Professional Documents

Culture Documents

Performance Tasks #11

Performance Tasks #11

Uploaded by

Abinal Jhe-annOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Tasks #11

Performance Tasks #11

Uploaded by

Abinal Jhe-annCopyright:

Available Formats

Republic of the Philippines

CAMARINES SUR POLYTECHNIC COLLEGES

Nabua, Camarines Sur

Name: _______________________ Course/Year: _____________ Rating: __________

TASKSHEET No. 11 – THREE STAGE - CONVEYOR

TASKSHEET No. 9

LEARNING OUTCOME:

Create, modify, connect and test basic PLC program using FX1N-20MR PLC.

LEARNING ACTIVITY:

Basic programming of FX1N-20MR using ladder logic diagram.

EQUIPMENT/RESOURCES:

Installed PLC components (FX1N-20MR).

Computer with installed GX Developer PLC software.

OBJECTIVE:

At the end of this activity, the students should be able to create, modify

and test basic PLC program.

PROCEDURE:

Modify your installed components according to your instructor’s by adding

additional components. Read each description of operation below then design a

ladder logic diagram to meet the conditions. Program it in PLC then test in your

installed components.

Description of Operations:

Refer to the picture shown for three stages conveyor with sensors. Design the ladder

logic diagram. The following operation shall be perform in this unit.

1. When [PB1] (X20) on the operation panel is pressed, supply command (Y7) for the

robot is turned ON if the robot is at starting point (X5). When the [PB1] (X20) is

released, supply command (Y7) is latched on until the robot returns to the starting

point (X5).

2. When Sensor (X0) detects a part, Upper conveyor forward (Y0) is set ON and Y20

on the operation panel ON and flashing (1 sec. ON/OFF).

3. When Sensor (X1) detects a part, Middle conveyor forward (Y2) is set ON and Y21

on the operation panel ON and flashing (1 sec. ON/OFF) and Upper conveyor (Y0)

and Y20 stops.

4. When Sensor (X2) detects a part, Lower conveyor forward (Y4) is set ON and Y22

on the operation panel ON and flashing (1 sec. ON/OFF). The Middle conveyor

forward (Y2) and Y22 stops.

5. When Sensor (X3) detects a part, Lower conveyor (Y4) and Y22 stops.

Prepared by: Engr. Eddie L. Cabaltera

Associate Professor V 45

College of Engineering

Republic of the Philippines

CAMARINES SUR POLYTECHNIC COLLEGES

Nabua, Camarines Sur

6. When Sensor (X3) is set ON, Supply command (Y7) for the robot is turned ON and a

new part is supplied if the robot is at Starting point (X5).

7. Pressed [PB2] (X21) will stop the operations.

Note: In this task, draw the ladder logic program on the assumption that only one part is put on

the conveyor at a time. Robot will only supply parts when the part reached the box and Sensor

(X3) is ON. Apply one direction only, do not use the reverse output Y1, Y3 and Y5.

Prepared by: Engr. Eddie L. Cabaltera

Associate Professor V 46

College of Engineering

Republic of the Philippines

CAMARINES SUR POLYTECHNIC COLLEGES

Nabua, Camarines Sur

Ladder Logic Diagram:

Prepared by: Engr. Eddie L. Cabaltera

Associate Professor V 47

College of Engineering

Republic of the Philippines

CAMARINES SUR POLYTECHNIC COLLEGES

Nabua, Camarines Sur

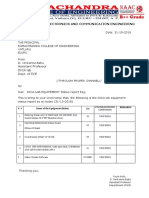

Actual Wiring Module:

PBX2

1

PBX2 Y20

1

X0 Y21

X1 Y22

X2

X3 Motor 1 Motor 2 Motor 3

Prepared by: Engr. Eddie L. Cabaltera

Associate Professor V 48

College of Engineering

You might also like

- CMC4+ Commisioning Oct 14-1Document28 pagesCMC4+ Commisioning Oct 14-1Pedro Kalvin89% (9)

- Jet Frame 625 Move Tool - ENG PDFDocument94 pagesJet Frame 625 Move Tool - ENG PDFAndrés Echavarria CárdenasNo ratings yet

- Electronics Lab Manual Volume 2 - Free PDF DownloadsDocument16 pagesElectronics Lab Manual Volume 2 - Free PDF DownloadsNidhin Mn20% (5)

