Professional Documents

Culture Documents

Speed Sensor TASS

Speed Sensor TASS

Uploaded by

Victor YosafatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Speed Sensor TASS

Speed Sensor TASS

Uploaded by

Victor YosafatCopyright:

Available Formats

Continuous Weighing

Speed Sensors

Milltronics TASS

■ Technical data

Mode of operation

Measuring principle Proximity sensor provides pulse

to integrator

Typical application Mobile crusher

Input • Bi-directional wheel rotation

• 25 to 350 rpm

Output • Magnetic proximity sensor

2 • Open collector, NPN, sinking

output, max. 200 mA

• Pulses: 5 per revolution

9.947 pulses/m, 3.03 pulses/ft.

Rated operating conditions

Operating temperature -25 to 70 °C (-13 to 158 °F)

Design

Fig. 2/20 Milltronics TASS Speed Sensor Trailing arm assembly Painted mild steel

■ Application

Wheel 160 mm (6.3”) diameter cast

aluminum with polyurethane tread

The Milltronics TASS speed sensor is a compact, low-profile, Power supply 10 to 35 V DC, 15 mA at 24 V DC

wheel-driven return belt speed sensor. It operates in conjunction maximum

with a conveyor belt scale, providing signals to an integrator Wiring

which computes the rate of material being conveyed. The trailing Brown + excitation (+15 V DC)

arm speed sensor monitors conveyor belt speed, with the output

Black + signal

signal transmitted by cable connection to the integrator.

Blue - common

Easily installed close to the belt scale assembly, the TASS provi-

des a signal generated as the wheel rotates on the return belt. Cable

Pulses are generated by the internal proximity switch detecting Option • 2 m, 3 condutor shielded PVC

the rotation of the five spoked wheel. The TASS is mounted to the cable, 3 x 0.25 mm2 (23 AWG),

static beam of the belt scale or to a structural cross member via protected with 1000 mm of fle-

xible conduit

a pivoting bracket assembly.

• 300 m (1000 ft.) maximum cable

The TASS is a compact, low-profile, rugged speed sensor, most run

often used on mobile crusher applications where space is

Approvals CE

limited. The TASS output can be applied to any Milltronics belt

scale integrator.

■ Benefits

7 Rugged design

7 Easy, low cost installation

7 Compact, low-profile speed sensor

7 IP65 rated

2/28 Siemens WT 02 · 2004

Continuous Weighing

Speed Sensors

Milltronics TASS

■ Dimensional drawings

TASS Mounting Bracket

20 mm 9 mm (0.35”),

158 mm (0.79”) 2 places

(6.22”)

conduit fitting

M16

567 mm

(22.32”) 60 mm

(2.36”)

25 mm

2

48 mm 6 mm (0.24”), (0.89”)

508 mm (1.89”)

(20”) 2 places

534 mm 12 mm (0.48”),

(21.02”) 2 places

66 mm

(2.6”)

53 mm

(2.09”)

160 mm

(6.3”) dia.

50 mm

(1.97”)

40 mm

(1.57”)

40 mm 105 mm

(1.57”) (4.13”)

120 mm

(4.72”)

Fig. 2/21 TASS dimensions

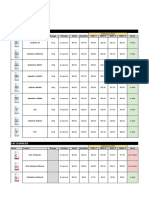

■ Installation Ordering data Order No.

Milltronics TASS Speed Sensor 7 MH 7 1 3 1 -

Note: The TASS can be mounted to Compact, low-profile, wheel driven return belt

7777 0

the belt scale static beam as shown, speed sensor

or to a conveyor cross member or to Model

a non-weighing ilder frame.

5 pulses per revolution 1

Fabrication

Painted mild steel A

Mounting Options

Complete with standard mounting kit A

Approvals

CE 1

Instruction Manual

English A) 7ML1998-5HL01

Note: The instruction manual should be ordered as

a separate item on the order.

