Professional Documents

Culture Documents

STAR Column Splice DesignR2

STAR Column Splice DesignR2

Uploaded by

Aamir SuhailCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STAR Column Splice DesignR2

STAR Column Splice DesignR2

Uploaded by

Aamir SuhailCopyright:

Available Formats

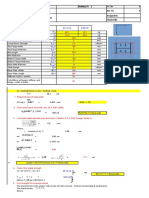

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN 25

(Above First Floor)

Moment, Mz = 824 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 1200 kNm

Shear, Fz = 391 kN

Shear, Fy = 677 kN

Axial, P = 341 kN

Properties of Column A Properties of Column B

D = 1000 mm D = 1000 mm

tw = 45 mm tw = 45 mm

tf = 50 mm tf = 50 mm

b = 500 mm b = 700 mm

A = 89487.5 mm2 A = 109487.5 mm2

Total Area = 198975 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,A sb = pi*db^2/4 = 314 mm2

Dia of Bolt, db = 16 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 160.768 mm2

Shank area of bolt,A sb = pi*db^2/4 = 200.96 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 226.08 kN

= 321.13636364 kN

Tnf = 226.08 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 180.864 kN

For single shear ( 28 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 77.3696 kN

For double shear (28 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 154.7392 kN

For single shear ( 16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 112.5376 kN

Vnsf = 61.89568

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 49.516544 kN

For double shear (16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 112.5376 kN

Vnsf = 123.79136

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 99.033088 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 824 kN

Vertical load carried by each Flange = 42.845 kN

Total Force in each plate = 866.84457846 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 6.7224 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 500 mm

Total available width of inner splice plate for flange = 227.5 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 7.8967 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 1200 kN

Vertical load carried by each Flange = 59.98240985 kN

Total Force in each plate = 1259.9824099 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 9.7711 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 700 mm

Total available width of inner splice plate for flange = 327.5 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 6.5

No. of bolts provided, N = 6

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 580 mm

Thickness of Flange splice plate reqd. = 8.3117 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 24 nos. of 20 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 677 kN

Vertical load carried by each Flange = 67.673011685 kN

Total Force in each plate = 680.37389464 kN

No. of bolts reqd. on one side of flange plate = 6.8702 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 5.165 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 16 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 391 kN

Vertical load carried by each Flange = 67.673011685 kN

Total Force in each plate = 396.81310023 kN

No. of bolts reqd. on one side of flange plate = 4.0069 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 3.0124 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 16 bolts

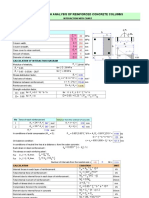

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN 25

(Above Second Floor)

Moment, Mz = 5032 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 1190 kNm

Shear, Fz = 935 kN

Shear, Fy = 1970 kN

Axial, P = 428 kN

Properties of Column A Properties of Column B

D = 1000 mm D = 1000 mm

tw = 45 mm tw = 45 mm

tf = 50 mm tf = 50 mm

b = 500 mm b = 700 mm

A = 89487.5 mm2 A = 109487.5 mm2

Total Area = 198975 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 30 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 565.2 mm2

Shank area of bolt,A sb = pi*db^2/4 = 706.5 mm2

Dia of Bolt, db = 24 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 361.728 mm2

Shank area of bolt,A sb = pi*db^2/4 = 452.16 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 508.68 kN

= 722.55681818 kN

Tnf = 508.68 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 406.944 kN

For single shear ( 28 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 395.64 kN

Vnsf = 217.602

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 174.0816 kN

For double shear (28 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 395.64 kN

Vnsf = 435.204

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 348.1632 kN

For single shear ( 16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 253.2096 kN

Vnsf = 139.26528

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 111.412224 kN

For double shear (16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 253.2096 kN

Vnsf = 278.53056

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 222.824448 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 5032 kN

Vertical load carried by each Flange = 53.776 kN

Total Force in each plate = 5085.7755999 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 17.529 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 700 mm

Total available width of inner splice plate for flange = 227.5 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 6.5

No. of bolts provided, N = 6

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 520 mm

Thickness of Flange splice plate reqd. = 37.42 mm

Thickness of Flange splice plate provided = 20 mm

No. of bolts rows in Flange(one side of splice center) = 3

Length of splice plate on one side of splice center = 350 mm

Total length of Flange splice plate = 700 mm

Provide 36 nos. of 30 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 1190 kN

