Professional Documents

Culture Documents

RPBX Datasheet

RPBX Datasheet

Uploaded by

yadokapitaaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RPBX Datasheet

RPBX Datasheet

Uploaded by

yadokapitaaraCopyright:

Available Formats

RPB/X Series

RPB 600 - 1800

The reliable and effective RPB series

Evaporative Air Conditioners are

proven performers for heavy duty

industrial and commercial cooling.

They have long been preferred by

mechanical contractors for their

outstanding reliability and cost

effectiveness. Installed in a myriad of

applications, these coolers have

provided low cost, low energy and

maintenance cooling year after year.

Australian Greenhouse Office

Breezair ICON Series Airconditioner Energy Efficiency Star Awards

Braemar TG Ducted Gas Heater Entreprise Award 2006

Recognition of achievement at the

2006 Energy & Water Green Globe Awards

Seeley International

375

350 *RPB1000D&T

325

300

Static Pressure Pa

6.0

275

Kw

250

Hig

225

h

200

175

150

Lo

125

w

100

75

50

25

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

AIRFLOW ( litres / sec )

Cabinet Cooler Rating 375

350 RPB1200

The cabinet is constructed from Coolers are factory set to run, 325

4.

300

marine grade aluminium “free discharge” at the motor

5

Static Pressure Pa

K

275 w

H

ig

incorporating channel section rated current, unless operating

250

225

h

corner pillars, mounted on a conditions are specified.

200

175

heavy gauge base frame for 150

125

Lo

w

stuctual stability. Many compo-

Motor Ratings, Pulley and

100

75

nents have been powder-coated

Belt sizes are nominal, and

50

25

for extra corrosion protection.

Cabinet fasteners are Stainless may vary slightly due to manufac-

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

steel, Monel, Nylon and turing tolerances. Larger & AIRFLOW ( litres / sec )

Aluminium. smaller motor pulleys and belts

available on request.

Blower Wheel

375

350 RPB1300

325

The Blower wheel is a double Special Features 300

Static Pressure Pa

6.

0

275 K

w

inlet, multi blade, forward curved, Bleed off adjustment provided via 250

225

H

ig

h

centrifugal type. Constructed from external valve located at the 200

175

galvanised steel, the wheel is corner pillar. A main power 150

125

Lo

w

statically balanced. The blower isolation switch is provided. 100

75

shaft is mounted in plumber 50

25

blocks with, self-aligning, single

row ball bearings.

6000

6500

7000

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

AIRFLOW ( litres / sec )

Water Resevoir

The water resevoir is a one piece 375

350 RPB1400

Rotational Moulding of Polyethyl- 325 8.

Static Pressure Pa 300 0

ene, providing a thick walled, 275

K

w

H

ig

h

corrosion-free component with 250

225

excellent sound deadening 200

175

properties. 150

125

Lo

w

100

Fan Motors

75

50

25

Three phase motors are TEFC

7500

8000

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

tropic proof, Aluminium frame,

IP55 enclosures to AS 1359. AIRFLOW ( litres / sec )

225

Motor amperes can vary depend- RPB600 375

200 350 RPB1500

ing on supplier. 325

Static Pressure Pa

Static Pressure Pa

175 300

Electrical Control

10

275 .0

150

250

K

w

2.0

225

H

125

ig

The Three Phase Starter Assem-

h

Kw

200

Hig

100 175

bly is prewired within the cooler

h

150

75 125

Lo

and incorporates a dual contactor

w

100

Low

50

75

assembly for control of the high 25

50

25

and low speeds. Current

overloads are fitted to both high

8500

9000

9500

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

2500 3000 3500 4000 4500 5000 5500 6000 6500

Airflow Litres/Sec

and low speed contactors. The AIRFLOW ( litres / sec )

enclosure is hose proof to IP55 450

425 *RPB1800D&T

and incorporates an isolation 225

RPB700

400

375

switch. The wall control switch 200

350 15

Static Pressure Pa

325 .0

Static Pressure Pa

175 Kw

supplied incorporates the pump, 150

300

275

Hig

h

fan and speed variation mecha- 125

250

225

nisms 200

2.

