Professional Documents

Culture Documents

Experimental and Thermodynamic Investigation of The Ni-Al-Mo System

Experimental and Thermodynamic Investigation of The Ni-Al-Mo System

Uploaded by

api-3804910Copyright:

Available Formats

You might also like

- Solvent Extraction Lab ReportDocument11 pagesSolvent Extraction Lab ReportFaiz Farhan80% (5)

- Tube To Tube SheetDocument59 pagesTube To Tube Sheet0101100175% (12)

- J.C. Zhao, V. Ravikumar, A.M. Beltran, Met. Trans. A. Phase Precipitation and Phase Stability in Nimonic 263Document2 pagesJ.C. Zhao, V. Ravikumar, A.M. Beltran, Met. Trans. A. Phase Precipitation and Phase Stability in Nimonic 263Henry León HenaoNo ratings yet

- Experimental Study and Thermodynamic Assessment of The Ni-Mo-Ta Ternary SystemDocument10 pagesExperimental Study and Thermodynamic Assessment of The Ni-Mo-Ta Ternary Systemapi-3804910No ratings yet

- Efectul AluminiuluiDocument15 pagesEfectul AluminiuluiGhermeniNo ratings yet

- ZnO MNDocument8 pagesZnO MNmohapatra.manojNo ratings yet

- Nanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsDocument5 pagesNanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsMohamed KhalifaNo ratings yet

- Aluminetos de TitânioDocument7 pagesAluminetos de TitânioMarcionilo NeriNo ratings yet

- 2015-TransNonferrousMetSocChina-Formation Mechanism of Ni-Al Intermetallics During Heat Treatment of Ni Coating On Al SusbtrateDocument8 pages2015-TransNonferrousMetSocChina-Formation Mechanism of Ni-Al Intermetallics During Heat Treatment of Ni Coating On Al SusbtrateSIVAJI TADISETTYNo ratings yet

- Kleppa 1951Document3 pagesKleppa 1951Fred Duarte CaldeiraNo ratings yet

- Optics and Laser Technology: Full Length ArticleDocument9 pagesOptics and Laser Technology: Full Length Articlesrinathgudur11No ratings yet

- Magnetic Properties of Iron-Oxide and (Iron, Cobalt) - Oxide Nanoparticles Synthesized in Polystyrene Resin MatrixDocument3 pagesMagnetic Properties of Iron-Oxide and (Iron, Cobalt) - Oxide Nanoparticles Synthesized in Polystyrene Resin MatrixPpa Gpat AmitNo ratings yet

- The Development of Highly Magnetostrictive Rare Earth-Iron AlloysDocument12 pagesThe Development of Highly Magnetostrictive Rare Earth-Iron AlloysYASHANSHU DIXITNo ratings yet

- FKNJNDocument6 pagesFKNJNIlham Mahrojan SulaimanNo ratings yet

- Mehra J 2015Document9 pagesMehra J 2015hussanmuhammadNo ratings yet

- Thermodynamic Calculation of The In-Sn-Zn Ternary SystemDocument8 pagesThermodynamic Calculation of The In-Sn-Zn Ternary Systemapi-3804910No ratings yet

- A Three Dimensional Finite Element Analysis of The Temperature Field During Laser Melting of Metal Powders in Additive Layer ManufacturingDocument8 pagesA Three Dimensional Finite Element Analysis of The Temperature Field During Laser Melting of Metal Powders in Additive Layer Manufacturingsahilnagula0504No ratings yet

- Thermodynamic Reassessment of Au-Ni-Sn Ternary System: Calphad December 2013Document11 pagesThermodynamic Reassessment of Au-Ni-Sn Ternary System: Calphad December 2013Pei-YuChenNo ratings yet

- 2004wu - JMMM - A Study On The Role of NB in Melt-Spun NanocrystallineDocument9 pages2004wu - JMMM - A Study On The Role of NB in Melt-Spun NanocrystallinePatrícia CanazartNo ratings yet

- MTIPROFEDocument9 pagesMTIPROFEMar Cerda SilvaNo ratings yet

- The Microstructure and PrecipitationDocument4 pagesThe Microstructure and PrecipitationDACAMOGO DCMGNo ratings yet

- Shi 1999Document6 pagesShi 1999Tatiane NascimentoNo ratings yet

- Fe-Nb-Ni (Iron-Niobium-Nickel) : Binary SystemsDocument4 pagesFe-Nb-Ni (Iron-Niobium-Nickel) : Binary Systemsabdul basitNo ratings yet

- Tensile Behaviour of As Deposited and Heat-Treated Electroless Ni-P DepositsDocument14 pagesTensile Behaviour of As Deposited and Heat-Treated Electroless Ni-P DepositslinNo ratings yet

- TMP 37 E9Document9 pagesTMP 37 E9FrontiersNo ratings yet

- 49 6 BeronskaDocument10 pages49 6 BeronskasaifbenNo ratings yet

- Mno2 Apl 1Document3 pagesMno2 Apl 1CHEMISTRYNo ratings yet

- Large Negative Thermal Expansion in The Cubic Phase of Camn ODocument6 pagesLarge Negative Thermal Expansion in The Cubic Phase of Camn OKamini GautamNo ratings yet

- Low-Density, Refractory Multi-Principal Element AlloysDocument13 pagesLow-Density, Refractory Multi-Principal Element AlloysMauricio RosasNo ratings yet

- ZnSwire-ribbon-JPCBDocument6 pagesZnSwire-ribbon-JPCBKrishnendu metiaNo ratings yet

- Generation of Copper, Nickel, and Cuni Alloy Nanoparticles by Spark DischargeDocument9 pagesGeneration of Copper, Nickel, and Cuni Alloy Nanoparticles by Spark DischargeThanh DinhNo ratings yet

- The Influence of Cooling Rate On The Microstructure and Phase Fraction of Gas Atomized NiAl3 Alloy Powders During Rapid SolidificationDocument7 pagesThe Influence of Cooling Rate On The Microstructure and Phase Fraction of Gas Atomized NiAl3 Alloy Powders During Rapid SolidificationJotaNo ratings yet

