Professional Documents

Culture Documents

EBECRYL-168 Americas EN

EBECRYL-168 Americas EN

Uploaded by

ricardo.f.d.silva.2004Copyright:

Available Formats

You might also like

- TR 25-1-2022 PreviewDocument9 pagesTR 25-1-2022 Previewkanarendran50% (2)

- Uvitex EDB Textile Whitener: Technical Data SheetDocument7 pagesUvitex EDB Textile Whitener: Technical Data Sheetraju_hosssenNo ratings yet

- 90 EPIKOTE Resin 845 - EPIKURE Curing Agent 05378-EnglishDocument10 pages90 EPIKOTE Resin 845 - EPIKURE Curing Agent 05378-EnglishCesar Candelaria ChavezNo ratings yet

- Black & DeckerDocument28 pagesBlack & DeckerSunny ShresthaNo ratings yet

- Ebecryl 85: Technical Data Sheet EBECRYL® UV/EB Energy Curable ResinsDocument1 pageEbecryl 85: Technical Data Sheet EBECRYL® UV/EB Energy Curable ResinsSi PhamNo ratings yet

- Ebecryl-1271 en A4Document2 pagesEbecryl-1271 en A4I Love MusicNo ratings yet

- Pekasol L Datenblatt GB 4S 11 2015Document4 pagesPekasol L Datenblatt GB 4S 11 2015tungxuanbrNo ratings yet

- Laropal A 81 June 2014 R2 ICDocument3 pagesLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNo ratings yet

- Amirez 142 TDSDocument1 pageAmirez 142 TDSNganNo ratings yet

- Cymel-Nf-2000a en A4Document2 pagesCymel-Nf-2000a en A4DidarNo ratings yet

- Ebecryl-898 en A4Document2 pagesEbecryl-898 en A4I Love MusicNo ratings yet

- Epikote Resin 828lvelDocument2 pagesEpikote Resin 828lvelLê TiếnNo ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Introduction To The Basics of UV/EB Chemistry and FormulationsDocument64 pagesIntroduction To The Basics of UV/EB Chemistry and FormulationsdamiendamNo ratings yet

- Tds Acronaleco702ap enDocument3 pagesTds Acronaleco702ap enShreyashi MukhopadhayNo ratings yet

- Obemul Sa352 - TDSDocument1 pageObemul Sa352 - TDSAhmed HosniNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- Description: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Document2 pagesDescription: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)LONG LASTNo ratings yet

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDocument8 pagesEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗNo ratings yet

- Cymel-Nf-3041 en A4Document1 pageCymel-Nf-3041 en A4DidarNo ratings yet

- Cobratec TT 100CDocument1 pageCobratec TT 100CDiego SamayoaNo ratings yet

- Bermocoll EHM 300 PDSDocument3 pagesBermocoll EHM 300 PDSAkbar NouryonNo ratings yet

- Solbin A Tds 3.2014rsDocument2 pagesSolbin A Tds 3.2014rsGarvit GuptaNo ratings yet

- Bioneptan: Environmentally Acceptable Lubricants (EAL)Document1 pageBioneptan: Environmentally Acceptable Lubricants (EAL)satNo ratings yet

- Carbopol Ultrez 21 Hoja Tecnica PDFDocument4 pagesCarbopol Ultrez 21 Hoja Tecnica PDFCelia Atauqui100% (1)

- TDS 187 Carbopol ETD 2020 Personal Care Applications PDFDocument2 pagesTDS 187 Carbopol ETD 2020 Personal Care Applications PDFPatrick BurnsNo ratings yet

- Ultrez 21Document4 pagesUltrez 21Raíde PachecoNo ratings yet

- Cymel-Nf-3030 en A4Document1 pageCymel-Nf-3030 en A4DidarNo ratings yet

- TDS-243 Optimizing Performance Carbopol ETD 2020 Ultrez 10 Partial Neutralization Polymer DispersionsDocument2 pagesTDS-243 Optimizing Performance Carbopol ETD 2020 Ultrez 10 Partial Neutralization Polymer DispersionsCarlos Gonzalez CastroNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- TDS RD 108Document2 pagesTDS RD 108APEX SONNo ratings yet

