Professional Documents

Culture Documents

JSA For Replacement of Metal Roofsheet (East) .AB.1

JSA For Replacement of Metal Roofsheet (East) .AB.1

Uploaded by

hse2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA For Replacement of Metal Roofsheet (East) .AB.1

JSA For Replacement of Metal Roofsheet (East) .AB.1

Uploaded by

hse2Copyright:

Available Formats

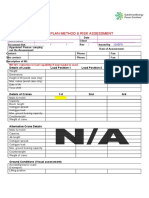

JOB SAFETY ANALYSIS WORKSHEET

Ref No: EHS/JSA/ Date:

Company: ABIRAMI BUILDERS

Project: sand unit-1 (SMML)

Location: sand unit-1, (smml), viralimalai , Trichy

The type of work, nature of work: REPLACEMENT OF METAL ROOF (east)

The tools and equipment used: Mobile Crane, Chain Slings, hooks, ladder, drillers , roof knife , hammer ,dumpster ,

The training and skill required for the job: all workers must conduct TBT meeting , before start the job must conduct pre-task meeting and they aware about work at

height , crane activity,

Personal Protective Equipment Required: full body hardness, goo glass, safety gloves , hard helmets, safety net must be implemented.

Prepared By: BOSE SIRANJEEVI.S (SAFETY OFFICER)

Reviewed and approved by:

16 February 2023 Page 1 of 4

JOB STEP HAZARDS IDENTIFIED CONTROLS REQUIRED ACTION BY/RECORD

1. Pre start check Site engineer, project manager

1. mobilization of 1. Faults with crane.

2. The site to be stick to designed road ways and

crane to onsite 2. The site becomes bogged

location with sand and mud. turning areas.

3. Onsite traffic regulations.

3. Alternative pathways arranged by bollards and

reflective tapes.

2.Pre-job meetings 1. Un experienced workers 1. Sufficiency skilled employs to complete task Site engineer,

and tool box talk 2. In adequate consultation

2. Adequate consultation with all relevant employees

3. Inadequate understanding of

equipment. 3. Adequate competent supervision to the employees

4. Site hazards and emergency

procedures not to known.

3.locate crane into 1. Traffic 1. Asses the roads are available and soundly constructed

lifting position on site 2. Other equipments

with suitable entry point.

3. Building power lines and Site engineer, project manager

underground utilities. 2. The workplace is adequately prepared for the incoming of the

4. Ground condition. mobile crane where the possible of clear pre defined area.

3. Check and conform the exclusion areas; barricades with

danger tapes and warning signs.

4. Any obstruction overhead include wires cables restricted.

5. Crew should inspect site prior to positioning of crane in final

position.

16 February 2023 Page 2 of 4

4. Inspect chains and 1. Crane overturning due 1. Outriggers must be positioned on flat surface.

or slings and shackles to unstable ground 2. Using timbers or suitable material for pads to evenly Site engineer, safety team

hooks and attachment condition distribute the load to the ground.

points in preparation 2. Personal being cruised 3. Crane to located with radios for the loads being lifted.

of use. by out riggers. 4. Where space is limited , crane should be configured to

maximum capacity.

5. Where the space permits outriggers shall always extended.

5. Attaching fly or pin Working at height/falling object 1. Follow w/h permit use appropriate attachments points & Site engineer, safety team

jib to the crane. from height. safety hardness when walking along crane boom.

2. Erection area should be barricaded and warning signs

shall be provided and visible.

3. Do not stand under the suspended load.

4. Area should be restricted for unauthorized entrants.

5. Crane operator ensures travelling route is free of

obstruction.

6. Crane to be equipped with horn, alarm operator to be

provided with whistle to warn of workers during lifting

operations.

7. Proper means of communication must be provided.

8. No one go Around the counter weights when the crane

is operational.

6. Working at height 1. Fall of person 1. Workers must have working at height training prior Site supervisor, safety team

work.