Vertical load carried by each Flange = 75.28583993 kN

Total Force in each plate = 1265.2858399 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 6.8141 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 500 mm

Total available width of inner splice plate for flange = 327.5 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 380 mm

Thickness of Flange splice plate reqd. = 12.74 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 24 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 1970 kN

Vertical load carried by each Flange = 84.938560121 kN

Total Force in each plate = 1971.8302561 kN

No. of bolts reqd. on one side of flange plate = 8.8493 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 380 mm

Thickness of Flange splice plate reqd. = 16.545 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 3

Length of splice plate on one side of splice center = 350 mm

Total length of Flange splice plate = 700 mm

Provide 24 nos. of 22 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 935 kN

Vertical load carried by each Flange = 84.938560121 kN

Total Force in each plate = 938.85012595 kN

No. of bolts reqd. on one side of flange plate = 4.2134 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 380 mm

Thickness of Flange splice plate reqd. = 7.8775 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 24 nos. of 22 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN 25A

(Above First Floor)

Moment, Mz = 478 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 1267 kNm

Shear, Fz = 321 kN

Shear, Fy = 416 kN

Axial, P = 324 kN

Properties of Column A Properties of Column B

D = 1000 mm D = 1000 mm

tw = 40 mm tw = 40 mm

tf = 50 mm tf = 50 mm

b = 600 mm b = 600 mm

A = 95200 mm2 A = 95200 mm2

Total Area = 190400 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,A sb = pi*db^2/4 = 314 mm2

Dia of Bolt, db = 16 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 160.768 mm2

Shank area of bolt,A sb = pi*db^2/4 = 200.96 mm2

Dia of Bolt, db = 36 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 813.888 mm2

Shank area of bolt,A sb = pi*db^2/4 = 1017.36 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 226.08 kN

= 321.13636364 kN

Tnf = 226.08 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 180.864 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 77.3696 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 154.7392 kN

For single shear ( 16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 112.5376 kN

Vnsf = 61.89568

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 49.516544 kN

For double shear (16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 112.5376 kN

Vnsf = 123.79136

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 99.033088 kN

For single shear ( 36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 313.34688

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 250.677504 kN

For double shear (36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 626.69376

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 501.355008 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 478 kN

Vertical load carried by each Flange = 51.050 kN

Total Force in each plate = 529.05042017 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 4.1028 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 280 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 456 mm

Thickness of Flange splice plate reqd. = 4.439 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 1267 kN

Vertical load carried by each Flange = 51.050420168 kN

Total Force in each plate = 1318.0504202 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 10.221 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 280 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 536 mm

Thickness of Flange splice plate reqd. = 9.4085 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 3

Length of splice plate on one side of splice center = 350 mm

Total length of Flange splice plate = 700 mm

Provide 24 nos. of 20 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 416 kN

Vertical load carried by each Flange = 59.899159664 kN

Total Force in each plate = 420.29026794 kN

No. of bolts reqd. on one side of flange plate = 4.2439 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 3.1906 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 16 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 321 kN

Vertical load carried by each Flange = 59.899159664 kN

Total Force in each plate = 326.54082337 kN

No. of bolts reqd. on one side of flange plate = 3.2973 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 2.4789 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 1

Length of splice plate on one side of splice center = 150 mm

Total length of Flange splice plate = 300 mm

Provide 8 nos. of 16 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN 25A

(Above Second Floor)

Moment, Mz = 1212 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 5000 kNm

Shear, Fz = 1550 kN

Shear, Fy = 740 kN

Axial, P = 324 kN

Properties of Column A Properties of Column B

D = 1000 mm D = 1000 mm

tw = 40 mm tw = 40 mm

tf = 50 mm tf = 50 mm

b = 600 mm b = 600 mm

A = 95200 mm2 A = 95200 mm2

Total Area = 190400 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 36 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 813.888 mm2

Shank area of bolt,A sb = pi*db^2/4 = 1017.36 mm2

Dia of Bolt, db = 24 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 361.728 mm2

Shank area of bolt,A sb = pi*db^2/4 = 452.16 mm2

Dia of Bolt, db = 36 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 813.888 mm2

Shank area of bolt,A sb = pi*db^2/4 = 1017.36 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 732.4992 kN

= 1040.4818182 kN

Tnf = 732.4992 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 585.99936 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 313.34688

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 250.677504 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 626.69376

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 501.355008 kN

For single shear ( 16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 253.2096 kN