5

100 175

Kw

150

Hig

Water Connection

75 125

h

100 Lo w

Lo

50 75

w

Water supply connection is 1/2” 25

50

25

BSP, this connects directly to a

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

17500

18000

9500

1/2” NB standard approved ball 3000 3500 4000 4500

Airflow Litres/Sec

5000 5500 6000 6500 7000 7500

AIRFLOW ( litres / sec )

valve.

450

Cooling Pads 375 425 RPB1800S

400

350 RPB900 375

Cooling pads are Chillcell™ with 325 350

Static Pressure Pa

300 325

4.5

Static Pressure Pa

a minimum operating saturation 275 300

Kw

250 275 15

Hig

.0

efficiency of 80%. The cooling 225 250 Kw

h

225 Hig

200 h

200

pads are housed in UV stabilized 175

150

175

150

polypropelene pad frames, 125 125

Lo

100

w

100

structually very strong and 75

50

75

50

Low

gauranteed against corrosion for 25 25

25 years.

10000

10500

11000

11500

12000

12500

13000

13500

14000

14500

15000

15500

16000

16500

17000

17500

18000

9500

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

AIRFLOW ( litres / sec ) AIRFLOW ( litres / sec )

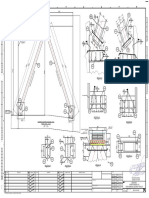

RPB600 - 1000 Cabinet details RPB600 - 1000 Services and Mounting details

295 ± 5

RPB600-900 Top discharge Shown WATER ENTRY

RPB1000 Down & Top discharge

have pads on all sides

1520

OPTIONAL LIFTING

ALL MODELS

Services Layout

VIEWED FROM TOP

965± 5

FLOAT VALVE

1520

OVERFLOW PIPE / (OPTIONAL DRAIN VALVE)

786

ELECTRICAL

ENTRY

MOTOR

CONTROL BOX 415± 10

350

122

ILL20 64

45 757 ISOLOATION

WATER ENTRY PUMPS SWITCH

RPB1000D&T ONLY 185 ± 10

RPB600-900 x 1

RPB1000 x 2

RPB600 - 900 Side discharge Shown

(Not available in RPB1000) 1475

1457

Distance between mount hole centres

796

1520

760

MOUNT HOLES

16 X 9.5

785

1510

ELECTRICAL

ENTRY

778

350

590

210

45

100

WATER ENTRY

22

typ

150

Ill 2064

295

NOTE 748

Down discharge units not shown as they 760

are dimensionally the same as above. 130±10 Mounting Detail

VIEWED FROM BOTTOM

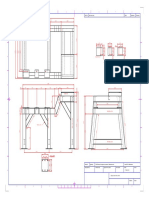

RPB1200 - 1800 Cabinet details RPB1200 - 1800 Services and Mounting details

RPB1200-1500 Top discharge Shown

2030 TYPICAL

RPB1800 Down & Top discharge

have pads on all sides Optional Lifting Eyes

(All models) PUMP

890 PUMP

230

MOTOR

Services Layout

OVERFLOW PIPE VIEWED FROM TOP

CONTROL BOX

WATER

ENTRY

DRAIN VALVE

PUMP LOCATION

FLOAT VALVE (OPTIONAL)

