of the personnel N 1500

7 Weight of fittings N 1500

8 Assumed no of CSM ( W csm = 450 gms / m2) Nos 17

9 Assumed no of WRM ( W wrm = 610 gms / m2) Nos 10

10 tlam= (ncsmxx Wcsm x tgcsm+ nwrm x Wwrm x tgwrm)/1000 mm 24.83

11 Xlam = (ncsm x Wcsm x Xcsm+ nwrm x Wwrm x Xwrm)/1000 N/mm 204700.00

12 Elam = Xlam / tlam N/mm2 8244.81

13 Ual = (ncsm x Wcsm x Uzcsm+ nwrm x Wwrm x Ucwrm)/1000 N/mm 358.04

14 Wlam = (ncsm x Wcsm/ Wfcsm + nwrm x Wwrm/Wfwrm) / 1000 in kg/m2 Kg/m2 38.85

Pressure Psw due to self-weight

15 N/mm2 0.0003811

Psw = 9.81 x Wlam/1000000

16 hi / Di ratio - 0.2

17 tlam / Di ratio - 0.0062

18 ri / Di ratio - 0.1

19 Shape Factor Ks from EN 13121 - 2.95

Tensile Unit Load in

20 N/mm 0

Qct = 0.5 x ( Po - Psw) x Ks x Di

Is Design acceptable?

21 - YES

Yes if Qc < Ual

Compressive Unit Load Qcc

22 N/mm 15.27

Qcc = 0.66 x ( Pin + 0.4 x Pw + Psw ) x Ks x Di

Is Design Acceptable ?

23 - YES

yes if Qcc < Ual

24 Ro = 0.5 x ( Di + 2 x tlam) x Ke - 5629

25 Ke from Fig 15 EN 13121 - 2.78

Minimum Laminate Thickness to prevent buckling

26 mm 9.33

tm = 1.7 x Ro x sqrt ( 4 x (Pin + 0.4 x Pw +Psw)/Elam)

Is Design acceptable ?

27 - YES

Yes tm < tlam

Load transmitted by cover to the shell

28 N 5748

W = 0.3 x 3.142 x Di2 x Wlam x 9.81 / 10 6

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 6 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

DESIGN OF MAIN SHELL

Sr. No. Description - - - -

1 No of shell segments ns 1 - - -

Length of Distance

Length of segment li and distance from the top hi

2 Segment each from top -

in mm

segment li hi

1 8000 8000 -

2 0 8000 -

3 0 8000 -

4 0 8000 -

5 0 8000 -

6 0 8000 -

3 Pressure due to liquid height Pf in N / mm2 Segment Pressure Pf - -

1 0.094176 - -

2 NA - -

3 NA - -

4 NA - -

5 NA - -

6 NA - -

Circumferecial unit tensile load Qct and unit

4 Segment Qct Qcc -

compressive load Qcc in N / mm

1 188.35 1.96 -

Qct = ( Pf+Pi) x Di / 2 2 NA NA -

3 NA NA -

Qcc = Pv*Di / 2 4 NA NA -

5 NA NA -

6 NA NA -

5 Assumed No of CSM and WRM Segment Appr. CSM WRM

1 7.31 17 10

2 NA - -

3 NA - -

4 NA - -

5 NA - -

6 NA - -

Laminate Thickness tlam in mm , Extensitbility

6 Segment tlam Xlam Elam

Xlam and Modulus Elam

1 24.83 204700.00 8244.81

tlam= (ncsmx Wcsm x tgcsm+ nwrmx Wwrmx tgwrm)/1000 2 NA NA NA

3 NA NA NA

Xlam = (ncsmx Wcsmx Xcsm+ nwrmx Wwrm x Xwrm)/1000 4 NA NA NA

5 NA NA NA

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 7 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Elam = Xlam / tlam 6 NA NA NA

Allowable unit load Ual and critical bucklingload Ub

7 Segment Ual Ub -

in N / mm

1 358.04 188.25 -

Ual=(ncsm x Wcsm x Ulcsm+ nwrm x Wwrm x Ulwrm)/1000 2 NA NA -

3 NA NA -

Ub= 0.6 x Xlam x tlam / (4 x (Di + 2x tlam)) 4 NA NA -

5 NA NA -

6 NA NA -

Is Design acceptable?