Vnsf = 139.26528

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 111.412224 kN

For double shear (16 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 253.2096 kN

Vnsf = 278.53056

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 222.824448 kN

For single shear ( 36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 313.34688

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 250.677504 kN

For double shear (36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 626.69376

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 501.355008 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 1212 kN

Vertical load carried by each Flange = 51.050 kN

Total Force in each plate = 1263.0504202 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 3.0231 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 280 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 456 mm

Thickness of Flange splice plate reqd. = 10.598 mm

Thickness of Flange splice plate provided = 20 mm

No. of bolts rows in Flange(one side of splice center) = 1

Length of splice plate on one side of splice center = 150 mm

Total length of Flange splice plate = 300 mm

Provide 8 nos. of 20 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 5000 kN

Vertical load carried by each Flange = 51.050420168 kN

Total Force in each plate = 5051.0504202 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 12.09 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 280 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 504 mm

Thickness of Flange splice plate reqd. = 38.345 mm

Thickness of Flange splice plate provided = 20 mm

No. of bolts rows in Flange(one side of splice center) = 4

Length of splice plate on one side of splice center = 450 mm

Total length of Flange splice plate = 900 mm

Provide 24 nos. of 36 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 740 kN

Vertical load carried by each Flange = 59.899159664 kN

Total Force in each plate = 742.42030504 kN

No. of bolts reqd. on one side of flange plate = 3.3319 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 356 mm

Thickness of Flange splice plate reqd. = 6.6493 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 1

Length of splice plate on one side of splice center = 150 mm

Total length of Flange splice plate = 300 mm

Provide 8 nos. of 24 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 1550 kN

Vertical load carried by each Flange = 59.899159664 kN

Total Force in each plate = 1551.1569583 kN

No. of bolts reqd. on one side of flange plate = 6.9613 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 356 mm

Thickness of Flange splice plate reqd. = 13.892 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 24 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C24

(Above First Floor)

Moment, Mz = 1790 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 1704 kNm

Shear, Fz = 1050 kN

Shear, Fy = 1120 kN

Axial, P = 104 kN

Properties of Column A Properties of Column B

D = 900 mm D = 900 mm

tw = 28 mm tw = 28 mm

tf = 50 mm tf = 50 mm

b = 500 mm b = 600 mm

A = 72008 mm2 A = 82008 mm2

Total Area = 154016 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,A sb = pi*db^2/4 = 314 mm2

Dia of Bolt, db = 32 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 643.072 mm2

Shank area of bolt,A sb = pi*db^2/4 = 803.84 mm2

Dia of Bolt, db = 36 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 813.888 mm2

Shank area of bolt,A sb = pi*db^2/4 = 1017.36 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 226.08 kN

= 321.13636364 kN

Tnf = 226.08 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 180.864 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 77.3696 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 154.7392 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 247.58272

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 198.066176 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 495.16544

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 396.132352 kN

For single shear ( 36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 313.34688

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 250.677504 kN

For double shear (36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 626.69376

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 501.355008 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 1893.3333333 kN

Vertical load carried by each Flange = 16.881 kN

Total Force in each plate = 1910.2146963 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 14.814 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 500 mm

Total available width of inner splice plate for flange = 236 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 17.402 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 4

Length of splice plate on one side of splice center = 450 mm

Total length of Flange splice plate = 900 mm

Provide 32 nos. of 20 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 1988.8888889 kN

Vertical load carried by each Flange = 20.25763557 kN

Total Force in each plate = 2009.1465245 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 15.581 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 286 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 520 mm

Thickness of Flange splice plate reqd. = 14.783 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 4

Length of splice plate on one side of splice center = 450 mm

Total length of Flange splice plate = 900 mm

Provide 32 nos. of 20 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 1050 kN

Vertical load carried by each Flange = 14.861001454 kN

Total Force in each plate = 1050.1051611 kN

No. of bolts reqd. on one side of flange plate = 6.7863 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 7.9718 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 1120 kN

Vertical load carried by each Flange = 14.861001454 kN

Total Force in each plate = 1120.0985891 kN

No. of bolts reqd. on one side of flange plate = 7.2386 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 8.5032 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C26

(Above First Floor)

Moment, Mz = 1810 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 890 kNm

Shear, Fz = 463 kN

Shear, Fy = 1130 kN

Axial, P = 117.2 kN

Properties of Column A

D = 850 mm

tw = 25 mm

tf = 40 mm

b = 600 mm

A = 66937.5 mm2

Total Area = 66937.5 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, fub = 1000 MPa