430

PUMP

ISOLATION

1275

SWITCH

RPB1200 - 1800 Side discharge Shown 1937

1917

Distance between mount holes centres

2030 2030

1625

1025

MOUNT HOLES

16 X 9.5

890

124

1854

48

Isolating switch

Bleed Adjustment Tap

776

Water

25 entry 350 Water entry point

ty

p (Units with 1058

8 Pads Only) 160

890

260

430

NOTE

Down discharge units not shown as they

are dimensionally the same as above. 890 890 SQ 230

170±10 Mounting Detail

VIEWED FROM BOTTOM

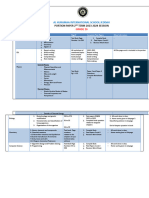

Specifications RPB/X RPB/X RPB/X RPB/X RPB/X RPB/X RPB/X RPB/X RPB/X

600 700 900 1000 1200 1300 1400 1500 1800

Airflow High (L/Sec) 6100 7200 8900 9900 11400 12800 14200 15100 17900

(@ zero static)

Low (L/Sec) 4360 4620 6000 6625 6625 8545 9435 10005 12052

Cooling Capacity D&T 63.3

High Speed (kW) 20.7 23.7 30.4 34.2 39.0 44.3 49.8 53.1

(@ 80 Pa & 80% Sat. Efficiency) S 56.9

Blower Wheel Dia x Width (mm) 760x635 760x635 760x635 760x635 820x800 820x800 820x800 820x800 820x800

Shaft (mm) 31.75 31.75 31.75 31.75 40 40 40 40 40

Pulley (mm) 455x2A 455x2A 455x2A 455x2A 455x2A 455x2B 615x2B 615x2B 615x2B

Speed (RPM) 285/190 355/224 398/262 421/277 319/210 376/248 354/233 377/248 453/304

Tip speed (m/s) 11.3 13.4 15.9 16.7 13.7 16.1 15.2 16.2 19.4

Outlet (mm) 775x755 775x755 775x755 775x755 890x890 890x890 890x890 890x890 890x890

Outlet vel (m/s) 10.5 12.3 15.1 16.9 14.5 16.1 17.8 19.0 22.3

Motor 2 Speed 2 Speed 2 Speed 2 Speed 2 Speed 2 Speed 2 Speed 2 Speed 2 Speed

Type

3 Phase 3 Phase 3 Phase 3 Phase 3 Phase 3 Phase 3 Phase 3 Phase 3 Phase

Speed (RPM) 1450/950 1450/950 1450/950 1450/950 1450/950 1450/950 1450/950 1450/950 1450/950

Rating (kW) 2.0 2.5 4.5 6.0 4.5 6.0 8.0 10.0 15.0

Current (amp) 4.3:2.9 4.7:2.9 8.5:5.3 11.7:6.6 8.5:5.3 11.7:6.6 16.2:7.0 18.5:10.8 26:10.5

415v/50hz 415v/50hz 415v/50hz 415v/50hz 415v/50hz 415v/50hz 415v/50hz 415v/50hz 415v/50hz

Supply

3 phase 3 phase 3 phase 3 phase 3 phase 3 phase 3 phase 3 phase 3 phase

Overload Manual reset Manual reset Manual reset Manual reset Manual reset Manual reset Manual reset Manual reset Manual reset

Pulley (mm) 90 x 28 x 2A 106 x 28 x 2A 125 x 38 x 2A 132 x 38 x 2A 100 x 38 x 2A 118 x 28 x 2B 150 x 42 x 2B 160 x 42 x 2B 190 x 42 x 2B

Pump Type Cent x 1 Cent x 1 Cent x 1 Cent x 2 Cent x 3 Cent x 3 Cent x 3 Cent x 3 Cent x (S)3 (D&T) 4

Rating (watts) 50 50 50 50 50 50 50 50 50

Flow Rate (L/min) 24 24 24 24 24 24 24 24 24

Overload Auto reset Auto reset Auto reset Auto reset Auto reset Auto reset Auto reset Auto reset Auto reset

Cooling Pads Size mm (top) 595 x 580 (6) 595 x 580 (6) 595 x 580 (6) 595 x 580 (8) 795 x 580 (6) 795 x 580 (6) 795 x 580 (6) 795 x 580 (6) 795 x 580 (8)

