Professional Documents

Culture Documents

Qa10 Pi PC 200-8 (Lower Area)

Qa10 Pi PC 200-8 (Lower Area)

Uploaded by

ahlan robianorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qa10 Pi PC 200-8 (Lower Area)

Qa10 Pi PC 200-8 (Lower Area)

Uploaded by

ahlan robianorCopyright:

Available Formats

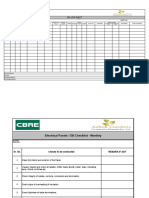

Form No.

PC200-8/3465/00/QA10/13

DAILY INSPECTION SHEET

WO/JO NO.

QA 10 MAINTENANCE SHEET PC 200-8

Date

Zone 2 : lower Rear Area Code Unit

S/N Unit

SMR

Location

Inspection time start : Time finish :

Condition Note Priority

G Good Condition 1 Leaking 5 Worn 1 Action now

B Bad Condition 2 Broken 6 Crack 2 Action at change shift

U Unchecked 3 Missing 7 Others 3 Action on next PS

4 Loose 4 Action on schedule backlog

Beri tanda (V) pada kolom sesuai dengan kondisi

Pada kolom foto cantumkan nomor image yang sesuai dengan kondisi

Condition Note Priority

No Description Remark Foto

G B U 1 2 3 4 5 6 7 1 2 3 4

A. Bucket Area

1 Bucket

2 Link Bucket

3 Teeth Bucket

5 Pin Bucket

7 Hose Grease Pin

B. Cylinder Attachment Area

1 Boom Cylinder RH

2 Boom Cylinder LH

3 Bucket Cylinder

4 Arm Cylinder

C. Working Attachment Area

1 Boom Attachment

2 Arm Attachment

3 LH lock pin boom pivot

4 RH lock pin boom pivot

D.Central Frame Area

1 Tighten Frame Std :

2 Tube and nipple grease

3 Swivel Joint

4 Swing motor

5 Swing Machinery

6 Level Swing Machinery Low : Med : High :

7 Swing Circle

E. Control valve Area

1 Control Valve

2 Related Hose of C/V

3 Electric Sensor & Wiring Condition

4 Piping around control valve

F. Track Group Area

1 Track Frame RH

2 Idler RH

3 Tension of Track RH

4 Track Roller RH

5 Carrier Roller RH

6 Track Shoe RH

7 Shoe Bolt RH

8 Track Link RH

9 Sprocket RH

10 Travel Motor RH

11 Level Final drive RH Low : Med : High :

12 Cover RH

13 Track Frame LH

14 Idler LH

15 Tension of Track LH

16 Track Roller LH

17 Carrier Roller LH

18 Track Shoe LH

19 Shoe Bolt LH

20 Track Link LH

21 Sprocket LH

22 Travel Motor LH

23 Level Final drive LH Low : Med : High :

24 Cover LH

No Additional of Fluid (Oil,Coolant,Grease ) Quantity ( Liter )

1

2

3

4

5

Operator Name : Signature Mechanic Name Supervisor Name

Comment : Signature : Signature :

Sign Date : Sign Date :

You might also like

- Electrical Machines Drives and Power Systems PDFDocument907 pagesElectrical Machines Drives and Power Systems PDFSami Boukhris100% (2)

- Flange Management ReportDocument2 pagesFlange Management ReportMark Darrel Aranas100% (1)

- Sony KP Fx432m91Document220 pagesSony KP Fx432m91Iftikhar DaniNo ratings yet

- ENDURANCE Price List WITH MRP & HSN-18-APRIL-2018Document54 pagesENDURANCE Price List WITH MRP & HSN-18-APRIL-2018Shreyansh Doshi80% (5)

- Inspection Sheet ExcavatorDocument3 pagesInspection Sheet Excavatormonarch 69No ratings yet

- QA10 PI HD 785-7 (Left Area)Document2 pagesQA10 PI HD 785-7 (Left Area)ahlan robianorNo ratings yet

- QA10 PI HD 785-7 (Front & Upper Area)Document1 pageQA10 PI HD 785-7 (Front & Upper Area)ahlan robianorNo ratings yet

- Daily Check Sheet SCANIA P/F/K/N Series: Beri Tanda (V) Pada Kolom Sesuai Dengan Aktual KondisiDocument5 pagesDaily Check Sheet SCANIA P/F/K/N Series: Beri Tanda (V) Pada Kolom Sesuai Dengan Aktual KondisiOlab BolaNo ratings yet

- WK 32 Geom Report - 001Document2 pagesWK 32 Geom Report - 001Midhunkumar KsNo ratings yet

- Jurnal Harian RefrigerasiDocument1 pageJurnal Harian RefrigerasiAgus WibowoNo ratings yet

- Layout Inspection Report: I.Performance Inspection ParametersDocument3 pagesLayout Inspection Report: I.Performance Inspection ParametersPearlsgodNo ratings yet