- Role of Sintering Temperature On The Phase Stability and Electrical Properties of 0.94 (K Na Nbo) - 0.06 (Lisbo) CeramicsDocument5 pagesRole of Sintering Temperature On The Phase Stability and Electrical Properties of 0.94 (K Na Nbo) - 0.06 (Lisbo) CeramicsprakashpaleiNo ratings yet

- Molecular Dynamic Study For Ultrathin Ni Fe Alloy: 3 M. D. Starostenkov M. M. AishDocument7 pagesMolecular Dynamic Study For Ultrathin Ni Fe Alloy: 3 M. D. Starostenkov M. M. AishIbrahim HasanNo ratings yet

- Temperature Changes of Copper Nanoparticle in 2014 Journal of Materials ProcDocument9 pagesTemperature Changes of Copper Nanoparticle in 2014 Journal of Materials ProcEdipo SantosNo ratings yet

- Thermal Conductivity of Zinc Oxide Micro - and NanoDocument4 pagesThermal Conductivity of Zinc Oxide Micro - and NanoMiki MikicNo ratings yet

- Thermo-Mechanical Analysis of Carbon Nanotube Based Functionally Graded Timoshenko BeamDocument44 pagesThermo-Mechanical Analysis of Carbon Nanotube Based Functionally Graded Timoshenko BeamajayNo ratings yet

- Mechanocaloric Materials For Solid-State Cooling 2015Document8 pagesMechanocaloric Materials For Solid-State Cooling 2015Jose MatutesNo ratings yet

- Articulo AlnicoDocument5 pagesArticulo Alnicojose baenaNo ratings yet

- Haruyama Etal 1993 SolarHeating OrtDocument12 pagesHaruyama Etal 1993 SolarHeating OrtLuciano del ValleNo ratings yet

- Materials Science & Engineering A: F. Mokdad, D.L. Chen, Z.Y. Liu, D.R. Ni, B.L. Xiao, Z.Y. MaDocument10 pagesMaterials Science & Engineering A: F. Mokdad, D.L. Chen, Z.Y. Liu, D.R. Ni, B.L. Xiao, Z.Y. Maפּואַ פּוגאַNo ratings yet

- Structural Transformation of Moo Nanobelts Into Mos NanotubesDocument7 pagesStructural Transformation of Moo Nanobelts Into Mos NanotubesSHUO SUNNo ratings yet

- Roy 2020Document7 pagesRoy 2020Agen KolarNo ratings yet

- Mössbauer Study On Martensite Phase in Ni 50 MN 36.5 Fe 0.5 57 SN 13 Metamagnetic Shape Memory AlloyDocument4 pagesMössbauer Study On Martensite Phase in Ni 50 MN 36.5 Fe 0.5 57 SN 13 Metamagnetic Shape Memory AlloyRicardo AlvesNo ratings yet

- Formation Structure and Magnetic Properties of PolDocument10 pagesFormation Structure and Magnetic Properties of Pol087Ervan PratamaNo ratings yet

- Article CIS 2021 21 pp.43-46Document4 pagesArticle CIS 2021 21 pp.43-46Maroš BobulaNo ratings yet

- Fe Ni Ti Alloy SystemsDocument14 pagesFe Ni Ti Alloy Systemssajjad moattarNo ratings yet

- 1.AirOxidationofFeCoNi BaseEqui MolarAlloysDocument24 pages1.AirOxidationofFeCoNi BaseEqui MolarAlloysWL JangNo ratings yet

- Hydrogen Storage in Solar Produced Single-Walled Carbon NanotubesDocument6 pagesHydrogen Storage in Solar Produced Single-Walled Carbon NanotubesMohammad Javad TavakkoliNo ratings yet

- Study of Ferromagnetic and Ferroelectric Properties of Nanocrystalline Bi MN ODocument11 pagesStudy of Ferromagnetic and Ferroelectric Properties of Nanocrystalline Bi MN ODeym GómezNo ratings yet

- Journal of The American Ceramic Society - November 1960 - LEE - Radiation Energy Transfer and Thermal Conductivity ofDocument14 pagesJournal of The American Ceramic Society - November 1960 - LEE - Radiation Energy Transfer and Thermal Conductivity ofamannigam19940914No ratings yet

- 1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 ParticlesDocument6 pages1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 Particlesyaswanth1992No ratings yet

- Biswas2011 Article Thermo-mechanicalAndExperimentDocument9 pagesBiswas2011 Article Thermo-mechanicalAndExperimentPardeepNo ratings yet

- Phase Diagram PMN PZ PTDocument6 pagesPhase Diagram PMN PZ PTAnaghaNo ratings yet

- Nickel and Iron Nano-Particles in Natural Rubber CompositesDocument6 pagesNickel and Iron Nano-Particles in Natural Rubber Compositeshoneywell123No ratings yet

- Kim2017 ODGREVANJEDocument23 pagesKim2017 ODGREVANJEAMS Lab.No ratings yet

- 10.1515 - MSP 2016 0027Document8 pages10.1515 - MSP 2016 0027G.L.R StudiosNo ratings yet

- Nickel Base Reformer TubesDocument8 pagesNickel Base Reformer TubesOwais MalikNo ratings yet

- Comparison of Experimental and Modelling Results of Thermal Properties in Cu-Aln Composite MaterialsDocument8 pagesComparison of Experimental and Modelling Results of Thermal Properties in Cu-Aln Composite MaterialsKamel FedaouiNo ratings yet

- 1 2960551 PDFDocument4 pages1 2960551 PDFRicardo AlvesNo ratings yet

- Hen - Effect of HeatDocument5 pagesHen - Effect of HeatGustavo FagundesNo ratings yet

- Ceramics Science and Technology, Volume 1: StructuresFrom EverandCeramics Science and Technology, Volume 1: StructuresRalf RiedelNo ratings yet