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmNo ratings yet

- Ascotran H 14 (Anti Flash Rust)Document1 pageAscotran H 14 (Anti Flash Rust)Yến HoàngNo ratings yet

- Ebecryl-P115 en A4Document1 pageEbecryl-P115 en A4ichsan hakimNo ratings yet

- TDS Abitol E Hydroabietyl AlcoholDocument2 pagesTDS Abitol E Hydroabietyl AlcoholCaio OliveiraNo ratings yet

- EPODIL® 748 Reactive Diluent: DescriptionDocument2 pagesEPODIL® 748 Reactive Diluent: DescriptionArturo BarjauNo ratings yet

- Laropal A81: Industrial CoatingsDocument3 pagesLaropal A81: Industrial CoatingsMOEEN KHAN ASLAM KHAN RISALDARNo ratings yet

- Optifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintDocument16 pagesOptifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintAPEX SONNo ratings yet

- UNIQEMA HypermerPolymericSurfactantsDocument2 pagesUNIQEMA HypermerPolymericSurfactantsKushagradhi DebnathNo ratings yet

- Basis 59 - TDSDocument2 pagesBasis 59 - TDSsriatul2006No ratings yet

- DS Abil em 180Document6 pagesDS Abil em 180celmorcelliNo ratings yet

- Chemistry and Technology: Uv&EbDocument8 pagesChemistry and Technology: Uv&EbjdcarnNo ratings yet

- Hempathane HS 55610Document4 pagesHempathane HS 55610Hussein MohamedNo ratings yet

- Sasol Olefins & Surfactants: Isotridecanol Ethoxylates Marlipal® O13Document24 pagesSasol Olefins & Surfactants: Isotridecanol Ethoxylates Marlipal® O13Farooq AhmedNo ratings yet

- Hempathane HS 55610Document4 pagesHempathane HS 55610projectraayirathNo ratings yet

- 7m150-Tds-Ebecryl IbomaDocument1 page7m150-Tds-Ebecryl Ibomashahin774No ratings yet

- Amicure 101 UsDocument4 pagesAmicure 101 Usmandy.chenxi1009No ratings yet

- Kollicoat EMM 30 DDocument12 pagesKollicoat EMM 30 DMd.ali-bin-saifullah100% (1)

- Hyperbranched Polymers For Hardcoat With Superior PerformancesDocument5 pagesHyperbranched Polymers For Hardcoat With Superior PerformancesBernard HassonNo ratings yet

- Tds Elotex Mp2050 enDocument2 pagesTds Elotex Mp2050 end6cmc5jscfNo ratings yet

- Bayhydrol UV 26891 - en - 79962983 12942311 14257784Document3 pagesBayhydrol UV 26891 - en - 79962983 12942311 14257784zaryab khanNo ratings yet

- Epotec YDFM 253 PDFDocument2 pagesEpotec YDFM 253 PDFsriatul2006No ratings yet

- Sabic PlaDocument4 pagesSabic PlavgciasenNo ratings yet

- TDS - LUBRILOG Distributed by TOTAL - LUBRICLEAN EP - F6N - 201401 - ENDocument1 pageTDS - LUBRILOG Distributed by TOTAL - LUBRICLEAN EP - F6N - 201401 - ENDaniel CaviedesNo ratings yet

- Clariant AdditivesDocument3 pagesClariant AdditivesZelal Harputlu OzbunarNo ratings yet

- Bermocoll EM 7000 FQ PDSDocument3 pagesBermocoll EM 7000 FQ PDSAkbar NouryonNo ratings yet

- Ecovio M2351Document3 pagesEcovio M2351ssczusNo ratings yet

- TDS RD 104Document2 pagesTDS RD 104LONG LASTNo ratings yet

- Cymel® 303 LF: Product Description Typical PropertiesDocument2 pagesCymel® 303 LF: Product Description Typical Propertiesهیمن مNo ratings yet

- Isophthalic Resin - AROPOL IN 5334Document3 pagesIsophthalic Resin - AROPOL IN 5334GautamNo ratings yet

- Ebecryl-P116 en A4Document1 pageEbecryl-P116 en A4I Love MusicNo ratings yet

- 12608computer Class XDocument2 pages12608computer Class XAnish LahiriNo ratings yet

