Professional Documents

Culture Documents

Ayvaz CV11 Disco Cekvalf ENG

Ayvaz CV11 Disco Cekvalf ENG

Uploaded by

Mouayed ZeadanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ayvaz CV11 Disco Cekvalf ENG

Ayvaz CV11 Disco Cekvalf ENG

Uploaded by

Mouayed ZeadanCopyright:

Available Formats

CV11

CHECK VALVES

GENERAL FEATURES

Check valves are commonly used

armatures that can be applied for

liquid, gaseous and steam applications. Typical Applications

They increase the process safety and Heating, airconditioning pipe lines Technical Specifications

can be used instead of complicated Wood-working, pulp and paper industry Max. Working 16 bar

armatures. Because of short installation Iron and steel industry, mining industry Pressure

time and installation distance, small Mineral-oil industry Max. Working 250ºC

dimensions; Ayvaz disco check valve Textile industry Temperature

appears to be advantageous. Ship building

Water,condensate and steam lines Diameters

Check valves provide the flows just

one way. When liquid flows through to DN (mm) inch

flowing direction, check valves open 125-200 5" - 10"

and let it pass. But liquid tries to flow

opposite direction of flowing, check

valves close and prevent passing.

CONNECTIONS

Connection: CV 11 Between Flanges/ BS 10 tables D,E,F DIN 2501 (PN/6/10/16)

Wafer type Wafer Tip ANSI B 16.1 class 125 FF

Installation: WORKING CONDITIONS

Installation can be done every position. Nominal Pressure (PN) 16

Min. Temperature (°C) -10

Max. Working Pressure (bar) 16-13-13

06.2018 Temp. related to Pressure(°C) 120-200-300

CV11 CHECK VALVES

Pressure Graph

The curves given in the chart are valid for water at 20°C.

To read the pressure drop for other fluids the equivalent water

volume flow rate must be calculated and used in the graph.

The values indicated in the chart are applicable to spring-loaded

valves with horizontal flow.

4 5 6

2018 - Non contractual document - Reproduction forbidden without prior authorization

Volume Flow

1

L

Pressure Drop

2 3

6

SPARE PARTS CV 11

1 Body GG-25 Cast Iron

2 Disc GG-25 Cast Iron 5

3 Spring Stainless Steel

4 Centering Part Stainless Steel

5 Segment Holder Cast Iron

6 Segment Stainless Steel 4

Dimensions 3

Dia. mm 125 150 200 250

D ( mm ) 183 210 264 328

L ( mm ) 90 106 142 200 2

OPENING PRESSURE MBAR

Flow Direction

Without Spring

DN Spring

125 10,5 31 20,5 10

150 11,5 33 21,5 10

1

200 11,2 32,4 21.2 10

HEAD OFFICE - FACTORY

Atatürk Sanayi Bölgesi Hadımköy Mahallesi Mustafa İnan Caddesi No: 44 Arnavutköy - İSTANBUL

Tel: +90 212 771 01 45 (pbx) | Fax: +90 212 771 47 27

info@ayvaz.com | www.ayvaz.com

Cona Ayvaz Germany Ayvaz Ukraine Tricorr Ayvaz Azerbaijan Ayvaz Egypt

Caserta/Italy Viernheim/Germany Kiev/Ukraine Warsaw/Poland Baku/Azerbaijan Cairo/Egypt

Tel: +39 0823 187 3988 Tel: +49 62046014399 Tel: +380 44 390 57 57 Tel: +48 530 030 810 Tel: +99 (455) 579-84-32 Tel: +20 122 819 78 29

rmolaro@ayvaz.com germany@ayvaz.com info@ayvaz.com.ua +48 533 603 335 ahayatov@ayvaz.com andrew.eid@ayvaz.com

tricorr@tricorr.eu

Ayvaz Gulf Ayvaz China Ayvaz Kazakhstan LLP Ayvaz N Ayvaz Serbia Ayvaz Vietnam Ayvaz Americas