2. Fall of material 2. Ensure necessary permits for the work or task.

3. Suitable sign barriers to be positioned directly below

3. Material damage the work

4. Above 1.8 metre work the harness to be used

4. Occurring injury to workers compulsory.

5. Coordinate the work so the people do not have to work

below overhead operations.

6. Materials must kept safe place and squired.

7. Keep floor materials away from floor edges (min 2 metre

away from the edge).

8. Affected (underneath) area should be barricaded.

9. All lose of materials must kept in containers

16 February 2023 Page 3 of 4

7. Manual 1. Lifting and carrying heavy tools 1. Ask help from others when lifting manually. Site supervisor, HSE team

handling/pitch point 2. pitch point that may results to cut 2. Avoid lifting more than 25 kgs . if the weight is beyond

strains, broken finger. Cursing manual handling capability ( more than 25kgs). Avoid

hazards due to underground rebar manual handling and use mechanical aids.

cutting hazards during manual 3. Follow safe manual handling techniques.

handling 4. Use of approved and correct PPE.

5. Keep hands fingers away from the trap/pitch points.

6. Ensure adequate manpower for the job.

7. Keep hand and body parts away from line of fire.

8. Adverse weather Heavy rain, poor visibility 1. Move more slowly and carefully to prevent slipping and site engineer, safety team

conditions. falling whilst.

2. Do not use electrical tools and equipment that are not

specifically rated for outdoor.

3. Hand tools to be with textured nonslip grip handles.

4. Stop all outdoor works in case of heavy rain.

5. Ensure area is graded to avoid slippery of personnel.

6. The waterproof pants are extended to ankles clean

safety glasses and high visibility vest.

16 February 2023 Page 4 of 4

You might also like

- Jobs Safety Analysis (JSA)Document8 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasFrom EverandCargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and GasRating: 5 out of 5 stars5/5 (11)

- Method Statement of Gantry Crane Dismantling - DIFD 20-09-18Document8 pagesMethod Statement of Gantry Crane Dismantling - DIFD 20-09-18mechajay2002100% (1)

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat80% (5)

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Job Safety Analysis WorksheetDocument1 pageJob Safety Analysis Worksheetsrinivasa raoNo ratings yet

- JSA FOR Crane OperationDocument6 pagesJSA FOR Crane OperationDenease CrummieNo ratings yet

- WORK at HEIGHT Job Hazard AnalysisDocument3 pagesWORK at HEIGHT Job Hazard Analysistosin babayomi0% (1)

- Jsa For Steel ErectionDocument7 pagesJsa For Steel ErectionRajuNo ratings yet

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (4)

- JSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Document7 pagesJSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Sebin VargheseNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav33% (3)

- JSA FOR Crane OperationDocument5 pagesJSA FOR Crane Operationwahyu nugrohoNo ratings yet

- Crane Erection Work SWMDocument4 pagesCrane Erection Work SWMSanjay GuptaNo ratings yet

- Risk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Reinforcement Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- C063 JSA For Installaiton of I Beam at Laundry AreaDocument7 pagesC063 JSA For Installaiton of I Beam at Laundry Areaiftikhar ahmadNo ratings yet

- Risk Mitigation Plan 1Document25 pagesRisk Mitigation Plan 1Omar BahakimNo ratings yet

- Risk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument3 pagesRisk Assessment Shuttering Work: What Work Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadavNo ratings yet

- JOB SAFETY ANALYSIS DikonversiDocument4 pagesJOB SAFETY ANALYSIS DikonversiAgung Tri SugihartoNo ratings yet

- MIP17-HSE-JSA-RTT-004 JSA For Construction of Thrust Anchor in Ras Tanura Terminal PlantDocument7 pagesMIP17-HSE-JSA-RTT-004 JSA For Construction of Thrust Anchor in Ras Tanura Terminal PlantAmeerHamzaWarraichNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- JSA For Crane Columan Foundation - AB.1Document9 pagesJSA For Crane Columan Foundation - AB.1hse2No ratings yet

