Professional Documents

Culture Documents

DIN 2.0371 - CuZn38Pb1.5

DIN 2.0371 - CuZn38Pb1.5

Uploaded by

Taner DemirelCopyright:

Available Formats

You might also like

- Cu Ni 18 ZN 19 PB 1Document1 pageCu Ni 18 ZN 19 PB 1Isa CatNo ratings yet

- Aisi 420 PDFDocument1 pageAisi 420 PDFJusril HidayatNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRemo StortiniNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contractedlijojose1No ratings yet

- TitaneGrade2 PDFDocument1 pageTitaneGrade2 PDFLucho de BarNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedsreckoNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiNo ratings yet

- Cuzn37-Pna 243 enDocument2 pagesCuzn37-Pna 243 enAbrahan Tinco PariNo ratings yet

- Nas - 185N - e - 254 Smo - Uns - S31254Document4 pagesNas - 185N - e - 254 Smo - Uns - S31254Marvin BasdenNo ratings yet

- 02 Asae 101892Document1 page02 Asae 101892raviteja036No ratings yet

- SAE 1018 - Data Sheet PDFDocument1 pageSAE 1018 - Data Sheet PDFHari SuthanNo ratings yet

- (UNS N08825) : NAS High Corrosion Resistant Nickel AlloyDocument4 pages(UNS N08825) : NAS High Corrosion Resistant Nickel AlloySunil Kumar GoudaNo ratings yet

- Carbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)Document7 pagesCarbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)alvida pramudiantiNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- 16 MN CR 5Document2 pages16 MN CR 5bd54No ratings yet

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 pageHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersNo ratings yet

- Cu Etp c11000 Pna - 211 sm0008 - enDocument2 pagesCu Etp c11000 Pna - 211 sm0008 - enNitin KumarNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetjon perez diezNo ratings yet

- Nas 254N: (Uns S32053)Document4 pagesNas 254N: (Uns S32053)munif finumNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- Datasheet Sanicro 72hpDocument2 pagesDatasheet Sanicro 72hpphillipskincaidNo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

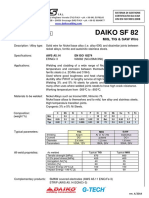

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- CuZn30-PNA 226 - ENDocument2 pagesCuZn30-PNA 226 - ENNHadesNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Cucrzr c18160 Pna 372 - enDocument2 pagesCucrzr c18160 Pna 372 - enSulistyo widiatmokoNo ratings yet

- (UNS N08904) : NAS High Corrosion Resistant Stainless SteelDocument4 pages(UNS N08904) : NAS High Corrosion Resistant Stainless SteelMiguel Martinez GuerreroNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- Ampd Data Sheet Vacuum Casting Resin 8263Document2 pagesAmpd Data Sheet Vacuum Casting Resin 8263Lorenzo Guida0% (1)

- PNA 400_Cu-OF_C10200-E.NDocument2 pagesPNA 400_Cu-OF_C10200-E.Ntatto198No ratings yet

- (UNS S66286) : NAS Heat-Resistant Stainless SteelDocument4 pages(UNS S66286) : NAS Heat-Resistant Stainless Steelsafat parNo ratings yet

- CuFe2p - AurubisDocument2 pagesCuFe2p - AurubisJan NoscilNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- NIC Component Series NTIDocument4 pagesNIC Component Series NTINICCompNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Quality 1.4362 Chemical Composition: Technical CardDocument2 pagesQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Datasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1Document12 pagesDatasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1mini p shendeNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- 1528450631SAE1018080A15Document2 pages1528450631SAE1018080A15bs7698210No ratings yet

- 30crnimo8: Steel GradeDocument2 pages30crnimo8: Steel GradewemersonsrNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- NIC Components NPIM - C SeriesDocument6 pagesNIC Components NPIM - C SeriesNICCompNo ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- Nas 64 eDocument4 pagesNas 64 eDaoNo ratings yet

- 61 Si CR 7Document2 pages61 Si CR 7RaduIonNo ratings yet

- Supercored 81-K2Document8 pagesSupercored 81-K2허원No ratings yet

- Linear Ways IndiaDocument19 pagesLinear Ways IndiaTaner DemirelNo ratings yet

- 920 - 0 - Diamond Compounds G NPDocument2 pages920 - 0 - Diamond Compounds G NPTaner DemirelNo ratings yet