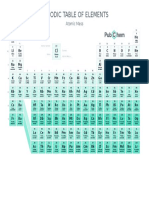

- Periodic Table of Elements W Atomic Mass PubChemDocument1 pagePeriodic Table of Elements W Atomic Mass PubChemImmaculada AcantoNo ratings yet

- W6 - Distillation UnitDocument36 pagesW6 - Distillation UnitRoza SavitriNo ratings yet

- 7 Corona: 7.1. Effect of Corona On Transmission LineDocument5 pages7 Corona: 7.1. Effect of Corona On Transmission LineParimal PatelNo ratings yet

- Pressure MeterDocument17 pagesPressure MeterRakesh7770No ratings yet

- 68 Multiple Choice Questions: No Answer GivenDocument18 pages68 Multiple Choice Questions: No Answer GivenAkram AlhaddadNo ratings yet

- Linear Viscoelastic BehaviorDocument2 pagesLinear Viscoelastic BehaviorKaustubh BhaveNo ratings yet

- 03 - Ans To Gaseous State Supplemtary QN - 2012Document4 pages03 - Ans To Gaseous State Supplemtary QN - 2012caspersoongNo ratings yet

- Section 1 - Reading Comprehension Read The Text Carefully and Answer The Questions That Follow. Choose The Most Appropriate AnswerDocument3 pagesSection 1 - Reading Comprehension Read The Text Carefully and Answer The Questions That Follow. Choose The Most Appropriate AnswerlenakaNo ratings yet

- Self-Reading - Fatigue Rainflow CountingDocument106 pagesSelf-Reading - Fatigue Rainflow CountingMilkiNo ratings yet

- Material Removal ProcessDocument25 pagesMaterial Removal ProcessisharaNo ratings yet

- Equinox International LTD - Stainless Steel - ST ST Corrosion Resistance - 106 PDFDocument2 pagesEquinox International LTD - Stainless Steel - ST ST Corrosion Resistance - 106 PDFeugenio.gutenbertNo ratings yet

- Questions of CEM PDFDocument2 pagesQuestions of CEM PDFAnonymous Anzt6fAeM100% (1)

- Sample Final Intern ReportDocument56 pagesSample Final Intern ReportBirhan SeteNo ratings yet

- Week 3-Design of One Way SlabDocument4 pagesWeek 3-Design of One Way SlabMAYHAY, ADRIAN PAULNo ratings yet

- Combined Use of Calcium Chloride and Fly Ash in Road Base StabilizationDocument10 pagesCombined Use of Calcium Chloride and Fly Ash in Road Base StabilizationGeorge SorosNo ratings yet

- Experiment 7 Chemistry IndicatorsDocument3 pagesExperiment 7 Chemistry IndicatorsNova MattisonNo ratings yet

- Aci sp-219-2004Document174 pagesAci sp-219-2004Abigael Valles RamirezNo ratings yet

- Catalogs: Material (Articles)Document3 pagesCatalogs: Material (Articles)NishanthanNo ratings yet

- A-Sub Structure: Work Shop Group-4Document19 pagesA-Sub Structure: Work Shop Group-4Ermiyas EndashawNo ratings yet

- Importat Question of Building ConstructionDocument19 pagesImportat Question of Building Constructionamol bardeNo ratings yet

- CH 3 - AE Analysis and Design of Two-Way SlabsDocument111 pagesCH 3 - AE Analysis and Design of Two-Way Slabsephrem100% (3)

- Siaran Khas 2 (SM) Dis 14Document32 pagesSiaran Khas 2 (SM) Dis 14Tengku Jalal Tengku Abu BakarNo ratings yet

- Fyp LatestDocument18 pagesFyp Latestnaveen vmaNo ratings yet

- SPC Company BrochureDocument22 pagesSPC Company BrochureDaivasigamaniNo ratings yet

- Acids and BasesDocument44 pagesAcids and BasesSai Sasivardhan GampaNo ratings yet

- On Bending, Drawing, Forming & Fine Blanking.Document145 pagesOn Bending, Drawing, Forming & Fine Blanking.Rasadnya SirNo ratings yet

- Study and Experimental Analysis On BitumenDocument7 pagesStudy and Experimental Analysis On BitumenIJRASETPublicationsNo ratings yet

- Ww15 Act Sludge 1 AkDocument5 pagesWw15 Act Sludge 1 AkDAHBIA AMROUCHENo ratings yet

Experimental and Thermodynamic Investigation of The Ni-Al-Mo System

Experimental and Thermodynamic Investigation of The Ni-Al-Mo System

Uploaded by

api-3804910Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental and Thermodynamic Investigation of The Ni-Al-Mo System

Experimental and Thermodynamic Investigation of The Ni-Al-Mo System

Uploaded by

api-3804910Copyright:

Available Formats

Experimental and Thermodynamic Investigation of the

Ni-Al-Mo System

XIAOGANG LU, YUWEN CUI, and ZHANPENG JIN

The diffusion triple and electron probe microanalysis (EPMA) techniques have been adopted to study

the isothermal section of the Ni-Al-Mo system at 1373 K. Experimental data from present work and

literature have been assessed to evaluate the thermodynamic parameters of the ternary system by

means of the calculation of phase diagram (CALPHAD) method. A substitutional-solution model is

used to describe liquid, fcc, and bcc phases, while a sublattice model is used to describe intermetallic

phases. Two sets of thermodynamic descriptions have been obtained, and comparison has been made

between them. Also, calculations of equilibrium-phase diagrams compared to the experimental data

have been presented. There is good agreement between the calculations and the experimental data.

