Professional Documents

Culture Documents

WPS Summary Details

WPS Summary Details

Uploaded by

jubieethegreat0 ratings0% found this document useful (0 votes)

3 views6 pagesWPS Summary Details

Original Title

WPS Summary details

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS Summary Details

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views6 pagesWPS Summary Details

WPS Summary Details

Uploaded by

jubieethegreatWPS Summary Details

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

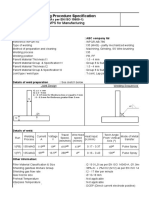

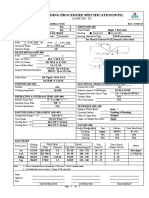

WPS No WC – WPS-004/15-16

Summary of WPS

WPQR No

WC/WPQR-004/15-16

Sl. No. Description Parameter

1 Parent material S690QL

2 Parent material designation EN 10025-6:2004(Group 3.1,2,1)

3 Material thickness(mm) 20mm

4 Welding position PA,PB,PF

Welding range qualification for

5 Multi run: 10mm to 40mm

butt

Welding range qualification for

6 Single run: 15mm to 30mm, B. Multi run – No Restriction

fillet throat thickness

7 Welding details

Welding Size of filler Run out length/Travel

Run Current (A) Voltage (V)

process material Speed (mm / min)

7.1 Root MMAW Ø 2.5 mm 75 - 93 23 - 25 138 - 168

7.2 2 & further MMAW Ø 3.15 mm 85 - 167 23 - 28 80 - 235

8 Filler material designation E 11018M

9 Any special Baking or Drying 350˚C – 2 Hrs / 100˚C Holding

10 Details of Back Gouging By Grinding

11 Preheat Temperature Min 100˚C

12 Inter pass Temperature 150˚C Max

13 Post - heating Not Done

Pre - heat maintenance

14 ≥100˚C

temperature

Post -weld heat treatment and /

15 NA

or Ageing

16 Time, Temperature, Method NA

17 Heating and Cooling Rates NA

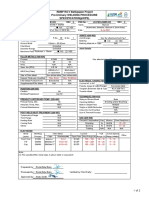

WPS No WC – WPS-005/15-16

Summary of WPS

WPQR No

WC/WPQR-005D/15-16

Sl. No. Description Parameter

1 Parent material S690QL

2 Parent material designation EN 10025-6:2004(Group 3.1,2,1)

3 Material thickness(mm) 30mm

4 Welding position PA,PB,PF

Welding range qualification for

5 Multi run: 15mm to 60mm

butt

Welding range qualification for

6 fillet throat thickness- 15mm to Single run: NA, B. Multi run – No Restriction

36mm

7 Welding details

Welding Size of filler Run out length/Travel

Run Current (A) Voltage (V)

process material Speed (mm / min)

7.1 Root MMAW Ø 3.15 mm 91 - 112 27 - 29 45 - 55

7.2 2 & further MMAW Ø 4 mm 105 - 173 23 - 31 38 - 89

8 Filler material designation E 11018M

9 Any special Baking or Drying 350˚C – 2 Hrs / 100˚C Holding

10 Details of Back Gouging By Grinding

11 Preheat Temperature Min 100˚C

12 Inter pass Temperature 150˚C Max

13 Post - heating Not Done

Pre - heat maintenance

14 ≥100˚C

temperature

Post -weld heat treatment and /

15 NA

or Ageing

16 Time, Temperature, Method NA

17 Heating and Cooling Rates NA

WPS No WC – WPS-006/15-16

Summary of WPS

WPQR No

WC/WPQR-006/15-16

Sl. No. Description Parameter

1 Parent material S690QL

2 Parent material designation EN 10025-6:2004(Group 3.1,2,1)

3 Material thickness(mm) 30mm

4 Welding position Horizontal Position (PB)

Welding range qualification for

5 A.Single run: 3mm to 6mm, B. Multi run: No Restriction

fillet weld

6 Welding details

Welding Size of filler Run out length/Travel

Run Current (A) Voltage (V)

process material Speed (mm / min)

6.1 1st side MMAW Ø 3.15 mm 128 - 159 28 - 30 118 - 144

6.2 2nd side MMAW Ø 4 mm 148 - 201 27 - 35 140 - 158

7 Filler material designation E 11018M

8 Any special Baking or Drying 350˚C – 2 Hrs / 100˚C Holding

9 Details of Back Gouging By Grinding

10 Preheat Temperature Min 100˚C

11 Inter pass Temperature 150˚C Max

12 Post - heating Not Done

Pre - heat maintenance

13 ≥100˚C

temperature

Post -weld heat treatment and /

14 NA

or Ageing

15 Time, Temperature, Method NA

16 Heating and Cooling Rates NA

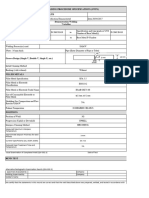

WPS No WC – WPS-007/15-16

Summary of WPS

WPQR No

WC/PQR-007D/15-16

Sl. No. Description Parameter

1 Parent material IS 2062 Gr.B

2 Parent material designation IS 2062 Gr.B

3 Material thickness(mm) 20mm

4 Welding position 3G

Welding range qualification for

5 5mm to 40mm

groove

Welding range qualification for

6 All

fillet throat thickness

7 Welding details

Welding Size of filler Run out length/Travel

Run Current (A) Voltage (V)

process material Speed (mm / min)