- Ansell Annual Report 2018 FINAL For Website PDFDocument128 pagesAnsell Annual Report 2018 FINAL For Website PDFWilliam Veloz DiazNo ratings yet

- Fast Guide To DTVDocument6 pagesFast Guide To DTVnsilverguyNo ratings yet

- Computer MCQ FOR BANK PO & CLERK EXAMDocument26 pagesComputer MCQ FOR BANK PO & CLERK EXAMShubhajit Nandi80% (5)

- Base Camp - Zamzales1Document14 pagesBase Camp - Zamzales1egay cambeNo ratings yet

- Final 2Document72 pagesFinal 2VM MittalNo ratings yet

- Fressoli, Dias, Thomas Innovation and Inclusive Develpment in South AmericaDocument16 pagesFressoli, Dias, Thomas Innovation and Inclusive Develpment in South AmericaLorena Paz100% (1)

- Kashmir Moeed PirzadaDocument13 pagesKashmir Moeed Pirzadamanojkp33No ratings yet

- 5-4-3 Wire Apartment Intercom Amp: Wiring InstructionsDocument8 pages5-4-3 Wire Apartment Intercom Amp: Wiring InstructionsVlasta Polic ZileNo ratings yet

- BH42SH60 0854PL 46kgcmDocument1 pageBH42SH60 0854PL 46kgcmYash PanchalNo ratings yet

- Portfolio Channel BeginnersDocument9 pagesPortfolio Channel BeginnersFerenc BárándiNo ratings yet

- Moly-D Technical HandbookDocument16 pagesMoly-D Technical HandbookJessAlcaláNo ratings yet

- Avc A1d enDocument2 pagesAvc A1d enenergiculNo ratings yet

- 5BSW (Syllabus) Revised and Approved by The Board of Studies of Social WorkDocument18 pages5BSW (Syllabus) Revised and Approved by The Board of Studies of Social WorkRohit SinghNo ratings yet

- Homesick: Why I Live in A Shed ExtractDocument42 pagesHomesick: Why I Live in A Shed ExtractQuercus Books100% (2)

- ShrsDocument16 pagesShrsKevin Patel100% (1)

- 5862 55630 1 PBDocument12 pages5862 55630 1 PBkomiiakihimeNo ratings yet

- Question 1. Calculate Covariance and Correlation Between Below Two Columns A and B?Document5 pagesQuestion 1. Calculate Covariance and Correlation Between Below Two Columns A and B?navdeepNo ratings yet

- Answers & QuestionsDocument2 pagesAnswers & QuestionsZayeb IKONIKNo ratings yet

- United States v. Eric Millan, A/K/A Eric Millan Colon, A/K/A Eric Colon, A/K/A Luis Colon, A/K/A Ejay, A/K/A Moe Ralph Rivera, A/K/A Tj, A/K/A Rafael Rivera Vincent Basciano, A/K/A Vinnie Alfred v. Bottone, Sr., A/K/A Valentino A. Bottone, A/K/A Fat Al Alfred Bottone, Jr., A/K/A Alfie and Noel Melendez, Myles Coker Anthony Bottone Albert Biscaglio, A/K/A Allie John O'rourke, A/K/A Xyz Raimundo Hurdle, A/K/A Carlos Hurdly, A/K/A Panama William Mendoza, A/K/A Willie Porfipio Ortiz Mildred Hernandez Carmen Mendoza, A/K/A Belilo Samanta Torres and Larry Weinstein, A/K/A Larry Burns, 17 F.3d 14, 2d Cir. (1994)Document12 pagesUnited States v. Eric Millan, A/K/A Eric Millan Colon, A/K/A Eric Colon, A/K/A Luis Colon, A/K/A Ejay, A/K/A Moe Ralph Rivera, A/K/A Tj, A/K/A Rafael Rivera Vincent Basciano, A/K/A Vinnie Alfred v. Bottone, Sr., A/K/A Valentino A. Bottone, A/K/A Fat Al Alfred Bottone, Jr., A/K/A Alfie and Noel Melendez, Myles Coker Anthony Bottone Albert Biscaglio, A/K/A Allie John O'rourke, A/K/A Xyz Raimundo Hurdle, A/K/A Carlos Hurdly, A/K/A Panama William Mendoza, A/K/A Willie Porfipio Ortiz Mildred Hernandez Carmen Mendoza, A/K/A Belilo Samanta Torres and Larry Weinstein, A/K/A Larry Burns, 17 F.3d 14, 2d Cir. (1994)Scribd Government DocsNo ratings yet