- Rsearch Methods Exam QuestionsDocument82 pagesRsearch Methods Exam Questionsjohn baptesNo ratings yet

- XC4418 dataSheetMain PDFDocument1 pageXC4418 dataSheetMain PDFikiakunNo ratings yet

- Philips Plasma Panel Repair Training 2006Document97 pagesPhilips Plasma Panel Repair Training 2006kevinalleinNo ratings yet

- Lab 10 - PLC Programming: F o R M A TDocument3 pagesLab 10 - PLC Programming: F o R M A TRichard De Medeiros CastroNo ratings yet

- Elektor 1994 03 PDFDocument76 pagesElektor 1994 03 PDFsebastian maldonado0% (1)

- Lecture1 Intro Dynamics AnnotatedDocument44 pagesLecture1 Intro Dynamics AnnotatedJoseph AndrewesNo ratings yet

- Daily Site Diary 23 04 24Document3 pagesDaily Site Diary 23 04 24Victor ChirembaNo ratings yet

- ENGR2105 - Laboratory 3 - Seven Segment LED Stop Clock in Assembly and CDocument6 pagesENGR2105 - Laboratory 3 - Seven Segment LED Stop Clock in Assembly and CReeseNo ratings yet

- Department of Electronics and Communication Engineering: Assistant Professor DICA Lab Dept. of ECEDocument1 pageDepartment of Electronics and Communication Engineering: Assistant Professor DICA Lab Dept. of ECELALRAZNo ratings yet

- Laboratory Report 1 Power in Series and in Parallel CircuitsDocument5 pagesLaboratory Report 1 Power in Series and in Parallel CircuitsKen Argil GriñoNo ratings yet

- Daily Site Diary 02 05 24Document3 pagesDaily Site Diary 02 05 24Victor ChirembaNo ratings yet

- Fundamental of Robotics: Lab Report # 1Document8 pagesFundamental of Robotics: Lab Report # 1jawad naseerNo ratings yet

- LABSHEET BEKB 1131 Module AC SEM 1 2021 (B012110089)Document22 pagesLABSHEET BEKB 1131 Module AC SEM 1 2021 (B012110089)Chew Zhi HaoNo ratings yet

- DAILY SITE PROGRESS REPORT (8-Dec-2023)Document1 pageDAILY SITE PROGRESS REPORT (8-Dec-2023)Amila Srimaal GamageNo ratings yet

- Ec1019A Processor Lab: SRM UniveristyDocument70 pagesEc1019A Processor Lab: SRM UniveristyDAMA RUPESH BABUNo ratings yet

- Lift Controller: Proff. Manish K. PatelDocument26 pagesLift Controller: Proff. Manish K. PatelVaibhav KothariNo ratings yet

- Inverse Kinematics Solution of 3DOF Planar Robot Using ANFISDocument7 pagesInverse Kinematics Solution of 3DOF Planar Robot Using ANFISasasNo ratings yet

- Universal: System Simulation LabDocument55 pagesUniversal: System Simulation LabharimadhavareddyNo ratings yet

- 1425 E UniTrain R ShortDocument54 pages1425 E UniTrain R ShortAlberto MarsicoNo ratings yet

- Daily Site Progress Report (7-Dec-2023)Document1 pageDaily Site Progress Report (7-Dec-2023)Amila Srimaal GamageNo ratings yet

- Service Manual: TC-21PM30RDocument29 pagesService Manual: TC-21PM30RJose Angel TorrealbaNo ratings yet

- FPGA Implementation of Pipelined Restoring Division Algorithm.Document8 pagesFPGA Implementation of Pipelined Restoring Division Algorithm.Lijo P JoseNo ratings yet

- 11050002G4 Biplane ConfigurationDocument20 pages11050002G4 Biplane Configurationtha_ansNo ratings yet

- DAILY SITE PROGRESS REPORT (6-Dec-2023)Document1 pageDAILY SITE PROGRESS REPORT (6-Dec-2023)Amila Srimaal GamageNo ratings yet

- Smallest Radio Circuit Using Two Transistors - Engineering Projects12Document4 pagesSmallest Radio Circuit Using Two Transistors - Engineering Projects12max_orwellNo ratings yet

