Professional Documents

Culture Documents

Fiber Optic Drill

Fiber Optic Drill

Uploaded by

Michelle Rose Fernandez-Bernardo0 ratings0% found this document useful (0 votes)

1 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views3 pagesFiber Optic Drill

Fiber Optic Drill

Uploaded by

Michelle Rose Fernandez-BernardoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

PROJECT EXECUTION METHODOLOGY

HORIZONTAL DIAGONAL DRILLING (HDD)

1. Site Clearing and Preparation

2. Installation of Precautionary Measures

3. Delivery of Materials

4. Positioning of Machines

5. Drilling on the Pilot Hole

6. Preparation of Exit Hole

7. Pull Back of HDPE

8. Removal of Machine and/or Equipment

9. Restoration

PROJECT EXECUTION METHODOLOGY

HORIZONTAL DIAGONAL DRILLING (HDD)

Site Clearing and Preparation of Precautionary Measures

To ensure site safety, work efficiency, and mitigate risk, the process of Site

Clearing and Preparation of Precautionary Measures take place. These involve

preparations of road crossing that will be affected by the said scope of work, along with

installations of precautionary tools and/or materials that will and can enhance the stability

and flow of work with geotechnical report and surveys that include historical information

regarding the site and samples of the ground as a basis.

Delivery of Machine and/or Equipment and Positioning of Machine

The proper and appropriate machine and/or equipment for the Horizontal Diagonal

Drilling work will be delivered and set-up on a stable ground with the right bearing capacity

for a continuous flow of work to avoid sensitive areas that can cause work disturbance.

This certain part of the activity will include the proper system of positioning of the machine

to evade or minimize the interference to the workers and also to the passing vehicles.

Drilling on the Pilot Hole

The main execution of the Horizontal Diagonal Drilling work will start with the

drilling on the Pilot Hole. With the predetermined design path, a pilot hole is horizontally

drilled and continues under and across the established and aligned obstacle. The

electronic transmitter that directs a signal to the surface which is read by the receiver,

which transmittal of information back to the directional drill rig operator will take place will

be placed in a housing which is directly behind the directional drilling cutting head. With

the transmitted information, the directional driller can steer the bore path in the right trail

to avoid deviation.

Preparation of Exit Hole

Exit hole will be pierces by a drill bit and the downhole assembly will be removed

from the drill string which will be pulled back to the borehole to reach the required and/or

suitable diameter. The reamer will then be attached to the drill string on the opposite end

of the borehole from the drill and pulled back into the pilot hole.

Pull back of HDPE

Once the directionally drilled hole reached the required and/or suitable diameter,

a pullback assembly is made up to the prefabricated pull section. Then a reamer is

attached to the drill string, and will be connected to the product by a pulling head and

swivel. The swivel allows the rotation of the drill string and reamer without rotating the

entire pull section. The directional drilling rig then begins the pullback operation, rotating

and pulling on the drill string as well as circulating drilling fluids. The pullback continues

until the reamer exits the bore path by the directional drill rig and the pipeline is in place.

Removal of Machine and/or Equipment

When the work is considered and confirmed successful, machineries and equipment will

be demobilized and dismantled carefully.

You might also like

- Method Statement For Installation of Diesel Generator SetDocument3 pagesMethod Statement For Installation of Diesel Generator SetIngersol Duraikannu100% (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Method Statement For ScaffoldingDocument12 pagesMethod Statement For ScaffoldingChirag SharmaNo ratings yet

- METHOD STATEMENT - Floor Drain & FCO InstallationDocument5 pagesMETHOD STATEMENT - Floor Drain & FCO InstallationGerlie Dimayuga100% (2)

- Method Statement DuctingDocument29 pagesMethod Statement DuctingAnish Kumar100% (8)

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNo ratings yet

- Work Methodology FOR Chipping and Restoration Works For ElectricalDocument5 pagesWork Methodology FOR Chipping and Restoration Works For ElectricalJohn Paul Hernandez100% (1)

- MS Manhole ChambersDocument24 pagesMS Manhole ChambersAbdul Muneer PalapraNo ratings yet

- Method Statement For Drainage Pipes InstallationDocument11 pagesMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Horizontal Directional Drilling (HDD) MosDocument7 pagesHorizontal Directional Drilling (HDD) MosMuhammad FahmiNo ratings yet