Yield stress of bolt of bolt, fyb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,Asb = pi*db^2/4 = 314 mm2

Dia of Bolt, db = 32 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 643.072 mm2

Shank area of bolt,Asb = pi*db^2/4 = 803.84 mm2

Dia of Bolt, db = 28 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 492.352 mm2

Shank area of bolt,Asb = pi*db^2/4 = 615.44 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, Tnf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 226.08 kN

= 321.13636364 kN

0

Tnf = 226.08 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 180.864 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 77.3696 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 154.7392 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 247.58272

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 198.066176 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 495.16544

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 396.132352 kN

For single shear ( 28 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 189.55552

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 151.644416 kN

For double shear (28 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 379.11104

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 303.288832 kN

Design of Flange splice Plate

Force in Flange due to moment = 2129.4117647 kN

Force in Flange due to moment = 1977.7777778 kN

Resultant Force = 2906.2001655 kN

Vertical load carried by each Flange = 42.021 kN

Total Force in each plate = 2948.221 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 11.665 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 287.5 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 520 mm

Thickness of Flange splice plate reqd. = 21.693 mm

Thickness of Flange splice plate provided = 12 mm

No. of bolts rows in Flange(one side of splice center) = 3

Length of splice plate on one side of splice center = 350 mm

Total length of Flange splice plate = 700 mm

Provide 24 nos. of 28 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 463 kN

Force in Web due to shear = 1130 kN

Resultant Shear = 1221.1752536 kN

Vertical load carried by each Flange = 33.157422969 kN

Total Force in each plate = 1221.6253168 kN

No. of bolts reqd. on one side of flange plate = 7.8947 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 420 mm

Thickness of Flange splice plate reqd. = 9.2739 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C20

(Above First Floor)

Moment, Mz = 1707 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 2990 kNm

Shear, Fz = 988 kN

Shear, Fy = 936 kN

Axial, P = 538 kN

Properties of Column A Properties of Column B

D = 850 mm D = 850 mm

tw = 40 mm tw = 40 mm

tf = 40 mm tf = 40 mm

b = 500 mm b = 600 mm

A = 70000 mm2 A = 78000 mm2

Total Area = 148000 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 32 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 643.072 mm2

Shank area of bolt,A sb = pi*db^2/4 = 803.84 mm2

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,A sb = pi*db^2/4 = 314 mm2

Dia of Bolt, db = 36 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 813.888 mm2

Shank area of bolt,A sb = pi*db^2/4 = 1017.36 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 578.7648 kN

= 822.10909091 kN

Tnf = 578.7648 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 463.01184 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 247.58272

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 198.066176 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 495.16544

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 396.132352 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 77.3696 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 154.7392 kN

For single shear ( 36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 313.34688

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 250.677504 kN

For double shear (36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 626.69376

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 501.355008 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 3517.6470588 kN

Vertical load carried by each Flange = 72.703 kN

Total Force in each plate = 3590.3497615 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 10.876 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 500 mm

Total available width of inner splice plate for flange = 230 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 372 mm

Thickness of Flange splice plate reqd. = 36.927 mm

Thickness of Flange splice plate provided = 20 mm

No. of bolts rows in Flange(one side of splice center) = 3

Length of splice plate on one side of splice center = 350 mm

Total length of Flange splice plate = 700 mm

Provide 24 nos. of 32 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 2008.2352941 kN

Vertical load carried by each Flange = 87.243243243 kN

Total Force in each plate = 2095.4785374 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 6.3478 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 280 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 472 mm

Thickness of Flange splice plate reqd. = 16.986 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 32 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 988 kN

Vertical load carried by each Flange = 109.05405405 kN

Total Force in each plate = 994.00039573 kN

No. of bolts reqd. on one side of flange plate = 6.4237 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 372 mm

Thickness of Flange splice plate reqd. = 8.5196 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 936 kN

Vertical load carried by each Flange = 109.05405405 kN

Total Force in each plate = 942.33156941 kN

No. of bolts reqd. on one side of flange plate = 6.0898 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 372 mm

Thickness of Flange splice plate reqd. = 8.0767 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C20

(Above First Floor)