8 Segment Qct < Ual Qcc < Ub -

yes if Qct < Ual and Qcc < Ub

1 YES YES -

2 NA NA -

3 NA NA -

4 NA NA -

5 NA NA -

6 NA NA -

Laminate Weight Wlam in Kgs/ m2 and Self Weight

9 Segment Wlam Wsw -

of the segment Wsw in Kgs

1 39.35 3956.66 -

Wlam = ncsm x Wcsm/Wfcsm + nwrm x Wwrm/Wfwrm 2 NA NA -

3 NA NA -

Wsw = 3.142 x li x Di x Wlam/ 106 4 NA NA -

5 NA NA -

6 NA NA -

10 Load Transimitted to the shell Wt in N Segment Wt - -

Wt = load transimitted by cover + self load 1 44562.88 - -

2 NA - -

3 NA - -

4 NA - -

5 NA - -

6 NA - -

Load causing axcial bending in N /mm

11 qb = Max ( 0.7x Pwx Di , 3.142 x αH x Di2 x ρ x 9.81 11.84 - - -

/ 4/ 106)

Unit Axcial Compressive load Qac and Unit Axcial

12 Segment M Qac Qat

Tensile Load Qat in N /mm

1 378753270 5.507 30.136

M = qb x li2 / 2 2 NA NA NA

3 NA NA NA

Qac = Pv x Di / 4 + Wt / 3.142 / Di 4 NA NA NA

5 NA NA NA

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 8 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Qat = Pi x Di / 4 - Wt / 3.142 / Di + 4 x M / 3.142 / Di2 6 NA NA NA

Is design acceptable?

13 Segment Qat < Ual Qac < Ub -

yes if Qat < Ual and Qac < Ub

1 YES YES -

2 NA NA -

3 NA NA -

4 NA NA -

5 NA NA -

6 NA NA -

14 X min 204700.00 - - -

15 tmin 24.83 - - -

Effective Length Le in mm

16 Segment Le - -

le = li x (Xmin/Xlam) x (tmin/tlam)1.5

1 8000.00 - -

2 NA - -

3 NA - -

4 NA - -

5 NA - -

6 NA - -

Total Effective Length in mm

17 8000.00 - - -

L = sum of Le

18 Do = Di + 2 x tmin 4049.66 - - -

19 S = Le/Do 1.9755 - - -

0.17

20 q = 1.35 x (Emin/4/Po) 14.1721 - - -

tm = Do(4 x Po/2/Elam)0.33 if (S>=q) ( EN 13121 -

21 14.59 - - -

Eq. - 15)

Is ring stiffner required?

22 NO - - -

yes if tm > tmin

RING STIFFNER DESIGN

23 Assumed no of CSM 5 - - -

24 Assumed no of WRM 3 - - -

25 ts= (ncsm x Wcsm x tgcsm+ nwrm x Wwrm x tgwrm)/1000 7.35 - - -

26 Xs = (ncsm x Wcsm x Xcsm+ nwrm x Wwrm x Xwrm)/1000 60780 - - -

27 Es = X s / t s 8270.62 - - -

28 Us = (ncsm x Wcsm x Ucsm+ nwrm x Wwrm x Uwrm)/1000 106.31 - - -

29 Assume width of stiffener bs 150 - - -

30 Assume height of stiffener hs 150 - - -

31 Effective flange width bf = 0.75*sqrt( tmin* Do) 237.81 - - -

Area of stiffeners As in mm2

32 9211.41 - - -

As = Ws x tlam + 2 x hs x ts + bs x ts

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 9 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Moment of area MOA

33 MOA = Ws x tlam2 / 2 + hs*x ts/(hs/2+tlam)+bs x 568778.06 - - -

ts x (hs+tlam+ts/2)

Distance of centre of MOA y

34 61.75 - - -

y = MOA / As

Moment of inertia Is

Is = Ws x tlam3/12 + 2 x ts x hs3/12 +bs x ts3/12 +

35 52062571.82 - - -

Ws x tlam x (y-tlam/12)2+ 2 x hs x ts x (hs/2 + tlam

- y)2 + bs x ts x ( tlam +hs + ts -y)2

36 Ds = Do + 2 x y 4173.15 - - -

Bending parameter Ip

37 25013197.61 - - -

Ip = 0.18 x Do x L x Ds2 x Pb / Elam

Is design acceptable?

