Professional Documents

Culture Documents

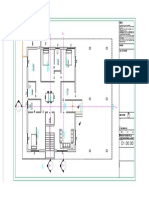

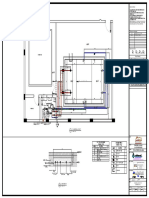

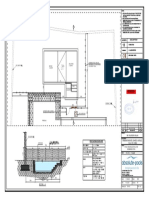

WIZA LWENJE ASSIGNMENT2, 202102612-Layout1

WIZA LWENJE ASSIGNMENT2, 202102612-Layout1

Uploaded by

mumbab2002Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WIZA LWENJE ASSIGNMENT2, 202102612-Layout1

WIZA LWENJE ASSIGNMENT2, 202102612-Layout1

Uploaded by

mumbab2002Copyright:

Available Formats

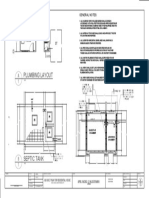

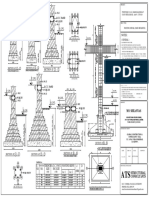

NOTES

GENERAL

1.)TO PROVIDE LOAD SUPPORT AND DISTRIBUTION

OF LOAD TO ALL DEGSINATED LOAD BEARING

COMPONENT DESIGNS.

2.) REPORT ANY UNFORESEEN CONDITIONS TO THE

GENERAL CONTRACTOR AND CONSULTANT

BEFORE PROCEEDING.

3.) ALL DIMENSIONS ARE IN MILIMETERS

4.) GIVE TOP OF SLAB, A TROWEL FINISH. THE SLAB

MUST BE RECTANGULAR HENCE IN SHORT

DISTANCE EXISTS THE MAIN BARS WHILE IN THE

LONGEST DISTANCE MUST BE THE DISTRIBUTION

BARS.

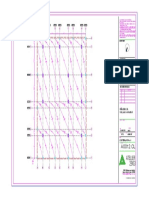

N REINFORCING STEEL

1.) ALL REINFORCING STEEL TO BE HIGH YIELD

STEEL.

2.)ALL REINFORCING IS TO BE DETAILED IN

ACCORDANCE WITH BS 4466 DETAILING MANUAL

EXCEPT AS OTHERWISE NOTED.

3.) CONCRETE COVER TO STEEL TO BE AS FOLLOWS

A B C D UNLESS OTHERWISE: 50

4.) LAPPING NOT TO BE DONE ON THE BEAMS IN

THE SLAB.

5.) ALL REINFORCING TO HELD IN PLACE, AND TIED

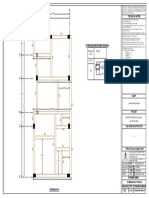

5500 5500 5500 BY THE USE OF PROPER ACCESSORIES, SUCH AS

HI-CHAIRS, SPACERS, ETC. TO BE SUPPLIED BY THE

REINFORCING STEEL FABRICATOR.

200 100 6.)SLAB REINFORCEMENT USED TO RESIST

PRINCIPAL OR TEMPERATURE STRESSES SHALL BE

200 SECURELY TIED.

100

B CAST-IN-PLACE CONCRETE

1.) CONCRETE SHOULD HAVE COMPRESSIVE

STRENGTH AT THE END OF 28 DAYS BY STANDARD

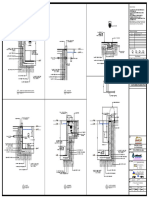

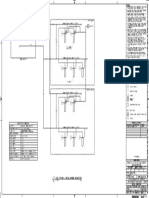

1 56Y16-01-300c/c B1

CYLINDER TEST AS FOLLOWS:

400

5500

2.) ALL CONCRETE IS TO BE CAST CONTINUOUSLY

BETWEEN PREDETERMINED CONSTRUCTION AND

CONTROL JOINTS.

3.) JOINTS TO BE FILLED WITH APPROVED

A A 84Y12-04-200c/c B2

JOINT/CRACK FILLER.

4.) BONDING AGENT - SHALL BE A PROPRIETARY

PRODUCT WHICH IS NO WATER SOLUBLE AND

ENSURE FULL BOND BETWEEN HARDENED AND

2 FRESH CONCRETE.

BACKFILLING GRADE BEAM ON BOTH SIDES

1.) GRADE BEAMS ARE NOT DESIGNED TO CARRY

5500

CANTILEVER LOADS, AND ARE TO BE BACKFILLED

SIMULTANEOUSLY INSIDE AND OUT, USING A

38Y10-02-300 NON-EXPANDING AND NON-ORGANIC TYPE OF

SOIL INLIFTS NOT EXCEEDING 8" (200 mm)

COMPACTED TO MINIMUM 98% STANDARD

112Y10-03-300c/c PROCTOR MAX. DRY DENSITY.