- Corrosionresistance Guide For Fastners GrabberDocument10 pagesCorrosionresistance Guide For Fastners GrabberTaner DemirelNo ratings yet

- CZ 131Document1 pageCZ 131Taner DemirelNo ratings yet

- CZ 130Document1 pageCZ 130Taner DemirelNo ratings yet

- CZ 132Document1 pageCZ 132Taner DemirelNo ratings yet

- CuZn38Pb1 (CW607N)Document2 pagesCuZn38Pb1 (CW607N)Taner DemirelNo ratings yet

- BCS 051 Solved AssignmentsDocument11 pagesBCS 051 Solved AssignmentsAmit GuptaNo ratings yet

- 3.steel Members (Unit III)Document31 pages3.steel Members (Unit III)tauseefNo ratings yet

- H 99 Sec 8 D 1 App 1Document9 pagesH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DNo ratings yet

- HW 4 - DR ShekDocument24 pagesHW 4 - DR ShekHadirah HanafiNo ratings yet

- Arbore Cotit DesenDocument1 pageArbore Cotit DesenIonel Bogdan NeacșuNo ratings yet

- RR2009 - Generale-RrDocument39 pagesRR2009 - Generale-Rrhemant9315No ratings yet

- MAD Lab SyllabusDocument2 pagesMAD Lab SyllabusPhani KumarNo ratings yet

- The Art of Maya 3rd EditionDocument22 pagesThe Art of Maya 3rd EditionMic Thim100% (1)

- PGG-EG Governor ActuatorDocument4 pagesPGG-EG Governor Actuatorrodruren010% (1)

- APX Portable Accessory CatalogDocument12 pagesAPX Portable Accessory Catalogcraig_ochsNo ratings yet

- Improvement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaDocument2 pagesImprovement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaChandan MoharanaNo ratings yet

- CollisionDocument7 pagesCollisionboltuNo ratings yet

- GD Apex Series 25-30 HP Rotary Screw Compressor BrochureDocument24 pagesGD Apex Series 25-30 HP Rotary Screw Compressor BrochureRene Gabriel CatorcenoNo ratings yet

- Iec 364 4 41Document12 pagesIec 364 4 41Ramadan Dwiputra NurrachmadNo ratings yet

- Module 4 - Speed of SoundDocument16 pagesModule 4 - Speed of SoundLaiza GranaNo ratings yet

- PBA Therm Clad BrochureDocument2 pagesPBA Therm Clad BrochureJames DickinsonNo ratings yet

- Allplan TutorialDocument330 pagesAllplan TutorialOana ScutarasuNo ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- Class II Oral QuestionsDocument18 pagesClass II Oral QuestionsStewardGriffindorNo ratings yet

- Why It Does Not MatterDocument31 pagesWhy It Does Not MatterDavid I AgogoNo ratings yet

- Gas LiftDocument43 pagesGas LiftAhmad FaizilNo ratings yet

- Manual Conefor 26Document19 pagesManual Conefor 26J. Francisco Lavado ContadorNo ratings yet

- Moisture BarriersDocument31 pagesMoisture BarriersraviciviltNo ratings yet

- 1308020EN Electrical EngineeringDocument20 pages1308020EN Electrical EngineeringamrehmaniNo ratings yet

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BDocument11 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BJignesh TrivediNo ratings yet

- 19-GB 50030-91氧气站设计规范en PDFDocument34 pages19-GB 50030-91氧气站设计规范en PDFyyyy071220No ratings yet

- Chapter 3 Scope - QuestionsDocument2 pagesChapter 3 Scope - QuestionsnsadnanNo ratings yet

- Mve Vapor Shippers (Regular) - Cryogenic Vapor Shippers - Cryo Cube - Cryo Moover - Mini Moover - Cryo Shipper - Cryo Shipper XCDocument9 pagesMve Vapor Shippers (Regular) - Cryogenic Vapor Shippers - Cryo Cube - Cryo Moover - Mini Moover - Cryo Shipper - Cryo Shipper XCPrincestonNo ratings yet