Siemens Milltronics belt scale

Spare Parts

TASS TASS Wheel A) 7MH7723-1AN

TASS Proximity Switch A) 7MH7723-1AP

Fig. 2/22 TASS Installation A) Subject to export regulations AL: N, ECCN: EAR99

Siemens WT 02 · 2004 2/29

You might also like

- Siemens Siremobil Compact Error CodesDocument160 pagesSiemens Siremobil Compact Error CodesHabib93% (30)

- AGS-688 ManualDocument60 pagesAGS-688 Manualvatcslav0% (1)

- Power Up Level 2 FlashcardsDocument180 pagesPower Up Level 2 FlashcardsRoberto BekembauerNo ratings yet

- New Sialkot International AirportDocument7 pagesNew Sialkot International Airportm.suleman Khushi100% (1)

- SEatex MRU 5 PDFDocument2 pagesSEatex MRU 5 PDFCindy100% (1)

- DLF Lease DeedDocument19 pagesDLF Lease DeedOkkishoreNo ratings yet

- Mru 9Document2 pagesMru 9Daniel LiuNo ratings yet

- Sensors SpeedhallDocument2 pagesSensors SpeedhallahmadshikemohmadNo ratings yet

- For Position Control Applications: Your Ultimate Solution PartnerDocument40 pagesFor Position Control Applications: Your Ultimate Solution PartnerAbhay AbhyankarNo ratings yet

- Sitransl Probelu240 Fi01 enDocument6 pagesSitransl Probelu240 Fi01 enCristian MenesesNo ratings yet

- Belt WeigherDocument3 pagesBelt Weigherjyothish pillaiNo ratings yet

- Milltronics RBSS Wt10 enDocument3 pagesMilltronics RBSS Wt10 enLARRYNo ratings yet

- Speed Sensors: Belt WeighingDocument3 pagesSpeed Sensors: Belt WeighingLARRYNo ratings yet

- Sensor Linea Type 9195G PDFDocument2 pagesSensor Linea Type 9195G PDFAnonymous lx0DDKNo ratings yet

- Horizontal In-Place MEMS Inclinometer ICB0032HDocument2 pagesHorizontal In-Place MEMS Inclinometer ICB0032HCristian StenbergNo ratings yet

- LVDT Displacement SensorsDocument8 pagesLVDT Displacement SensorslelixNo ratings yet

- Configuration: Continuous Level Measurement Ultrasonic TransmittersDocument7 pagesConfiguration: Continuous Level Measurement Ultrasonic TransmittersVictor Abraham Lim Su KangNo ratings yet

- CHM 300 DTDocument2 pagesCHM 300 DTDaniel AceitunoNo ratings yet

- Flow Measurement: Sitrans F MDocument11 pagesFlow Measurement: Sitrans F MMuja MalikNo ratings yet

- B. Brosur - SUNCENT-X8 Product Brochure S Ver1 0 2021Document5 pagesB. Brosur - SUNCENT-X8 Product Brochure S Ver1 0 2021Muhammad Rizki SetiawanNo ratings yet

- Magnetoresistive Sensor Ics: 2Ss52M SeriesDocument7 pagesMagnetoresistive Sensor Ics: 2Ss52M SeriesGeorgyNo ratings yet

- RSS With Pure Signal Technology - Datasheet - 20220706Document2 pagesRSS With Pure Signal Technology - Datasheet - 20220706Đức MinhNo ratings yet

- Encoders Draw WireDocument36 pagesEncoders Draw WireCharles Claudino SilvaNo ratings yet

- MAG 5100W SensorDocument13 pagesMAG 5100W Sensormuneer ahmedNo ratings yet

- BSTe B405 EN Sensors 2018 Low PDFDocument4 pagesBSTe B405 EN Sensors 2018 Low PDFPapaleguas gamesNo ratings yet

- Inductive Proximity SensorsDocument2 pagesInductive Proximity Sensorsnew2trackNo ratings yet

- Sontek RiversurveyorDocument2 pagesSontek RiversurveyorRodolfo Antonio Poma ValdiviaNo ratings yet