I. INTRODUCTION effective and powerful approach to determining phase dia-

grams, plays a dominant role in the study of complex metallic

A NEW generation of turbine-blade materials, necessary systems. Accordingly, this method is utilized in this study.

for advanced high-performance engines, has been under

development for decades. The Ni-Al-Mo system was chosen

as a base, since great attention has been focused on direc- A. Experimental Procedures

tional solidification of fcc(Ni)/L12 (Ni3Al) 1 bcc(Mo) eutec-

Starting materials were high-purity aluminum (99.99 wt

tic superalloys, which show excellentproperties both at room

pct), electrolytic nickel (99.97 wt pct), and a molybdenum

and at elevated temperatures. Much work has been done to

bar (99.97 wt pct).

investigate phase stabilities and to establish phase relations,

Alloys 1 and 2 were prepared by argon are melting on

such as that by Henry,[1] Yoshizawa et al.,[2,3] Wakashima

a cooled copper hearth, using a nonconsumable tungsten

et. al.,[4] Nash et al.,[5] Miracle et al.,[6] and Maslenkov et

electrode. Each alloy button was turned over three times

al.[7,8] However, they are not always consistent with each

and remelted to make it more homogeneous. No significant

other and even result in contradictions. To fully understand

loss in weight occurred, so the alloys were believed to have

the microstructural evolution of Ni-Al-Mo superalloys dur-

the desired compositions. The nominal compositions of the

ing processing and long-term exposure to various working

alloys are listed in Table I.

conditions, all related information should be assessed and a

Polished bulk Mo and Ni were first bound with thin Mo

complete thermodynamic description should also be

cords and put into vacuumed (1021 Pa) quartz tubes. After

obtained for the purpose of further theoretical prediction and

heating in a GK-2B–type diffusion furnace at 1373 K for

simulation. Early work by Kaufman and Nesor[9] has been

96 hours, a layer of compound appeared, binding the bulk

done to calculate some isothermal sections of the Ni-Al-Mo

Mo and Ni together to form the so-called diffusion couple.

system. However, due to the lack of experimental data at

Then, the couples and alloys were polished and assembled

that time, that work needs to be improved. Recent work by

to form well-contacted metal-alloy diffusion triples, as illus-

Huang and Chang,[10] Ansara et al.,[11] Saunders,[12] and Cui

trated in Figure 1. Triples 1 and 2 were again sealed in

and Jin,[13] which focused on sub-binary systems of the Ni-

evacuated (1021 Pa) quartz tubes, and triple 3 was argon

Al-Mo system, have formed the basis of the present work.

protected. All the triples were heated in the same type of

The objective of the present work is mainly centered on the

furnace, at 1373 K, for different times. The heat-treatment

assessment of thermodynamic parameters of each phase as

conditions are shown in Table II. The temperature was con-

well as experimental study.

trolled to within 65 K. After annealing, the triples were air-

quenched, during which the cooling rate is fast enough to

keep the microstructure at room temperature. The triples

II. EXPERIMENTAL INVESTIGATION were then polished parallel to the diffusion direction. Finally,

Almost all experiments conducted on the Ni-Al-Mo sys- the local compositions were analyzed by electron probe

tem to establish phase relations are based on the method of microanalysis (EPMA) performed on a CAMECA SX-50

analyzing the microstructure of alloys (Wakashima et al.,[4] electron probe. The measurement was operated at 15 kV

Nash et al.,[5] Miracle et al.,[6] and Maslenkov et al.[7,8]). using pure Ni, Al, and Mo as standards. The microprobe

The diffusion triple technique, on the other hand, as an intensity data were corrected using the ZAF computer soft-

ware program. The relative error of the compositional analy-

sis is estimated to be less than 1 pct of the individual element.

XIAOGANG LU and YUWEN CUI, Postdoctoral Students, and ZHAN-

PENG JIN, Professor, are with the Department of Materials Science and B. Results and Discussion

Engineering, Central South University of Technology, Hunan 410083, Peo-

ple’s Republic of China. Figure 2(a) is the back-scattered electron (BSE) image of

Manuscript submitted August 24, 1998. triple 2 in the contacted region, which contains a two-phase

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 30A, JULY 1999—1785

Table I. Nominal Compositions of Binary Alloys

Alloy Number Al(At. Pct) Second Element(At. Pct)

1 51.00 49.00 (Ni)

2 73.38 26.62 (Mo)

(a)

Fig. 1—Assembly of diffusion triple.

Table II. Heat Treatment Conditions of Diffusion Triples

Diffusion (b)

Triple Time

Number Assembly Parts Atmosphere (Hour) Fig. 2—(a) BSE image of triple 2 in the contacted region between Mo,Ni

and alloy. (b) Schematic diagram of phase distribution.

1 Mo-Ni 1 alloy 1 vacuum (10 Pa)

21

840

2 Mo-Ni 1 alloy 1 vacuum (1021 Pa) 696

3 Mo-Ni 1 alloy 2 argon protected 840 average value of several groups of individual measurements.

The measurements of triple 3, however, give imprecise com-

positions due to its fine particles and porous structure. So,

the tie-lines coming from triple 3, plotted in Figure 4, should

area. The BSE images of triple 3 are shown in Figures 3(a)

serve only as the indicative phase relations.

through (c), which correspond to areas A, B, and C in Figure

No ternary phase was found in the present experiment.

3(d), respectively. Figure 3(a) shows the contacted region

Guard and Smith[14] detected a ternary compound in the

between the bulk Mo, Ni, and alloy 2. In Figure 3(b), three

vicinity of 58 at. pct Ni-34.5 at. pct Al-7.5 at. pct Mo, but did

two-phase layers can be seen. In Figure 3(c), two single-

not determine the crystal structure. Since their homogenizing

phase layers are located between the bulk Ni and the afore-

time was only 72 hours at 1448 K, this phase may not be

mentioned two-phase layers. The dark black areas found in

the stable one. Markiv[16] and Virkar and Raman[15] found

Figures 3(a) through (c) are caused by small pores, which

three ternary phases in the Al-rich corner at 1073 and 1223

are difficult to avoid when polished. Area D in Figure 3(d)

K, respectively. However, no experiment confirms their

is also full of pores, and measurement cannot be performed

observations. Further work is needed to study the ternary

in this area.

phase.