38 YES - - -

yes if I > Ip

Maximu permitted Height between stiffeners

39 mm 24757.42 - -

Hp= Xmin x tmin 1.5/ ( 0.4 x F x p x Do^1.5)

40 He/Hp - 0.32 - -

41 No of Stiffeners required - 0 - -

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 10 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

DESIGN OF FLAT BOTTOM COVER

Note: If there is vacuum or internal pressure causing bending then only it is required to design bottom cover

separately. In case of fully supported flat bottom (no vacuum / internal pressure) will have same laminate

structure as that of the bottom shell segment

Sr. No. Description Unit Input

1 Liquid pressure Pf (0 because not causing bending) N/mm2 0

Outward pressure Po

2 N/mm2 0

Po = Pf + Pi

Inward pressure Pin

3 N/mm2 0.000980681

Pin = Pv + Pe

Max design pressure Pd in N / mm2

4 N/mm2 0.000980681

Pd = Max ( Po,Pin)

Bending moment assuming fixed edges

5 N mm/mm 490.34

Mc = 0.03125 x Pd x Di2

6 Assumed no of CSM Nos. 17

7 Assumed no of WRM Nos. 10

8 tlam= (ncsm*Wcsm*tgcsm+ nwrm*Wwrm*tgwrm)/1000 mm 24.83

9 Xlam = (ncsm*Wcsm*Xcsm+ nwrm*Wwrm*Xwrm)/1000 N/mm 204700

10 Elam = Xlam / tlam N/mm2 8244.81

11 Ual = (ncsm*Wcsm*Ucsm+ nwrm*Wwrm*Uwrm)/1000 N/mm 358.04

12 Wlam = ncsm*Wcsm/Wfcsm + nwrm*Wwrm/Wfwrm N 35.15

Minimum Laminate Thickness to prevent buckling

13 mm 21.57

tm = (0.01066 x Pd x Di4 / 1.5*Elam ) 0.25

Is Design acceptable ?

14 - YES

Yes tm < tlam

15 Allowable bending moment, Mal N-mm/mm 500.00

16 Is design acceptable? ( yes if Mc <= Mal) -- YES

Conclution : Structural Thickness of Dished Top (mm): 25.00

Structural Thickness of Cylindrical Shell (mm): 25.00

Structural Thickness of Dished Bottom (mm): 25.00

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 11 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

276TK1A/B/C/D/E/F/G/H/I/J/K/L/M/N/O - HYDROCHLORIC

ACID STORAGE TANK

SECTION 3

FINITE ELEMENT METHOD ANALYSIS REPORT

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 12 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Simulation of 100 KL

TANK 4000 DIA x

HEIGHT 8000

Date: 03 February 2023

Designer: Mayank Chauhan

Study name: Static 1

Analysis type: Static

Table of Contents

Description ..................................................... 13

Model Information ......................................... 14

Study Properties ............................................ 15

Units ............................................................... 16

Material Properties ........................................ 16

Description

Loads and Fixtures ......................................... 17

FEM Analysis of 100 KL Tank 4000 Dia x Height 8000

Mesh information .......................................... 18

Resultant Forces............................................. 19

Study Results .................................................. 20

Conclusion ...................................................... 23

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 13 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Model Information

Model name: 100 KL TANK 4000 DIA x HEIGHT 8000

Current Configuration: Default

Solid Bodies

Document Name and Document Path/Date

Treated As Volumetric Properties

Reference Modified

Revolve2

Mass:6,712.49 kg

Volume:4.33064 m^3

Solid Body Density:1,550 kg/m^3 -

Weight:65,782.4 N

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 14 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Study Properties

Study name Static 1

Analysis type Static

Mesh type Solid Mesh

Thermal Effect: On

Thermal option Include temperature loads

Zero strain temperature 298 Kelvin

Include fluid pressure effects from SOLIDWORKS Off

Flow Simulation

Solver type Automatic

Inplane Effect: Off

Soft Spring: Off

Inertial Relief: Off

Incompatible bonding options Automatic

Large displacement Off

Compute free body forces On

Friction Off

Use Adaptive Method: Off

Result folder SOLIDWORKS document (D:\SH ENGITECH\22423

- INDORAMA\100 KL TANK 4000 DIA x HEIGHT

8000)

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 15 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/mm^2 (MPa)

Material Properties

Model Reference Properties Components

Name: FRP HAND LAY SolidBody 1(Revolve2)(100 KL TANK

UP 4000 DIA x HEIGHT 8000)

