Professional Documents

Culture Documents

TS 1 289 SF014

TS 1 289 SF014

Uploaded by

CeciliaHenríquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS 1 289 SF014

TS 1 289 SF014

Uploaded by

CeciliaHenríquezCopyright:

Available Formats

FABRIC STYLE / ESTILO DE TELA SF014

8.4 oz/yd2 80% COTTON 20% POLY FOR SOLIDS & ASH GREY, 75% COTTON 25% POLY FOR SPG, 50% COTTON 50% POLY FOR HEATHERS TWO END FLEECE

ESPECIFICACION TEXTIL / TEXTILE SPECIFICATION

TS_1_01_2000

TEX-DDF-002 / V.6 / 23-Jan-2024

JDE Codes / Códigos JDE:

Primary Option Alternate Option

Composition Greige SKU Yarn SKU Description Greige SKU Yarn SKU Description

YKRS205C100 20.5/1 100% Cotton KPRS YKRS205C100 20.5/1 100% Cotton KPRS

Naturals / Solids GT2FSF0IVM00002 GT2FSF0HZM00002

YKVO14C50P50 14/1 50% Cotton 50% Poly MVS YKRS14C50P50 14/1 50% Cotton 50% Poly KPRS

Sport Grey YKRS20C90B10 20/1 90% Cotton 10% Black Poly KPRS YKRS20C90B10 20/1 90% Cotton 10% Black Poly KPRS

GT2FSF0IWM00014 GT2FSF0FGM00014

YKVO14C50P50 14/1 50% Cotton 50% Poly MVS YKRS14C50P50 14/1 50% Cotton 50% Poly KPRS

Heathers YKRS20C50P50 20/1 50% Cotton 50% Poly KPRS YKRS20C50P50 20/1 50% Cotton 50% Poly KPRS

GT2FSF0IWM00010 GT2FSF0FGM00010

YKVO14C50P50 14/1 50% Cotton 50% Poly MVS YKRS14C50P50 14/1 50% Cotton 50% Poly KPRS

YKRS20C99B01 20/1 99% Cotton 1% Black Poly KPRS

Ash Grey GT2FSF0IWM00016 YKVO14C50P50 14/1 50% Cotton 50% Poly MVS

Routing process / Ruta de proceso:

*For visual reference only

T

i

g

h

t

n

e

s

GREIGE/CRUDO s FINISHED/ACABADO

F

F

a

Yarn 1 - Hilaza 1 (Face) Yarn 2 - Hilaza 2 (Backing) a

c

ct

Machine / Máquina to

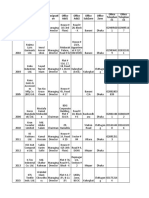

Yarn % Tightness Yarn % Yield - Consumo

Needles Wesco Stitch Length Factor Wesco Stitch Length o

r Width - Ancho (g/lm) - (g/ml)

# Rolls / # # Rolls / # r

Kgs/Roll /

Rollos Rollos

Rollos/Kgs

Cut / CHOLTEX SULATEX d

Real Cut / Diameter / Diametro Inches

Corte % De Hilaza (cm/tour) (cm/stitch) % De Hilaza (cm/tour) (cm/stitch) e

Corte Real Pulgadas

(#) (cm/vuelta) (cm/puntada) Factor de (cm/vuelta) (cm/puntada) Tol Bleached Dyed

Agujas Tol +/- 2 Puntada Tensión Tol +/- 2 Puntada Tensión Min Max Blanqueado Color

19.2 19 17 8 2&4 117.5 1024 58 338 0.330 16.3 42 145 0.142 - 18 " 1/4 1/4 254 261

19.3 19 17 8 2&4 117.5 1032 58 341 0.330 16.3 42 147 0.142 - 18 " 1/4 1/4 254 261