- GL1200. .Service - ManualDocument415 pagesGL1200. .Service - ManualIpavec RokNo ratings yet

- 1948, E.R.Lapwood, Convection of A Fluid in A Porous Medium, Math. Pro. Cam. Phil. Soc.Document15 pages1948, E.R.Lapwood, Convection of A Fluid in A Porous Medium, Math. Pro. Cam. Phil. Soc.Prabal AcharyaNo ratings yet

DIN 2.0371 - CuZn38Pb1.5

DIN 2.0371 - CuZn38Pb1.5

Uploaded by

Taner DemirelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 2.0371 - CuZn38Pb1.5

DIN 2.0371 - CuZn38Pb1.5

Uploaded by

Taner DemirelCopyright:

Available Formats

UNS C37000 EN CW608N DIN 2.0371 - CuZn38Pb1.

5

General Characteristics

Leaded a + b brass with satisfactorily cold forming aptitude, and good hot formability and machinability. Machinability +

The electrical conductivity is 28% IACS. Machinability increases Quench hardening no

with lead content, whereas cold formability increases with decreasing zinc content. Polishing -

This brass can easily be soldered but welding is difficult.

Magnetic no

Age hardening no

Welding

MIG,TIG,WIG no

Arc no

Resistance no

Autogenous no

Laser no

Chemical composition (ASTM) [wt.%]

Cu Pb Fe AT Zn

58 - 62 1.0 - 2.0 < 0.3 < 0.5 Balance

Physical properties

Density Electrical resistivity Specific heat Thermal conductivity

r [kg·m-3] r [µW·m] Cp [J·kg-1·K-1] l [W·m-1·K-1]

8'500 0.064 at 20°C 380 120

Coefficient of thermal expansion Elastic modulus

a [10-6·°C-1] between 20°C and E [GPa]

100 °C 200 °C 300 °C 400 °C 500 °C 600 °C 700 °C 100 at 20°C

20.7 20.7 20.7

Mechanical properties

Yield strength Tensile Elongation Vickers

State Rp0.2 [MPa] strength Hardness

20°C 100°C 200°C 300°C Rm [MPa] A5 [%] [HV]

Annealed 150 340 35 75

Full hard 520 610 3 190

Thermal treatment

Type Temperature Time Protective atmosphere Cooling

[°C] [minutes]

Annealing 425 - 500 30 - 60 Air, argon or N2 + H2 not critical

Stress relief 250 - 300 240 Air, argon or N2 + H2 not critical

Surface treatment

Type Solution Remarks

Pickling H2SO4 4 - 15% during 0.5 to 15 minutes RT or at 60°C

Pickling HCl 40 - 90 % during 1 to 3 minutes RT

Fabrication characteristics

The suitability of this brass for cold forming, stamping and deep drawing is limited. A lead-free brass with lower zinc content is recommended for

these operations. By contrast, the alloy is very suited for hot forming (650°C - 825°C). Annealing in air requires subsequent pickling to

remove the surface oxide layer. Annealing can also be done in a neutral (Argon) or reducing (cracked ammoniac, N2 + H2) atmosphere.

The most performant microstructures and mechanical properties are achieved with annealing temperatures to the lower bound of the temperature

interval given above. Very good

machinability, estimated at 80% on a scale with the free cutting brass CuZn35.5Pb3 at 100%.

Welding, brazing and soldering

This alloy can easily be brazed and soldered. Welding, in contrast, is not recommended.

Available products

Sheets, ribbons, wires, profiles, tubes, dimensions and tolerances on request.

The indications are basically founded on our actual know-how. This technical data sheet is without

commitment and not contracted.

You might also like

- Cu Ni 18 ZN 19 PB 1Document1 pageCu Ni 18 ZN 19 PB 1Isa CatNo ratings yet

- Aisi 420 PDFDocument1 pageAisi 420 PDFJusril HidayatNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRemo StortiniNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contractedlijojose1No ratings yet

- TitaneGrade2 PDFDocument1 pageTitaneGrade2 PDFLucho de BarNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedsreckoNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiNo ratings yet

- Cuzn37-Pna 243 enDocument2 pagesCuzn37-Pna 243 enAbrahan Tinco PariNo ratings yet