- Air Gap Capacitive Sensor: ApplicationsDocument2 pagesAir Gap Capacitive Sensor: ApplicationsCesar BarrigaNo ratings yet

- Cảm Biến Báo Mức (Rada Báo Mức Liệu Trong Két)Document255 pagesCảm Biến Báo Mức (Rada Báo Mức Liệu Trong Két)Trần Văn PhúcNo ratings yet

- ASC DriveBay BrochureDocument2 pagesASC DriveBay Brochureaudy2010No ratings yet

- AccelometerDocument2 pagesAccelometerShelton RajaNo ratings yet

- RSF EncoderDocument4 pagesRSF EncoderMuhammad Atir SharifNo ratings yet

- Dax Indusensor LDR en UsDocument6 pagesDax Indusensor LDR en Us17juanisanchezNo ratings yet

- Almag Is 150109Document4 pagesAlmag Is 150109alisuseNo ratings yet

- SAFMAG Beta Meter Data SheetDocument3 pagesSAFMAG Beta Meter Data Sheetvalentine misanaNo ratings yet

- RK400-09 Miniature Tipping Bucket Rainfall Sensor: FeaturesDocument2 pagesRK400-09 Miniature Tipping Bucket Rainfall Sensor: FeaturesigreenNo ratings yet

- Series T / TS Series TR / TRS: Short Stroke Transducer Potentiometric 10 MM Up To 150 MMDocument10 pagesSeries T / TS Series TR / TRS: Short Stroke Transducer Potentiometric 10 MM Up To 150 MMatila.cardellaNo ratings yet

- RT3000 DualDocument2 pagesRT3000 DualbaruaeeeNo ratings yet

- MAGFLO SensorDocument14 pagesMAGFLO SensorStenio LanzaNo ratings yet

- SKF Transmitter Module (CMPT Ctu) : FeaturesDocument2 pagesSKF Transmitter Module (CMPT Ctu) : FeaturesOrlando VenturaNo ratings yet

- DoseView1D BR 1369-21Document4 pagesDoseView1D BR 1369-21Quyet PhungNo ratings yet

- Datasheet - Mục III.6 Tuabin Và BOP -67 Cảm Biến Hall Hãng Emerson PR9376 Bổ SungDocument2 pagesDatasheet - Mục III.6 Tuabin Và BOP -67 Cảm Biến Hall Hãng Emerson PR9376 Bổ Sungnamdongvan8143No ratings yet

- MDS 056 Accelerometer Vibration Meter Data SheetDocument5 pagesMDS 056 Accelerometer Vibration Meter Data SheetJoe TempaNo ratings yet

- Rail Titan Modular TIG MIG MAG Welding and Cutting Rail Tractor 22.02Document8 pagesRail Titan Modular TIG MIG MAG Welding and Cutting Rail Tractor 22.02Kashif MohiuddinNo ratings yet

- HRT 3mm Tension MeterDocument2 pagesHRT 3mm Tension MeterMeasurementTechNo ratings yet

- Gyrodata SWDDocument1 pageGyrodata SWDRodolfo CastroNo ratings yet

- Use Function: Operating Instructions Vane Anemometer (1468)Document6 pagesUse Function: Operating Instructions Vane Anemometer (1468)andreNo ratings yet

- Magnet Mount Strain Sensor: Main FeaturesDocument4 pagesMagnet Mount Strain Sensor: Main Featuresmuhammad taufik rahmanNo ratings yet

- Instrumentation: Hydropower and Water Control ApplicationsDocument6 pagesInstrumentation: Hydropower and Water Control Applicationsperkinstop2000No ratings yet

- L-9517-9417-06-B Data Sheet RTLC enDocument9 pagesL-9517-9417-06-B Data Sheet RTLC enShafiqul IslamNo ratings yet

- Catalogo Transductores Novotechnik PDFDocument4 pagesCatalogo Transductores Novotechnik PDFGerEspNo ratings yet