16.9 17 17 5 2&4 210 900 58 297 0.330 16.3 42 154 0.171 - 16 " 1/4 1/4 226 232

17.1 17 17 5 2&4 210 912 58 301 0.330 16.3 42 156 0.171 - 16 " 1/4 1/4 226 232

16.1 16 18 5 2&4 210 912 58 301 0.330 16.3 42 156 0.171 - 16 " 1/4 1/4 226 232

16.3 16 18 5 2&4 210 924 58 305 0.330 16.3 42 158 0.171 - 16 " 1/4 1/4 226 232

18.2 18 17 5 2&4 210 972 58 321 0.330 16.3 42 156 0.160 - 17 " 1/4 1/4 240 246

17.2 17 18 5 2&4 210 972 58 321 0.330 16.3 42 166 0.171 - 17 " 1/4 1/4 240 246

18.1 18 18 5 2&4 210 1024 58 338 0.330 16.3 42 164 0.160 - 18 " 1/4 1/4 254 261

16.3 16 20 5 2&4 210 1024 58 338 0.330 16.3 42 175 0.171 - 18 " 1/4 1/4 254 261

19.3 19 17 5 2&4 210 1032 58 341 0.330 16.3 42 147 0.142 - 18 " 1/4 1/4 254 261

16.6 17 20 5 2&4 210 1044 58 345 0.330 16.3 42 179 0.171 - 18 " 1/4 1/4 254 261

17.0 17 20 5 2&4 210 1068 58 352 0.330 16.3 42 183 0.171 - 19 " 1/4 1/4 268 275

18.0 18 20 5 2&4 205 1128 58 372 0.330 16.3 42 180 0.160 - 20 " 1/4 1/4 282 290

19.9 20 18 5 2&4 205 1128 58 372 0.330 16.3 42 160 0.142 - 20 " 1/4 1/4 282 290

18.1 18 20 5 2&4 205 1136 58 375 0.330 16.3 42 182 0.160 - 20 " 1/4 1/4 282 290

18.1 18 22 5 2&4 210 1248 58 412 0.330 16.3 42 200 0.160 - 22 " 1/4 1/4 311 319

18.1 18 24 5 2&4 210 1364 58 450 0.330 16.3 42 218 0.160 - 24 " 1/4 1/4 339 347

18.1 18 24 5 2&4 210 1368 58 451 0.330 16.3 42 219 0.160 - 24 " 1/4 1/4 339 347

16.8 17 28 5 2&4 210 1476 58 487 0.330 16.3 42 252 0.171 - 26 " 1/4 1/4 367 376

18.1 18 26 5 2&4 210 1476 58 487 0.330 16.3 42 236 0.160 - 26 " 1/4 1/4 367 376

16.9 17 28 5 2&4 210 1484 58 490 0.330 16.3 42 254 0.171 - 26 " 1/4 1/4 367 376

16.9 17 28 5 2&4 210 1484 58 490 0.330 16.3 42 254 0.171 - 26.5 " 1/4 1/4 374 384

16.9 17 30 5 2&4 210 1592 58 525 0.330 16.3 42 272 0.171 - 28 " 1/4 1/4 395 405

18.0 18 28 5 2&4 210 1584 58 523 0.330 16.3 42 253 0.160 - 28 " 1/4 1/4 395 405

16.8 17 30 5 2&4 210 1584 58 523 0.330 16.3 42 271 0.171 - 28 " 1/4 1/4 395 405

18.1 18 28 5 2&4 210 1588 58 524 0.330 16.3 42 254 0.160 - 28 " 1/4 1/4 395 405

17.8 18 30 5 2&4 210 1680 58 554 0.330 16.3 42 269 0.160 - 30 " 1/4 1/4 424 434

18.0 18 30 5 2&4 210 1692 58 558 0.330 16.3 42 271 0.160 - 30 " 1/4 1/4 424 434

16.8 17 32 5 2&4 210 1692 58 558 0.330 16.3 42 289 0.171 - 30 " 1/4 1/4 424 434

18.0 18 32 5 2&4 205 1812 58 598 0.330 16.3 42 290 0.160 - 32 " 1/4 1/4 452 463

17.9 18 32 5 2&4 205 1800 58 594 0.330 16.3 42 288 0.160 - 32 " 1/4 1/4 452 463

FABRIC PERFORMANCE - COMPORTAMIENTO DE LA TELA COMMENTS / COMENTARIOS

20.5/1 20/1 20.5/1 (oz/yd²) 20/1 (oz/yd²)

Parameters - Parámetros

Min Std Max Min Std Max Min - Std - Max Min - Std - Max

Finished weight (Bleached) - Peso acabado (Blanqueado) g/m2 264 278 292 268 282 296 7.8 - 8.2 - 8.6 7.9 - 8.3 - 8.7

Finished weight (Dyed) - Peso acabado (Color) g/m2 271 285 299 276 290 305 8.0 - 8.4 - 8.8 8.1 - 8.6 - 9.0

Garment weight (Bleached) - Peso en prenda (Blanqueado) g/m2 259 272 286 263 276 290 7.6 - 8.0 - 8.4 7.7 - 8.2 - 8.6

Garment weight (Dyed) - Peso en prenda (Color) g/m2 265 279 293 270 284 298 7.8 - 8.2 - 8.6 8.0 - 8.4 - 8.8

