Professional Documents

Culture Documents

LG Chem - TDS - PC1201-15 - Eng

LG Chem - TDS - PC1201-15 - Eng

Uploaded by

MamdouhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LG Chem - TDS - PC1201-15 - Eng

LG Chem - TDS - PC1201-15 - Eng

Uploaded by

MamdouhCopyright:

Available Formats

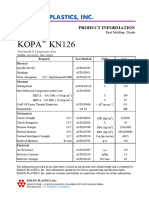

PC 1201-15

Description

It is designed for FDA related or general injection molding with high flowability and transparency.

Application Key Features

Compound, Food Packaging, Vacuum Cleaner, E&E Others, FDA, Good Mold Release, High Flow, High Transparency

Sundry Goods

Properties Method Unit PC 1201-15

Physical

Melt Flow Rate (300 °C /1.2 kg) ASTM D1238 g/10min 15

Density ASTM D792 kg/m³ 1200

Mold Shrinkage ASTM D955 ㎜/㎜ 0.005~0.007

Water Absorption @ 24 hrs, 23°C ASTM D570 % 0.15

Water Absorption @ equilibrium, 50%RH, 23°C ASTM D570 % 0.32

Optical

Refractive Index, nD ASTM D542 1.586

Light Transmittance ASTM D1003 % 89

Haze ASTM D1003 % 0.7~1.5

Thermal

Deflection Temperature Under Load (DTUL) @ 4 mm 66

ASTM D648 ℃ 143

psi (0.45 MPa), annealed

Deflection Temperature Under Load (DTUL) @ 4 mm

ASTM D648 ℃ 140

264 psi (1.8 MPa), annealed

Deflection Temperature Under Load (DTUL) @ 4 mm

ASTM D648 ℃ 127

264 psi (1.8 MPa), unannealed

Vicat Softening Point, 50°C /hr, 50N Load ASTM D1525 ℃ 148

Coefficient of Linear Thermal Expansion, @ -40 to 82°C ASTM D696 mm/mm/℃ 68 x 10^-6

Mechanical

Tensile Yield Strength ASTM D638 MPa 60

Ultimate Tensile Strength ASTM D638 MPa 71

Elongation at Yield ASTM D638 % 6

Elongation at Break ASTM D638 % 150

Tensile Modulus ASTM D638 MPa 2340

Flexural Strength ASTM D790 MPa 96

Flexural Modulus ASTM D790 MPa 2410

Notched Izod Impact @ 23 °C ASTM D256 J/m 850

Unnotched Izod Impact @ 23 °C ASTM D256 No break

Instrumented Dart Impact, Total Energy @ 23 °C ASTM D3763 J 87

Rockwell Hardness @ R Scale ASTM D785 R Scale 118

Rockwell Hardness @ M Scale ASTM D785 M Scale 72

Taber Abrasion Resistance (D Haze) ASTM D1044 % 45

Ignition Resistance

UL-94 @ 0.5 mm ASTM D635 V-2

UL-94 @ 1.6 mm ASTM D635 V-2

UL-94 @ 2.5-2.7 mm ASTM D635 V-2

UL-94 @ 3.0 mm ASTM D635 HB

Limiting Oxygen Index ASTM D2863 % 26

Ball Indentation Temperature IEC 598-1 ℃ >125

Average Extent of Burning ASTM D635 mm 25

Electrical

GWT 2.0 mm, 5 second IEC 695-2-1 ℃ 850

Comparative Tracking Index @ 2.0 mm IEC 112 V 250

Dielectric Strength ASTM D149 KV/mm 17

Dielectric Constant @ 60 Hz ASTM D150 3

Dissipation Factor @ 60 Hz ASTM D150 0.001

Volume Resistivity @ 23 °C, dry ASTM D257 W-cm 2.0 x 10^17

Note

1. When used unmodified for the manufacture of food contact articles LUPOY 1201-15 Polycarbonate resins comply with the U.S. Food, Drug, and Cosmetic

Act and Food Additive Regulations 21

CFR 177.1580 and E.U. Food Contact Regulations. The uses cited above are subject to GMP (Good Manufacturing Practices) and any limitations that are part

of the regulations.The regulations

should be consulted for complete details.

2. Typical properties; not to be constructed as specifications.

3. Tensile Test @ 23 °C; 50 mm/min.

4. 0.125 in; 10 mil notch (3.2 mm; 0.25 mm notch).

5. 0.125 in; 8000 ipm (3.2 mm; 203 m/min).

6. 1,000 g; CS-10 F wheel; 500 cycles.

7. These numerical flame spread ratings are small-scale test values and are not intended to reflect hazards presented by these or any other materials under

actual fire conditions. UL 94 file: E67171.

※ Typical values are only for material selection purpose, and variation within normal tolerances are for various colors.

Values given should not be interpreted as specification and not be used for part or tool design.

All properties, except melt flow rate are measured on injection molded specimens and after 48 hours storage at 23℃, 50% relative humidity.