Size mm (bottom) 595 x 580 (6) 595 x 580 (6) 595 x 580 (6) 595 x 580 (8) 795 x 890 (6) 795 x 890 (6) 795 x 890 (6) 795 x 890 (6) 795 x 890 (8)

Area (m2) 4.14 4.14 4.14 5.52 7.0 7.0 7.0 7.0 9.4

Velocity (m/sec) 1.48 1.74 2.13 1.79 1.64 1.82 2.01 2.15 1.89

Material ChillcelTM ChillcelTM ChillcelTM ChillcelTM ChillcelTM ChillcelTM ChillcelTM ChillcelTM ChillcelTM

Water Capacity (L) 65 65 65 65 100 100 100 100 100

Drain Size (mm) 48/40 48/40 48/40 48/40 48/40 48/40 48/40 48/40 48/40

Shipping Height (mm) 1630 1630 1630 1630 2050 2050 2050 2050 2050

Length (mm) 1560 1560 1560 1560 2100 2100 2100 2100 2100

Width (mm) 1560 1560 1560 1560 2100 2100 2100 2100 2100

Volume (m3) 3.97 3.97 3.97 3.97 9.04 9.04 9.04 9.04 9.04

Mass (kg) 295 295 331 376 415 447 457 468 513

Net unit (kg) 265 265 301 346 375 417 427 438 473

Operating (kg) 330 330 366 411 475 517 527 538 573

© Seeley International Pty Ltd. Publication No: Bz0048:0207EN Printed in Austrlalia.

www.seeleyinternational.com

You might also like

- Operating - Instructions SD20 - SD185 - enDocument6 pagesOperating - Instructions SD20 - SD185 - enAswin AntonyNo ratings yet

- Patricia Faisca - A Concise Introduction To Thermodynamics For Physicists-CRC Press (2022)Document237 pagesPatricia Faisca - A Concise Introduction To Thermodynamics For Physicists-CRC Press (2022)Piotr Jankowski100% (1)

- SiteDocument1 pageSitecRi SocietyNo ratings yet

- Sub Structure AnanyaDocument1 pageSub Structure AnanyaShubhadip MondalNo ratings yet

- Lus CP10J Ajp Le 2099 - Z00Document1 pageLus CP10J Ajp Le 2099 - Z00Mohammed NadeemNo ratings yet

- SCALE 1:50 SCALE 1:50: Ground Floor First FloorDocument1 pageSCALE 1:50 SCALE 1:50: Ground Floor First Floortesfayeseid7No ratings yet

- SRE BNC V 204 0 - BkkNoiDeviator PDFDocument1 pageSRE BNC V 204 0 - BkkNoiDeviator PDFkeaoreNo ratings yet

- ROFI160360 WDocument1 pageROFI160360 WchetanbakkerNo ratings yet

- Elevation Section: Roof BeamDocument1 pageElevation Section: Roof BeamCONFIANCE INFRATECH MANAGEMENT PVT LTDNo ratings yet

- Third Floor Plan: G H I Deck 5000 5000 3000 989 3323 13000Document1 pageThird Floor Plan: G H I Deck 5000 5000 3000 989 3323 13000Mark Kristoffer HilarionNo ratings yet

- A Straight Pipe Details: T1 T2 T3 T4Document1 pageA Straight Pipe Details: T1 T2 T3 T4hoanghc98hn1 hoanghc98hn1No ratings yet

- Gambar Kerja Perencanaan Gedung Hotel MelatiDocument5 pagesGambar Kerja Perencanaan Gedung Hotel MelatiBagas BudiartoNo ratings yet

- Eed-1-S-Pd-001 N +0.00 +7.50 Mod. (Detalles)Document1 pageEed-1-S-Pd-001 N +0.00 +7.50 Mod. (Detalles)John Cartagena CondorNo ratings yet

- Chasis Jaw Crusher 750 X 1060-ModelDocument1 pageChasis Jaw Crusher 750 X 1060-ModelArdi Nal0% (1)