- JSA For Crane Columan Foundation - AB.1Document9 pagesJSA For Crane Columan Foundation - AB.1hse2No ratings yet

- 02 Job Hazard Analysis For Deep Excavation & TrenchingDocument3 pages02 Job Hazard Analysis For Deep Excavation & TrenchingAmanNo ratings yet

- Tower CarneDocument2 pagesTower CarnenabeelNo ratings yet

- Work Method Statement: BNPP-HSE-JHA-2014-210 6Document8 pagesWork Method Statement: BNPP-HSE-JHA-2014-210 6Karthik babuNo ratings yet

- AGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMDocument1 pageAGF-01-115 62 Job Safety Analysis - INTAKE PIT ASPIRATION SYSTEM - GFMArslanNo ratings yet

- Job Safety Analysis: Job Description: Crane OperationDocument5 pagesJob Safety Analysis: Job Description: Crane OperationSAI ARUNNo ratings yet

- SOP For Mobile CraneDocument1 pageSOP For Mobile CraneloganathanNo ratings yet

- All JsaDocument88 pagesAll JsaPankaj BhattNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Risk Assessment: Concrete Work (PCC/RCC)Document2 pagesRisk Assessment: Concrete Work (PCC/RCC)hemant yadavNo ratings yet

- Safety Procedure For Pile TestDocument2 pagesSafety Procedure For Pile TestIsna MuthoharohNo ratings yet

- Jobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding WorkDocument4 pagesJobs Safety Analysis (JSA) : JOB/ACTIVITY NAME: Scaffolding Erection, Dismantling Work, Work at Height, Welding Workuttam mishraNo ratings yet

- Jsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortDocument7 pagesJsa For Installation of Additional Storm Down Ties and Stow Pin Slots On Crane Rail at West Pier of City Comercial PortSebin VargheseNo ratings yet

- JOB SAFETY ANALYSIS Steel ErectionDocument9 pagesJOB SAFETY ANALYSIS Steel ErectionKhalid IrfanNo ratings yet

- Crane Lifting Plan Method Statement and Risk Assessment 1Document4 pagesCrane Lifting Plan Method Statement and Risk Assessment 1Muhammad BabarNo ratings yet

- HIP-Aramco-Yanpet Sales Gas BI-21-00008Document9 pagesHIP-Aramco-Yanpet Sales Gas BI-21-00008Darius DsouzaNo ratings yet

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk AssessmentSayed Darwish100% (1)

- JHA For Temp Structure ErectionDocument1 pageJHA For Temp Structure Erectiongullipalli srinivasa raoNo ratings yet

- Tool Box Talk Lifting Works of Porta CabinDocument2 pagesTool Box Talk Lifting Works of Porta CabinRyan PertezNo ratings yet

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk AssessmentMuhammad BabarNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Job Safety Analysis - Precast Manhole Installtion.Document5 pagesJob Safety Analysis - Precast Manhole Installtion.salauddin0mohammedNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocument5 pagesJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (4)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- Jsa of Boiler Drum LiftingDocument10 pagesJsa of Boiler Drum LiftingGyanendra Narayan NayakNo ratings yet

- 05 WMS - CHWP InstallationDocument15 pages05 WMS - CHWP InstallationHimanshu Niveriya100% (1)

- 12 - Method Statement For Steel Structure ErectionDocument5 pages12 - Method Statement For Steel Structure ErectionidzwanNo ratings yet

- Management Health and Safety Risk Assessment: ClientDocument3 pagesManagement Health and Safety Risk Assessment: ClientMohammed MuneebNo ratings yet

- Backfilling in FoundationDocument1 pageBackfilling in Foundationm.rehanhseNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Performance Comparison of Aeronautical Telemetry in S-Band and C-BandDocument11 pagesPerformance Comparison of Aeronautical Telemetry in S-Band and C-BandfakeNo ratings yet

- Chapter 15Document117 pagesChapter 15Karla Selman100% (1)