Issued Date : 2021-12-22

The information contained herein, including, but not limited to, data, statements and typical values, are given in good faith. LG Chem makes no warranty or guarantee, expressed or implied, (i) that the

result described herein will be obtained under end - use conditions, or (ii) as to the effectiveness or safety of any design incorporating LG Chem materials, products, recommendations or advice.

Further, any information contained herein shall not be construed as a part of legally binding offer. Especially, the typical values should be regarded as reference values only and not as binding

minimum values. Each user bear full responsibility for making its own determination as to the suitability of LG Chem's materials, products, recommendations, or advice for its own particular use. Each

user must identify and perform all tests and analyses necessary to assure that its finished parts incorporating LG Chem material or products will be safe and suitable for use under end - use

conditions. The data contained herein can be changed without notice as a result of the quality improvement of the products.

You might also like

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- LEXAN™ Resin - 241R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 241R - Americas - Technical - Data - Sheetr92g5478cxNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- LEXAN™ Resin - 141 - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141 - Americas - Technical - Data - Sheetrichardhe528000No ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Injection Molding: Description ApplicationsDocument2 pagesInjection Molding: Description ApplicationsPhuoc Thinh TruongNo ratings yet

- Shell Diala S2 ZX-A - TDSDocument2 pagesShell Diala S2 ZX-A - TDSXavier DiazNo ratings yet

- Injection Molding Grade: Description ApplicationsDocument2 pagesInjection Molding Grade: Description ApplicationsSangharshBhustalimathNo ratings yet

- PC-ABS Cycoloy™ C6600Document2 pagesPC-ABS Cycoloy™ C6600countzeroaslNo ratings yet

- Shell Diala S2 Zx-A: Performance, Features & Benefits Main ApplicationsDocument3 pagesShell Diala S2 Zx-A: Performance, Features & Benefits Main ApplicationsDaniel Orlando Carballo FernándezNo ratings yet

- PC-ABS Cycoloy C2950HFDocument3 pagesPC-ABS Cycoloy C2950HFcountzeroaslNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Cycoloy®: C2950 Americas:COMMERCIAL ABS+PC Thermoplastic AlloyDocument3 pagesCycoloy®: C2950 Americas:COMMERCIAL ABS+PC Thermoplastic AlloymikeybhabaNo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Extrusion Molding: Description ApplicationsDocument2 pagesExtrusion Molding: Description ApplicationsbobNo ratings yet

- LG Abs - Hi100hDocument2 pagesLG Abs - Hi100hqshakimNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Lumiplas Ld7890: Description ApplicationDocument2 pagesLumiplas Ld7890: Description ApplicationLong HomaNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- PA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZDocument1 pagePA6, Unfilled, Cast Nylon (ASTM Data) : @frequency 1e+6 HZ @frequency 1e+6 HZroberto_perraciniNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- Transformer OilDocument2 pagesTransformer OilAdetunji TaiwoNo ratings yet

- PBT GF17% DR48-7001Document2 pagesPBT GF17% DR48-7001pava16230.meNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- LNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetDocument2 pagesLNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetYJ WangNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- ABS Cycolac MG47Document3 pagesABS Cycolac MG47countzeroaslNo ratings yet

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- T-Top800 T-Top800 Top81Document1 pageT-Top800 T-Top800 Top81CADTDDNo ratings yet

- Solvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataDocument4 pagesSolvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataFAUSANo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- Hoja Tecnica PEAD PE-100 Tipo P600Document1 pageHoja Tecnica PEAD PE-100 Tipo P600Manuel Agustin TeneNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Kpic Yuhwa p600Document1 pageKpic Yuhwa p600quanghoang10986No ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- 20.0 IFU - Measured Volume Without NeedleDocument2 pages20.0 IFU - Measured Volume Without NeedleMamdouhNo ratings yet

- 04 MDR Eudamed SC Eudamed2-MDRDocument5 pages04 MDR Eudamed SC Eudamed2-MDRMamdouhNo ratings yet

- 52 Eng 2023Document1 page52 Eng 2023MamdouhNo ratings yet

- 15.0 IFU - Volumetric SetDocument2 pages15.0 IFU - Volumetric SetMamdouhNo ratings yet

- Precautions For Handling, Storage and Installation: Info@caen - It WWW - Caen.itDocument1 pagePrecautions For Handling, Storage and Installation: Info@caen - It WWW - Caen.itMamdouhNo ratings yet

- Makrolon Rx3440 - en - 87242367 05124840 21462211Document3 pagesMakrolon Rx3440 - en - 87242367 05124840 21462211MamdouhNo ratings yet

- D C C D 93/42/EEC M D: Eclaration of Onformity TO Ouncil Irective Concerning Edical EvicesDocument1 pageD C C D 93/42/EEC M D: Eclaration of Onformity TO Ouncil Irective Concerning Edical EvicesMamdouhNo ratings yet

- Nose Bar CertificateDocument5 pagesNose Bar CertificateMamdouhNo ratings yet

- Dichiarazioni Di Conformita 50-657Document3 pagesDichiarazioni Di Conformita 50-657MamdouhNo ratings yet

- Sprint IQ Brochure Web SIQ022422v2Document6 pagesSprint IQ Brochure Web SIQ022422v2MamdouhNo ratings yet