CPI: 38 39 40 38 39 40

WPI: 27 28 29 27 28 29

Length shrinkage - Encogimiento a lo largo % 3HL 3 -6 -10 3 -6 -10

Width shrinkage - Encogimiento a lo ancho % 3HL 0 -4 -6 0 -4 -6

Fabric Innnovation TS_02_289_SF014 Rev 28: April 12 2024

FABRIC STYLE / ESTILO DE TELA SF014

8.4 oz/yd2 80% COTTON 20% POLY FOR SOLIDS & ASH GREY, 75% COTTON 25% POLY FOR SPG, 50% COTTON 50% POLY FOR HEATHERS TWO END FLEECE

TEXTILE SPECIFICATION

TEX-DDF-002 / V.6 / 23-Jan-2024

JDE Codes / Códigos JDE:

Composition Greige SKU Yarn SKU Description

YKRS20C100 20/1 100% Cotton KPRS

Bangladesh

Naturals / Solids GT2FSF0FGM00074

YKRS14RPC005 14/1 50% recycled poly 50% cotton KPRS

Sport Grey YKRS20C90B10 20/1 90% Cotton 10% Black Poly KPRS

GT2FSF0FGM00075

YKRS14RPC005 14/1 50% recycled poly 50% cotton KPRS

Heathers YKRS20C50P50 20/1 50% Cotton 50% Poly KPRS

GT2FSF0FGM00109

YKRS14RPC005 14/1 50% recycled poly 50% cotton KPRS

YKRS20C99B01 20/1 99% Cotton 1% Black Poly KPRS

Ash Grey GT2FSF0FGM00076 YKRS14RPC005 14/1 50% recycled poly 50% cotton KPRS

Routing process / Ruta de proceso: *For visual reference only

T

i

g

h

t

n

e

s

F

s

a

F

c

GREIGE/CRUDO a FINISHED/ACABADO

t

c

Yarn 1 - Hilaza 1 (Face) Yarn 2 - Hilaza 2 (Backing) o

t

Machine / Máquina r

Tightness o Yield - Consumo

Yarn % Yarn %

# Rolls / Kgs/Roll / Needles Wesco Stitch Length Factor Wesco Stitch Length r Width - Ancho (g/lm) - (g/ml)

d

Cut / Diameter / # Rollos Rollos/Kgs (cm/tour) (cm/stitch) (cm/tour) (cm/stitch) e

Real Cut / Corte Diametro % De Inches

(#) % De Hilaza (cm/vuelta) (cm/puntada) Factor de (cm/vuelta) (cm/puntada) Tol Bleached Dyed

Corte Real Hilaza Pulgadas

Agujas Tol +/- 2 Puntada Tensión Tol +/- 2 Puntada Tensión Min Max Blanqueado Color

16.44 16 22 4&6 210 1136 59 375 0.330 16.5 41 194 0.171 20 " 1/4 1/4 287 295

16.50 16 22 4&6 210 1140 59 376 0.330 16.5 41 195 0.171 20 " 1/4 1/4 287 295

16.88 17 24 4&6 210 1272 59 420 0.330 16.5 41 218 0.171 22 " 1/4 1/4 315 324

16.88 17 24 4&6 210 1272 59 420 0.330 16.5 41 218 0.171 22.5 " 1/4 1/4 322 331

16.76 17 26 4&6 210 1368 59 451 0.330 16.5 41 234 0.171 ### 24 " 1/4 1/4 344 354

16.90 17 26 4&6 210 1380 59 455 0.330 16.5 41 236 0.171 ### 24 " 1/4 1/4 344 354

16.79 17 28 4&6 210 1476 59 487 0.330 16.5 41 252 0.171 26 " 1/4 1/4 372 383

16.79 17 28 4&6 210 1476 59 487 0.330 16.5 41 252 0.171 26 " 1/4 1/4 372 383

16.92 17 28 4&6 210 1488 59 491 0.330 16.5 41 254 0.171 26 " 1/4 1/4 372 383

16.92 17 28 4&6 210 1488 59 491 0.330 16.5 41 254 0.171 26.5 " 1/4 1/4 380 390

16.94 17 30 4&6 210 1596 59 527 0.330 16.5 41 273 0.171 28 " 1/4 1/4 401 412

16.96 17 32 4&6 210 1704 59 562 0.330 16.5 41 291 0.171 30 " 1/4 1/4 430 442

18.03 18 32 4&6 205 1812 59 598 0.330 16.5 41 290 0.160 32 " 1/4 1/4 458 471

16.97 17 34 4&6 205 1812 59 598 0.330 16.5 41 310 0.171 32 " 1/4 1/4 458 471

FABRIC PERFORMANCE - COMPORTAMIENTO DE LA TELA COMMENTS / COMENTARIOS

20/1 20/1 (oz/yd²)