SLAB ON GRADE

3 1.) REMOVE ALL ORGANIC AND DELETERIOUS

MATERIAL.

B 2.) PROOFROLL SUBGRADE TO DELINEATE ANY

SOFT AREAS. ANY SOFT AREAS TO BE EXCAVATED

AND RECOMPACTED.

3.) CAST SLAB ON 0.15 mm POLYETHYLENE VAPOR

BARRIER.

4.) SAW CUT SLAB AS LOCATED ON DRAWINGS TO

DEPTH OF 200mm WITHIN 24 HOURS OF CASTING

CAULK WITH JOINT SEALANT.

5.) DO NOT CAST SLAB ON DESICCATED, FROZEN

OR WET SOIL OR BASE.

6.) DO NOT ALLOW SOIL BENEATH THE SLAB TO

FREEZE AFTER CASTING SLAB.

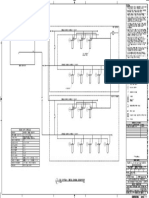

STRUCTURAL STEEL NOTES

1 2 3 1.) ALL STRUCTURAL STEEL MATERIALS,

FABRICATION, ERECTION, INSPECTION, AND

A B C D TESTING SHALL CONFIRM TO THE STANDARDS.

2.) THERE SHALL BE NO CUTTING OF THE

STRUCTURAL STEEL MEMBERS FOR THE WORK OF

OTHER TRADES WITHOUT PRIOR APPROVAL OF

THE STRUCTURAL CONSULTANT.

3.) PROVIDE ADEQUATE TEMPORARY BRACING OF

THE STRUCTURE TO RESIST LOADS AND ERECTION

STRESSES DURING CONSTRUCTION. DESIGN OF

TEMPORARY BRACING IS THE STRUCTURAL STEEL

CONTRACTOR'S RESPONSIBILITY.

14.) SUBMIT CHECKED SHOP AND ERECTION

DRAWINGS FOR ALL STEEL WORK TO THE

STRUCTURAL CONSULTANT FOR REVIEW PRIOR TO

FABRICATION.

15.) SHOP DRAWINGS FOR CONNECTIONS AND

5500 5500 5500 COMPONENTS DESIGNED BY THE FABRICATOR

SHALL BE SEALED BY A PROFESSIONAL ENGINEER

REGISTERED IN THE PROVINCE HAVING

JURISDICTION WHOM SHALL BE RESPONSIBLE FOR

38Y10-02-300 THE DESIGN AND NECESSARY INSPECTIONS

DURING FABRICATION & INSPECTION TO ENSURE

THAT THE WORK IN BUILT IN ACCORDANCE WITH

THE DESIGN.

112Y10-03-300 c/c 56Y16-01-300c/cB1

NAME: WIZA LWENJE.

84Y16-01-200c/c T1 STUDENTNUMBER:

202102612.

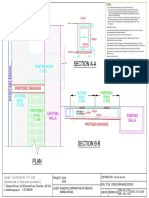

SECTION B-B SECTION A-A

CHECKED BY :

Ms SHABA

SCALE: DATE :

1:4000 23/05/2023

You might also like

- Method Statement - Roof VentilatorDocument7 pagesMethod Statement - Roof VentilatorJuwe Pkdo100% (2)

- ASTM A615-A615M-15aDocument8 pagesASTM A615-A615M-15aLydia100% (1)

- Handbook: Process Systems Engineering & ManufacturingDocument9 pagesHandbook: Process Systems Engineering & Manufacturingthomas_v501925No ratings yet

- Boundaray Wall BONPARA FIRE AEDocument1 pageBoundaray Wall BONPARA FIRE AENovember RainNo ratings yet

- General Notes StructuralDocument1 pageGeneral Notes StructuralnanipbenjieNo ratings yet

- Car Parking Shade Foundation-Model 1Document1 pageCar Parking Shade Foundation-Model 1Hussein AlallouchNo ratings yet

- Sample Sheet1 Slab Beam DetailsDocument5 pagesSample Sheet1 Slab Beam DetailsaNo ratings yet

- BHPQ SP 5698 SD 101.0Document1 pageBHPQ SP 5698 SD 101.0Mohammed NadeemNo ratings yet

- 410 S0.02 General NotesDocument1 page410 S0.02 General Notesnarjis banoNo ratings yet

- SW 005Document1 pageSW 005Anishm absolute-composite.comNo ratings yet

- Footing Schedule Column Schedule: WF-O1 C1Document1 pageFooting Schedule Column Schedule: WF-O1 C1Bj GutierrezNo ratings yet

- Existing Culvert C401 - Temporary Supports DetailsDocument1 pageExisting Culvert C401 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Rev - Foundation PlanDocument1 pageRev - Foundation PlanVarun TyagiNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- Tie Beam (TB) Reinforcement Schedule:: MR Mohideen DanubeDocument1 pageTie Beam (TB) Reinforcement Schedule:: MR Mohideen DanubeSimsonNo ratings yet