- A3 - Doors & Window ScheduleDocument1 pageA3 - Doors & Window Schedule62296bucoNo ratings yet

- Do An Be Tong Hoan Chinh-Model - pdf2Document1 pageDo An Be Tong Hoan Chinh-Model - pdf2Huy LêNo ratings yet

- 10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Document1 page10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Debasis BarmanNo ratings yet

- Vie Pc01 STN DWG MP Ppa 01109 0Document1 pageVie Pc01 STN DWG MP Ppa 01109 0Ashish BhartiNo ratings yet

- Mohammed Asras ARDocument1 pageMohammed Asras AReman65178No ratings yet

- Detail:C C Section-A A: Hifab International AB, SwedenDocument1 pageDetail:C C Section-A A: Hifab International AB, SwedenTanvir IslamNo ratings yet

- 220 V1A MJKG 00280 - (Rev2)Document1 page220 V1A MJKG 00280 - (Rev2)Patricio Ríos BarraNo ratings yet

- SRE BNC V 203 0 - BkkNoiAbutDim PDFDocument1 pageSRE BNC V 203 0 - BkkNoiAbutDim PDFkeaoreNo ratings yet

- MECHANICAL - 21.8.22t (1) - ModelDocument1 pageMECHANICAL - 21.8.22t (1) - ModelArif TirtaNo ratings yet

- Typical Detail Typical Detail: P-1.0 Design and Build of Typical Municipal Fire Station W/ MezzanineDocument3 pagesTypical Detail Typical Detail: P-1.0 Design and Build of Typical Municipal Fire Station W/ MezzanineJustine Noel De CastroNo ratings yet

- Cadproj Mlmincorporated Schedule 2-11-08 2019Document1 pageCadproj Mlmincorporated Schedule 2-11-08 2019IAN DOMINIC LAGMANNo ratings yet

- R0-STS-22 - 0082-111-Pile RaftDocument5 pagesR0-STS-22 - 0082-111-Pile Raftvishal.bbginfrastructureNo ratings yet

- 2023-01-24 - GROUND FLOOR - CENTERLINE-ModelDocument1 page2023-01-24 - GROUND FLOOR - CENTERLINE-ModelPranay GandhiNo ratings yet

- Corbel Rev.2 ModelDocument1 pageCorbel Rev.2 ModelBang OchimNo ratings yet

- Section (2-2) For Part (2) Section (3-3) For Part (3) : ElhusseinyDocument1 pageSection (2-2) For Part (2) Section (3-3) For Part (3) : Elhusseinymohandgaber1500No ratings yet

- Existing Basement Floor Plan: Hall 550 1200cmDocument1 pageExisting Basement Floor Plan: Hall 550 1200cmHamid ElmyNo ratings yet

- Toilet Plan: DPC Plinth LevelDocument1 pageToilet Plan: DPC Plinth LevelDushyant JadaunNo ratings yet

- Bali Oka 08122023Document21 pagesBali Oka 08122023setyawanagussetyawan523No ratings yet

- Project 2Document1 pageProject 2Abinadab kipngetichNo ratings yet

- Weight Boiler: 40.000kg Weight Water: 30.000kg Weight Total: 70.000kgDocument1 pageWeight Boiler: 40.000kg Weight Water: 30.000kg Weight Total: 70.000kgPinak ProjectsNo ratings yet

- Events PlanelevDocument1 pageEvents Planelevmxp.phangNo ratings yet

- Crate V33H Schematic 1Document2 pagesCrate V33H Schematic 1Danielo ErréNo ratings yet

- Detailed Design: REVISION 0 - 2022-10-31Document1 pageDetailed Design: REVISION 0 - 2022-10-31Daniel AlbanoNo ratings yet

- WIC 54M3 WIC 54M3 WIC 54M3 WIC 54M3: RCC Louver (600x100) MM Around The WindowDocument22 pagesWIC 54M3 WIC 54M3 WIC 54M3 WIC 54M3: RCC Louver (600x100) MM Around The WindowMohammad Taqi HamidiNo ratings yet