- Nas - 185N - e - 254 Smo - Uns - S31254Document4 pagesNas - 185N - e - 254 Smo - Uns - S31254Marvin BasdenNo ratings yet

- 02 Asae 101892Document1 page02 Asae 101892raviteja036No ratings yet

- SAE 1018 - Data Sheet PDFDocument1 pageSAE 1018 - Data Sheet PDFHari SuthanNo ratings yet

- (UNS N08825) : NAS High Corrosion Resistant Nickel AlloyDocument4 pages(UNS N08825) : NAS High Corrosion Resistant Nickel AlloySunil Kumar GoudaNo ratings yet

- Carbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)Document7 pagesCarbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)alvida pramudiantiNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- 16 MN CR 5Document2 pages16 MN CR 5bd54No ratings yet

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 pageHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersNo ratings yet

- Cu Etp c11000 Pna - 211 sm0008 - enDocument2 pagesCu Etp c11000 Pna - 211 sm0008 - enNitin KumarNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetjon perez diezNo ratings yet

- Nas 254N: (Uns S32053)Document4 pagesNas 254N: (Uns S32053)munif finumNo ratings yet

- DS Mold 4140Document3 pagesDS Mold 4140reza prasetiaNo ratings yet

- Datasheet Sanicro 72hpDocument2 pagesDatasheet Sanicro 72hpphillipskincaidNo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data Sheetdan howsNo ratings yet

- CuZn30-PNA 226 - ENDocument2 pagesCuZn30-PNA 226 - ENNHadesNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- Cucrzr c18160 Pna 372 - enDocument2 pagesCucrzr c18160 Pna 372 - enSulistyo widiatmokoNo ratings yet

- (UNS N08904) : NAS High Corrosion Resistant Stainless SteelDocument4 pages(UNS N08904) : NAS High Corrosion Resistant Stainless SteelMiguel Martinez GuerreroNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- Ampd Data Sheet Vacuum Casting Resin 8263Document2 pagesAmpd Data Sheet Vacuum Casting Resin 8263Lorenzo Guida0% (1)

- PNA 400_Cu-OF_C10200-E.NDocument2 pagesPNA 400_Cu-OF_C10200-E.Ntatto198No ratings yet

- (UNS S66286) : NAS Heat-Resistant Stainless SteelDocument4 pages(UNS S66286) : NAS Heat-Resistant Stainless Steelsafat parNo ratings yet

- CuFe2p - AurubisDocument2 pagesCuFe2p - AurubisJan NoscilNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- NIC Component Series NTIDocument4 pagesNIC Component Series NTINICCompNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Quality 1.4362 Chemical Composition: Technical CardDocument2 pagesQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Datasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1Document12 pagesDatasheet-Sandvik-253-Ma-En-V2019-08-19 09 - 46 Version 1mini p shendeNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- 20160331071021-6541 23MnNiCrMo52Document1 page20160331071021-6541 23MnNiCrMo52rusf123No ratings yet

- 1528450631SAE1018080A15Document2 pages1528450631SAE1018080A15bs7698210No ratings yet

- 30crnimo8: Steel GradeDocument2 pages30crnimo8: Steel GradewemersonsrNo ratings yet

- 100crmnsi6-4: Steel GradeDocument3 pages100crmnsi6-4: Steel GradeSama UmateNo ratings yet

- NIC Components NPIM - C SeriesDocument6 pagesNIC Components NPIM - C SeriesNICCompNo ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- Nas 64 eDocument4 pagesNas 64 eDaoNo ratings yet

- 61 Si CR 7Document2 pages61 Si CR 7RaduIonNo ratings yet

- Supercored 81-K2Document8 pagesSupercored 81-K2허원No ratings yet

- Linear Ways IndiaDocument19 pagesLinear Ways IndiaTaner DemirelNo ratings yet

- 920 - 0 - Diamond Compounds G NPDocument2 pages920 - 0 - Diamond Compounds G NPTaner DemirelNo ratings yet

- Corrosionresistance Guide For Fastners GrabberDocument10 pagesCorrosionresistance Guide For Fastners GrabberTaner DemirelNo ratings yet