Parameters - Parámetros

Min Std Max Min Std Max

Finished weight (Bleached) - Peso acabado (Blanqueado) g/m2 268 282 296 7.9 8.3 8.7

Finished weight (Dyed) - Peso acabado (Color) g/m2 276 290 305 8.1 8.6 9.0

Garment weight (Bleached) - Peso en prenda (Blanqueado) g/m2 263 276 290 7.7 8.2 8.6

Garment weight (Dyed) - Peso en prenda (Color) g/m2 270 284 298 8.0 8.4 8.8

CPI: 38 39 40

WPI: 27 28 29

Length shrinkage - Encogimiento a lo largo % 3HL 3 -6 -10

Width shrinkage - Encogimiento a lo ancho % 3HL 0 -4 -6

Fabric Innnovation TS_02_289_SF014 Rev 28: April 12 2024

FABRIC STYLE / ESTILO DE TELA SF014

8.4 oz/yd2 80% COTTON 20% POLY FOR SOLIDS & ASH GREY, 75% COTTON 25% POLY FOR SPG, 50% COTTON 50% POLY FOR HEATHERS TWO

END FLEECE

Special Claims

Finishing Chemical # 1 Chemical # 3 Chemical # 4 Torque Chemical Mechanical

Brand Garment Style Chemical # 2 (g/L) Pilling

Recipe (g/L) (g/L) (g/L) max% Finishing Finishing

GILSOFT GSF-1EP GILWAX 2F

GILDAN SF008 FB-21

250 (g/L) 120 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

GILDAN SF500 FB-21

250 (g/L) 120 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

GILDAN SF000 FB-21

250 (g/L) 120 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

GILDAN SF500B FB-21

250 (g/L) 120 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

GILDAN SF100 FB-21

250 (g/L) 120 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

GILDAN SF600 FB-21

250 (g/L) 120 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

AMAZON MMPOHP FB-22

250 (g/L) 160 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

AMAZON MMSC FB-22

250 (g/L) 160 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

AMAZON MMCSHT FB-22

250 (g/L) 160 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

AMAZON MMPOH FB-22

250 (g/L) 160 (g/L)

N/A N/A 10 Min. 3.0

GILSOFT GSF-1EP GILWAX 2F

AMAZON MMZH FB-22

250 (g/L) 160 (g/L)

N/A N/A 10 Min. 3.0

Comments section:

1

.

Fabric Innnovation TS_02_289_SF014 Rev 28: April 12 2024

FABRIC STYLE / ESTILO DE TELA SF014

8.4 oz/yd2 80% COTTON 20% POLY FOR SOLIDS & ASH GREY, 75% COTTON 25% POLY FOR SPG, 50% COTTON 50% POLY

FOR HEATHERS TWO END FLEECE

TEX-DDF-002 / V.5 / 20-Sep-2023

No. Revision Date Revision request by Reason of Change Updated by

Initial

0 August 6, 2020 MKT Yester Cruz

added machine Diam 32”, Cut 18, de 1800 agujas, para tejer final 32.

1 May 14, 2021 planning Lesby Gonzales

Added tab for Bangladesh

2 March 8, 2022 MKT Lesby Gonzales

Added MVS Backing (SKU YKVO14C50P50) as Primary option

3 May 30, 2022 MKT / Supply Chain Diana Florentino

4 July 1, 2022 Planning Added option 18/30" with 1692N Yester Cruz

changing # of rolls '' 5 roll instead of 4 Rolls and Changing Kgs/Roll as per Technical requirement: HN

Width 20 210 kgs/roll instead of 117.5 kgs/roll

Width 22 210 kgs/roll instead of 232.5 kgs/roll

Width 24 210 kgs/roll instead of 232.5 kgs/roll

5 September 19, 2022 Gustavo Jacome Width 26 210 kgs/roll instead of 232.5 kgs/roll lesby Gonzales

Width 28 210 kgs/roll instead of 235 kgs/roll

Width 30 210 kgs/roll instead of 235 kgs/roll

added new machine Diam 20”, Cut 18, de 1136N 20''

6 Mario Fuentes added new machine Diam 28”, Cut 18, de 1588N 28'' lesby Gonzales

added new machine Diam 30”, Cut 18, de 1680N 30''