- MCC5412 - Lecture 4Document38 pagesMCC5412 - Lecture 4Dickson ChanNo ratings yet

- Iso 3613 2000 FR PDFDocument6 pagesIso 3613 2000 FR PDFJeannie VargasNo ratings yet

- Bugs FixedDocument90 pagesBugs Fixedmariolgui68No ratings yet

- Chassis Design ExampleDocument9 pagesChassis Design ExampleWisdom Patrick EnangNo ratings yet

- Portfolio - Nagaraj Chandrashekar SiddeshwarDocument5 pagesPortfolio - Nagaraj Chandrashekar SiddeshwarNagaraj Chandrashekar SiddeshwarNo ratings yet

- Sensor Principle MH-C MH-C2 Electrical Data: Vert-X 48E - 24V / 4 - 20ma ApplicationsDocument5 pagesSensor Principle MH-C MH-C2 Electrical Data: Vert-X 48E - 24V / 4 - 20ma Applicationsrimmer boyNo ratings yet

- Abbas - Firoozabadi - Fractured Petroleum Reserviors PDFDocument284 pagesAbbas - Firoozabadi - Fractured Petroleum Reserviors PDFHugoNo ratings yet

- Bennet Trim Tabs PDFDocument12 pagesBennet Trim Tabs PDFjbozak100% (1)

EBECRYL-168 Americas EN

EBECRYL-168 Americas EN

Uploaded by

ricardo.f.d.silva.2004Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EBECRYL-168 Americas EN

EBECRYL-168 Americas EN

Uploaded by

ricardo.f.d.silva.2004Copyright:

Available Formats

TECHNICAL DATASHEET EBECRYL® UV/EB Energy Curable Resins

EBECRYL® 168

Acidic Methacrylate

March 2017

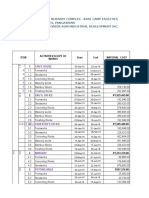

INTRODUCTION SPECIFICATIONS VALUE

EBECRYL 168 is an acidic methacrylate adhesion promoter designed as an additive Acid value, mg KOH/g 250-330

for ultraviolet (UV) and electron beam (EB) curable coatings on metal. Appearance Clear liquid

Color, Gardner, max. 1.5

PERFORMANCE HIGHLIGHTS Viscosity, 25°C, cone/plate, cP/mPa·s 900-1900

EBECRYL 168 is characterized by: Viscosity, 25°C, Höppler, cP/mPa·s 850-1850

• Light color

• Low viscosity TYPICAL PHYSICAL PROPERTIES

• Acid functionality Density, g/ml at 25°C 1.29

Functionality, theoretical(1) ~1.5

UV/EB curable formulated products containing EBECRYL 168 are characterized by: Oligomer, % by weight 100

• Good adhesion to metal substrates

• Improved compatibility (relative to EBECRYL 170) NOTES ON USAGE

Typical usage level is between 1% and 5% by weight of the total formulation. Due

The actual properties of UV/EB cured products also depend on the selection of to its acidic character, EBECRYL 168 can undergo hydrolysis, and therefore

other formulation components such as reactive diluents, additives and formulations containing EBECRYL 168 should be protected from humidity. Since

photoinitiators. EBECRYL 168 can react with alkaline materials, free amines, amino acrylates, basic

pigments and N-vinyl-2-pyrrolidone should not be used in combination with

SUGGESTED APPLICATIONS EBECRYL 168.

Formulated UV/EB curable products containing EBECRYL 168 may be applied via

direct or reverse roll, offset gravure, metering rod, slot die, knife over roll, air Formulations may exhibit turbidity with the addition of EBECRYL 168, though such

knife, curtain and immersion coating methods. EBECRYL 168 is recommended for turbidity may not be immediately apparent. The presence of turbidity is not

use in: normally indicative of coating performance problems, though in severe instances,

separation or precipitation may occur.