Moment, Mz = 1505 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 2134 kNm

Shear, Fz = 2030 kN

Shear, Fy = 1630 kN

Axial, P = 100 kN

Properties of Column A Properties of Column B

D = 850 mm D = 850 mm

tw = 40 mm tw = 40 mm

tf = 40 mm tf = 40 mm

b = 500 mm b = 600 mm

A = 70000 mm2 A = 78000 mm2

Total Area = 148000 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, f ub = 1000 MPa

Yield stress of bolt of bolt, f yb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 32 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 643.072 mm2

Shank area of bolt,A sb = pi*db^2/4 = 803.84 mm2

Dia of Bolt, db = 28 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 492.352 mm2

Shank area of bolt,A sb = pi*db^2/4 = 615.44 mm2

Dia of Bolt, db = 36 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 813.888 mm2

Shank area of bolt,A sb = pi*db^2/4 = 1017.36 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, T nf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 578.7648 kN

= 822.10909091 kN

Tnf = 578.7648 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 463.01184 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 247.58272

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 198.066176 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 450.1504 kN

Vnsf = 495.16544

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 396.132352 kN

For single shear ( 28 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 189.55552

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 151.644416 kN

For double shear (28 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 379.11104

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 303.288832 kN

For single shear ( 36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 313.34688

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 250.677504 kN

For double shear (36 mm dia.)

Nominal shear capacity of bolt,V nsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 569.7216 kN

Vnsf = 626.69376

Design shear capacity of bolt, V dsf = Vnsf /γmb

= 501.355008 kN

Design of Flange splice Plate(Column A)

Force in Flange due to moment = 2510.5882353 kN

Vertical load carried by each Flange = 13.514 kN

Total Force in each plate = 2524.1017488 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 7.6462 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 500 mm

Total available width of inner splice plate for flange = 230 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 372 mm

Thickness of Flange splice plate reqd. = 25.961 mm

Thickness of Flange splice plate provided = 14 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 32 bolts

Design of Flange splice Plate(Column B)

Force in Flange due to moment = 1770.5882353 kN

Vertical load carried by each Flange = 16.216216216 kN

Total Force in each plate = 1786.8044515 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 7.0697 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 600 mm

Total available width of inner splice plate for flange = 280 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 5.5

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 472 mm

Thickness of Flange splice plate reqd. = 14.484 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 28 bolts

Design of Web splice Plate(Column A)

Force in Web due to shear = 2030 kN

Vertical load carried by each Flange = 20.27027027 kN

Total Force in each plate = 2030.1012004 kN

No. of bolts reqd. on one side of flange plate = 6.6936 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 372 mm

Thickness of Flange splice plate reqd. = 17.4 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 28 bolts

Design of Web splice Plate(Column B)

Force in Web due to shear = 1630 kN

Vertical load carried by each Flange = 20.27027027 kN

Total Force in each plate = 1630.1260331 kN

No. of bolts reqd. on one side of flange plate = 5.3748 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 250 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 372 mm

Thickness of Flange splice plate reqd. = 13.972 mm

Thickness of Flange splice plate provided = 10 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 28 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C18

(Above First Floor)

Moment, Mz = 1657 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 429 kNm

Shear, Fz = 228 kN

Shear, Fy = 927 kN

Axial, P = 400 kN

Properties of Column A

D = 900 mm

tw = 40 mm

tf = 50 mm

b = 750 mm

A = 106200 mm2

Total Area = 106200 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, fub = 1000 MPa

Yield stress of bolt of bolt, fyb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,Asb = pi*db^2/4 = 314 mm2

Dia of Bolt, db = 30 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 565.2 mm2

Shank area of bolt,Asb = pi*db^2/4 = 706.5 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, Tnf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 226.08 kN

= 321.13636364 kN

Tnf = 226.08 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 180.864 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 77.3696 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 154.7392 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 395.64 kN

Vnsf = 217.602

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 174.0816 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 395.64 kN

Vnsf = 435.204

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 348.1632 kN

Design of Flange splice Plate

Force in Flange due to moment = 476.66666667 kN

Force in Flange due to moment = 2761.6666667 kN

Resultant Force = 2802.5013629 kN

Vertical load carried by each Flange = 141.243 kN

Total Force in each plate = 2943.744 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 10.146 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 750 mm

Total available width of inner splice plate for flange = 355 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 7

No. of bolts provided, N = 6

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 630 mm

Thickness of Flange splice plate reqd. = 17.878 mm

Thickness of Flange splice plate provided = 12 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 24 nos. of 30 bolts

