Professional Documents

Culture Documents

0.3mm Ni Test Report

0.3mm Ni Test Report

Uploaded by

swathiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0.3mm Ni Test Report

0.3mm Ni Test Report

Uploaded by

swathiCopyright:

Available Formats

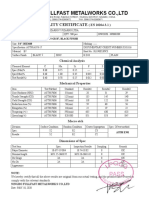

TEST REPORT

ULR‐TC1229124000001001F

Report No. : 38476125432 Date : 01‐03‐2024

Customer’s Name : M/s Ramani Steel House

Address : 65/73, C.P.Tank Road, Mumbai‐400004, India

Customer’s Ref No : Ref Date: 24‐02‐2024

Drawn By: Customer Sample Received on: 26‐02‐2024

Date of Completion: 01‐03‐2024

Material Description

Lab No Description ID. Size (mm) Material Specification

No

125432 Coil DY04 0.3 X 260 SB162 Nickel(UNS N02200) ASME.BPVC.II.B‐2021(Nickel

X 50‐60 200)/SB‐162 UNS No N02201 ASME.BPVC.II.B‐2021 (Nickel

201)

CHEMICAL SPECTRO ANALYSIS Test Method : ASTM E 3047:22

%Element Limit Result Test Method

Copper (Cu) 0.25 max. 0.25 max 0.0082 ASTM E 3047:22

Iron (Fe) 0.40 max. 0.40 max 0.0702 ASTM E 3047:22

Manganese (Mn) 0.35 max. 0.35 max 0.0010 ASTM E 3047:22

Carbon (C) 0.15 max. 0.02 max 0.0105 ASTM E 3047:22

Silicon (Si) 0.35 max. 0.35 max 0.0117 ASTM E 3047:22

Titanium (Ti) 0.0629 ASTM E 3047:22

Cobalt (Co) 0.0677 ASTM E 3047:22

Microhardness HV0.10 Test Method : ASTM E384:2022

Observed Value

Surface Hardness 141, 141, 142

Remark:‐ The above material conforms to SB162 Nickel(UNS N02200) ASME.BPVC.II.B‐

2021(Nickel 200)/SB‐162 UNS No N02201 ASME.BPVC.II.B‐2021 (Nickel 201) with

respect to element analyzed.

For Deep Metallurgical services

K.K.Karmakar

Authorized signatory

You might also like

- GB3077-1999 English VersionDocument20 pagesGB3077-1999 English VersionHermanto SupuNo ratings yet

- A 732 - A732M - 02 Equivalencia Ic AstmDocument8 pagesA 732 - A732M - 02 Equivalencia Ic AstmorivaldopenaNo ratings yet

- Chemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Document2 pagesChemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Claudia MmsNo ratings yet

- AMBICA 36mm Rod SS316L MTCDocument2 pagesAMBICA 36mm Rod SS316L MTCmetalexinNo ratings yet

- AMBICA 40mm Rod SS316L MTCDocument2 pagesAMBICA 40mm Rod SS316L MTCmetalexinNo ratings yet

- Material Verification Report: Elongation in 50 MM, Min % (Gauge Length 4D 50 MM)Document2 pagesMaterial Verification Report: Elongation in 50 MM, Min % (Gauge Length 4D 50 MM)shrikant mishraNo ratings yet

- Scope Location 1 TC 5671Document8 pagesScope Location 1 TC 5671MohamedNo ratings yet

- Metallic Material Specification: SUBJECT: AISI 8630 (UNS G86300), Modified Chemistry, 85 Ksi Minimum Yield StrengthDocument5 pagesMetallic Material Specification: SUBJECT: AISI 8630 (UNS G86300), Modified Chemistry, 85 Ksi Minimum Yield StrengthReginaldo SantosNo ratings yet

- Test Report: Page 1 of 2Document2 pagesTest Report: Page 1 of 2test qtesNo ratings yet

- GBT 3077-1999, Alloy Structure SteelsDocument24 pagesGBT 3077-1999, Alloy Structure SteelsThao NguyenNo ratings yet

- Inspection CertificateDocument1 pageInspection CertificatemohamedNo ratings yet

- Structurals and Standard Pipe EngDocument4 pagesStructurals and Standard Pipe EngUuka UkaNo ratings yet

- 20807testing SingleDocument1 page20807testing SingleHayderr HassNo ratings yet

- Structurals and Standard Pipe: ProducersDocument4 pagesStructurals and Standard Pipe: ProducersRudyNo ratings yet

- F8P4823-Sample TCDocument1 pageF8P4823-Sample TCDeepak BhatiNo ratings yet

- Specification For Welded Uns N08020, N08024, and N08026 Alloy TubesDocument3 pagesSpecification For Welded Uns N08020, N08024, and N08026 Alloy TubesSAMEERNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- Certificado Bothwell Ca1469Document1 pageCertificado Bothwell Ca1469erssonNo ratings yet