The phase relations determined from the three triples agree

well with previous experiments (Nash et al.,[5] Miracle et

al.,[6] and Maslenkov et al.[8]). As seen in Figure 4, measure- III. THERMODYNAMIC ASSESSMENT

ments of triples 1 and 2 produce almost the same results, A. Binary System

which are listed in Table III and have been used in the

present thermodynamic assessment. All the determined equi- Thermodynamic descriptions of the binary subsystem of

librium tie-lines in Table III have been obtained by extrapo- the Ni-Al-Mo system must be done prior to the present

lating the concentration profile across the interface, between assessment.

pairs of phases. The equilibrium triangle, on the other hand, 1. Ni-Al System

has been measured in the area very close to the contacting Huang and Chang[10] and Ansara et al.[11] have calculated

point of the three equilibrium phases by EPMA, and it is an Ni-Al, and their calculations agree with experimental data

1786—VOLUME 30A, JULY 1999 METALLURGICAL AND MATERIALS TRANSACTIONS A

(a)

(d )

(b)

(c)

Fig. 3—BSE images of triple 3. (a) Contacted region between Mo,Ni and alloy, 1: L12(dark) 1 NiMo(gray), 2: L12(dark) 1 bcc(gray), and 3: B2(dark)

1 bcc(gray); (b) two-phase layers, 1: B2(dark) 1 bcc(bright), 2: B2(dark) 1 AlMo3(bright), and 3: AlMo3(bright) 1 Al8Mo3 (gray); (c) single-phase layers;

and (d ) schematic diagram of phase distribution, areas 1, 2, and 3 corresponding to (a), (b), and (c), respectively.

fairly well. Concerning the fcc and L12 phases, they used 3. Mo-Ni system

the same method proposed by Ansara et al., which will be In Mo-Ni system, the solubility of Mo in the fcc phase,

reviewed briefly in Section III–B–3. But Huang and Chang determined by Casselton and Hume-Rothery,[17] is higher

simplified the modeling by using a virtual disordered phase than that of Heijwegen and Riech,[18] which was selected

other than fcc as the disordered contribution to the L12 phase, for assessment by Frisk.[19] Also, Ni4Mo decomposes to

which gave lesser parameters to describe this system. Table Ni3Mo and NiMo phases at very low temperatures, which

IV lists some of the key parameters which show such differ- is not confirmed by the experiment. So, the thermodynamic

ence. Figure 5 shows the calculated phase diagram by Huang descriptions have been modified by Cui and Jin,[13] based

and Chang. on the work of Frisk, to get a better agreement between

In this work, both sets of parameters are used to optimize the experiments and calculations. In the present work, it is

the ternary system, in order to determine which one is better. important to note that such modification makes the ternary

2. Al-Mo system assessment more easy and reasonable, which will be dis-

This system has been evaluated by Saunders,[12] and the cussed in Section III–D. Figure 7 is the modified Ni portion

calculated phase diagram is presented in Figure 6. Most of the Mo-Ni phase diagram[13] compared to the experimental

intermetallic phases in the Al-Mo system are treated as stoi- data and that calculated by Frisk. The whole system is shown

chiometric phases, except for the AlMo phase. in Figure 8.

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 30A, JULY 1999—1787

Table IV. The Thermodynamic Data of Ni-Al System from

Huang and Chang [10] and Ansara et al.[11]

Data from Huang

Parameters and Chang[10] Data from Ansara et al.[11]

Liquid:

0L

Al,Ni 2194,177 1 28.663T 2207,109.28 1 41.31501T

1L

Al,Ni 4829 210,185.79 1 5.87140T

2L

Al,Ni 53,042 2 9.121T 81,204.81 2 31.95713T

3

LAl,Ni — 4365.35 2 2.51632T

4L

Al,Ni — 222,101.64 1 13.16341T

Fcc:

0L

Al,Ni 2168,292 1 16T 2162,407.750 1 16.212965T

1

LAl,Ni 32,712 73,417.798 2 34.914T

2L

Al,Ni 27998 1 35T 33,471.014 2 9.837T

3

LAl,Ni — 230,758.01 1 10.253T

L12:

u1AlNi 243,686 1 8.6418T 240,246.545 1 6.2457741T

u4AlNi — 7088.736 2 3.6868954T

0

LAl,Ni:* 2u1AlNi 2u1AlNi

1L

Al,Ni:* — 3u4AlNi

1

L*:Al,Ni — u4AlNi

Disordered contribution to L12:

Fig. 4—Present measured equilibrium data (thick lines and marks) at 0L

218,928 1 12u1AlNi (the same as fcc)

Al,Ni

1373 K. 1L

Al,Ni 27813 1 34.404T

2

LAl,Ni 67,054

Table III. The Equilibrium Data Determined by EPMA at

1373 K (Atomic Percent)

fcc L12 (Ni3Al) B2 (NiA1) L12 (Ni3Al)

Ni Mo Ni Mo Ni Mo Ni Mo

83.7 2.9 78.5 2.9 63.3 0.3 71.4 1.3

78.6 11.5 75.5 5.0 63.1 0.1 72.9 1.7

83.0 0.0 76.0 0.0 62.4 0.3 72.3 2.0

Ll2(Ni3Al) NiMo 63.7 0.0 71.8 0.2

Ni Mo Ni Mo fcc NiMo

74.9 4.0 46.7 51.2 Ni Mo Ni Mo

fcc Ll2(Ni3Al) NiMo 76.5 23.1 50.0 49.8

Ni Mo Ni Mo Ni Mo

76.3 14.9 75.9 5.0 48.9 49.4

B. Thermodynamic Modeling of the Ternary System

All the phases considered in the present work are listed

in Table V with their formulae. No ternary phase is consid-

ered in the present work, since there is no confirmed experi- Fig. 5—Calculated Ni-Al system by Huang and Chang.[10]

mental information.