Design of Web splice Plate

Force in Web due to shear = 228 kN

Force in Web due to shear = 927 kN

Resultant Shear = 954.62715235 kN

Vertical load carried by each Flange = 117.51412429 kN

Total Force in each plate = 961.83292177 kN

No. of bolts reqd. on one side of flange plate = 6.2158 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 450 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 4

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 820 mm

Thickness of Flange splice plate reqd. = 3.7399 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 16 nos. of 20 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C18

(Above Second Floor)

Moment, Mz = 1372.5 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 215 kNm

Shear, Fz = 143 kN

Shear, Fy = 380 kN

Axial, P = 150 kN

Properties of Column A

D = 900 mm

tw = 20 mm

tf = 32 mm

b = 750 mm

A = 64520 mm2

Total Area = 64520 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, fub = 1000 MPa

Yield stress of bolt of bolt, fyb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 22 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 303.952 mm2

Shank area of bolt,Asb = pi*db^2/4 = 379.94 mm2

Dia of Bolt, db = 28 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 492.352 mm2

Shank area of bolt,Asb = pi*db^2/4 = 615.44 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, Tnf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 273.5568 kN

= 388.575 kN

Tnf = 273.5568 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 218.84544 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 212.7664 kN

Vnsf = 117.02152

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 93.617216 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 212.7664 kN

Vnsf = 234.04304

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 187.234432 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 189.55552

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 151.644416 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 379.11104

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 303.288832 kN

Design of Flange splice Plate

Force in Flange due to moment = 238.88888889 kN

Force in Flange due to moment = 2287.5 kN

Resultant Force = 2299.9400321 kN

Vertical load carried by each Flange = 55.797 kN

Total Force in each plate = 2355.737 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 9.3208 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 750 mm

Total available width of inner splice plate for flange = 365 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 7

No. of bolts provided, N = 6

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 618 mm

Thickness of Flange splice plate reqd. = 14.585 mm

Thickness of Flange splice plate provided = 12 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 24 nos. of 28 bolts

Design of Web splice Plate

Force in Web due to shear = 143 kN

Force in Web due to shear = 380 kN

Resultant Shear = 406.01600954 kN

Vertical load carried by each Flange = 38.406695598 kN

Total Force in each plate = 407.82848634 kN

No. of bolts reqd. on one side of flange plate = 2.1782 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 450 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 8

No. of bolts provided, N = 4

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 812 mm

Thickness of Flange splice plate reqd. = 1.6014 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 1

Length of splice plate on one side of splice center = 150 mm

Total length of Flange splice plate = 300 mm

Provide 8 nos. of 20 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C18A

(Above First Floor)

Moment, Mz = 500 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 329 kNm

Shear, Fz = 1140 kN

Shear, Fy = 814 kN

Axial, P = 400 kN

Properties of Column A

D = 1000 mm

tw = 20 mm

tf = 32 mm

b = 750 mm

A = 66520 mm2

Total Area = 66520 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, fub = 1000 MPa

Yield stress of bolt of bolt, fyb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 24 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 361.728 mm2

Shank area of bolt,Asb = pi*db^2/4 = 452.16 mm2

Dia of Bolt, db = 20 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 251.2 mm2

Shank area of bolt,Asb = pi*db^2/4 = 314 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, Tnf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 325.5552 kN

= 462.43636364 kN

Tnf = 325.5552 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 260.44416 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 253.2096 kN

Vnsf = 139.26528

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 111.412224 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 253.2096 kN

Vnsf = 278.53056

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 222.824448 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 96.712

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 77.3696 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 175.84 kN

Vnsf = 193.424

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 154.7392 kN

Design of Flange splice Plate

Force in Flange due to moment = 329 kN

Force in Flange due to moment = 833.33333333 kN

Resultant Force = 895.92714238 kN

Vertical load carried by each Flange = 144.317 kN

Total Force in each plate = 1040.245 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 8.0671 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 750 mm

Total available width of inner splice plate for flange = 365 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 7

No. of bolts provided, N = 6

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 606 mm

Thickness of Flange splice plate reqd. = 6.5678 mm

Thickness of Flange splice plate provided = 12 mm

No. of bolts rows in Flange(one side of splice center) = 2

Length of splice plate on one side of splice center = 250 mm

Total length of Flange splice plate = 500 mm

Provide 24 nos. of 20 bolts

Design of Web splice Plate

Force in Web due to shear = 1140 kN

Force in Web due to shear = 814 kN

Resultant Shear = 1400.7840662 kN

Vertical load carried by each Flange = 111.36500301 kN

Total Force in each plate = 1405.2039581 kN

No. of bolts reqd. on one side of flange plate = 6.3063 nos.