• General metal coatings and primers

• Coatings for galvanized pipe and tube

• Coil coatings PRECAUTIONS

• Solder resist formulations Before using EBECRYL 168, see the Safety Data Sheet (SDS) for information on the

identified hazards of the material and the recommended personal protective

equipment and procedures.

STORAGE AND HANDLING

Care should be taken not to expose the product to high temperature conditions,

direct sunlight, ignition sources, oxidizing agents, alkalis or acids. This might

cause uncontrollable polymerization of the product with the generation of heat.

Storage and handling should be in stainless steel, amber glass, amber

polyethylene or baked phenolic lined containers. Procedures that remove or

displace oxygen from the material should be avoided. Do not store this material

under an oxygen free atmosphere. Dry air is recommended to displace material

removed from the container. Wash thoroughly after handling. Keep container

tightly closed. Use with adequate ventilation.

Contamination of EBECRYL 168 with acetone or other ketones can cause

coloration of the product during storage.

See the SDS for the recommended storage temperature range for EBECRYL 168.

Please refer to the allnex Guide to Safety and Handling of Acrylate Oligomers and

Monomers for additional information on the safe handling of acrylates.

(1) Theoretical determination based on the undiluted oligomer.

www.allnex.com

Disclaimer: allnex Group companies ('allnex') decline any liability with respect to the use made by anyone of the information contained herein. The information contained herein represents allnex's best knowledge thereon without constituting any express or implied

guarantee or warranty of any kind (including, but not limited to, regarding the accuracy, the completeness or relevance of the data set out herein). Nothing contained herein shall be construed as conferring any license or right under any patent or other intellectual property

rights of allnex or of any third party. The information relating to the products is given for information purposes only. No guarantee or warranty is provided that the product and/or information is adapted for any specific use, performance or result and that product and/or

information do not infringe any allnex and/or third party intellectual property rights. The user should perform his/her own tests to determine the suitability for a particular purpose. The final choice of use of a product and/or information as well as the investigation of any

possible violation of intellectual property rights of allnex and/or third parties remains the sole responsibility of the user.

Notice: Trademarks indicated with ® , TM or * as well as the allnex name and logo are registered, unregistered or pending trademarks of Allnex IP s.à.r.l. or its directly or indirectly affiliated allnex Group companies.

©2017 allnex Group. All Rights Reserved. EBECRYL 168 - TDS 7/19/2017

You might also like

- TR 25-1-2022 PreviewDocument9 pagesTR 25-1-2022 Previewkanarendran50% (2)

- Uvitex EDB Textile Whitener: Technical Data SheetDocument7 pagesUvitex EDB Textile Whitener: Technical Data Sheetraju_hosssenNo ratings yet

- 90 EPIKOTE Resin 845 - EPIKURE Curing Agent 05378-EnglishDocument10 pages90 EPIKOTE Resin 845 - EPIKURE Curing Agent 05378-EnglishCesar Candelaria ChavezNo ratings yet

- Black & DeckerDocument28 pagesBlack & DeckerSunny ShresthaNo ratings yet

- Ebecryl 85: Technical Data Sheet EBECRYL® UV/EB Energy Curable ResinsDocument1 pageEbecryl 85: Technical Data Sheet EBECRYL® UV/EB Energy Curable ResinsSi PhamNo ratings yet

- Ebecryl-1271 en A4Document2 pagesEbecryl-1271 en A4I Love MusicNo ratings yet

- Pekasol L Datenblatt GB 4S 11 2015Document4 pagesPekasol L Datenblatt GB 4S 11 2015tungxuanbrNo ratings yet

- Laropal A 81 June 2014 R2 ICDocument3 pagesLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNo ratings yet

- Amirez 142 TDSDocument1 pageAmirez 142 TDSNganNo ratings yet

- Cymel-Nf-2000a en A4Document2 pagesCymel-Nf-2000a en A4DidarNo ratings yet

- Ebecryl-898 en A4Document2 pagesEbecryl-898 en A4I Love MusicNo ratings yet

- Epikote Resin 828lvelDocument2 pagesEpikote Resin 828lvelLê TiếnNo ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Introduction To The Basics of UV/EB Chemistry and FormulationsDocument64 pagesIntroduction To The Basics of UV/EB Chemistry and FormulationsdamiendamNo ratings yet