- Method Statement For Electrical Surface Conduit InstallationDocument14 pagesMethod Statement For Electrical Surface Conduit Installationshareyhou100% (1)

- Specification For Prefabricated Vertical DrainsDocument7 pagesSpecification For Prefabricated Vertical DrainsRecep Caner Akyılmaz100% (2)

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Citizen Instruction Manual C500Document11 pagesCitizen Instruction Manual C500Konstantinos MakrisNo ratings yet

- Trunnion Weld Size DesignDocument8 pagesTrunnion Weld Size DesignsridharNo ratings yet

- DB Boring SpecsDocument6 pagesDB Boring Specsdstv2005No ratings yet

- HDD Applications and ProcessDocument6 pagesHDD Applications and Processcatalinboja1100% (1)

- Method of Statement (Mos) : Elektrik Maya Sdn. Bhd. No 19 Jalan Kacung Satu, Kedai Sedc, 81200 Tampoi, Johor Bahru, JohorDocument15 pagesMethod of Statement (Mos) : Elektrik Maya Sdn. Bhd. No 19 Jalan Kacung Satu, Kedai Sedc, 81200 Tampoi, Johor Bahru, JohoradelenaNo ratings yet

- HDD GP Guidelines 2-1 Chapter 2: HDD Applications and ProcessDocument6 pagesHDD GP Guidelines 2-1 Chapter 2: HDD Applications and ProcessEnri05No ratings yet

- Method Statement For Construction of Pile CAP: DATE: 24-OCT-15 REV: 01Document8 pagesMethod Statement For Construction of Pile CAP: DATE: 24-OCT-15 REV: 01Joe PSNo ratings yet

- 1x115 MW HFD FIRED POWER PLANT PROJECT Thakurgaon MS PC Pile2Document11 pages1x115 MW HFD FIRED POWER PLANT PROJECT Thakurgaon MS PC Pile2mijanur rahmanNo ratings yet

- Excavation Work Guidelines For Irrigation and Water Supply ProjectsDocument9 pagesExcavation Work Guidelines For Irrigation and Water Supply ProjectsKaram MoatasemNo ratings yet

- Mos HDD Maya Harvest Green and Sime DarbyDocument13 pagesMos HDD Maya Harvest Green and Sime DarbyadelenaNo ratings yet

- Method Statement For Installation of Diesel Generator SetDocument7 pagesMethod Statement For Installation of Diesel Generator SetAnonymous 8xHUWB100% (5)

- RAMS - Raised Floor Works Rev.02Document15 pagesRAMS - Raised Floor Works Rev.02MAher AbbasNo ratings yet

- Section 555 Directional Bore 555-1 DescriptionDocument7 pagesSection 555 Directional Bore 555-1 Descriptiongplese0No ratings yet

- Method-Statement-For-Ppr-Pipes-And-Fittings-Installation-Pdf For FPCCDocument10 pagesMethod-Statement-For-Ppr-Pipes-And-Fittings-Installation-Pdf For FPCCArnold DelinaNo ratings yet

- Excavation METHOD STATEMENTDocument5 pagesExcavation METHOD STATEMENTMohammed NajathNo ratings yet

- FF Installation System Method StatementDocument9 pagesFF Installation System Method StatementAchmad Fikri Rabbani100% (1)

- MOS Air Handling Units AHUDocument5 pagesMOS Air Handling Units AHUSuban Hari100% (1)

- Method Statement For Sheet PilingDocument8 pagesMethod Statement For Sheet PilingAbdul Muneer PalapraNo ratings yet

- WMS (Earthwork)Document5 pagesWMS (Earthwork)PUI CHEE KHIANNo ratings yet

- Ms-Cable Tray InstallationDocument7 pagesMs-Cable Tray InstallationVane DG100% (1)

- ZRC Ms - For Scbd-BuzonDocument6 pagesZRC Ms - For Scbd-BuzonIqbal HossainNo ratings yet

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu Ashokan100% (1)

- Directional Drill SafetyDocument7 pagesDirectional Drill SafetyMartahan ManurungNo ratings yet

- HDD Profile and Statment PDFDocument35 pagesHDD Profile and Statment PDFfdfazfzNo ratings yet