Dubai/U.A.E Ningbo/China Almaty/Kazakhstan Isperih/Bulgaria Belgrade/Serbia HCMC/Vietnam Rhode Island/USA

Tel: +971 563550822 Tel: +86 152 5830 7361 Tel: +7 (727) 327 97 57 Tel: +359 8431 27 32 Tel: +381 61 658 70 52 ggursoy@ayvaz.com Tel: +1 401 737 8380

+971 501306871 msahin@ayvaz.com info_kz@ayvaz.com office@ayvaz-n.eu yakbiyik@ayvaz.com Tel: +84 89 8508345 americas@ayvaz.com

mideast@ayvaz.com

You might also like

- Icru Report 74Document113 pagesIcru Report 74Lida Velasquez Sierra50% (2)

- Habor enDocument28 pagesHabor enEmerson TerrelNo ratings yet

- Reductor Presiune Abur RP45 DN15-100Document2 pagesReductor Presiune Abur RP45 DN15-100vvlad34No ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsRonaldNo ratings yet

- Lead Free Valves: Catalogue2018Document11 pagesLead Free Valves: Catalogue2018Ratheesh KumarNo ratings yet

- CV20-25 Double Plate CheckvalveDocument5 pagesCV20-25 Double Plate CheckvalveVlad AncutaNo ratings yet

- FAMAT Cold Reheat Check Valves 2013 PDFDocument11 pagesFAMAT Cold Reheat Check Valves 2013 PDFAMITNo ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & Benefitsimtz2013No ratings yet

- Cmo Serie AbDocument20 pagesCmo Serie AbrafinhaleocadioNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparineNo ratings yet

- The F637 Is A Medium Duty Slurry Control Valve, Short Body Style With Replaceable Body SleeveDocument4 pagesThe F637 Is A Medium Duty Slurry Control Valve, Short Body Style With Replaceable Body SleeveCapacitacion TodocatNo ratings yet

- ADCAPure S-10H Clean Steam SeparatorDocument2 pagesADCAPure S-10H Clean Steam SeparatorBk VinNo ratings yet

- NPT Sop Pde 004 f06 Bom Ball ValveDocument40 pagesNPT Sop Pde 004 f06 Bom Ball ValveMohamed SelimNo ratings yet

- CVC Steel FullDocument28 pagesCVC Steel FullSergio Bacca SantiagoNo ratings yet

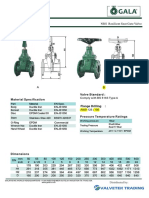

- Gala ValveDocument2 pagesGala ValveThomas JohnNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- NPT Sop Pde 004 f08 Bom Globe ValveDocument18 pagesNPT Sop Pde 004 f08 Bom Globe ValveMohamed SelimNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Macam Macam ValveDocument6 pagesMacam Macam ValveAhmadufiNo ratings yet

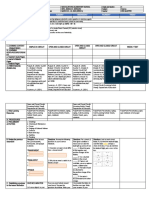

- NPT Sop Pde 004 f13 Bom Check ValveDocument18 pagesNPT Sop Pde 004 f13 Bom Check ValveMohamed SelimNo ratings yet

- Free Float Steam Trap: Model Stainless SteelDocument2 pagesFree Float Steam Trap: Model Stainless SteelJustin GentryNo ratings yet

- 447 - en - CAAV - DAAV (CAAV0620S)Document1 page447 - en - CAAV - DAAV (CAAV0620S)Mohammed NiqrisNo ratings yet

- FT - #1214 - Clapet Antiretour SIMILAIREDocument2 pagesFT - #1214 - Clapet Antiretour SIMILAIREHAMZANo ratings yet

- VU30Document2 pagesVU30ashay15No ratings yet

- AFA Rubber Exp Sing-99SFDocument2 pagesAFA Rubber Exp Sing-99SFamer albarikiNo ratings yet

- DW12G SSDocument1 pageDW12G SSQuyết Bạch ĐìnhNo ratings yet

- Jis 10k Flanged End Cast Iron Gate Valve - 5inch To 6inchDocument4 pagesJis 10k Flanged End Cast Iron Gate Valve - 5inch To 6inchctrijayaperkasaNo ratings yet