1. Substitutional solutions 2 3

Liquid, fcc, and bcc phases are treated as substitutional

solutions. The molar Gibbs energy is expressed as

ex

Gm 5 o o

i51 j5i11

[xi xj /(Vi,jVj,i)]?exGi,j

Gm 5 xAl8GAl 1 xNi8GNi 1 xMo8GMo 1 xAl xMo xNi(xAl8LAl,Mo,Ni 1 xMo1LAl,Mo,Ni [2]

2

1 RT (xAl ln xAl 1 xMo ln xMo 1 xNi ln xNi) [1] 1 xNi LAl,Mo,Ni)

1 ex Gm 1 mag

Gm where *LAl,Mo,Ni denotes ternary interaction parameters

which will be evaluated in the present work, and exGi,j

where R 5 8.31451 J mol21 K21, xi is the mole fraction of denotes the binary excess Gibbs energy. The terms Vi,j and

element i, and 8Gi is the molar Gibbs energy of the element Vj,i are represented by

i in a hypothetical nonmagnetic state, which can be taken

from the database of Dinsdale.[20] The excess Gibbs energy 1 1 Xi 2 Xj 1 1 Xj 2 Xi

Vi,j 5 , Vj,i 5 [3]

(ex Gm) is represented by 2 2

1788—VOLUME 30A, JULY 1999 METALLURGICAL AND MATERIALS TRANSACTIONS A

Fig. 6—Calculated Al-Mo system by Saunders.[12]

Fig. 8—The modified Mo-Ni system by Cui and Jin.[13]

Table V. All the Phases and their Formulae Included in

Ternary System

Phase Formula

Liquid, bcc, and fcc (Al,Mo,Ni)

Al3Ni (Al)0.75(Ni)0.25

Al3Ni2 (Al)3(Al,Mo,Ni)2(Mo,Ni,Va)1

Al3Ni5 (Al)0.375(Ni)0.625

B2(NiAl) (Al,Mo,Ni)1(Mo,Ni,Va)1

L12(Ni3Al) (Al,Mo,Ni)0.75(Al,Mo,Ni)0.25

Disordered contribution (Al,Mo,Ni)

Al12Mo (Al)0.923(Mo)0.077

Al4Mo (Al)0.8(Mo)0.2

Al5Mo (Al)0.833(Mo)0.167

Al63Mo37 (Al)0.63(Mo)0.37

Al8Mo3 (Al)0.727(Mo)0.273

AlMo (Al,Mo,Ni)1(Al,Mo,Ni)1

Cub A15(AlMo3) (Mo)0.75(Al)0.25

NiMo (Ni)24(Al,Mo,Ni)20(Mo)12

Ni4Mo (Mo)4(Ni)1

Ni3Mo (Al,Mo,Ni)3(Al,Mo,Ni)1

Fig. 7—The modified Ni-rich portion of the Mo-Ni system together with

the experimental data. Dashed lines are the calculated results by Frisk.[19]

characterize the L12 phase. The molar Gibbs free energy of

where both i and j represent the elements Al, Mo, and Ni the phase is expressed by

(i Þ j). The first group of terms in Eq. [2] represents the

binary contribution to the excess Gibbs energy, according Gm 5 y1Ni y2Ni 8GNi:Ni 1 y1Ni y2Al 8GNi:Al 1 y1Ni y2Mo 8GNi:Mo

to the extrapolation scheme suggested by Muggianu et al.[21] 1 y1Al y2Ni 8GAl:Ni 1 y1Al y2Al 8GAl:Al 1 y1Al y2Mo 8GAl:Mo

The last term is the ternary contribution. All the interaction

parameters may contain a temperature coefficient. The term 1 y1Mo y2Ni 8GMo:Ni 1 y1Mo y2Al 8GMo:Al 1 y1Mo y2Mo 8GMo:Mo

mag

Gm is the magnetic contribution described by Hillert and

Jarl.[22] This term is assumed to be zero for the liquid phase. 1 RT [0.75 ( y1Ni ln y1Ni 1 y1Al ln y1Al 1 y1Mo ln y1Mo)

2. Intermetallic phases 1 0.25 ( y2Ni ln y2Ni 1 y2Al ln y2Al 1 y2Mo ln y2Mo)] 1 ex Gm [4]

Six phases (Al3Ni2, B2, L12, AlMo, Ni3Mo, and NiMo) The site fraction of element i in sublattice s is denoted as

are treated as phases with solubilities in the ternary system. y si . The parameter 8GNi:Al is the Gibbs energy of phase L12,

They are described using the sublattice model developed by with Ni in the first sublattice and Al in the second. Its value

Hillert and Staffanson.[23] Here, an expression of molar is given by the following expression:

Gibbs energy is provided as an example.

The formula (Al, Ni, Mo)0.75(Al, Ni, Mo)0.25 is used to 8GNi:Al 5 0.75 8Gfcc fcc

Ni 1 0.25 8GAl 1 DG [5]

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 30A, JULY 1999—1789

where DG is obtained from optimization.Other 8G*:* parame- This model has been implemented in the ThermoCalc

ters have similar meanings. calculation package developed by Sundman et al.,[25] where

All other intermetallic phases have negligible solubility the Gibbs energy of L12 is separated into disordered and

ranges in binary systems. They are assumed to be stoichio- ordered contributions. So, the thermodynamic properties of

metric phases in the ternary system and are not remodeled the disordered phase (fcc phase, in this case) can be evaluated

in the present work. independently. This could be represented by the following

3. Fcc and L12 phases equation:

There is an order-disorder transformation between the fcc Gm 5 Gdis ord 1 2 ord

m (xi) 1 Gm ( y i , yi ) 2 Gm (xi) [9]

and L12 phases, which are based on the same fcc structure

despite of a different occupancy of atoms on each sublattice. where Gdis

m (xi) is the Gibbs energy of the disordered state.

So, it is reasonable to describe both phases with a united The term Gord 1 2

m ( yi , yi ) is the Gibbs energy as described by

model. To study such transformation in the Ni-Al system, the model (Eq. [4] or [6]) and contains, implicitly, a contribu-

Ansara et al.[11] used a two-sublattice model to describe tion of the disordered state. The term Gordm (xi) represents the

them after the formula (Ni, Al)0.75(Ni, Al)0.25. The molar energy contribution of the disordered state to the ordered

Gibbs free energy of the phases is expressed by phase. The last two terms cancel each other when y1i 5 y2i,

thus corresponding to the disordered state.