- TLH PDFDocument4 pagesTLH PDFhassanchaarNo ratings yet

- CMC mvm001 Vibration Sensor Ds Rev A00Document2 pagesCMC mvm001 Vibration Sensor Ds Rev A00bianhuiNo ratings yet

- M 300 C Specification BrochureDocument3 pagesM 300 C Specification BrochureSouidiNo ratings yet

- Mako User Manual - RevaDocument33 pagesMako User Manual - Revabaggo81No ratings yet

- Otkii 0950 TdsDocument2 pagesOtkii 0950 TdszaideidNo ratings yet

- Leaflet MTiDocument4 pagesLeaflet MTiAlexNo ratings yet

- Smart Sensor SS510Document2 pagesSmart Sensor SS510MarcinNo ratings yet

- WT901BLECL DataSheetDocument21 pagesWT901BLECL DataSheetsenchiNo ratings yet

- Flow Meter DatasheetDocument13 pagesFlow Meter DatasheetDidik HariantoNo ratings yet

- D400-10 (Meters & Accessories 49093) PDFDocument52 pagesD400-10 (Meters & Accessories 49093) PDFLazzarus Az GunawanNo ratings yet

- Familyoverview HighLine g287466 enDocument12 pagesFamilyoverview HighLine g287466 enTim JohnsonNo ratings yet

- Digital Linear Scale: Series LS 177 and LS 187Document5 pagesDigital Linear Scale: Series LS 177 and LS 187Nguyen Khac NamNo ratings yet

- MRU-5 Motion Reference UnitDocument2 pagesMRU-5 Motion Reference UnitAdi VNo ratings yet

- Pid TS101Document30 pagesPid TS101Victor YosafatNo ratings yet

- Varispeed g7Document499 pagesVarispeed g7Victor YosafatNo ratings yet

- Communication Profibus-Fms: Automation and DrivesDocument1 pageCommunication Profibus-Fms: Automation and DrivesVictor YosafatNo ratings yet

- Sending Emails Over Secure Email Connections With S7-1500 and S7-1200Document1 pageSending Emails Over Secure Email Connections With S7-1500 and S7-1200Victor YosafatNo ratings yet

- GRAPH BackDocument1 pageGRAPH BackVictor YosafatNo ratings yet

- Chonche ThouetDocument1 pageChonche ThouetVictor YosafatNo ratings yet

- S7komp BDocument29 pagesS7komp BVictor YosafatNo ratings yet

- Junction Box 1Document2 pagesJunction Box 1Victor YosafatNo ratings yet

- Siemens: Communication Simatic S5 Profibus (KO-KS5L2)Document1 pageSiemens: Communication Simatic S5 Profibus (KO-KS5L2)Victor YosafatNo ratings yet

- Simatic Wincc V6.2 Wincc Version SoftwareDocument2 pagesSimatic Wincc V6.2 Wincc Version SoftwareVictor YosafatNo ratings yet

- Data Sheet 6ES7718-1CC00-0AC0: General InformationDocument4 pagesData Sheet 6ES7718-1CC00-0AC0: General InformationVictor YosafatNo ratings yet

- Data Sheet 6AV7260-0DA20-0BX6: General InformationDocument4 pagesData Sheet 6AV7260-0DA20-0BX6: General InformationVictor YosafatNo ratings yet

- Winac KK Doku v10 e PDFDocument36 pagesWinac KK Doku v10 e PDFVictor YosafatNo ratings yet

- RA Faceplate Builder v1.1Document12 pagesRA Faceplate Builder v1.1Victor YosafatNo ratings yet

- RA Recipe Manager v1.1Document16 pagesRA Recipe Manager v1.1Victor YosafatNo ratings yet

- Tool Life When High Speed Ball Nose End Milling Inconel 718: Adrian Sharman, Richard C. Dewes, David K. AspinwallDocument7 pagesTool Life When High Speed Ball Nose End Milling Inconel 718: Adrian Sharman, Richard C. Dewes, David K. AspinwallKin HamzahNo ratings yet