- Osy 300fDocument4 pagesOsy 300fmaxgomotorNo ratings yet

- Fig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFDocument1 pageFig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFmarchus09No ratings yet

- Small Size Valves CatalogDocument5 pagesSmall Size Valves Cataloguli hasibuanNo ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- 3 80 e pv25g Pneumatic On Off Valves dn15 100Document4 pages3 80 e pv25g Pneumatic On Off Valves dn15 100Layton DfcNo ratings yet

- Series 7600 Triple Offset Butterfly ValveDocument13 pagesSeries 7600 Triple Offset Butterfly ValveAmro AmerNo ratings yet

- FC Sub Gav15 v01Document2 pagesFC Sub Gav15 v01Eliel AbadNo ratings yet

- ST Sub Figst1Document1 pageST Sub Figst1Logistica 1No ratings yet

- Ghibson GB015Document2 pagesGhibson GB015Jessicalba LouNo ratings yet

- Ball ValveDocument7 pagesBall ValveaerudzikriNo ratings yet

- Europa Check and Foot Valves: Technical CatalogueDocument16 pagesEuropa Check and Foot Valves: Technical CatalogueDomagoj ButumovićNo ratings yet

- Crane Butterfly ValvesDocument1 pageCrane Butterfly ValvesstephenlongislandNo ratings yet

- Bellows Sealed DN20Document3 pagesBellows Sealed DN20Turbo Snail RNo ratings yet

- Pentair VM FIG GRW y GRL - MTJE KEYSTONE PDFDocument8 pagesPentair VM FIG GRW y GRL - MTJE KEYSTONE PDFFlavio Garcia ValenteNo ratings yet

- Specification - 9110 - 201510 at Globe (Rev.03)Document10 pagesSpecification - 9110 - 201510 at Globe (Rev.03)Công PhạmNo ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- Dm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Document1 pageDm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Hasan V SNo ratings yet

- KZ 2017 Bro Ka 2001XDocument1 pageKZ 2017 Bro Ka 2001XmarusahaNo ratings yet

- SFDEJDocument1 pageSFDEJkevin.larocquepbNo ratings yet

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- Forged Gate, Globe & Check ValvesDocument4 pagesForged Gate, Globe & Check ValvesRavi KantNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- 11.8a Ghibson GB015Document2 pages11.8a Ghibson GB015Shah Rizal AbidNo ratings yet

- VAL Team: Non-Return Valve RT25Document2 pagesVAL Team: Non-Return Valve RT25Octavio DavidNo ratings yet

- 2.3.02-L 2-Way Control Valves Type M1F Cast Iron, PN 16, DN 15/4 - 50 MMDocument2 pages2.3.02-L 2-Way Control Valves Type M1F Cast Iron, PN 16, DN 15/4 - 50 MMHusna FarihahNo ratings yet

- BV502Document3 pagesBV502plvillarrealNo ratings yet

- Van C NG OS & Y GATE VALVE KVS-4150Document1 pageVan C NG OS & Y GATE VALVE KVS-4150Nguyễn Kỳ TúNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- Butterfly Valve GRWDocument8 pagesButterfly Valve GRWilkinNo ratings yet

- VU50Document2 pagesVU50ashay15No ratings yet

- Belimo Control ValveDocument106 pagesBelimo Control ValveAnderson SiqueiraNo ratings yet

- Technical Bid For Construction of Under Ground Water Tanks at Boys HostelDocument36 pagesTechnical Bid For Construction of Under Ground Water Tanks at Boys HostelMouayed ZeadanNo ratings yet

- RFP 20-006 Equipment Installtion For Marine Repower Project FINAL1 PDFDocument52 pagesRFP 20-006 Equipment Installtion For Marine Repower Project FINAL1 PDFMouayed ZeadanNo ratings yet