September 23, 2022

added new machine Cut/Diam 18/24" de 1368N 24F

7 added new machine Cut/Diam 17/28" de 1484N 26F lesby Gonzales

added new machine Cut/Diam 17/30" de 1584N 28F

September 28, 2022 planning

added new machine Cut/Diam 17/17" de 912N 16F

added new machine Cut/Diam 17/18" de 972N 17F

8 October 24, 2022 planning lesby Gonzales

added new machine Cut/Diam 18/18" de 1024N 18F

added new machine Cut/Diam 17/20" de 1068N 19F

Added options:

16/18" of 924N for final width 16"

9 December 16, 2022 Planning 17/18" of 972N for final width 17" Lesby Gonzales

18/18" of 1024N for final width 18"

19/17" of 1032N for final width 18"

Added options:

9 April 10, 2023 Planning 17/17" of 900N for final width 16" Yester Cruz

17/17" of 912N for final width 16"

10 Planning Added options:16/20" of 1024N for final width 18" lesby Gonzales

April 11, 2023

11 May 2, 2023 Alba Chavez 18F con un cilindro Cut/Diam 15/20" de 1044 agujas lesby Gonzales

Chaninging the backing SL to 0.171 cm in machines:

17/18" 972N

16/20" 1024N

17/20" 1044N

17/20" 1068N

17/28" 1476N

17/28" 1484N

12 May 11, 2023 Knitting Technical team 17/30" 1592N

17/30" 1584N

17/32" 1692N

Changing the backing yarn to 0.142 cm in machines:

19/17" 1024N

19/17" 1032N

20/18" 1128N

13 August 22, 2023 Kamal Lanza Added STD for wicking, Finishing & pilling lesby Gonzales

Fabric Innnovation TS_02_289_SF014 Rev 28: April 12 2024

FABRIC STYLE / ESTILO DE TELA SF014

8.4 oz/yd2 80% COTTON 20% POLY FOR SOLIDS & ASH GREY, 75% COTTON 25% POLY FOR SPG, 50% COTTON 50% POLY

FOR HEATHERS TWO END FLEECE

TEX-DDF-002 / V.5 / 20-Sep-2023

No. Revision Date Revision request by Reason of Change Updated by

Removed Machine Bnag;ladesh

24"F Cut /Dim 17/18" 1368N

26"F Cut /Dim 18/28" 1488N

14 October 18, 2023 Md. Abdullah Al Mamun 26''F Cut /Dim 17/18" 1488N

Added 17/26 " 1380N

26"F Cut /Dim 17/28" 1476N

Lesby Gonzales

15 October 24, 2023 Mohammad Abdul Mannan Added machine CUT/DIA 1728 needles 1476 Finish 26F for KOHINOOR Lesby Gonzales

16 November 6, 2023 Diana Florentino / Moises Torres standardization of Stitch Length between regions Lesby Gonzales

17 December 15, 2023 Marker teams added machine 17/24 22.5'' Lesby Gonzales

18

January 16, 2024 Ingar Madrid Added Option for ASH GREY yarn YKRS20C99B01 Lesby Gonzales

19 Updating primary Yarn from YKRS14C50P50 to YKRS14RPC005 for BANGLADESH lesby Gonzales

January 17, 2024 Supply Chain

Changing Kgs/Roll as per Technical requirement: BANGLADESH

Width 20 210 kgs/roll instead of 170 kgs/roll

Width 22 210 kgs/roll instead of 190 kgs/roll

Width 24 210 kgs/roll instead o f 200 kgs/roll

20 January 18, 2024 Mohammad Abdul Mannan Width 26 210 kgs/roll instead of 200 kgs/roll Lesby Gonzales

Width 28 210 kgs/roll instead of 205 kgs/roll

Width 30 210 kgs/roll instead of 205 kgs/roll

21 February 6, 2024 Habibullah Added machine CUT/DIA 1728 needles 1488 Finish 26F for KOHINOOR Lesby Gonzales

22 February 29, 2024 Fabric innovation Addition of new tab for Specific Requirements and replaced the garment styles section with the Routing process Lesby Gonzales

23 March 1, 2024 Planning Added machine Cut/Dia 18/28" of 1584N for finish width 28" Lesby Gonzales

Changing Kgs/Roll as per Technical requirement: HN

24 March 18, 2024 Gustavo Jacome Width 20'' 205 kgs/roll instead of 210 kgs/roll Lesby Gonzales

added machine 17/28 26.5''