- Ultramed E-Catalogue 2021Document49 pagesUltramed E-Catalogue 2021MamdouhNo ratings yet

- MDR Tecnical Sheet With Digital SignatureDocument103 pagesMDR Tecnical Sheet With Digital SignatureMamdouhNo ratings yet

- Technical Annex For The Factsheet On Eto Ech ResiduesDocument4 pagesTechnical Annex For The Factsheet On Eto Ech ResiduesMamdouhNo ratings yet

- 1 - Melt Blown Certificate (Huzhou Chuangsu New Material Technology Co.,ltd)Document4 pages1 - Melt Blown Certificate (Huzhou Chuangsu New Material Technology Co.,ltd)MamdouhNo ratings yet

- Msds Ub SheetDocument5 pagesMsds Ub SheetMamdouhNo ratings yet

- TESTING REPORT-Mask EarloopDocument4 pagesTESTING REPORT-Mask EarloopMamdouhNo ratings yet

- Technical Service Systems I (GSE366a) Acoustics and IlluminationDocument23 pagesTechnical Service Systems I (GSE366a) Acoustics and Illuminationahmed madoooNo ratings yet

- Move Standard Course Agenda PDFDocument1 pageMove Standard Course Agenda PDFSyed Adnan Haider ZaidiNo ratings yet

- Refrigeration Training Assesment FormDocument2 pagesRefrigeration Training Assesment FormAdrian MicuNo ratings yet

- Electric Charges and Field - Practice Sheet - Lakshya JEE 2024Document5 pagesElectric Charges and Field - Practice Sheet - Lakshya JEE 2024Divya KumariNo ratings yet

- Introduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsDocument81 pagesIntroduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsMichael KaoNo ratings yet

- MetFloor MagnelisDocument1 pageMetFloor Magnelismatan dvirNo ratings yet

- 01-Matter and Its Properties PDFDocument36 pages01-Matter and Its Properties PDFDevee Rose BravoNo ratings yet

- Guidance Note: Heritage Railway AssociationDocument23 pagesGuidance Note: Heritage Railway AssociationPaul PridhamNo ratings yet

- Ch6 - Drilling FluidsDocument54 pagesCh6 - Drilling Fluidsretrii27No ratings yet

- JSS 52300-1992 PDFDocument68 pagesJSS 52300-1992 PDFNaga Prasad100% (2)

- Tabela Trans SMDDocument12 pagesTabela Trans SMDMarcelo Oliveira50% (2)

- Raman Spectral Analysis of Electrophoretically Separated Metallic and Semiconducting Carbon NanotubesDocument4 pagesRaman Spectral Analysis of Electrophoretically Separated Metallic and Semiconducting Carbon NanotubesMarkNo ratings yet

- Modeling of The How Properties and Discharge of Halon Replacement AgentsDocument14 pagesModeling of The How Properties and Discharge of Halon Replacement AgentsNikolaos XiradakisNo ratings yet

- Outcome1 T2 PDFDocument6 pagesOutcome1 T2 PDFVignesh WaranNo ratings yet

- BS 1881Document8 pagesBS 1881Nurul Izzati Raihan RamziNo ratings yet

- Gagan Abt Stem Draft PDFDocument8 pagesGagan Abt Stem Draft PDFHimal KafleNo ratings yet

- Plasma Beam MachiningDocument26 pagesPlasma Beam MachiningManish krNo ratings yet

- Negative Temperature: Below Absolute Zero-What Does Negative Temperature Mean?Document4 pagesNegative Temperature: Below Absolute Zero-What Does Negative Temperature Mean?Arkayan LahaNo ratings yet

- SolutionDocument26 pagesSolutionlxndare musik m100% (1)

- Tutorial 2 2 PDFDocument12 pagesTutorial 2 2 PDFAvish GunnuckNo ratings yet

- Materials 10 00342Document20 pagesMaterials 10 00342Wahid KarolNo ratings yet

- Solar Cell Master ThesisDocument5 pagesSolar Cell Master Thesisafktgmqaouoixx100% (2)

- Physical Properties of Glycerine and Its SolutionsDocument28 pagesPhysical Properties of Glycerine and Its Solutionsmilitiamon100% (1)

- Excellant WaxDocument35 pagesExcellant Waxvivek9199100% (1)

- Porosity Peameability RealationDocument22 pagesPorosity Peameability RealationStephen OcheNo ratings yet

- Unsteady or Transient Heat ConductionDocument9 pagesUnsteady or Transient Heat ConductionChemical EngineeringNo ratings yet

- Polypropylene As A Promising Plastic: A ReviewDocument11 pagesPolypropylene As A Promising Plastic: A ReviewMuna Alfi ANo ratings yet

- TYFTY Qs BankDocument7 pagesTYFTY Qs BankgurusamyNo ratings yet

- Full Beginner's Guide To ESD Protection Circuit Design For PCBDocument12 pagesFull Beginner's Guide To ESD Protection Circuit Design For PCBjackNo ratings yet

- HW 7Document5 pagesHW 7anonymoussionNo ratings yet