- SRE BNC V 202 0 - BkkNoiPierSeg PDFDocument1 pageSRE BNC V 202 0 - BkkNoiPierSeg PDFkeaoreNo ratings yet

- Randwick For TenderDocument1 pageRandwick For Tenderrao_vinay8296No ratings yet

- DWG Add Fiberflow Pma Civil Bagian 1Document17 pagesDWG Add Fiberflow Pma Civil Bagian 1Hermon PakpahanNo ratings yet

- Chassis Jaw 1300 x300Document1 pageChassis Jaw 1300 x300Ardi NalNo ratings yet

- Details of Wall Footing 1 (Wf-1) Detail of Foot TIE BEAM-2 (FB-2)Document1 pageDetails of Wall Footing 1 (Wf-1) Detail of Foot TIE BEAM-2 (FB-2)Charlene Anne Austria VillarozaNo ratings yet

- Concrete Wall For Cattle Grid With CommentsDocument1 pageConcrete Wall For Cattle Grid With Commentsකණිෂ්ක ගුණසේකරNo ratings yet

- Interland: PD GarbageDocument1 pageInterland: PD GarbageDuy Giáp NguyễnNo ratings yet

- CBD 245-3150 + CD 101 - C25036ecdc10 - C PDFDocument7 pagesCBD 245-3150 + CD 101 - C25036ecdc10 - C PDFAhmed Nasr (By NAZRi)No ratings yet

- Internship PortfolioDocument80 pagesInternship PortfolioAdil A S 191006No ratings yet

- ROAD-3: 450mm THKDocument1 pageROAD-3: 450mm THKAhmed MandorNo ratings yet

- Bangkok Noi: Jmi Pacific Limited Ch. KarnchangDocument1 pageBangkok Noi: Jmi Pacific Limited Ch. KarnchangkeaoreNo ratings yet

- Ascott Office New AreaDocument1 pageAscott Office New AreaMuh IhwanzNo ratings yet

- Final Project Site & SecDocument1 pageFinal Project Site & SecNah WorNo ratings yet

- Arp Hid Ab 550 Detl r00cDocument1 pageArp Hid Ab 550 Detl r00cPrisma Engenharia ConstruçãoNo ratings yet

- Ejercicio Estratigrafía Metodología BioestratigrafíaDocument1 pageEjercicio Estratigrafía Metodología Bioestratigrafíayimy.fontechaNo ratings yet

- Bending Schedule: Sect A-ADocument1 pageBending Schedule: Sect A-AYaw KrahNo ratings yet

- Planuri Licenta 2019 La Profesor-ModelDocument1 pagePlanuri Licenta 2019 La Profesor-ModelkiradavidNo ratings yet

- Denah Lantai 10 (Top Floor) - ModelDocument1 pageDenah Lantai 10 (Top Floor) - Modelari dwi nNo ratings yet

- Chart of Thermodynamic & Transport Properties of CO2 - ManualDocument34 pagesChart of Thermodynamic & Transport Properties of CO2 - ManualAbdus Saboor KhalidNo ratings yet

- Pintu Air Saluran UtamaDocument1 pagePintu Air Saluran UtamaHadi FarhanNo ratings yet

- General Detail Abut & WWDocument1 pageGeneral Detail Abut & WWUmesgNo ratings yet

- Ab STR 103 B124Document1 pageAb STR 103 B124arainzada807No ratings yet

- EXW-P008-0003-SE-CCC-DG-41050-014 - Rev CADocument1 pageEXW-P008-0003-SE-CCC-DG-41050-014 - Rev CAAbdul basithNo ratings yet

- Protection Functions of Simocode Pro According Ansi Systematic v0 2Document4 pagesProtection Functions of Simocode Pro According Ansi Systematic v0 2koko MeNo ratings yet