- Tds Acronaleco702ap enDocument3 pagesTds Acronaleco702ap enShreyashi MukhopadhayNo ratings yet

- Obemul Sa352 - TDSDocument1 pageObemul Sa352 - TDSAhmed HosniNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- Description: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Document2 pagesDescription: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)LONG LASTNo ratings yet

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDocument8 pagesEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗNo ratings yet

- Cymel-Nf-3041 en A4Document1 pageCymel-Nf-3041 en A4DidarNo ratings yet

- Cobratec TT 100CDocument1 pageCobratec TT 100CDiego SamayoaNo ratings yet

- Bermocoll EHM 300 PDSDocument3 pagesBermocoll EHM 300 PDSAkbar NouryonNo ratings yet

- Solbin A Tds 3.2014rsDocument2 pagesSolbin A Tds 3.2014rsGarvit GuptaNo ratings yet

- Bioneptan: Environmentally Acceptable Lubricants (EAL)Document1 pageBioneptan: Environmentally Acceptable Lubricants (EAL)satNo ratings yet

- Carbopol Ultrez 21 Hoja Tecnica PDFDocument4 pagesCarbopol Ultrez 21 Hoja Tecnica PDFCelia Atauqui100% (1)

- TDS 187 Carbopol ETD 2020 Personal Care Applications PDFDocument2 pagesTDS 187 Carbopol ETD 2020 Personal Care Applications PDFPatrick BurnsNo ratings yet

- Ultrez 21Document4 pagesUltrez 21Raíde PachecoNo ratings yet

- Cymel-Nf-3030 en A4Document1 pageCymel-Nf-3030 en A4DidarNo ratings yet

- TDS-243 Optimizing Performance Carbopol ETD 2020 Ultrez 10 Partial Neutralization Polymer DispersionsDocument2 pagesTDS-243 Optimizing Performance Carbopol ETD 2020 Ultrez 10 Partial Neutralization Polymer DispersionsCarlos Gonzalez CastroNo ratings yet

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- TDS RD 108Document2 pagesTDS RD 108APEX SONNo ratings yet

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmNo ratings yet

- Ascotran H 14 (Anti Flash Rust)Document1 pageAscotran H 14 (Anti Flash Rust)Yến HoàngNo ratings yet

- Ebecryl-P115 en A4Document1 pageEbecryl-P115 en A4ichsan hakimNo ratings yet

- TDS Abitol E Hydroabietyl AlcoholDocument2 pagesTDS Abitol E Hydroabietyl AlcoholCaio OliveiraNo ratings yet

- EPODIL® 748 Reactive Diluent: DescriptionDocument2 pagesEPODIL® 748 Reactive Diluent: DescriptionArturo BarjauNo ratings yet

- Laropal A81: Industrial CoatingsDocument3 pagesLaropal A81: Industrial CoatingsMOEEN KHAN ASLAM KHAN RISALDARNo ratings yet

- Optifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintDocument16 pagesOptifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintAPEX SONNo ratings yet

- UNIQEMA HypermerPolymericSurfactantsDocument2 pagesUNIQEMA HypermerPolymericSurfactantsKushagradhi DebnathNo ratings yet

- Basis 59 - TDSDocument2 pagesBasis 59 - TDSsriatul2006No ratings yet

- DS Abil em 180Document6 pagesDS Abil em 180celmorcelliNo ratings yet

- Chemistry and Technology: Uv&EbDocument8 pagesChemistry and Technology: Uv&EbjdcarnNo ratings yet

- Hempathane HS 55610Document4 pagesHempathane HS 55610Hussein MohamedNo ratings yet

- Sasol Olefins & Surfactants: Isotridecanol Ethoxylates Marlipal® O13Document24 pagesSasol Olefins & Surfactants: Isotridecanol Ethoxylates Marlipal® O13Farooq AhmedNo ratings yet