- CZ 131Document1 pageCZ 131Taner DemirelNo ratings yet

- CZ 130Document1 pageCZ 130Taner DemirelNo ratings yet

- CZ 132Document1 pageCZ 132Taner DemirelNo ratings yet

- CuZn38Pb1 (CW607N)Document2 pagesCuZn38Pb1 (CW607N)Taner DemirelNo ratings yet

- BCS 051 Solved AssignmentsDocument11 pagesBCS 051 Solved AssignmentsAmit GuptaNo ratings yet

- 3.steel Members (Unit III)Document31 pages3.steel Members (Unit III)tauseefNo ratings yet

- H 99 Sec 8 D 1 App 1Document9 pagesH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DNo ratings yet

- HW 4 - DR ShekDocument24 pagesHW 4 - DR ShekHadirah HanafiNo ratings yet

- Arbore Cotit DesenDocument1 pageArbore Cotit DesenIonel Bogdan NeacșuNo ratings yet

- RR2009 - Generale-RrDocument39 pagesRR2009 - Generale-Rrhemant9315No ratings yet

- MAD Lab SyllabusDocument2 pagesMAD Lab SyllabusPhani KumarNo ratings yet

- The Art of Maya 3rd EditionDocument22 pagesThe Art of Maya 3rd EditionMic Thim100% (1)

- PGG-EG Governor ActuatorDocument4 pagesPGG-EG Governor Actuatorrodruren010% (1)

- APX Portable Accessory CatalogDocument12 pagesAPX Portable Accessory Catalogcraig_ochsNo ratings yet

- Improvement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaDocument2 pagesImprovement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaChandan MoharanaNo ratings yet

- CollisionDocument7 pagesCollisionboltuNo ratings yet

- GD Apex Series 25-30 HP Rotary Screw Compressor BrochureDocument24 pagesGD Apex Series 25-30 HP Rotary Screw Compressor BrochureRene Gabriel CatorcenoNo ratings yet

- Iec 364 4 41Document12 pagesIec 364 4 41Ramadan Dwiputra NurrachmadNo ratings yet

- Module 4 - Speed of SoundDocument16 pagesModule 4 - Speed of SoundLaiza GranaNo ratings yet

- PBA Therm Clad BrochureDocument2 pagesPBA Therm Clad BrochureJames DickinsonNo ratings yet

- Allplan TutorialDocument330 pagesAllplan TutorialOana ScutarasuNo ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- Class II Oral QuestionsDocument18 pagesClass II Oral QuestionsStewardGriffindorNo ratings yet

- Why It Does Not MatterDocument31 pagesWhy It Does Not MatterDavid I AgogoNo ratings yet

- Gas LiftDocument43 pagesGas LiftAhmad FaizilNo ratings yet

- Manual Conefor 26Document19 pagesManual Conefor 26J. Francisco Lavado ContadorNo ratings yet

- Moisture BarriersDocument31 pagesMoisture BarriersraviciviltNo ratings yet

- 1308020EN Electrical EngineeringDocument20 pages1308020EN Electrical EngineeringamrehmaniNo ratings yet

- Indian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BDocument11 pagesIndian Standard: Hexagon Head Bolts, Screws and Nuts of Product Grades A and BJignesh TrivediNo ratings yet

- 19-GB 50030-91氧气站设计规范en PDFDocument34 pages19-GB 50030-91氧气站设计规范en PDFyyyy071220No ratings yet

- Chapter 3 Scope - QuestionsDocument2 pagesChapter 3 Scope - QuestionsnsadnanNo ratings yet

- Mve Vapor Shippers (Regular) - Cryogenic Vapor Shippers - Cryo Cube - Cryo Moover - Mini Moover - Cryo Shipper - Cryo Shipper XCDocument9 pagesMve Vapor Shippers (Regular) - Cryogenic Vapor Shippers - Cryo Cube - Cryo Moover - Mini Moover - Cryo Shipper - Cryo Shipper XCPrincestonNo ratings yet

- GL1200. .Service - ManualDocument415 pagesGL1200. .Service - ManualIpavec RokNo ratings yet

- 1948, E.R.Lapwood, Convection of A Fluid in A Porous Medium, Math. Pro. Cam. Phil. Soc.Document15 pages1948, E.R.Lapwood, Convection of A Fluid in A Porous Medium, Math. Pro. Cam. Phil. Soc.Prabal AcharyaNo ratings yet