Model type: Linear Elastic

Isotropic

Default failure Unknown

criterion:

Yield strength: 20.6 N/mm^2

Tensile strength: 103 N/mm^2

Compressive 375.7 N/mm^2

strength:

Elastic modulus: 10,342 N/mm^2

Poisson's ratio: 0.3

Mass density: 1.55 g/cm^3

Shear modulus: 3,300 N/mm^2

Curve Data:N/A

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 16 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Loads and Fixtures

Fixture name Fixture Image Fixture Details

Entities: 3 face(s)

Type: Fixed Geometry

Fixed-1

Resultant Forces

Components X Y Z Resultant

Reaction force(N) 35.3032 60.0986 -27.1915 74.8167

Reaction Moment(N.m) 0 0 0 0

Load name Load Image Load Details

Entities: 5 face(s)

Type: Normal to selected face

Value: -0.00098

0.01 bar

Units: N/mm^2 (MPa)

Vacuum Phase Angle: 0

Units: deg

Entities: 5 face(s)

Type: Normal to selected face

Value: 0.0942

STATIC HEAD Units: N/mm^2 (MPa)

Phase Angle: 0

Units: deg

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 17 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Mesh information

Mesh type Solid Mesh

Mesher Used: Curvature-based mesh

Jacobian points for High quality mesh 16 Points

Maximum element size 74.1711 mm

Minimum element size 74.1711 mm

Mesh Quality High

Mesh information - Details

Total Nodes 359450

Total Elements 180811

Maximum Aspect Ratio 8.6078

% of elements with Aspect Ratio < 3 79.7

Percentage of elements with Aspect Ratio > 10 0

Percentage of distorted elements 0

Time to complete mesh(hh;mm;ss): 00:00:18

Computer name:

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 18 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Resultant Forces

Reaction forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N 35.3032 60.0986 -27.1915 74.8167

Reaction Moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 0

Free body forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N 4,171.12 -1,691.17 -4,419.37 6,307.86

Free body moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 1e-33

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 19 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Study Results

Name Type Min Max

Stress1 VON: von Mises Stress 0.029N/mm^2 (MPa) 18.752N/mm^2 (MPa)

Node: 161315 Node: 124831

100 KL TANK 4000 DIA x HEIGHT 8000-Static 1-Stress-Stress1

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 20 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Name Type Min Max

Displacement1 URES: Resultant Displacement 0.000mm 7.494mm

Node: 1178 Node: 31841

100 KL TANK 4000 DIA x HEIGHT 8000-Static 1-Displacement-Displacement1

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 21 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Name Type Min Max

Strain1 ESTRN: Equivalent Strain 0.000 0.001

Element: 26862 Element: 83037

100 KL TANK 4000 DIA x HEIGHT 8000-Static 1-Strain-Strain1

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 22 of 23

An ISO 9001:2015 Company

CIN: U29100GJ2019PTC108748 www.shengitech.com

Head Office & Manufacturing Facility Sales Office Product Development Center

Plot No. 168, 169, 174, 175, Radha Madhav Eco Office No. 12, 2nd floor, GNP Arcadia, opp. Plot No. 4611, Plastic Zone, GIDC Sarigam,

Industrial Park, NH 56, Vapi, Pendharkar college, Dombivli (East) Bhilad West, Valsad - 396155,

Valsad - 396191, Gujarat, India. Thane - 421203, Maharashtra, India. Gujarat, India.

📞 +91- 903379 8866 / +91 - 903379 8877 📞 +91-903379 8872 / 903379 8874 📞 +91-903379 8870 / +91-903379 8875

📧 info@shengitech.com 📧 sales.bom@shengitech.com 📧 rd@shengitech.com

Conclusion

Stress Conditions:

Maximum Stress: 18.752 N/mm^2 (MPa) at Node: 124831

Tensile Strength of Material: 103 N/mm^2

Factor Of Safety: 5

Allowable Stress = Strength/FOS = 103/5 = 20.6 N/mm^2

Conclusion: Maximum Stress is Less Than Allowable Stress Hence, Result is Pass in Stress Conditions.

Displacement Conditions:

Maximum Displacement: 7.494 mm at Node: 31841

Allowable Displacement: ≤ 2%D (As per EN-13121 Figure 67 — Dimension tolerances for tanks or vessels)

Allowable Displacement: ≤ 2% x 2200 = 44 mm

Conclusion: Maximum Displacement is Less Than Allowable Displacement Hence, Result is Pass in

Displacement Conditions.