- 9th Physics Full Book McqsDocument30 pages9th Physics Full Book Mcqssky.blueNo ratings yet

- VHT VK enDocument16 pagesVHT VK enalialmalki1515No ratings yet

- PN JunctionDocument7 pagesPN JunctionChannabasavagouda BNo ratings yet

- ANT-ADU4521R3v06 Datasheet (High Gain ANT)Document2 pagesANT-ADU4521R3v06 Datasheet (High Gain ANT)hafid irawanNo ratings yet

- Analysis of PV Modules by Electroluminescence and Ir ThermographyDocument5 pagesAnalysis of PV Modules by Electroluminescence and Ir ThermographyReham El-tuhamyNo ratings yet

- The Laplace TransformDocument22 pagesThe Laplace Transformindrayadi2009No ratings yet

- Vib FileDocument3 pagesVib FileJohn Louie PimentelNo ratings yet

- Trane Fcu - Old CCRDocument82 pagesTrane Fcu - Old CCRHVAC Technical DurocleanNo ratings yet

- Eccentrically Loaded FootingsDocument7 pagesEccentrically Loaded Footingsmathewsujith31No ratings yet

- Chapter 3 - Differential CalculusDocument25 pagesChapter 3 - Differential CalculusEdison SioNo ratings yet

- Pretest, RC Part 1Document3 pagesPretest, RC Part 1leanne DespaNo ratings yet

- Air Navigation Full-1Document12 pagesAir Navigation Full-1Harshit dubeyNo ratings yet

- Electronics Module G10 Q4 Week 1 2Document26 pagesElectronics Module G10 Q4 Week 1 2Florence FernandezNo ratings yet

- The Formation of Heavier Elements During Star Formation and EvolutionDocument8 pagesThe Formation of Heavier Elements During Star Formation and EvolutionJohn Nerlo DequiñaNo ratings yet

- Design, Modeling and Simulation of An Electric Vehicle SystemDocument12 pagesDesign, Modeling and Simulation of An Electric Vehicle SystemsushruthanNo ratings yet

- NITK Surathkal About The FDP RegistrationDocument1 pageNITK Surathkal About The FDP RegistrationKumar ReddyNo ratings yet

- Potion Grade 10Document4 pagesPotion Grade 10gestrojackNo ratings yet

- Chemistry Lab e Content Updated 2Document35 pagesChemistry Lab e Content Updated 2Debarghya DuttaNo ratings yet

- Screen & Conveyorgad, Data Sheet & Qap - SP-1326Document14 pagesScreen & Conveyorgad, Data Sheet & Qap - SP-1326ankit singlaNo ratings yet

- EC 252:signals and Systems Laboratory: Generating Signals Using Matlab SimulatorDocument11 pagesEC 252:signals and Systems Laboratory: Generating Signals Using Matlab SimulatorSHOAIB WARJRINo ratings yet

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleNo ratings yet

- BD QBC Centrifuge ManualDocument31 pagesBD QBC Centrifuge ManualService BlockNo ratings yet

- First Seminar (Literature Review)Document40 pagesFirst Seminar (Literature Review)Muhammad Muazu KibiyaNo ratings yet

- Vanderfleet, Cranston - 2021 - Production Routes To Tailor The Performance of Cellulose NanocrystalsDocument21 pagesVanderfleet, Cranston - 2021 - Production Routes To Tailor The Performance of Cellulose Nanocrystalscat.zeNo ratings yet

- ECE 226 Chapter 1 Tutorial QuestionsDocument20 pagesECE 226 Chapter 1 Tutorial QuestionsFilbert OmbongiNo ratings yet

- Ti-005 - TCVT 72-1200Document4 pagesTi-005 - TCVT 72-1200Julio Gonzalo Robles PalmaNo ratings yet

- Mathematical Model of The Vehicle in Matlab SimulinkDocument7 pagesMathematical Model of The Vehicle in Matlab SimulinkgarylikeuNo ratings yet