- New Updated Wms ResidentialDocument17 pagesNew Updated Wms Residentialhassan shaikhNo ratings yet

- Method of Statement - Earthing With Inwell MachineDocument3 pagesMethod of Statement - Earthing With Inwell Machinehari ramNo ratings yet

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanNo ratings yet

- Auxiliary Boiler MSDocument10 pagesAuxiliary Boiler MSsharif339No ratings yet

- Method Statements of Road WorksDocument38 pagesMethod Statements of Road WorksivanlewizNo ratings yet

- Hvac-Mos Saint Gobain-SreewariDocument39 pagesHvac-Mos Saint Gobain-SreewarisreewariplanningNo ratings yet

- Method Statement For Instalation of CCTV Camera and Junction Boc FoundationDocument18 pagesMethod Statement For Instalation of CCTV Camera and Junction Boc Foundationashishakare50% (2)

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNo ratings yet

- 00 - MS - Diesel Generator InstallationDocument8 pages00 - MS - Diesel Generator InstallationHassen LazharNo ratings yet

- Mechanical - Method of StatementDocument21 pagesMechanical - Method of StatementSEA ROCK TECHNICALNo ratings yet

- 01 - Method Statement For Excavation Work222Document9 pages01 - Method Statement For Excavation Work222Ahmed Samir SalimNo ratings yet

- Method Statement Ground Slab Work: Revision History Sheet Rev No. Date Description of RevisionDocument11 pagesMethod Statement Ground Slab Work: Revision History Sheet Rev No. Date Description of RevisionGalant ArgaNo ratings yet

- Auger Boring MachineDocument8 pagesAuger Boring MachineMohamed Hazem MofeedNo ratings yet

- RAMS - Demolition of Flooring Rev.02Document14 pagesRAMS - Demolition of Flooring Rev.02MAher AbbasNo ratings yet

- A1F9V8 - CP Rail and Cargill HDD Execution PlanDocument17 pagesA1F9V8 - CP Rail and Cargill HDD Execution PlanSbitNo ratings yet

- Method Statement of ExcavationDocument14 pagesMethod Statement of ExcavationNaeem100% (1)

- 12.rotary Erection ProcedureDocument8 pages12.rotary Erection ProcedureDebashish ChatterjeeNo ratings yet

- FootingsDocument7 pagesFootingsAlbertyNo ratings yet

- Trenching Method StatementDocument10 pagesTrenching Method StatementCezar DasiNo ratings yet

- Contec Project FinaleDocument15 pagesContec Project FinaleephragekaroNo ratings yet

- 静设备英文 Static Equipment Installation ProcedureDocument6 pages静设备英文 Static Equipment Installation Procedurejie100% (4)

- Pontoon Installation Method: Schedule of WorksDocument3 pagesPontoon Installation Method: Schedule of WorksDexu QiNo ratings yet

- UntitledDocument18 pagesUntitledPramod SinghNo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- Midas/Setf: 1. Geometry and MaterialsDocument2 pagesMidas/Setf: 1. Geometry and MaterialsMichelle Rose Fernandez-BernardoNo ratings yet

- ColumnsDocument3 pagesColumnsMichelle Rose Fernandez-BernardoNo ratings yet

- 6, B1-End&midDocument2 pages6, B1-End&midMichelle Rose Fernandez-BernardoNo ratings yet

- Fence Structural DesignDocument6 pagesFence Structural DesignMichelle Rose Fernandez-BernardoNo ratings yet

- Seismic AnalysisDocument4 pagesSeismic AnalysisMichelle Rose Fernandez-BernardoNo ratings yet

- Ubc AnalysisDocument5 pagesUbc AnalysisMichelle Rose Fernandez-BernardoNo ratings yet

- Bacani - Renovation Structural Analysis and DesignDocument36 pagesBacani - Renovation Structural Analysis and DesignMichelle Rose Fernandez-BernardoNo ratings yet

- Seismic AnalysisDocument1 pageSeismic AnalysisMichelle Rose Fernandez-BernardoNo ratings yet

- StaadDocument11 pagesStaadMichelle Rose Fernandez-BernardoNo ratings yet

- Worksheet of Reading Comprehension B1Document1 pageWorksheet of Reading Comprehension B1Farizki WinsuajiNo ratings yet