Let the splice plates be on both sides of each web

Total width of splice plate for web = 450 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 8

No. of bolts provided, N = 8

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 708 mm

Thickness of Flange splice plate reqd. = 6.3282 mm

Thickness of Flange splice plate provided = 8 mm

No. of bolts rows in Flange(one side of splice center) = 1

Length of splice plate on one side of splice center = 150 mm

Total length of Flange splice plate = 300 mm

Provide 16 nos. of 24 bolts

PROJECT:- MSPVL MUNDRA

DESIGN OF SPLICE PLATE FOR COLUMN C18A

(Above Second Floor)

Moment, Mz = 400 kNm Yield stress of steel for plate = 345 MPa

Moment, My = 400 kNm

Shear, Fz = 1450 kN

Shear, Fy = 1360 kN

Axial, P = 150 kN

Properties of Column A

D = 1000 mm

tw = 20 mm

tf = 32 mm

b = 750 mm

A = 66520 mm2

Total Area = 66520 mm2

Properties of Connecting Bolts

Grade of Bolts used 10.9 (HSFG Bolts)

Ultimate tensile stress of bolt, fub = 1000 MPa

Yield stress of bolt of bolt, fyb = 900 MPa

Proof Stress, fo = 0.7*fub = 700 MPa

Dia of Bolt, db = 28 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 492.352 mm2

Shank area of bolt,Asb = pi*db^2/4 = 615.44 mm2

Dia of Bolt, db = 28 mm

Net Area of Bolt, Anb = 0.8*pi*db^2/4 = 492.352 mm2

Shank area of bolt,Asb = pi*db^2/4 = 615.44 mm2

Partial safety factor for Material, γmo = 1.1

Partial safety factor for bolt, γmb = 1.25

Nominal tensile capacity of bolt, Tnf =

As per IS:800-2007, Clause 10.4.5 (min of values)

= 443.1168 kN

= 629.42727273 kN

Tnf = 443.1168 kN

Design Tensile capacity of bolt , Tdf = Tnf/γmb

Tdf = 354.49344 kN

For single shear ( 20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 189.55552

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 151.644416 kN

For double shear (20 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 379.11104

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 303.288832 kN

For single shear ( 32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 1 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 189.55552

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 151.644416 kN

For double shear (32 mm dia.)

Nominal shear capacity of bolt,Vnsf = μf ne Kh Fo

μf = 0.55 (as per Table 20 of IS 800:2007)

ne = 2 (no. of effective interfaces )

Kh = 1 (as per Clause 10.4.3 of IS 800:2007)

Fo = 344.6464 kN

Vnsf = 379.11104

Design shear capacity of bolt, Vdsf = Vnsf /γmb

= 303.288832 kN

Design of Flange splice Plate

Force in Flange due to moment = 400 kN

Force in Flange due to moment = 666.66666667 kN

Resultant Force = 777.46025265 kN

Vertical load carried by each Flange = 54.119 kN

Total Force in each plate = 831.579 kN

Flange Splice Plate area and No. of bolts has been increased by 1.2 times as per Chapter 12.

No. of bolts reqd. on one side of flange plate = 3.2902 nos.

Let the flange plates be on both sides of each flanges

Total available width of outer splice plate for flange = 750 mm

Total available width of inner splice plate for flange = 365 mm

pitch for bolts, p = 100 mm

Edge distance considered = 75 mm

No. of bolts in one row of flange splice = 7

No. of bolts provided, N = 6

Total net width of flange splice plate at one flange (deducting dia of bolts in one row)

= 582 mm

Thickness of Flange splice plate reqd. = 5.4668 mm

Thickness of Flange splice plate provided = 12 mm

No. of bolts rows in Flange(one side of splice center) = 1

Length of splice plate on one side of splice center = 150 mm

Total length of Flange splice plate = 300 mm

Provide 12 nos. of 28 bolts

Design of Web splice Plate

Force in Web due to shear = 1450 kN

Force in Web due to shear = 1360 kN

Resultant Shear = 1987.9889336 kN

Vertical load carried by each Flange = 41.761876127 kN