- Fess 102Document13 pagesFess 102Shivani YadavNo ratings yet

- ZoneID and PoreHD ServiceDocument1 pageZoneID and PoreHD ServicedownbuliaoNo ratings yet

- The Semiotics of Aroko in Yoruba TraditionDocument26 pagesThe Semiotics of Aroko in Yoruba TraditionBolarinwa MowemiNo ratings yet

- Quanta G31a Dag31amb6d0 Y61x-6l Rev 1aDocument49 pagesQuanta G31a Dag31amb6d0 Y61x-6l Rev 1aKrystian PalaciosNo ratings yet

- SP Bti CP658 V2.2Document4 pagesSP Bti CP658 V2.2Ry GiNo ratings yet

- Keratin TreatmentDocument2 pagesKeratin TreatmentDilinika PriyadarshaniNo ratings yet

- Class Notes, Trajectory Planning, COMS4733: 1 TrajectoriesDocument11 pagesClass Notes, Trajectory Planning, COMS4733: 1 TrajectoriesAustin Tyson DsouzaNo ratings yet

- Apply Good Dispensing Principles - NEW-1Document49 pagesApply Good Dispensing Principles - NEW-1abelashe2No ratings yet

- LAB14Document5 pagesLAB14Aizaz HabibNo ratings yet

- GP MCQ 6Document4 pagesGP MCQ 6Marta MoreiraNo ratings yet

- (DPR1000) Modbus Map Tech Data en 201909Document2 pages(DPR1000) Modbus Map Tech Data en 201909Duẩn Nguyễn VănNo ratings yet

- Method 1: IB Questionbank Mathematics Higher Level 3rd Edition 1Document8 pagesMethod 1: IB Questionbank Mathematics Higher Level 3rd Edition 1Muhamad Zahwan AnwarNo ratings yet

- Lesson Plan 2 WeeblyDocument5 pagesLesson Plan 2 Weeblyapi-176731501No ratings yet

- Full Download Advanced Accounting Hoyle 10th Edition Solutions Manual PDF Full ChapterDocument36 pagesFull Download Advanced Accounting Hoyle 10th Edition Solutions Manual PDF Full Chapterbeatencadiemha94100% (13)

- Concept FormationDocument8 pagesConcept FormationSehaj BediNo ratings yet

- Kakuban - The Esoteric Meaning of Amida 2Document4 pagesKakuban - The Esoteric Meaning of Amida 2Rhys SchauwekerNo ratings yet

- Types of PelvisDocument23 pagesTypes of PelvisChinju Jose SajithNo ratings yet

- Biaxol Price List 2023Document3 pagesBiaxol Price List 2023CodeNo ratings yet

- Analysis of Diaphragm WallDocument6 pagesAnalysis of Diaphragm WallSanthosh BabuNo ratings yet

- Wolverton Chapter 25 Photodynamic TherapyDocument9 pagesWolverton Chapter 25 Photodynamic TherapyNahas NazarNo ratings yet

- Foundation Settlements: Settlement of Shallow Foundation in Cohesive SoilDocument16 pagesFoundation Settlements: Settlement of Shallow Foundation in Cohesive SoilBashdar M. TahirNo ratings yet

- Federal Register / Vol. 88, No. 81 / Thursday, April 27, 2023 / Proposed RulesDocument236 pagesFederal Register / Vol. 88, No. 81 / Thursday, April 27, 2023 / Proposed RulesSimon AlvarezNo ratings yet

- Atlox™ 4913 Graft Comb' Copolymer - Dispersant For Aqueous Suspension Concentrates - PDF - Emulsion - Suspension (Chemistry)Document2 pagesAtlox™ 4913 Graft Comb' Copolymer - Dispersant For Aqueous Suspension Concentrates - PDF - Emulsion - Suspension (Chemistry)Alfredo MéndezNo ratings yet

- CB 3Document3 pagesCB 3badisa booksNo ratings yet