- PM Clinic Excavator PDFDocument3 pagesPM Clinic Excavator PDFjheison valencia100% (1)

- 7b.head Truck 02 Checklist WeeklyDocument2 pages7b.head Truck 02 Checklist WeeklyAndroidNo ratings yet

- Condition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Document6 pagesCondition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Shandi Hasnul FarizalNo ratings yet

- Test Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Document3 pagesTest Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Ranil KanchanaNo ratings yet

- Die Dynamic Buyoff Check Sheet For Non Air Cushion DiesDocument2 pagesDie Dynamic Buyoff Check Sheet For Non Air Cushion DiesTarang ShandilyaNo ratings yet

- List of QC Inspection Form For Mechanical: Tanjung Jati B, Boiler of BopDocument34 pagesList of QC Inspection Form For Mechanical: Tanjung Jati B, Boiler of BopAlif Rahmat FebriantoNo ratings yet

- Coil 2 Piece T U: o - Ljaccn-WcDocument3 pagesCoil 2 Piece T U: o - Ljaccn-WcsselhbbplNo ratings yet

- ITR-MFH (Fired Heater)Document30 pagesITR-MFH (Fired Heater)mahmoudNo ratings yet

- Form PM CheckDocument8 pagesForm PM CheckAsisten Workshop100% (1)

- Function Check List - ChillerDocument2 pagesFunction Check List - ChillerĐường Vinh ToànNo ratings yet

- Mobile Crane Maintenance ChecklistDocument2 pagesMobile Crane Maintenance ChecklistAbdul Halim100% (1)

- Woosu PTC & PMCDocument15 pagesWoosu PTC & PMCMani VannanNo ratings yet

- Master SampleDocument14 pagesMaster SampleAnonymous fkOdcsW9MUNo ratings yet

- Qa10 RF Pc210-10mo (5320)Document1 pageQa10 RF Pc210-10mo (5320)daffaprastiadwiputeraNo ratings yet

- Circuit Breaker - For SwitchayrdDocument9 pagesCircuit Breaker - For SwitchayrdSindhuKumarNo ratings yet

- 51Q-BU-0010 - Rev.1 Plaster Works ChecklistDocument1 page51Q-BU-0010 - Rev.1 Plaster Works Checklistnazim7No ratings yet

- V 2155 508 A 600 - 0 - ITP - CodeBDocument13 pagesV 2155 508 A 600 - 0 - ITP - CodeBHanh BuiminhNo ratings yet

- Transformer Failure DetailsDocument6 pagesTransformer Failure DetailsSantosh BagadeNo ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Oil CentrifugeDocument2 pagesOil CentrifugeMuttappa T JainapurNo ratings yet

- Checklist - Ashok GardenDocument27 pagesChecklist - Ashok GardenmayurchaturNo ratings yet

- JICS TemplateDocument2 pagesJICS TemplateMohd Effiezool YaserNo ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoudNo ratings yet

- Ge 745Document8 pagesGe 745nathansri93No ratings yet

- Pda Mechatro - Handbook 070226Document40 pagesPda Mechatro - Handbook 070226Paul Galvez100% (6)

- TA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753TDocument22 pagesTA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753Tahmed el sayedNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type Tractor (Oval Track)Document8 pagesTA1 Visual Inspection Form Master - Track-Type Tractor (Oval Track)CarlosNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type Tractor (Hydrostatic)Document8 pagesTA1 Visual Inspection Form Master - Track-Type Tractor (Hydrostatic)CarlosNo ratings yet

- Customer Engineering ApprovalDocument28 pagesCustomer Engineering Approvalgagandeep isherNo ratings yet

- Log Sheet GENSET (Status)Document5 pagesLog Sheet GENSET (Status)Muhamad ArlanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- DT ManDocument12 pagesDT MankkmechNo ratings yet

- Mark Andy 2200 PM Evaluation Checklist General InformationDocument14 pagesMark Andy 2200 PM Evaluation Checklist General InformationEdwin PerezNo ratings yet

- Cerato 1.6 2010 - Transmissão A4CF1 - EspecificaçõesDocument3 pagesCerato 1.6 2010 - Transmissão A4CF1 - EspecificaçõesWiterMarcosNo ratings yet

- Field Service Report: Claim Warranty StandardDocument4 pagesField Service Report: Claim Warranty StandardEkoSusetiyoNo ratings yet

- Daily Mould Check SheetDocument1 pageDaily Mould Check SheetAvijit DeyNo ratings yet

- Chapter 03Document49 pagesChapter 03Ubeimar Rivera Ospina100% (1)

- Form Inspeksi Bored PileDocument6 pagesForm Inspeksi Bored PileBorneo ChannelNo ratings yet

- Chapter 03 Machine FamiliarizationDocument57 pagesChapter 03 Machine FamiliarizationUbeimar RiveraNo ratings yet