Strain Conditions:

Maximum Strain: 0.001 at Element: 83037

Allowable Strain: 0.1 (As per EN-13121 8.2.3 Limit Strain for Laminate)

Conclusion: Maximum Displacement is Less Than Allowable Displacement Hence, Result is Pass in Strain

Conditions.

Concluded Thickness:

Torispherical Top Thickness: 25 mm

Shell Thickness: 25 mm

Flat Bottom Thickness: 25 mm

Confidentiality

This document contains confidential and legally privileged information that is intended only for the intended recipient. Any disclosure, copying, distribution or reliance upon

the contents of this document is solely used at the discretion of S.H. ENGITECH PVT LTD authorized personnel.

Copyright © S.H. ENGITECH PVT LTD 2022 Page 23 of 23

You might also like

- Solutions Manual Brief Course in Mathematical Statistics 1st Edition TanisDocument3 pagesSolutions Manual Brief Course in Mathematical Statistics 1st Edition Tanisstephensimon3297No ratings yet

- Examen FinalDocument16 pagesExamen FinalMario MerinoNo ratings yet

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDocument23 pagesFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidNo ratings yet

- Dentsply GAC - CatalogDocument336 pagesDentsply GAC - Catalogsorc50% (2)

- Degalan 64/12 N: Binder For Concrete Coatings and Metal CoatingsDocument2 pagesDegalan 64/12 N: Binder For Concrete Coatings and Metal Coatingssriatul2006No ratings yet

- INSPECTION Procedure For GalvanizingDocument14 pagesINSPECTION Procedure For Galvanizingjasminnee100% (1)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- TDS047-02 (GT-F-09C SUMPRO) New StandardDocument7 pagesTDS047-02 (GT-F-09C SUMPRO) New Standardprismatama.kreasindoNo ratings yet

- TDS462-14 (PI6 (5) GY SUMPRO) New StandardDocument6 pagesTDS462-14 (PI6 (5) GY SUMPRO) New Standardprismatama.kreasindoNo ratings yet

- Orion WB2 Propeller Polishing ReportDocument5 pagesOrion WB2 Propeller Polishing Reportjoel jeffery SarkarNo ratings yet

- EnglishDocument57 pagesEnglishnivasssvNo ratings yet

- International GTA220: Thinners & SolventsDocument2 pagesInternational GTA220: Thinners & SolventsAndri AjaNo ratings yet

- Docking Report of Orion wb2Document7 pagesDocking Report of Orion wb2joel jeffery SarkarNo ratings yet

- Kester 977 Soldering Flux en 17feb21 TBDocument4 pagesKester 977 Soldering Flux en 17feb21 TBhugoavchavezNo ratings yet

- Test 123Document11 pagesTest 123herlinaNo ratings yet

- Company Profile Piling PipeDocument52 pagesCompany Profile Piling PipeMargaretta WijayantiNo ratings yet

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDocument23 pagesFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidNo ratings yet

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDocument23 pagesFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidNo ratings yet

- C2C Case StudyDocument6 pagesC2C Case StudyMathan FlufyNo ratings yet

- TDS587-17-P (PL6 BK) - SUMPRO New Standard WaDocument5 pagesTDS587-17-P (PL6 BK) - SUMPRO New Standard Waprismatama.kreasindoNo ratings yet

- Jushi-Glass Fiber-MSDSDocument9 pagesJushi-Glass Fiber-MSDSTarek BenNo ratings yet

- Provisional Product Data Sheet: Sumitomo PolypropyleneDocument2 pagesProvisional Product Data Sheet: Sumitomo PolypropyleneortizmauricioNo ratings yet

- Company Profile: PT Mitra Agung SejatiDocument12 pagesCompany Profile: PT Mitra Agung SejatiDimas Theo PNo ratings yet

- PG770Document2 pagesPG770akankshas06No ratings yet

- GL-ST-500WA Data SheetDocument3 pagesGL-ST-500WA Data SheetAntónio RamosNo ratings yet

- SOFTAK1637Document3 pagesSOFTAK1637Marco JuarezNo ratings yet

- Copy Training Report 2Document21 pagesCopy Training Report 2sachinsinghal199270% (10)