- Hempathane HS 55610Document4 pagesHempathane HS 55610projectraayirathNo ratings yet

- 7m150-Tds-Ebecryl IbomaDocument1 page7m150-Tds-Ebecryl Ibomashahin774No ratings yet

- Amicure 101 UsDocument4 pagesAmicure 101 Usmandy.chenxi1009No ratings yet

- Kollicoat EMM 30 DDocument12 pagesKollicoat EMM 30 DMd.ali-bin-saifullah100% (1)

- Hyperbranched Polymers For Hardcoat With Superior PerformancesDocument5 pagesHyperbranched Polymers For Hardcoat With Superior PerformancesBernard HassonNo ratings yet

- Tds Elotex Mp2050 enDocument2 pagesTds Elotex Mp2050 end6cmc5jscfNo ratings yet

- Bayhydrol UV 26891 - en - 79962983 12942311 14257784Document3 pagesBayhydrol UV 26891 - en - 79962983 12942311 14257784zaryab khanNo ratings yet

- Epotec YDFM 253 PDFDocument2 pagesEpotec YDFM 253 PDFsriatul2006No ratings yet

- Sabic PlaDocument4 pagesSabic PlavgciasenNo ratings yet

- TDS - LUBRILOG Distributed by TOTAL - LUBRICLEAN EP - F6N - 201401 - ENDocument1 pageTDS - LUBRILOG Distributed by TOTAL - LUBRICLEAN EP - F6N - 201401 - ENDaniel CaviedesNo ratings yet

- Clariant AdditivesDocument3 pagesClariant AdditivesZelal Harputlu OzbunarNo ratings yet

- Bermocoll EM 7000 FQ PDSDocument3 pagesBermocoll EM 7000 FQ PDSAkbar NouryonNo ratings yet

- Ecovio M2351Document3 pagesEcovio M2351ssczusNo ratings yet

- TDS RD 104Document2 pagesTDS RD 104LONG LASTNo ratings yet

- Cymel® 303 LF: Product Description Typical PropertiesDocument2 pagesCymel® 303 LF: Product Description Typical Propertiesهیمن مNo ratings yet

- Isophthalic Resin - AROPOL IN 5334Document3 pagesIsophthalic Resin - AROPOL IN 5334GautamNo ratings yet

- Ebecryl-P116 en A4Document1 pageEbecryl-P116 en A4I Love MusicNo ratings yet

- 12608computer Class XDocument2 pages12608computer Class XAnish LahiriNo ratings yet

- Ansell Annual Report 2018 FINAL For Website PDFDocument128 pagesAnsell Annual Report 2018 FINAL For Website PDFWilliam Veloz DiazNo ratings yet

- Fast Guide To DTVDocument6 pagesFast Guide To DTVnsilverguyNo ratings yet

- Computer MCQ FOR BANK PO & CLERK EXAMDocument26 pagesComputer MCQ FOR BANK PO & CLERK EXAMShubhajit Nandi80% (5)

- Base Camp - Zamzales1Document14 pagesBase Camp - Zamzales1egay cambeNo ratings yet

- Final 2Document72 pagesFinal 2VM MittalNo ratings yet

- Fressoli, Dias, Thomas Innovation and Inclusive Develpment in South AmericaDocument16 pagesFressoli, Dias, Thomas Innovation and Inclusive Develpment in South AmericaLorena Paz100% (1)

- Kashmir Moeed PirzadaDocument13 pagesKashmir Moeed Pirzadamanojkp33No ratings yet

- 5-4-3 Wire Apartment Intercom Amp: Wiring InstructionsDocument8 pages5-4-3 Wire Apartment Intercom Amp: Wiring InstructionsVlasta Polic ZileNo ratings yet

- BH42SH60 0854PL 46kgcmDocument1 pageBH42SH60 0854PL 46kgcmYash PanchalNo ratings yet

- Portfolio Channel BeginnersDocument9 pagesPortfolio Channel BeginnersFerenc BárándiNo ratings yet

- Moly-D Technical HandbookDocument16 pagesMoly-D Technical HandbookJessAlcaláNo ratings yet