Gm 5 y1Ni y2Ni 8GNi:Ni 1 y1Ni y2Al 8GNi:Al 1 y1Al y2Ni 8GAl:Ni

1 y1Al y2Al 8GAl:Al 1 RT [0.75 ( y1Ni ln y1Ni 1 y1Al ln y1Al)

C. Selection of Experimental Information

1 0.25 ( y2Ni ln y2Ni 1 y2Al ln y2Al)]

Miracle et al.[6] analyzed alloys of desired compositions

1 y1Ni y1Al ( y2Ni 8LNi,Al:Ni 1 y2Al 8LNi,Al:Al) after long-term heat treatment (up to 2500 hours) by EPMA

and X-ray diffraction and constructed an experimentally vali-

1 y2Ni y2Al ( y1Ni 8LNi:Ni,Al 1 y1Al 8LAl:Ni,Al) [6] dated ternary equilibrium-phasediagram at 1200, 1311, l366,

The meaning of the symbols in Eq. [6] is the same as 1444, and 1533 K. Systematic experimental studies by

those in Eq. [4]. When y1i 5 y2i 5 xi, where xi is the mole Wakashima et al.,[4] by means of transmission electron

fraction of element i of the phase, this is the case of a microscopy and selected-area diffraction along with differ-

disordered state, i.e., the fcc phase; thus, Eq. [6] is equivalent ential thermal analysis (DTA) have been carried out on a

to the molar Gibbs energy of the substitutional model. When series of alloys containing about 65 at. pct Ni. Based on the

y1i Þ y2i, there is ordering on each sublattice, i.e., the phase experimental observations, the phase diagram is recon-

exists with the structure of the L12 phase. In order to ensure structed with emphasis on the isothermal section at 1273 K.

that the disordered state is always possible, there are con- They also presented a flow chart of invariant reactions in

straints for the parameters in Eq. [6]:[11] the Ni-rich part. Hong et al.[26] measured the fcc solvus at

four temperatures, employing DTA and scanning electron

8GNi:Al 5 u1

microscopy–energy-dispersive X-ray. These experiments

8GAl:Ni 5 u2 and the present experimental work are believed to be well

conducted, and the present optimization sets high weight on

8LNi,Al:Ni 5 3u1 1 u2/2 1 3u3 these data. Other experimental data are compared to

8LNi,Al:Al 5 3u2 1 u1/2 1 3u3 calculations.

8LNi:Ni,Al 5 u2/2 1 u3

D. Results and Discussion

8LAl:Ni,Al 5 u1/2 1 u3

The optimization and calculations were conducted using

8LNi,Al:Ni,Al 5 4u4 2 4u5 the ThermoCalc package. The optimization was performed

1 1 with the selected experimental data, and each piece of infor-

LNi,Al:Ni 5 3u4 LNi,Al:Al 5 3u5

mation was given a certain weight, reflecting the experimen-

1

LNi:Ni,Al 5 u4 1

LAl:Ni,Al 5 u5 [7] tal uncertainty.

Much attention has been paid to the fcc solvus at the

where u1 through u5 are variables which need to be opti- Ni-rich corner. There appears to be a trend that, with the

mized. In practice, the number of parameters can be reduced temperature decreasing, the experimental Mo contents of

by assuming that u1 5 u2, u4 5 u5, and u3 5 0. the fcc phase in fcc 1 L12 1 NiMo (or fcc 1 L12 1

In the ternary system, a similar formula, (Al, Ni, bcc) three-phase equilibria are somewhat higher than the

Mo)0.75(Al, Ni, Mo)0.25, is used,[24] and there are also con- calculated ones and also that the experimental fcc solvus is

straints for parameters. more Ni-rich (Figures 9 through 15(a) and (b)). Such devia-

8Gi:j 5 8Gj:i 5 u1ij tions can be eliminated with unusual large temperature coef-

ficients of the ternary interaction parameters of the fcc phase

8Li,j:A 5 8Li,j:B 5 8Li,j:C 5 2u1ij 1 3u3ij in Eq. [2], but this is not favorable. In order to fit the

8LA:i,j 5 8LB:i,j 5 8LC:i,j 5 u3ij experimental data, it seems that it is not adequate to adjust

the ternary interaction parameters only; the binary systems

1

Li,j:A 5 1Li,j:B 5 1Li,j:C 5 3u4ij have to be reexamined as well. So, modification of the binary

1 Mo-Ni system has been made,[13] as mentioned previously,

LA:i,j 5 1LB:i,j 5 1LC:i,j 5 u4ij [8]

and it actually improves the situation. Also, two sets of

where i, j, A, B, and C represent the elements Ni, Al, and Mo. parameters about the Ni-Al system are used to optimize

1790—VOLUME 30A, JULY 1999 METALLURGICAL AND MATERIALS TRANSACTIONS A

Fig. 9—Calculated isothermal section (thin lines) compared with experi-

mental data at 1373 K. I: L12 1 NiMo 1 bcc; and II: L12 1 B2 1 bcc. Fig. 11—Calculated isothermal section (thin lines) compared with experi-

mental data at 1311 K. I: L12 1 NiMo 1 bcc; and II: L12 1 B2 1 bcc.