- AG LabDocument15 pagesAG Labsmskdevil008No ratings yet

- Analog Electronics Workbook PDFDocument43 pagesAnalog Electronics Workbook PDFGokul GNo ratings yet

- Equipment List: Assistant Electrician (CON/Q0602)Document3 pagesEquipment List: Assistant Electrician (CON/Q0602)tdlccsSTP academyNo ratings yet

- Quadcopter - PPT 231Document34 pagesQuadcopter - PPT 231Md Faiyaz Ahmed 2019RME53No ratings yet

- Mca Etc Jdcoem Lab Manual AkiDocument26 pagesMca Etc Jdcoem Lab Manual AkiAshwini MateNo ratings yet

- 777 Apfc Project Report LastDocument49 pages777 Apfc Project Report LastManimuthu K. SNo ratings yet

- Hybrid Simulation of Structural CollapseDocument26 pagesHybrid Simulation of Structural Collapseflaco_astrozaNo ratings yet

- MICOM P12x-TechnicalDataSheetDocument28 pagesMICOM P12x-TechnicalDataSheetSeba GonzálezNo ratings yet

- Sie10183 - CT - VT Tester Specification Rev09Document38 pagesSie10183 - CT - VT Tester Specification Rev09andrew.vistoNo ratings yet

- S4 RedCanDocument6 pagesS4 RedCanFranciscoCasaisNo ratings yet

- PDFDocument30 pagesPDFSyed UmerNo ratings yet

- Sequential Logic Circuits: ObjectiveDocument23 pagesSequential Logic Circuits: ObjectiveTrần TânNo ratings yet

- IQ4 Promo 2017Document2 pagesIQ4 Promo 2017rajaram shettyNo ratings yet

- 5OptiX OSN 9800 - 9600 System Hardware Introduction-20130702-BDocument35 pages5OptiX OSN 9800 - 9600 System Hardware Introduction-20130702-BJImmy CahuanaNo ratings yet

- 2ndPUC ELECTRONICS QBDocument69 pages2ndPUC ELECTRONICS QBKrupa SathishNo ratings yet

- Exp 4Document5 pagesExp 4heyejay293No ratings yet

- CMC4+ Only CommisioningDocument24 pagesCMC4+ Only CommisioningKhwaja KhanzadeNo ratings yet

- Multiplexers: Digital Logic Design LaboratoryDocument8 pagesMultiplexers: Digital Logic Design LaboratoryTrương Quang TườngNo ratings yet

- DIY Drone: DescriptionDocument3 pagesDIY Drone: Descriptionmyname isNo ratings yet

- University of Perpetual Help System Dalta: FAUSTINO, Vicente SDocument11 pagesUniversity of Perpetual Help System Dalta: FAUSTINO, Vicente SMio SuenagaNo ratings yet

- TU Series Hardware Specification: Itron SMART TFT Modules TU800X480C-RT RangeDocument16 pagesTU Series Hardware Specification: Itron SMART TFT Modules TU800X480C-RT Rangeusman sajidNo ratings yet

- Daily Site Diary 01 05 24Document3 pagesDaily Site Diary 01 05 24Victor ChirembaNo ratings yet

- Technical Specification of Power Transformer: Ministry of Electricity (MOE) Planning and Studies Office Baghdad - IRAQDocument26 pagesTechnical Specification of Power Transformer: Ministry of Electricity (MOE) Planning and Studies Office Baghdad - IRAQAMARPALNo ratings yet

- BSB Chassis IDocument4 pagesBSB Chassis IFlavin MedinaNo ratings yet

- Scientech-2261ADocument2 pagesScientech-2261Amanual imb100% (1)

- Contactless Controlled Low-Cost Robotic System: Srđan A. MilojevićDocument5 pagesContactless Controlled Low-Cost Robotic System: Srđan A. Milojevićdao trong nghiaNo ratings yet

- 13A03702 Automation & RoboticsDocument2 pages13A03702 Automation & Roboticsrammohan reddyNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- C Multiphysics: OmsolDocument98 pagesC Multiphysics: OmsolWill BenavidesNo ratings yet

- Lect - 2 - Earthquake - Resistant - Systems - Part 3Document5 pagesLect - 2 - Earthquake - Resistant - Systems - Part 3jana ShmaysemNo ratings yet