- It - 100 20c TdsDocument2 pagesIt - 100 20c TdsNagaraju PanguluriNo ratings yet

- TDI Alcomer 80 Vers 10 2015Document2 pagesTDI Alcomer 80 Vers 10 2015PrototypeNo ratings yet

- Alsons PresentationDocument19 pagesAlsons PresentationAditya VuthaNo ratings yet

- A Project Report Unsaturated Polyester Resin at Daman: Technologies Technical Know-How - A Gateway To ProsperityDocument49 pagesA Project Report Unsaturated Polyester Resin at Daman: Technologies Technical Know-How - A Gateway To Prosperityrajesh kothariNo ratings yet

- Project Report - SunriseDocument15 pagesProject Report - SunriserajuNo ratings yet

- Tds Britex-95 inDocument1 pageTds Britex-95 inLaboratorio Inkctech0% (1)

- Jushi MSDSDocument12 pagesJushi MSDSOlaniyan SamsonNo ratings yet

- TDS - 985M Soldering FluxDocument2 pagesTDS - 985M Soldering FluxChoice OrganoNo ratings yet

- Cristal 121 - FinalDocument1 pageCristal 121 - FinalSajukurian7No ratings yet

- Mantash Quatation PDFDocument4 pagesMantash Quatation PDFshoaib khanNo ratings yet

- TDS Polyvest MA 75Document3 pagesTDS Polyvest MA 75Fairmont Ind Quality DivisionNo ratings yet

- Company Profile WQCDocument5 pagesCompany Profile WQCharigroupphilippinesNo ratings yet

- Portable Economical Conductivity MeterDocument4 pagesPortable Economical Conductivity Metersaurabh_acmasNo ratings yet

- Company Profile of ROKEE+BREE Lighting-2021Document78 pagesCompany Profile of ROKEE+BREE Lighting-2021Yu AmandaNo ratings yet

- SBN Corp Profile - 2 PDFDocument33 pagesSBN Corp Profile - 2 PDFSyafiq KamaluddinNo ratings yet

- Gypsum RatioDocument3 pagesGypsum RatioAthena MontefalcoNo ratings yet

- Summer Training ReportDocument44 pagesSummer Training ReportMayank GargNo ratings yet

- News Letter April 18Document16 pagesNews Letter April 18HamzaNoumanNo ratings yet

- Mosil Sam - 2825: Heavy Duty GreaseDocument2 pagesMosil Sam - 2825: Heavy Duty GreaseUdit JainNo ratings yet

- Mar Painting 2Document24 pagesMar Painting 2Teguh IndrawanNo ratings yet

- Product Data Sheet AV161 ASTM 20130121Document2 pagesProduct Data Sheet AV161 ASTM 20130121Yuli NugraheniNo ratings yet

- Calguard Anti-Spatter Spray TDS enDocument2 pagesCalguard Anti-Spatter Spray TDS enJeremy OngNo ratings yet

- Litech Company Profile 2020Document12 pagesLitech Company Profile 2020Ven KabNo ratings yet

- Sinopec Super Grease NLGI 2Document2 pagesSinopec Super Grease NLGI 2Yoong TanNo ratings yet

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- Gasket Remover (DS) 125-03017Document2 pagesGasket Remover (DS) 125-03017Teguh RiswantoNo ratings yet

- Protank T11 Chemical TanksDocument4 pagesProtank T11 Chemical TanksMariana HusainNo ratings yet

- Spectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Document6 pagesSpectro Lab Surface Burring Report - D201003041 - 1 - N35287 - F D201003041 1RST13207221020014741Dtl DiagNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- 2015 Shurjoint General Catalog v3Document217 pages2015 Shurjoint General Catalog v3Jesus Javier100% (1)

- ADD: 2 #18 Building Xihainan RD Liwan District Guangzhou China Tel:+86 2034097637Document18 pagesADD: 2 #18 Building Xihainan RD Liwan District Guangzhou China Tel:+86 2034097637raulNo ratings yet

- 186 Soldering Flux: Mildly Activated Rosin Liquid FluxDocument4 pages186 Soldering Flux: Mildly Activated Rosin Liquid FluxAmirNo ratings yet

- E-010814-A-Wuxi Deep-091019Document7 pagesE-010814-A-Wuxi Deep-091019PT. Sahabat Karib IndonesiaNo ratings yet