- Chapter 03 CompleteDocument80 pagesChapter 03 CompleteUbeimar Rivera OspinaNo ratings yet

- Transformer Test Report: Transformers Technical Data Field Service RepresentiveDocument14 pagesTransformer Test Report: Transformers Technical Data Field Service RepresentiveAldhi PriambudiNo ratings yet

- Check SheetsDocument31 pagesCheck SheetsAmali LakmaliNo ratings yet

- Micom p841 - Ar Synchro-CheckDocument8 pagesMicom p841 - Ar Synchro-ChecksaiNo ratings yet

- Installation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListDocument1 pageInstallation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListZulfequar R. Ali Khan100% (1)

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Comp 10 6 X 7 Phe7 Ba2Document2 pagesComp 10 6 X 7 Phe7 Ba2Ravi KantNo ratings yet

- 360 BP'MCV, ReceivingDocument2 pages360 BP'MCV, ReceivingAimHighNo ratings yet

- Inspection Pirate P V Insp Report Check List 2008 11 15Document3 pagesInspection Pirate P V Insp Report Check List 2008 11 15api-26988647No ratings yet

- Parker Pneumatic Sensors PDFDocument25 pagesParker Pneumatic Sensors PDFyouri59490No ratings yet

- Highh Mast LightingDocument6 pagesHighh Mast LightingAsghar KhanNo ratings yet

- Accord 1998 Auto Tranny DiagramDocument12 pagesAccord 1998 Auto Tranny Diagramzeolite1100% (13)

- Container Substation: Safe Reliable CompactDocument2 pagesContainer Substation: Safe Reliable CompactjipunNo ratings yet

- Iss6 - Control Cylinder - ASSISTOR SPRINGDocument8 pagesIss6 - Control Cylinder - ASSISTOR SPRINGLuisaNo ratings yet

- 45relay Rm4uaDocument1 page45relay Rm4uapedrovicentexNo ratings yet

- Metal Detector Mci RevisedDocument9 pagesMetal Detector Mci RevisedGourishankar Mahapatra100% (1)

- EFC ActuatorDocument4 pagesEFC ActuatorRonald BoocNo ratings yet

- D11RDocument24 pagesD11RFulkan HadiyanNo ratings yet

- Conductors and InsulatorsDocument9 pagesConductors and Insulatorsaashi bhardwajNo ratings yet

- DLP ProjectorDocument24 pagesDLP ProjectordanyNo ratings yet

- Coach Bus: Family Name Design / System FunctionDocument48 pagesCoach Bus: Family Name Design / System FunctionHariNo ratings yet

- 6GK50042BF001AB2 Datasheet enDocument2 pages6GK50042BF001AB2 Datasheet enPeterNo ratings yet

- Seecion 2 PDFDocument10 pagesSeecion 2 PDFfiguev2208No ratings yet

- Rs 3 Sportback-A1mdsnfvDocument11 pagesRs 3 Sportback-A1mdsnfvMotswadisi Abram NoeNo ratings yet

- Datasheet 3A 150Khz 40V Buck DC To DC Converter Xl1507 Features General DescriptionDocument12 pagesDatasheet 3A 150Khz 40V Buck DC To DC Converter Xl1507 Features General DescriptionJulio Rafael GamboaNo ratings yet

- Proximity Switch (FO Venting) 106406 - EngDocument4 pagesProximity Switch (FO Venting) 106406 - EngfarisazharuNo ratings yet

- Synchronous Drive InstallationDocument4 pagesSynchronous Drive InstallationryanmackintoshNo ratings yet

- Operation 1800 2 1Document275 pagesOperation 1800 2 1ussama abdo100% (2)

- 1 Arduino 23Document42 pages1 Arduino 23Anurag ByalaNo ratings yet

- DS19310 SM5110244 05 04 02 01Document0 pagesDS19310 SM5110244 05 04 02 01parascoliNo ratings yet

- HAGERR Protection DevicesDocument92 pagesHAGERR Protection DevicesJit JagNo ratings yet

- PMM Works, Inc: 1.-5.5Mw Wartsila Masbate Power Plant Project - UpgradeDocument5 pagesPMM Works, Inc: 1.-5.5Mw Wartsila Masbate Power Plant Project - UpgradeCharlie MendozaNo ratings yet

- Training Materials Alternator 200mw Power PlantDocument31 pagesTraining Materials Alternator 200mw Power PlantLio MessiNo ratings yet

- Test UM Product CatalogDocument28 pagesTest UM Product Catalogdonhacbang100% (1)

- SM Ricoh Af 2022 2027Document863 pagesSM Ricoh Af 2022 2027Guido Alberto Maquera QuispeNo ratings yet

- Dexretail-Capo-LED ColourDocument8 pagesDexretail-Capo-LED ColourFarag MohamedNo ratings yet