- Request For Proposals Dual Media Pressure Vessels FEBRUARY 14, 2020Document44 pagesRequest For Proposals Dual Media Pressure Vessels FEBRUARY 14, 2020Mouayed ZeadanNo ratings yet

- Inspection & Test Plan For Earthworks Excavation and Backfill For Underground FacilitiesDocument7 pagesInspection & Test Plan For Earthworks Excavation and Backfill For Underground FacilitiesMouayed ZeadanNo ratings yet

- Appendix 2 - Technical SpecificationsDocument32 pagesAppendix 2 - Technical SpecificationsMouayed ZeadanNo ratings yet

- Environmental Measurement SolutionsDocument4 pagesEnvironmental Measurement SolutionsMouayed ZeadanNo ratings yet

- Spectrum Sensor PL Series Real Tech Inc.Document3 pagesSpectrum Sensor PL Series Real Tech Inc.Mouayed ZeadanNo ratings yet

- Documentation & Maintenance: Princípy Tvorby Softvéru, FMFI UK Jana Kostičová, 16.5.2016Document26 pagesDocumentation & Maintenance: Princípy Tvorby Softvéru, FMFI UK Jana Kostičová, 16.5.2016Mouayed ZeadanNo ratings yet

- Process Analyzer: No Flow Point Analyzer Model P-840/P-840LTDocument5 pagesProcess Analyzer: No Flow Point Analyzer Model P-840/P-840LTMouayed ZeadanNo ratings yet

- MEX Scheduler ReportDocument31 pagesMEX Scheduler ReportMouayed ZeadanNo ratings yet

- Maintenance Management Plan: Name of Project Contract #XXXXXDocument31 pagesMaintenance Management Plan: Name of Project Contract #XXXXXMouayed ZeadanNo ratings yet

- Dow Water Management in Oil and Gas LenntechDocument12 pagesDow Water Management in Oil and Gas LenntechMouayed ZeadanNo ratings yet

- LT - Leaflet - Oil & Gas - Rev02Document6 pagesLT - Leaflet - Oil & Gas - Rev02Mouayed ZeadanNo ratings yet

- WeeklyDocument4 pagesWeeklyMouayed ZeadanNo ratings yet

- Y-Strainers - LenntechDocument2 pagesY-Strainers - LenntechMouayed ZeadanNo ratings yet

- Specification Section 07810 Interior Cementitious Spray - Applied FireproofingDocument10 pagesSpecification Section 07810 Interior Cementitious Spray - Applied FireproofingMouayed ZeadanNo ratings yet

- Preservation & ConservationDocument3 pagesPreservation & ConservationMouayed ZeadanNo ratings yet

- International Maintenance StandardsDocument13 pagesInternational Maintenance StandardsMouayed ZeadanNo ratings yet

- ITP For Cable Pulling, Termination, Jointing and ConduitDocument2 pagesITP For Cable Pulling, Termination, Jointing and ConduitMouayed Zeadan100% (1)

- GEA Post Treatment Test ReportDocument38 pagesGEA Post Treatment Test ReportMouayed ZeadanNo ratings yet

- S L M P I D S P /R /S: Ample Ighting Anagement Lan For Nternational ARK KY Arks Eserves AnctuariesDocument5 pagesS L M P I D S P /R /S: Ample Ighting Anagement Lan For Nternational ARK KY Arks Eserves AnctuariesMouayed ZeadanNo ratings yet

- GEA Post Treatment Test PlanDocument28 pagesGEA Post Treatment Test PlanMouayed ZeadanNo ratings yet

- II-D Append. 3 Ext - Press. BasisDocument6 pagesII-D Append. 3 Ext - Press. BasisMuhammed Abo-FandoodNo ratings yet

- Daily Lesson Log: Monday Tuesday Wednesday Thursday FridayDocument8 pagesDaily Lesson Log: Monday Tuesday Wednesday Thursday FridayMaicah Alcantara MarquezNo ratings yet

- Preboards Exam Part III Answer Key 1Document11 pagesPreboards Exam Part III Answer Key 1Peter ian AutenticoNo ratings yet