25 March 26, 2024 Fabric innovation Lesby Gonzales

26 April 1, 2024 Habibullah Added machine CUT/DIA 17/26 needles 1368 Finish 24F for Bangladesh Lesby Gonzales

27 April 9, 2024 Alba Chavez Added machine -Cut/Diam 17/34” de 1812 agujas para tejer SF014-32F for Bangladesh Lesby Gonzales

28 April 12, 2024 Alba Chavez Added machine -Cut/Diam 16/22” de 1140 agujas para tejer SF014-20F for Bangladesh Lesby Gonzales

Fabric Innnovation TS_02_289_SF014 Rev 28: April 12 2024

You might also like

- Pest Analysis For Textile IndustryDocument5 pagesPest Analysis For Textile IndustryAdil Malik60% (5)

- Spin PlanDocument7 pagesSpin Planhassan SardarNo ratings yet

- Spin Plan - Spinning MillDocument21 pagesSpin Plan - Spinning MillPurvansh TrivediNo ratings yet

- Prescribed Fees FOR Processing Services AND Yarn Products: Philippine Textile Research InstituteDocument4 pagesPrescribed Fees FOR Processing Services AND Yarn Products: Philippine Textile Research InstituteCharles Warren GoNo ratings yet

- Atak Textile Fabric Catalogue EnglishDocument15 pagesAtak Textile Fabric Catalogue EnglishFerhatNo ratings yet

- Baby Clothes Pricelist PDFDocument11 pagesBaby Clothes Pricelist PDFChristophoros ToumbasNo ratings yet

- Bahan Baku Olah by Uraian BarangDocument212 pagesBahan Baku Olah by Uraian BarangsuhenimoseNo ratings yet

- Merchandising Counter Buyer SpringfieldDocument11 pagesMerchandising Counter Buyer SpringfieldM.a. Hamid RealNo ratings yet

- Sample 1Document16 pagesSample 1rajanbdNo ratings yet

- Yarns Used in Socks: S.no Yarn Counts Rate Per KGDocument2 pagesYarns Used in Socks: S.no Yarn Counts Rate Per KGHarshit JainNo ratings yet

- Costing SummaryDocument5 pagesCosting SummaryBabu UchihaNo ratings yet

- Tried True Trusted: Fine JerseyDocument1 pageTried True Trusted: Fine JerseyAsad AsgharNo ratings yet

- Kumaragiri Price List-01.05.2021Document1 pageKumaragiri Price List-01.05.2021N.M. EESWARANNo ratings yet

- A&a Men's Product Catalogue Update 11.06.16Document5 pagesA&a Men's Product Catalogue Update 11.06.16Ali Sazzad KhanNo ratings yet

- Pt. Selim Textile BC 2.3 Periode Januari 2019: Tanggal NO Tanggal Penerimaan Dokumen DokumenDocument54 pagesPt. Selim Textile BC 2.3 Periode Januari 2019: Tanggal NO Tanggal Penerimaan Dokumen Dokumendicky firmansyahNo ratings yet

- Ashish 123Document28 pagesAshish 123Ajay RaikarNo ratings yet

- Training On Yarn Manufacturing TechnologyDocument38 pagesTraining On Yarn Manufacturing TechnologySk sujoy420No ratings yet

- Crew Clothing List of Styles For Costing by Ish 041222Document29 pagesCrew Clothing List of Styles For Costing by Ish 041222MainuddinNo ratings yet

- Yarns Used in Socks: S.no Yarn Counts Rate Per KGDocument2 pagesYarns Used in Socks: S.no Yarn Counts Rate Per KGHarshit JainNo ratings yet

- SL Trans. Date Trans. Ref. Challan No Buyer: Date Wise Item Receive Issue ReportDocument5 pagesSL Trans. Date Trans. Ref. Challan No Buyer: Date Wise Item Receive Issue ReportMasudur rahmanNo ratings yet

- Add 4Document3 pagesAdd 4nazmultxe11013No ratings yet

- DF-399 e Catalog - 1Document6 pagesDF-399 e Catalog - 1grasshoppermedia08No ratings yet

- Perubahan Data Stock Local FabricDocument3 pagesPerubahan Data Stock Local Fabriczicode.jNo ratings yet

- Fabric CostingDocument3 pagesFabric CostingAsif Newton100% (1)

- Serims Men's Product Catalogue Update 01.07.2017Document5 pagesSerims Men's Product Catalogue Update 01.07.2017Ali Sazzad KhanNo ratings yet