- 3D TransformationDocument73 pages3D TransformationEr RishabNo ratings yet

- Log InformationDocument2 pagesLog InformationYakov Márcio MoraisNo ratings yet

- 1-2. Unit OperationsDocument45 pages1-2. Unit OperationsIqbalMananiNo ratings yet

- 5-STP Principle and Configuration ISSUE1.00Document32 pages5-STP Principle and Configuration ISSUE1.00thato69No ratings yet

- Database Management System (DBMS) NotesDocument56 pagesDatabase Management System (DBMS) NotesVivekKhandelwalNo ratings yet

- Lab 1204Document5 pagesLab 1204Yash RajNo ratings yet

- Lab Report Marking Rubrics Phy645Document3 pagesLab Report Marking Rubrics Phy645Ridhwan RosliNo ratings yet

- For All Sanfoundry MCQ (1000+ MCQ) JOIN Telegram GroupDocument472 pagesFor All Sanfoundry MCQ (1000+ MCQ) JOIN Telegram GroupRitesh DeshmukhNo ratings yet

- 2nd Year PPT ModelDocument14 pages2nd Year PPT ModelanbuelectricalNo ratings yet

- 5 - Spiral SpringDocument2 pages5 - Spiral SpringKavindu MunasingheNo ratings yet

- Antenna Basic R&SDocument32 pagesAntenna Basic R&SKelvin AranaNo ratings yet

- (Auditing and Accounting Studies) Kristina Yankova (Auth.)-The Influence of Information Order Effects and Trait Professional Skepticism on Auditors’ Belief Revisions_ a Theoretical and Empirical AnalyDocument321 pages(Auditing and Accounting Studies) Kristina Yankova (Auth.)-The Influence of Information Order Effects and Trait Professional Skepticism on Auditors’ Belief Revisions_ a Theoretical and Empirical AnalyYahya Chiguer100% (1)

- Nano Atomic Bit ProcessingDocument296 pagesNano Atomic Bit ProcessingtrineshNo ratings yet

- Science Comprehensive Worksheet For Midterm Class 7 Ans KeyDocument8 pagesScience Comprehensive Worksheet For Midterm Class 7 Ans KeyALI ImranNo ratings yet

- C2 MatrixDocument30 pagesC2 MatrixetilawolNo ratings yet

- IR General Calibration InstructionsDocument1 pageIR General Calibration Instructionsw.ross.scott6185No ratings yet

- PH of Buffers Hydrolysed SaltsDocument27 pagesPH of Buffers Hydrolysed SaltsFmipa Khaeru NisaaNo ratings yet

- The UniverseDocument5 pagesThe UniverseAn MaNo ratings yet

- Palm Pixi Plus - How To Install Homebrew Apps - WebOS NationDocument28 pagesPalm Pixi Plus - How To Install Homebrew Apps - WebOS NationCA_KenNo ratings yet

- Reactive Power Problems and System: Submitted By:-Section: - Roll No: - SubjectDocument16 pagesReactive Power Problems and System: Submitted By:-Section: - Roll No: - SubjectShubham AgrawalNo ratings yet

- BS en 00059-2016Document14 pagesBS en 00059-2016anurag yadavNo ratings yet

- Chap 123 Final Paper N Aunt ADocument48 pagesChap 123 Final Paper N Aunt AjoannaotawayNo ratings yet

- Optimization Techniques: Amrita Vishwa VidyapeethamDocument38 pagesOptimization Techniques: Amrita Vishwa Vidyapeethamsivasrinivas venigallaNo ratings yet

- Trimdek Optima: LysaghtDocument8 pagesTrimdek Optima: Lysaghtariezz kurniawanNo ratings yet

- Paste This Code in Your Text-Editor and Save With - ExtensionDocument9 pagesPaste This Code in Your Text-Editor and Save With - Extensionaldi iskandarNo ratings yet

- Dental Materials Lecture - Mechanical PropertiesDocument27 pagesDental Materials Lecture - Mechanical PropertiesFatima SiddiquiNo ratings yet

- Automatizari Complexe - Lucrarea 1: Three - Phase Asynchronous MachineDocument1 pageAutomatizari Complexe - Lucrarea 1: Three - Phase Asynchronous MachineAlexandru AichimoaieNo ratings yet