- Metals, Test Methods and Analytical ProceduresDocument1 pageMetals, Test Methods and Analytical ProceduresSARATH KRISHNAKUMARNo ratings yet

- 4 Material StandardsDocument29 pages4 Material Standardsloqueluq100% (3)

- Comparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Document7 pagesComparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Erijanio Silva100% (1)

- CPR26Document8 pagesCPR26jasbir.iitdNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- 70 S2 NaceDocument1 page70 S2 NaceShailesh DeshmukhNo ratings yet

- Mechanical Properties: Chemical CompositionDocument1 pageMechanical Properties: Chemical CompositionHERSON FARID BUENO PIÑEROSNo ratings yet

- 12B - MTC D BracketDocument1 page12B - MTC D Bracketarmanhussain3proNo ratings yet

- Technical Specifications For Boiler Quality Steel Plates For LPGDocument51 pagesTechnical Specifications For Boiler Quality Steel Plates For LPGGerick Eleazar RogadoNo ratings yet

- Metallic Material Specification: Title: AISI 8630 Mod Alloy Steel, 80 KSI Min Yield StrengthDocument5 pagesMetallic Material Specification: Title: AISI 8630 Mod Alloy Steel, 80 KSI Min Yield StrengthReginaldo SantosNo ratings yet

- Test Report DBWSDocument1 pageTest Report DBWSDwijamani SinghaNo ratings yet

- Spring Steel - Medium Carbon Wire Indian Standard Equivalent International StandardsDocument2 pagesSpring Steel - Medium Carbon Wire Indian Standard Equivalent International Standardsm natarajanNo ratings yet

- 1211PD03-PL-1211-01033 (Fw02co Base Metal)Document3 pages1211PD03-PL-1211-01033 (Fw02co Base Metal)HanifZawawiNo ratings yet

- B 211M - 03 - Qjixmu0Document10 pagesB 211M - 03 - Qjixmu0mercab15No ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- Purchase Spec. For Plates (Sa240 304L)Document3 pagesPurchase Spec. For Plates (Sa240 304L)Daison PaulNo ratings yet

- AH MergedDocument6 pagesAH MergedReginaldo SantosNo ratings yet

- Minfm67089 Astm A1011 Ss Grade 250 Type 1Document4 pagesMinfm67089 Astm A1011 Ss Grade 250 Type 1أبومحمدالزياتNo ratings yet

- Astm A240 A240m 16Document6 pagesAstm A240 A240m 16Anh Võ ĐứcNo ratings yet

- BUTTING Duplex 2018Document20 pagesBUTTING Duplex 2018Benny PoNo ratings yet

- Metallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNDocument5 pagesMetallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNReginaldo SantosNo ratings yet

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- ASTM B111 - Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockDocument18 pagesASTM B111 - Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stockfininho555No ratings yet

- Minfm66916 Astm A352 Grade LCC PDFDocument2 pagesMinfm66916 Astm A352 Grade LCC PDFChiranjeevi AnilNo ratings yet

- Minfm66916 Astm A352 Grade LCCDocument2 pagesMinfm66916 Astm A352 Grade LCCChiranjeevi AnilNo ratings yet

- Minfm66916 Astm A352 Grade LCCDocument2 pagesMinfm66916 Astm A352 Grade LCCChiranjeevi AnilNo ratings yet

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Document1 pageZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNo ratings yet

- Mechanical Test Codes and Standards ListDocument6 pagesMechanical Test Codes and Standards ListIsmail TpNo ratings yet

- Coreweld 46LS - 1.2mm - PV6141288Document1 pageCoreweld 46LS - 1.2mm - PV6141288Okan KkslNo ratings yet

- Astm A490m 10Document4 pagesAstm A490m 10ahmed romiehNo ratings yet

- SB 151 PDFDocument6 pagesSB 151 PDFAnilNo ratings yet

- Coreweld 46LS - 1.2mm - PV5381753Document2 pagesCoreweld 46LS - 1.2mm - PV5381753Okan KkslNo ratings yet

- Metallic Material SpecificationDocument8 pagesMetallic Material SpecificationReginaldo SantosNo ratings yet

- Columbus Castings Metal Grades PDFDocument1 pageColumbus Castings Metal Grades PDFksangeeth2000No ratings yet

- ESPARRAGO A-193 B7 3l4-10 X 3660Document1 pageESPARRAGO A-193 B7 3l4-10 X 3660Incoservspa cl100% (1)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Welding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsFrom EverandWelding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsNo ratings yet