- Kamadhenu ReportDocument6 pagesKamadhenu ReportRajaram IyengarNo ratings yet

- Magpie Lab Student Guide Updated 2014 FinalDocument13 pagesMagpie Lab Student Guide Updated 2014 FinalAmanueNo ratings yet

- Niranjan A Murthy 2018Document15 pagesNiranjan A Murthy 2018Tim KNo ratings yet

- 10 5923 J Ijmee 20120106 04Document5 pages10 5923 J Ijmee 20120106 04SafetyanaNo ratings yet

- Sling Aircraft Lsa POHDocument160 pagesSling Aircraft Lsa POHGourav DasNo ratings yet

- I-765 Online Filing Instructions - FINALDocument13 pagesI-765 Online Filing Instructions - FINALTrân LêNo ratings yet

- SmartWorks MFP - User Manual v3.50 - ENDocument133 pagesSmartWorks MFP - User Manual v3.50 - ENeserwisNo ratings yet

- 416F SpecalogDocument9 pages416F Specalogagegnehutamirat100% (1)

- Tax Reporter Guide - 2009Document90 pagesTax Reporter Guide - 2009bpathri0% (1)

- Ir SensorDocument4 pagesIr SensorSundari LeoraNo ratings yet

- Valve Employee HandbookDocument37 pagesValve Employee HandbookMilan ThakkerNo ratings yet

- A To Z: Social Media MarketingDocument89 pagesA To Z: Social Media MarketingJordan Kasteler100% (1)

- Case Digest - Asset Builders Vs StrongholdDocument3 pagesCase Digest - Asset Builders Vs StrongholdDianaVillafuerteNo ratings yet

- In-The-Lab Full ESX:VMotion Test Lab in A BoxDocument65 pagesIn-The-Lab Full ESX:VMotion Test Lab in A BoxmnwarrenNo ratings yet

- Sikafloor®-169: Product Data SheetDocument4 pagesSikafloor®-169: Product Data SheetMohammed AwfNo ratings yet

- 2.5 - S464G1007 Estacion ManualDocument2 pages2.5 - S464G1007 Estacion ManualCarlos Jesus Cañamero GutierrezNo ratings yet

- Artificial Intelligence (AI) : Amina Irizarry-Nones Anjali Palepu Merrick WallaceDocument14 pagesArtificial Intelligence (AI) : Amina Irizarry-Nones Anjali Palepu Merrick WallaceIrfan AhmedNo ratings yet

- Manuals PDFDocument65 pagesManuals PDFRafael NievesNo ratings yet

- Project Title: (Company Name) (Project Lead)Document3 pagesProject Title: (Company Name) (Project Lead)Harsha SamagaraNo ratings yet

- Korando 2012Document1,082 pagesKorando 2012mirrahel paim67% (3)

- Comparison Between C and C++ and Lisp and PrologDocument18 pagesComparison Between C and C++ and Lisp and PrologAhmed HeshamNo ratings yet

- Benin V NigerDocument9 pagesBenin V NigerRonika ThapaNo ratings yet

- Diass-Week 3Document8 pagesDiass-Week 3Gia MarieNo ratings yet

- Modeling and SimulationDocument11 pagesModeling and SimulationZain MughalNo ratings yet

- Behavioural and Psychiatric Symptoms in People With Dementia Admitted To The Acute Hospital Prospective Cohort StudyDocument8 pagesBehavioural and Psychiatric Symptoms in People With Dementia Admitted To The Acute Hospital Prospective Cohort StudyJosue GarciaNo ratings yet

- Definition & Classification of Power System StabilityDocument21 pagesDefinition & Classification of Power System StabilityShahab khan100% (4)

- Blaupunkt Chicago Ivdm 7002Document4 pagesBlaupunkt Chicago Ivdm 7002Onix AdiNo ratings yet

- 4183 17321 1 PBDocument12 pages4183 17321 1 PBUmiKulsumNo ratings yet