- Pdd-101786-203722-Lay-206-Rev - 2Document3 pagesPdd-101786-203722-Lay-206-Rev - 2A ZamanNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Plumbing Layout: General NotesDocument1 pagePlumbing Layout: General NotesMiiNo ratings yet

- Notes: Ground Floor Plan With Furniture LayoutDocument1 pageNotes: Ground Floor Plan With Furniture LayoutRoxzen ColladoNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- RailingDocument1 pageRailingAnushka BhavsarNo ratings yet

- Wall Elevation - C - Kitchen - Second Floor: RevisionsDocument1 pageWall Elevation - C - Kitchen - Second Floor: RevisionsAnishma AyyappanNo ratings yet

- Boys Toilet: W.C 1000x1600 W.C 1000x1600 W.C 1000x1600 W.C 1000x1600Document1 pageBoys Toilet: W.C 1000x1600 W.C 1000x1600 W.C 1000x1600 W.C 1000x1600yash ayreNo ratings yet

- TypeDocument1 pageTypemist ce19No ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- Gate ElevationDocument1 pageGate Elevationno oneNo ratings yet

- Preliminary: Lineshop LineshopDocument1 pagePreliminary: Lineshop LineshopDarren LaiNo ratings yet

- General Notes:: Proposed 12 Villas (G+1St+Penthouse)Document1 pageGeneral Notes:: Proposed 12 Villas (G+1St+Penthouse)Mohammed NadeemNo ratings yet

- Etp 40 KLD 29.05.2023Document1 pageEtp 40 KLD 29.05.2023Ravpreet SinghNo ratings yet

- Etp 29.05.2023Document1 pageEtp 29.05.2023Ravpreet SinghNo ratings yet

- SW 012Document1 pageSW 012Anishm absolute-composite.comNo ratings yet

- Anushka Bhavsar T.Y B.Arch Working Drawing 2 Trinity College of Architecture Date: Sign: StampDocument1 pageAnushka Bhavsar T.Y B.Arch Working Drawing 2 Trinity College of Architecture Date: Sign: StampAnushka BhavsarNo ratings yet

- General Notes FBDocument3 pagesGeneral Notes FBEnglish for KidsNo ratings yet

- General Notes TunnelDocument3 pagesGeneral Notes TunnelEnglish for KidsNo ratings yet

- Center Line Plan PDFDocument1 pageCenter Line Plan PDFammuNo ratings yet

- Plinth Beam Layout: (3) Schedule of Plinth Level BeamsDocument1 pagePlinth Beam Layout: (3) Schedule of Plinth Level BeamsgundlavinayakNo ratings yet

- Existing Culvert C405 - Temporary Supports DetailsDocument1 pageExisting Culvert C405 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Notes:: Saudi Arabian Oil CompanyDocument1 pageNotes:: Saudi Arabian Oil Companysaleem shahidNo ratings yet

- Existing Culvert C440 - Temporary Supports DetailsDocument1 pageExisting Culvert C440 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Existing Culvert C409 - Temporary Supports DetailsDocument1 pageExisting Culvert C409 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- WDD First Floor Plaster-Layout1Document1 pageWDD First Floor Plaster-Layout1Aaron lisboaNo ratings yet

- WDD First Floor Plaster-ELEVATIONS-Layout1Document1 pageWDD First Floor Plaster-ELEVATIONS-Layout1Aaron lisboaNo ratings yet

- General Notes:: Construction Joints 5.0Document1 pageGeneral Notes:: Construction Joints 5.0Jack O SalemNo ratings yet

- Footing DetailDocument1 pageFooting DetailRatnesh PatelNo ratings yet

- T SHD Ug 23377 01 23 0539 00Document5 pagesT SHD Ug 23377 01 23 0539 00Taiwo OshinNo ratings yet

- Saudi Arabian Oil Company: PA-00B103 001 B C K04 RestrictedDocument1 pageSaudi Arabian Oil Company: PA-00B103 001 B C K04 RestrictedWaqarNo ratings yet

- North Direction: Makkah: Steel Structural PlatformDocument8 pagesNorth Direction: Makkah: Steel Structural PlatformDer3'am Al m7armehNo ratings yet

- Existing Culvert C407 - Temporary Supports DetailsDocument1 pageExisting Culvert C407 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesWaqarNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- Cross Drain DrawingDocument1 pageCross Drain DrawingManoj BatraNo ratings yet

- General Notes: Makati - Mandaluyong BridgeDocument1 pageGeneral Notes: Makati - Mandaluyong BridgegregNo ratings yet