7.1 Root GMAW Ø 1.2 mm 99 - 105 19 – 19.2 80

7.2 Subsequent layers GMAW Ø 1.2 mm 100 - 110 19 – 19.8 75.8

8 Filler material designation E R70S

9 Any special Baking or Drying NA

10 Details of Back Gouging NA

11 Preheat Temperature Min 50˚C

12 Inter pass Temperature 150˚C Max

13 Post - heating Not Done

Pre - heat maintenance

14 NA

temperature

Post -weld heat treatment and /

15 NA

or Ageing

16 Time, Temperature, Method NA

17 Heating and Cooling Rates NA

WPS No WC – WPS-008/17-18

Summary of WPS

WPQR No

WC/PQR-008/17-18

Sl. No. Description Parameter

1 Parent material ASTM SA36

2 Parent material designation ASTM SA36

3 Material thickness(mm) 40mm

4 Welding position 4G

Welding range qualification for

5 5mm to 200mm

groove

Welding range qualification for

6 All

fillet throat thickness

7 Welding details

Welding Size of filler Run out length/Travel

Run Current (A) Voltage (V)

process material Speed (mm / min)

7.1 Root Pass SMAW Ø 3.15 mm 100 - 130 19 – 22 70 - 100

7.2 Hot Pass SMAW Ø 3.15 mm 100 - 130 19 – 22 70 - 100

7.3 Filling SMAW Ø 4 mm 120 - 160 20 – 27 100 - 160

7.4 Capping SMAW Ø 4 mm 120 - 160 20 – 27 100 - 160

8 Filler material designation E 7018

9 Any special Baking or Drying 250˚C to 300˚C – 2 Hrs / 100˚C to 150˚C Holding

10 Details of Back Gouging NA

11 Preheat Temperature Min 20˚C

12 Inter pass Temperature 200˚C Max

13 Post - heating Not Done

Pre - heat maintenance

14 NA

temperature

Post -weld heat treatment and /

15 NA

or Ageing

16 Time, Temperature, Method NA

17 Heating and Cooling Rates NA

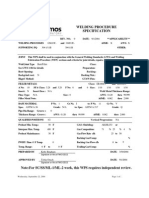

WPS No WC – WPS-010/19-20

Summary of WPS

WPQR No

WC/WPQR-010/19-20

Sl. No. Description Parameter

1 Parent material S690QL

2 Parent material designation EN 10025-6:2004(Group 3.2)

3 Material thickness(mm) 8mm

4 Welding position PC

Welding range qualification for

5 A.Single run: 3mm to 16mm, B. Multi run: No Restriction

fillet weld

6 Welding details

Welding Size of filler Run out length/Travel

Run Current (A) Voltage (V)

process material Speed (mm / min)

6.1 Root MMAW Ø 2.5 mm 100 - 110 22 - 26 110 - 120

6.2 2nd side MMAW Ø 2.5 mm 100 - 110 21 - 25 130 - 140

7 Filler material designation E 11018M

8 Any special Baking or Drying 350˚C – 2 Hrs / 100˚C Holding

9 Details of Back Gouging By Grinding

10 Preheat Temperature Min 100˚C

11 Inter pass Temperature 150˚C Max

12 Post - heating Not Done

Pre - heat maintenance

13 ≥100˚C

temperature

Post -weld heat treatment and /

14 NA

or Ageing

15 Time, Temperature, Method NA

16 Heating and Cooling Rates NA

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 page07.4 111 FW ML PF WPS 20mm ENGViktorNo ratings yet

- P91 WPSDocument6 pagesP91 WPSPepe SagitarioNo ratings yet

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyra100% (1)

- Astm D4662-03Document3 pagesAstm D4662-03Santiago Posso100% (1)

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- 01 - WPS - Welder Qualification and WPQR For MS 5.0 MM RAKESH Fillet T JointDocument5 pages01 - WPS - Welder Qualification and WPQR For MS 5.0 MM RAKESH Fillet T JointssqiindiapvtltdNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- 00 WPS STR 10-12-2018Document35 pages00 WPS STR 10-12-2018alok987No ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- WPSDocument5 pagesWPSParshottam Brahmxatriya100% (1)

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- WPS 1-SS 316 Rudder Stock With Letter HeadDocument2 pagesWPS 1-SS 316 Rudder Stock With Letter HeadNuwan RanaweeraNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationFrancisco HoyosNo ratings yet