- Cold Startup Procedure 250 MWDocument7 pagesCold Startup Procedure 250 MWPrudhvi RajNo ratings yet

- X52 L360xx Engl PDFDocument3 pagesX52 L360xx Engl PDFmuhamad yakubNo ratings yet

- Application of The K J and CTOD Param PDFDocument8 pagesApplication of The K J and CTOD Param PDFchandruNo ratings yet

- Stainless Steels and Alloys - Why They Resist Corrosion and How They FailDocument15 pagesStainless Steels and Alloys - Why They Resist Corrosion and How They FailMarcos LeiteNo ratings yet

- Fluid 9ed Solution Manual PDFDocument919 pagesFluid 9ed Solution Manual PDFDermz GayosoNo ratings yet

- Glycol ProblemsDocument4 pagesGlycol Problemsblinx4realNo ratings yet

- Astronomy - Measuring Sunlight at Earth's Surface - Build Your Own Pyranometer - Brooks - 2007Document18 pagesAstronomy - Measuring Sunlight at Earth's Surface - Build Your Own Pyranometer - Brooks - 2007오상진No ratings yet

- Paper Imp Twinning Aluminum MD PDFDocument16 pagesPaper Imp Twinning Aluminum MD PDFNitai GAURANGANo ratings yet

- 4 Catalog LeyboldDocument15 pages4 Catalog LeyboldAnshul JainNo ratings yet

- KOREA2 - Dielectric Response of Mineral Oil Impregnated Pressboard and Transformers Papers5 - Summary - EditDocument1 pageKOREA2 - Dielectric Response of Mineral Oil Impregnated Pressboard and Transformers Papers5 - Summary - EditFari PratomosiwiNo ratings yet

- Topsizer Product InformationDocument8 pagesTopsizer Product InformationJavier Hortencio Gonzales SamaméNo ratings yet

- Darkov, Kuznetsov - Structural Mechanics - MirpdfDocument710 pagesDarkov, Kuznetsov - Structural Mechanics - MirpdfIsidro Gutierrez Pari100% (1)

- Presentation On Condensers and EvaporatorsDocument32 pagesPresentation On Condensers and Evaporatorsvipul sharma100% (1)

- Finite Element Methods-FEMDocument2 pagesFinite Element Methods-FEMSuthari AmbikaNo ratings yet

- CH 14 ThermodynamicsDocument46 pagesCH 14 ThermodynamicsHarshad MehtaNo ratings yet

- PZTDocument6 pagesPZTsmjjazzab_288706263No ratings yet

- Interaction CurveDocument126 pagesInteraction CurveNikhilNo ratings yet

- Melting Point and Boiling PointDocument14 pagesMelting Point and Boiling PointMALOU ELEVERANo ratings yet

- Progressive GR 9 2nd Q CDocument21 pagesProgressive GR 9 2nd Q CRAMIL BAUTISTANo ratings yet

- Understanding Seismic AmplitudesDocument9 pagesUnderstanding Seismic Amplitudesbidyut_iitkgpNo ratings yet

- Rr411801 Electrometallurgy and CorrosionDocument7 pagesRr411801 Electrometallurgy and CorrosionSrinivasa Rao GNo ratings yet

- ACI 435.5R-73 R1989 Deflections of Continuous Concrete BeamsDocument7 pagesACI 435.5R-73 R1989 Deflections of Continuous Concrete BeamsMohamed alhaj EmadNo ratings yet

- Scaling of MOSFETs and Short Channel EffectsDocument35 pagesScaling of MOSFETs and Short Channel EffectsAnonymous zn5X2z0% (1)

- In A Nutshell Problem Set: Measurement of Horizontal DistanceDocument6 pagesIn A Nutshell Problem Set: Measurement of Horizontal DistanceVinloyd YbanezNo ratings yet

- Introduction To Compressed Air SystemDocument23 pagesIntroduction To Compressed Air SystemMohd Zulhairi Mohd NoorNo ratings yet