- Working DrawingDocument1 pageWorking Drawingabhilash123charuNo ratings yet

- Technical Notes: A B C D E 220.0 321.5 131.0 248.0 920.5Document1 pageTechnical Notes: A B C D E 220.0 321.5 131.0 248.0 920.5Tryds GroupNo ratings yet

- 04 Structural DrawingsDocument10 pages04 Structural DrawingszeipoibjasNo ratings yet

- Transportation Idaho Department: NotesDocument1 pageTransportation Idaho Department: NotesBikash SigdelNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: Notessaleem naheedNo ratings yet

- How To Polish Like A ProDocument1 pageHow To Polish Like A PromeletronNo ratings yet

- Metal Joining Processes: List Types of Welding, Description With Sketches of Arc Welding, Soldering and Brazing and Their ApplicationsDocument21 pagesMetal Joining Processes: List Types of Welding, Description With Sketches of Arc Welding, Soldering and Brazing and Their ApplicationseldhosekjnitNo ratings yet

- Severe Plastic Deformation SPD Process For MetalsDocument21 pagesSevere Plastic Deformation SPD Process For MetalsMarian SuciuNo ratings yet

- Design and Construction LadderDocument11 pagesDesign and Construction LadderValentina Rios VargasNo ratings yet

- Reihani 2015Document12 pagesReihani 2015CHONKARN CHIABLAMNo ratings yet

- Vci MBDocument23 pagesVci MBAyeshaNo ratings yet

- Types of Chemical ReactionsDocument4 pagesTypes of Chemical ReactionsVõ Thùy DươngNo ratings yet

- Effect of Trace Impurities On Hot Ductility of As-Cast Cupronickel AlloysDocument6 pagesEffect of Trace Impurities On Hot Ductility of As-Cast Cupronickel AlloysKay WhiteNo ratings yet

- Metalworks Canada Metal Roofing Siding ManualDocument18 pagesMetalworks Canada Metal Roofing Siding ManualWayne MillerNo ratings yet

- Feed Opening: ArrangementDocument6 pagesFeed Opening: ArrangementJavier Jimenez PerezNo ratings yet

- Basics of Sheet Metal WorkingDocument12 pagesBasics of Sheet Metal WorkingTooba100% (1)

- 00 - Assembly Instructions Wonder Woman Deluxe EngDocument12 pages00 - Assembly Instructions Wonder Woman Deluxe EngDavid StarkNo ratings yet

- Materials: Mechanical Properties of SLM-Printed Aluminium Alloys: A ReviewDocument51 pagesMaterials: Mechanical Properties of SLM-Printed Aluminium Alloys: A ReviewÁlvaro Nieto CastroNo ratings yet

- European Steel and Alloy Grades: 16nicrs4 (1.5715)Document2 pagesEuropean Steel and Alloy Grades: 16nicrs4 (1.5715)farshid KarpasandNo ratings yet

- Kawamura Time Switch Tm-30a ManualDocument2 pagesKawamura Time Switch Tm-30a ManualelimancorexNo ratings yet

- Catalog Wurth HardwareDocument296 pagesCatalog Wurth HardwareBillNo ratings yet

- RVR-Building Tech. 3 - Steel Construction - Ppt. PresentationDocument47 pagesRVR-Building Tech. 3 - Steel Construction - Ppt. Presentationtoyi kamiNo ratings yet

- Report About Casting DefectsDocument6 pagesReport About Casting DefectsAbdul Rehman FaisalNo ratings yet

- Presentatie John Van Der Zeeuw, AtotechDocument24 pagesPresentatie John Van Der Zeeuw, AtotechDinh TuNo ratings yet

- BSI Standards Ut ReferenceDocument9 pagesBSI Standards Ut ReferenceCarlos BustamanteNo ratings yet

- Lab 4 Metallography PDFDocument8 pagesLab 4 Metallography PDFjohn hayNo ratings yet

- Patent General 2Document29 pagesPatent General 2Ljubomir KljajicNo ratings yet

- Preheat and Heat Input To Reduce Hydrogen Cracking Risk - TWIDocument4 pagesPreheat and Heat Input To Reduce Hydrogen Cracking Risk - TWIFarid Ahmed KhwajaNo ratings yet

- ALUMINIUM Import Tariff RateDocument4 pagesALUMINIUM Import Tariff RateSamwovenNo ratings yet

- Technical Specifications: Project: Location: OwnerDocument7 pagesTechnical Specifications: Project: Location: Ownerjay vasquezNo ratings yet

- Pro - Super H Maintenance ManualDocument20 pagesPro - Super H Maintenance ManualSivaNo ratings yet

- C04. Spec - Inspection and Tests of Centrifugal Blowers and Fans HHCR-M-SP-GB210Document17 pagesC04. Spec - Inspection and Tests of Centrifugal Blowers and Fans HHCR-M-SP-GB210arissaNo ratings yet