- Yarn ThicknessDocument7 pagesYarn ThicknessChantal JansenNo ratings yet

- 30 05 2023Document288 pages30 05 2023md nasimul hossainNo ratings yet

- DPL 10032022 UpdatedDocument6 pagesDPL 10032022 UpdatedJatin KumarNo ratings yet

- MIRA Sra I-2023.xlsx - AW - 23 Price ListDocument3 pagesMIRA Sra I-2023.xlsx - AW - 23 Price ListCOCOON FOTONo ratings yet

- R&D Stock Fabric (Grey) List - 2021Document16 pagesR&D Stock Fabric (Grey) List - 2021saidurtexNo ratings yet

- 2102 M TECH SH (SMALL DROP) SS SET UP 12181581317244 - TfileDocument11 pages2102 M TECH SH (SMALL DROP) SS SET UP 12181581317244 - TfileBlack SoulNo ratings yet

- A&a Ladies Product Catalogue Update 11.06.16Document3 pagesA&a Ladies Product Catalogue Update 11.06.16Ali Sazzad KhanNo ratings yet

- Adidas Katalog 09Document76 pagesAdidas Katalog 09michael9508No ratings yet

- Lookbook Sunwill Winter 2021 22Document72 pagesLookbook Sunwill Winter 2021 22lucianadrian79No ratings yet

- Catalogue TableclothsDocument24 pagesCatalogue Tableclothsapi-3774742No ratings yet

- Serims Ladies Product Catalogue Update 01.07.2017Document3 pagesSerims Ladies Product Catalogue Update 01.07.2017Ali Sazzad KhanNo ratings yet

- GTA Sports LTD. Gohailbari, Zirani, Savar: Yarn Req No Date: 5-Dec-16Document2 pagesGTA Sports LTD. Gohailbari, Zirani, Savar: Yarn Req No Date: 5-Dec-16SAIDURTEXTILENo ratings yet

- Tesco Uk - Aw20 Season: Confection InstructionsDocument1 pageTesco Uk - Aw20 Season: Confection InstructionsFarrukh JamilNo ratings yet

- Laporan Import NEWDocument643 pagesLaporan Import NEWsuhenimoseNo ratings yet

- 2023 Catalogue - Shanghai Top Fortune (2024-03-29 01 - 31 - 17)Document9 pages2023 Catalogue - Shanghai Top Fortune (2024-03-29 01 - 31 - 17)bacharskateNo ratings yet

- Serims Ladies Product Catalogue Update 01.07.2017Document3 pagesSerims Ladies Product Catalogue Update 01.07.2017Ali Sazzad KhanNo ratings yet

- Sl. No Buyer Style GSM CompositionDocument23 pagesSl. No Buyer Style GSM Compositionrummanbsc8923No ratings yet

- 100% ViscoseDocument1 page100% ViscosesmbristyNo ratings yet

- Raw Materials SpecificationsDocument3 pagesRaw Materials SpecificationsRashadul Islam WalidNo ratings yet

- Counter Offer Inditex - SelectionDocument11 pagesCounter Offer Inditex - Selectiondereje assefaNo ratings yet

- Product & Prices-1Document3 pagesProduct & Prices-1faruq hosenNo ratings yet

- Company Profile of SM Knitwears LTDDocument30 pagesCompany Profile of SM Knitwears LTDSakib MahmudNo ratings yet

- ECOTECHDocument13 pagesECOTECHJovenal TuplanoNo ratings yet

- Popular PPRCDocument1 pagePopular PPRCUsman AnwarNo ratings yet

- Harga Per Meter Untuk Total Pembelian:: 100% Full CottonDocument2 pagesHarga Per Meter Untuk Total Pembelian:: 100% Full CottonPraja Samudra SinagaNo ratings yet

- Due To Over Consumption: Gta Sports LTDDocument12 pagesDue To Over Consumption: Gta Sports LTDSAIDURTEXTILENo ratings yet

- NZ Textile LTD: SUB: DELIVERY ORDER NO........... 20302 ...................Document2 pagesNZ Textile LTD: SUB: DELIVERY ORDER NO........... 20302 ...................Fazley RabbiNo ratings yet

- StockMaterial 01-08.06.2024Document34 pagesStockMaterial 01-08.06.2024misnassadenimNo ratings yet

- 越南Fabric SampleDocument23 pages越南Fabric SampleĐào NguyễnNo ratings yet

- 1 1 I LL R 1 F: N - and Date of L/CDocument2 pages1 1 I LL R 1 F: N - and Date of L/COSCAR BARAHONANo ratings yet