- WPS PQR - P22 SS 18042024Document5 pagesWPS PQR - P22 SS 18042024mahesh kumarNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- WPS 2-A36 Rudder Shaft To FlangeDocument2 pagesWPS 2-A36 Rudder Shaft To FlangeNuwan RanaweeraNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- W LD N PR Dur Fi Ti (WPS: e G Oce e Spec Ca oDocument1 pageW LD N PR Dur Fi Ti (WPS: e G Oce e Spec Ca oGulshan MehraNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Guidance 1GDocument5 pagesGuidance 1GWahyu HaryadiNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- GWAW Welding SpecificationDocument2 pagesGWAW Welding SpecificationSaurabh GuptaNo ratings yet

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- 13CrMo45 P12 T12 Engl PDFDocument3 pages13CrMo45 P12 T12 Engl PDFYankMulya MusaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Astm E2058 00Document10 pagesAstm E2058 00thanacha.mintNo ratings yet

- Topic: General Organic Chemistry-IDocument21 pagesTopic: General Organic Chemistry-IWTF GammerNo ratings yet

- HISTOPATH (Quizlet)Document4 pagesHISTOPATH (Quizlet)Allyssa AniNo ratings yet

- Revision Notes for Jan TestDocument10 pagesRevision Notes for Jan TestptkNo ratings yet

- Buchas - GGB - Ozyska - Slizgowe - GAR-MAX - Zwijane - Z - WoknaDocument6 pagesBuchas - GGB - Ozyska - Slizgowe - GAR-MAX - Zwijane - Z - WoknaEdson FelixNo ratings yet

- Very Short Answer Questions (PYQ)Document6 pagesVery Short Answer Questions (PYQ)ashok pradhanNo ratings yet

- Jenkins Summary of Chapter-1Document9 pagesJenkins Summary of Chapter-1Joshua Andre CalderonNo ratings yet

- Design and Development of Blow Molding DieDocument15 pagesDesign and Development of Blow Molding DieRahul VatsNo ratings yet

- PYQS CH Solutions Class 12 ChemistryDocument9 pagesPYQS CH Solutions Class 12 Chemistryanshuman.panda.odmNo ratings yet

- Perforation in Oil and Gas WellsDocument28 pagesPerforation in Oil and Gas WellsSandeep Suryavanshi100% (1)

- Physics Investiture ProjectDocument20 pagesPhysics Investiture Projectsinghnancy066No ratings yet

- ASTM D7928 Hydrometer AnalysisDocument27 pagesASTM D7928 Hydrometer AnalysisZargham ZarrarNo ratings yet

- Chemistry Practice Set BDocument4 pagesChemistry Practice Set BYash PawarNo ratings yet

- Advanced Sensor Technology Biomedical Environmental and Construction Applications Ahmed Barhoum Full ChapterDocument68 pagesAdvanced Sensor Technology Biomedical Environmental and Construction Applications Ahmed Barhoum Full Chapternaomi.parker972100% (9)

- LEARNING ACTIVITY SHEET 3 (Behavior of Gases) - Science 10 (4th Quarter)Document1 pageLEARNING ACTIVITY SHEET 3 (Behavior of Gases) - Science 10 (4th Quarter)cherrymaeregalario2001No ratings yet

- 2013 - Jhong - Electrochemical Conversion of CO2 To Useful Chemicals Current Status, Remaining Challenges, and Future OpportunitiesDocument9 pages2013 - Jhong - Electrochemical Conversion of CO2 To Useful Chemicals Current Status, Remaining Challenges, and Future OpportunitiesWasim WasimNo ratings yet

- Enhanced Sinterability and in Vitro Bioactivity of Barium-Doped AkermaniteDocument7 pagesEnhanced Sinterability and in Vitro Bioactivity of Barium-Doped AkermaniteJean AndradeNo ratings yet

- Nexgen-Pts: The EndosafeDocument2 pagesNexgen-Pts: The EndosafeAbu MigbilNo ratings yet

- CHEM: Lab Report: Mole-Mass Relationships in ReactionsDocument3 pagesCHEM: Lab Report: Mole-Mass Relationships in ReactionsIoannus de Verani100% (6)

- Leaching of Lepidolite and Recovery of Lithium Hydroxide From Pu - 2021 - HydromDocument21 pagesLeaching of Lepidolite and Recovery of Lithium Hydroxide From Pu - 2021 - HydromJazmiin SoLiis HdzNo ratings yet

- 自來水管埋設工程施說明書Document187 pages自來水管埋設工程施說明書富山No ratings yet

- Sheet 13 GhaithDocument15 pagesSheet 13 GhaithСаша ТищенкоNo ratings yet

- Paper 8911Document8 pagesPaper 8911IJARSCT JournalNo ratings yet

- Presentation 2Document9 pagesPresentation 2AdityaNo ratings yet

- Fountain SolutionDocument36 pagesFountain SolutionallUddinNo ratings yet

- AllopurinolDocument3 pagesAllopurinolVu AnNo ratings yet

- Chemistry 100-070Document2 pagesChemistry 100-070karlNo ratings yet

- Practical PH & Ec Determination Soil ScienceDocument6 pagesPractical PH & Ec Determination Soil Sciencedamiankabis41No ratings yet

- ResiGard SL2Document4 pagesResiGard SL2fhsn84No ratings yet