- Avc A1d enDocument2 pagesAvc A1d enenergiculNo ratings yet

- 5BSW (Syllabus) Revised and Approved by The Board of Studies of Social WorkDocument18 pages5BSW (Syllabus) Revised and Approved by The Board of Studies of Social WorkRohit SinghNo ratings yet

- Homesick: Why I Live in A Shed ExtractDocument42 pagesHomesick: Why I Live in A Shed ExtractQuercus Books100% (2)

- ShrsDocument16 pagesShrsKevin Patel100% (1)

- 5862 55630 1 PBDocument12 pages5862 55630 1 PBkomiiakihimeNo ratings yet

- Question 1. Calculate Covariance and Correlation Between Below Two Columns A and B?Document5 pagesQuestion 1. Calculate Covariance and Correlation Between Below Two Columns A and B?navdeepNo ratings yet

- Answers & QuestionsDocument2 pagesAnswers & QuestionsZayeb IKONIKNo ratings yet

- United States v. Eric Millan, A/K/A Eric Millan Colon, A/K/A Eric Colon, A/K/A Luis Colon, A/K/A Ejay, A/K/A Moe Ralph Rivera, A/K/A Tj, A/K/A Rafael Rivera Vincent Basciano, A/K/A Vinnie Alfred v. Bottone, Sr., A/K/A Valentino A. Bottone, A/K/A Fat Al Alfred Bottone, Jr., A/K/A Alfie and Noel Melendez, Myles Coker Anthony Bottone Albert Biscaglio, A/K/A Allie John O'rourke, A/K/A Xyz Raimundo Hurdle, A/K/A Carlos Hurdly, A/K/A Panama William Mendoza, A/K/A Willie Porfipio Ortiz Mildred Hernandez Carmen Mendoza, A/K/A Belilo Samanta Torres and Larry Weinstein, A/K/A Larry Burns, 17 F.3d 14, 2d Cir. (1994)Document12 pagesUnited States v. Eric Millan, A/K/A Eric Millan Colon, A/K/A Eric Colon, A/K/A Luis Colon, A/K/A Ejay, A/K/A Moe Ralph Rivera, A/K/A Tj, A/K/A Rafael Rivera Vincent Basciano, A/K/A Vinnie Alfred v. Bottone, Sr., A/K/A Valentino A. Bottone, A/K/A Fat Al Alfred Bottone, Jr., A/K/A Alfie and Noel Melendez, Myles Coker Anthony Bottone Albert Biscaglio, A/K/A Allie John O'rourke, A/K/A Xyz Raimundo Hurdle, A/K/A Carlos Hurdly, A/K/A Panama William Mendoza, A/K/A Willie Porfipio Ortiz Mildred Hernandez Carmen Mendoza, A/K/A Belilo Samanta Torres and Larry Weinstein, A/K/A Larry Burns, 17 F.3d 14, 2d Cir. (1994)Scribd Government DocsNo ratings yet

- MCC5412 - Lecture 4Document38 pagesMCC5412 - Lecture 4Dickson ChanNo ratings yet

- Iso 3613 2000 FR PDFDocument6 pagesIso 3613 2000 FR PDFJeannie VargasNo ratings yet

- Bugs FixedDocument90 pagesBugs Fixedmariolgui68No ratings yet

- Chassis Design ExampleDocument9 pagesChassis Design ExampleWisdom Patrick EnangNo ratings yet

- Portfolio - Nagaraj Chandrashekar SiddeshwarDocument5 pagesPortfolio - Nagaraj Chandrashekar SiddeshwarNagaraj Chandrashekar SiddeshwarNo ratings yet

- Sensor Principle MH-C MH-C2 Electrical Data: Vert-X 48E - 24V / 4 - 20ma ApplicationsDocument5 pagesSensor Principle MH-C MH-C2 Electrical Data: Vert-X 48E - 24V / 4 - 20ma Applicationsrimmer boyNo ratings yet

- Abbas - Firoozabadi - Fractured Petroleum Reserviors PDFDocument284 pagesAbbas - Firoozabadi - Fractured Petroleum Reserviors PDFHugoNo ratings yet

- Bennet Trim Tabs PDFDocument12 pagesBennet Trim Tabs PDFjbozak100% (1)