- Atmos Giga n150Document612 pagesAtmos Giga n150gilbert fristartoNo ratings yet

- STEK Claim Form - V1Document11 pagesSTEK Claim Form - V1STEK AutomotiveNo ratings yet

- Introduction and Types of Motion PDFDocument21 pagesIntroduction and Types of Motion PDFballDISCOVERIES PHballDISCOVERIESNo ratings yet

- Esr 1976Document6 pagesEsr 1976Anonymous x9STa9No ratings yet

- 026-Din en 1759 2005 001 Flanges - Their Joints - Circular Flanges For Pipes, Valves, Fittings - Steel FlangesDocument75 pages026-Din en 1759 2005 001 Flanges - Their Joints - Circular Flanges For Pipes, Valves, Fittings - Steel FlangesQuality MSIPL100% (2)

- Partner Valve/High Quality Ball Valve LENO™ MSV-S: Data SheetDocument8 pagesPartner Valve/High Quality Ball Valve LENO™ MSV-S: Data SheetZoran StanovnikNo ratings yet

- Eagle Hydraulic Cylinders - HBU - 2015Document5 pagesEagle Hydraulic Cylinders - HBU - 2015LJavierTaipeNo ratings yet

- Warrior Ninja 2000 Winch User MaualDocument21 pagesWarrior Ninja 2000 Winch User MaualkenNo ratings yet

- Maneurop® Reciprocating Compressors: MT/MTZDocument34 pagesManeurop® Reciprocating Compressors: MT/MTZLevi Lr'sNo ratings yet

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinNo ratings yet

- Beam Column DesignDocument28 pagesBeam Column DesignAmit PatelNo ratings yet

- RubberExpansionJoint SingleSphereBellowDocument2 pagesRubberExpansionJoint SingleSphereBellowagung wijayaNo ratings yet

- Pt. Griya Semeru PerdanaDocument1 pagePt. Griya Semeru PerdanaArya WijayaNo ratings yet

- Asme B31.8-2016Document1 pageAsme B31.8-2016buihoangphuong100% (1)

- JAKKA - Resetke I Anemostati Kompletan CenovnikDocument68 pagesJAKKA - Resetke I Anemostati Kompletan CenovnikAndjela StojanovicNo ratings yet

- A 516 A516+HIC A516+NACE A387 Other Steels Economic News: ASTM / ASTM A / SA 516 - CharacteristicsDocument2 pagesA 516 A516+HIC A516+NACE A387 Other Steels Economic News: ASTM / ASTM A / SA 516 - Characteristicsvinay1999No ratings yet

- Forklift MaintenanceDocument11 pagesForklift MaintenanceTrường NguyenNo ratings yet

- Comparativo Mandriles 0.375 y 0.5 in Abamex y E.U.Document2 pagesComparativo Mandriles 0.375 y 0.5 in Abamex y E.U.Jesús PeñaNo ratings yet

- Summary Mechanical CompletionDocument14 pagesSummary Mechanical Completionzat572000No ratings yet

- Grundfos DWK RSP LDocument1 pageGrundfos DWK RSP LAish MohammedNo ratings yet

- Oil and Gas Wells Casing Accessories CatalogueDocument24 pagesOil and Gas Wells Casing Accessories CatalogueAli AlakariNo ratings yet

- Structural Design Basis Report-R4Document8 pagesStructural Design Basis Report-R4anshutomar7915100% (1)

- Method of Statement For Foundation of P1 To P9Document15 pagesMethod of Statement For Foundation of P1 To P9Twin BullsNo ratings yet

- From Wikipedia, The Free Encyclopedia: Internal ExternalDocument15 pagesFrom Wikipedia, The Free Encyclopedia: Internal ExternalShishir DwivediNo ratings yet

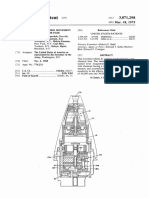

- Us 3871298Document13 pagesUs 3871298Phúc DuyNo ratings yet

- Mokveld Product Sheet Axial Control Valve 1Document2 pagesMokveld Product Sheet Axial Control Valve 1Belos SahajiNo ratings yet

- User Guide C-2500-21e C-2500-25eDocument36 pagesUser Guide C-2500-21e C-2500-25eSergei KurpishNo ratings yet