- TDS PP 500 Bi5.0ga 02Document2 pagesTDS PP 500 Bi5.0ga 02Adrianto GNo ratings yet

- Math 11 - Stat Prob - Q3Wk 1 2 Key.v. 02282021Document17 pagesMath 11 - Stat Prob - Q3Wk 1 2 Key.v. 02282021Cynthia LiaresNo ratings yet

- Uc Boyutlu Baglanma Stilleri Olcegi ToadDocument21 pagesUc Boyutlu Baglanma Stilleri Olcegi Toad4sq8vnbsv2No ratings yet

- 22ESC141 - SyllabusDocument4 pages22ESC141 - SyllabusW03 AKASHNo ratings yet

- MSDS - RacuminDocument6 pagesMSDS - RacuminRizka NataashaNo ratings yet

- Guided Writing (Informal Letter)Document11 pagesGuided Writing (Informal Letter)gnolaz100% (1)

- 3MS - All Sequences 1-2-3 in One - by Teacher Precious Rose 2018Document62 pages3MS - All Sequences 1-2-3 in One - by Teacher Precious Rose 2018Maman Randa Et AzizNo ratings yet

- RCPA Strategic PlanDocument16 pagesRCPA Strategic PlanAleka SevilleNo ratings yet

- K550X Sputter Coater Instruction ManualDocument32 pagesK550X Sputter Coater Instruction ManualCHARLES MICHAEL ALBERT -No ratings yet

- English - Academic Cultur of Universitas AirlanggaDocument27 pagesEnglish - Academic Cultur of Universitas AirlanggaImalinda RadyanisaNo ratings yet

- Policy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21Document9 pagesPolicy Brief 16 - Internal Migration in China-Integrating Migration With Urbanization Policies and Hukou Reform-Nov 21oreoolepNo ratings yet

- Criteria For Good Research-9Document19 pagesCriteria For Good Research-9vinnu kalyanNo ratings yet

- Travel Africa EditionDocument166 pagesTravel Africa EditionLuis Falcão100% (1)

- PythonDocument4 pagesPythonTrinh Tan Quang Bao K17 DNNo ratings yet

- Sadomasochism Accor Sadomasochism According To Freud's Psychosexual Stages of Chosexual Stages of Development TheoryDocument10 pagesSadomasochism Accor Sadomasochism According To Freud's Psychosexual Stages of Chosexual Stages of Development TheoryDolce BbNo ratings yet

- The Inner Universe Theoryof Dark Energy InterpretationDocument17 pagesThe Inner Universe Theoryof Dark Energy InterpretationCiprian Bitca100% (1)

- Cultural Marxism in The Works of BurroughsDocument1 pageCultural Marxism in The Works of BurroughsChandrapal S BhaskerNo ratings yet

- AbstractsDocument107 pagesAbstractsAnna KorompeliNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/04 February/March 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/04 February/March 2022jesuNo ratings yet

- DUAL ZONE System Reduces False Alarms, Making Outdoor Use More Reliable !Document2 pagesDUAL ZONE System Reduces False Alarms, Making Outdoor Use More Reliable !mcombaleNo ratings yet

- Option d1 PagesDocument9 pagesOption d1 PagesMohammad SuliemanNo ratings yet

- Schaffer HouseDocument39 pagesSchaffer HouseFrancisca CerdaNo ratings yet

- Sheeting Structure Verification Input DataDocument35 pagesSheeting Structure Verification Input DataanonimusazNo ratings yet

- Animal Behavior: Notes by Ali RashdiDocument8 pagesAnimal Behavior: Notes by Ali Rashdinatasha RajperNo ratings yet

- (5.3) Shear and Moment in BeamsDocument62 pages(5.3) Shear and Moment in BeamsIan Arnold FamiNo ratings yet

- Method For Producing Isopropanol by Acetone Hydrogenation: Download PDF Find Prior Art SimilarDocument8 pagesMethod For Producing Isopropanol by Acetone Hydrogenation: Download PDF Find Prior Art SimilaracetilenaNo ratings yet

- BEEE Unit 1.3Document16 pagesBEEE Unit 1.3senthil kumar rasappanNo ratings yet

- OOP ReviewDocument23 pagesOOP ReviewDuy AnhNo ratings yet

- Isaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4Document6 pagesIsaac Thomas - Introduction - Advocate (INFJ) Personality - 16personalities - B4isaacNo ratings yet