- Uploadfiles TVRVMGDocument1 pageUploadfiles TVRVMGrpacmexicoags2063No ratings yet

- 30S Makson Israq ON NRG Badsha BSB Mehmud 3.40 3.35 3.35 3.80 N 4.20Document1 page30S Makson Israq ON NRG Badsha BSB Mehmud 3.40 3.35 3.35 3.80 N 4.20smbristyNo ratings yet

- Shilton Revised PriceDocument2 pagesShilton Revised PriceBaston tonyNo ratings yet

- Tubetex and Lafer DifferenceDocument4 pagesTubetex and Lafer Differencerakibul islam100% (1)

- Hemp Excell ChartDocument10 pagesHemp Excell ChartRupesh VarmaNo ratings yet

- Industrial Visit at Aboni Knitwear Ltd. (FINAL) TE5Document15 pagesIndustrial Visit at Aboni Knitwear Ltd. (FINAL) TE5Zillur Rahman SaykatNo ratings yet

- BGMEA 2Document903 pagesBGMEA 2jamshed idcolNo ratings yet

- Mr. R.D. UdeshiDocument25 pagesMr. R.D. UdeshidebojyotigangulyNo ratings yet

- Jac ReportDocument4 pagesJac ReportNaveen GNo ratings yet

- Textile InternshipDocument8 pagesTextile InternshipPrakritiNo ratings yet

- RajatDocument83 pagesRajatrajatkattimani100% (1)

- Muzaffargarh 0 PDFDocument5 pagesMuzaffargarh 0 PDFRaheem Ullah KakarNo ratings yet

- CuelloDocument2 pagesCuelloFabi EscobarNo ratings yet

- Cottonology Activity Book - Learn About Cotton!Document14 pagesCottonology Activity Book - Learn About Cotton!Suhaas AhujaNo ratings yet

- Housekeeping LectureDocument57 pagesHousekeeping LectureLaira De GuiaNo ratings yet

- Fazal ClothDocument58 pagesFazal ClothHaider Sarwar100% (4)

- A Study On Recuirment and Selection Process in DSM Textile in KarurDocument104 pagesA Study On Recuirment and Selection Process in DSM Textile in Karurk eswari50% (2)

- Spinning JennyDocument10 pagesSpinning Jennyapi-583734272No ratings yet

- Unit 8TH 1aDocument12 pagesUnit 8TH 1aOscar Daniel Hernández OlveraNo ratings yet

- WLBDocument76 pagesWLBShravan VnNo ratings yet

- Knitting Capacity & Booking StatusDocument7 pagesKnitting Capacity & Booking StatussaidurtexNo ratings yet

- Party Wise Stock Local Party Wise Stock ExportDocument1 pageParty Wise Stock Local Party Wise Stock ExportRaghubendra SharmaNo ratings yet

- Compact Cotton YarnDocument5 pagesCompact Cotton Yarnmlganesh666No ratings yet

- Bestseller Factory List Dec 2022Document102 pagesBestseller Factory List Dec 2022viettao298No ratings yet

- Wetprocessingtechnology Internshipreport 151230113524 PDFDocument258 pagesWetprocessingtechnology Internshipreport 151230113524 PDFদীপ্তি হুমাইরাNo ratings yet

- Spirality of Knitted Fabrics: Part Ii: The Effect of Yarn Spinning Technology On Spirality M. D. Oe AreuroDocument7 pagesSpirality of Knitted Fabrics: Part Ii: The Effect of Yarn Spinning Technology On Spirality M. D. Oe AreuroAPARASU2010No ratings yet

- Introduction To Textile Engineering: Wet ProcessingDocument19 pagesIntroduction To Textile Engineering: Wet ProcessingKashif ChaudhryNo ratings yet

- INDUSTRY & COMPANY ProfileDocument22 pagesINDUSTRY & COMPANY Profilepranav chandruNo ratings yet

- S No. Exporter NTN Exporter Name Total in USD Millions: Top Exporters FY20Document3 pagesS No. Exporter NTN Exporter Name Total in USD Millions: Top Exporters FY20S AhmedNo ratings yet

- Faisalabad ChamberDocument49 pagesFaisalabad ChamberTALHA MAFBIS100% (2)

- Class 10 Geography SummeryDocument46 pagesClass 10 Geography SummeryTarini prasad DashNo ratings yet

- Useful Informations CancelledRC PanipatDocument57 pagesUseful Informations CancelledRC PanipatRavi KumarNo ratings yet

- Textile & ClothingDocument9 pagesTextile & ClothingAli SyedNo ratings yet