Fig. 10—Calculated isothermal section (thin lines) compared with experi-

mental data at 1200 K. I: L12 1 NiMo 1 bcc; and II: L12 1 B2 1 bcc. Fig. 12—Calculated isothermal section (thin lines) compared with experi-

mental data at 1366 K. I: L12 1 NiMo 1 bcc; and II: L12 1 B2 1 bcc.

the ternary system, as discussed in Section III–A–1. Here,

optimization using data from Huang and Chang[10] and thought to be better than assessment 2, and all the following

Ansara et al.[11] are denoted as assessments 1 and 2, respec- phase diagrams are calculated using data from assessment 1.

tively. The optimized thermodynamic parameters are listed Figures 4 and 9 show the calculated isothermal sections

in Table VI. Both assessments give almost the same results, compared to the present experimental work. Figures 10

except for the fcc solvus at the Ni-rich corner, as seen in through 14 illustrate the isothermal sections at 1200, 1311,

Figure 15(a). Assessment 1 results in smaller deviations to 1366, 1444, and 1533 K, respectively. There is good agree-

the fcc solvus than assessment 2, as shown in Figures 15(a) ment between the experiments and calculations. At 1366 K

and (b). In assessment 1, due to the limited experimental (Figure 12), the solubility of Mo in the B2 phase, as reported

data concerning the L12 phase, the excess Gibbs energy in by Miracle et al.,[6] was too large compared to that reported

Eq. [4] is neglected. So, assessment 1 gives lesser parameters by Nash et al.,[5] Maslenkov et al.,[8] and to the present

than assessment 2; i.e., the thermodynamic modeling in measurement. As mentioned by Miracle et al.,[6] the volume

assessment 1 is simpler than that in assessment 2. As the fraction of B2 was very low and the particles were very

experimental data, especially the thermodynamic ones, are small; thus, the measured composition may be unbelievable.

relatively few, the simple model may be preferred, even So, his measurement of B2 has not been considered in the

though the model proposed by Ansara et al. is more realistic present optimization.

and more reasonable. For these reasons, assessment 1 is Comparison is made between the fcc solvis measured by

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 30A, JULY 1999—1791

Fig. 13—Calculated isothermal section (thin lines) compared with experi-

mental data at 1444 K. I: fcc 1 NiMo 1 bcc; II: fcc 1 L12 1 bcc; and (a)

III: L12 1 B2 1 bcc.

(b)

Fig. 14—Calculated isothermal section (thin lines) compared with experi- Fig. 15—Calculated fcc solvus at 1200, 1300, and 1400 K in assessment

mental data at 1533 K. I: fcc 1 NiMo 1 bcc; II: fcc 1 L12 1 bcc; and 1 (solid lines) compared with (a) that in assessment 2 (dashed lines) and

III: L12 1 B2 1 bcc. (b) experimental data.

Hong et al.[26] and the calculated results, except at 1100 K seen that it is acceptable, except that the peritectic-eutectic

(Figure 15(b)). Since they have not detected Ni3Mo and reaction concerning the liquid, NiMo, fcc, and bcc phases

Ni4Mo phases at this temperature, the fcc solvus at 1100 K is a ternary eutectic reaction, L Ö NiMo 1 fcc 1 bcc,

may not be true and is not included in Figure 15(b). instead. As there is no experimental information to verify

As seen in Figures 16 and 17, the calculated phase dia- the type of reaction, it is also acceptable.

grams fit the experimental points well enough. At 1553 K, Figure 18 shows the calculated isothermal section, with

as discussed by Wakashima et al.,[4] the alloy with fcc 1 experimental information by Nash et al.[5] and Maslenkov

bcc phases and the alloys with fcc 1 bcc 1 L12 phases et al.,[8] at 1473 K. There is good agreement between the

(except the alloy with “1” marked in Figure 17) are actually calculations and the measurements of Nash et al., whereas

in the same phase region, but the latter ones have extra the fcc compositions in equilibria with NiMo, detected by

L12 phase due to ineffective quenching. This can be well Maslenkov et al., are more Mo depleted than the calculated

reproduced, as in Figure 17. The calculated temperatures of ones. At 1373 K, experimental data by Maslenkov et al.

Ni-corner invariant reactions, compared to those summa- also show such deviation, as seen in Figure 9.

rized by Wakashima et al., are listed in Table VII. It can be There are few equilibrium experimental data regarding

1792—VOLUME 30A, JULY 1999 METALLURGICAL AND MATERIALS TRANSACTIONS A

Table VI. Assessed Thermodynamic Parameters in the

Present Work (J/Mol)

Assessment 1 Assessment 2

Liquid:

8LAl,Mo,Ni 5 221,341 2

21.7926T 218,000 2 18.4362T

1L

Al,Mo,Ni 5 16,626 1 6.1815T 22,507.8 1 7.3334T

2L

Al,Mo,Ni 5 133,084 1 1.6964T 145,772 1 1.6244T

Fcc:

8LAl,Mo,Ni 5 243,250 2 94.38T 243,645 2 94.31T

1

LAl,Mo,Ni 5 264,492 1 98.74T 264,415 1 99.02T

2L

Al,Mo,Ni 5 271,000 2 75.075T 277,730 2 74.38T

Bcc:

8LAl,Mo,Ni 5 2160,000 2160,000

B2:(Al, Mo, Ni)1(Mo, Ni, Va)1:

8GMo:Ni 2 8Gbcc Mo 2 8GNi

bcc

5 213,176 1 31.4465T 213,176 1 31.4465T

8GNi:Mo 2 8Gbcc Mo 2 8GNi

bcc

5 213,176 1 31.4465T 213,176 1 31.4465T

8GMo:Va 2 8Gbcc Mo 5 150,000 150,000

8GAl:Mo 2 8Gbcc Mo 2 8GAl

bcc

Fig. 16—Calculated isothermal section (thin lines) compared with experi-

5 244,629 1 39.7878T 244,629 1 39.7878T mental data at 1273 K. I: L12 1 NiMo 1 bcc; and II: L12 1 bcc.

L12:(Al, Mo, Ni)0.75(Al, Mo, Ni)0.25:

8GMo:Ni 2 0.758Gfcc Mo 2 8GMo:Ni 2 0.758GfccMo 2

0.258Gfcc

Ni 5 213,849 1 0.258Gfcc

Ni 5 235,361 1

4.6243T 16.23T 5 u1NiMo

8GNi:Mo 2 0.758Gfcc Ni 2 8GNi:Mo 2 0.758GfccNi 2

0.258Gfcc

Mo 5 213,849 1 0.258Gfcc

Mo 5 235,361 1

4.6243T 16.23T 5 u1NiMo

8LMo,Ni:* 5 2u1NiMo

1

LMo,Ni:* 5 3u4NiMo

1L

*:Mo,Ni 5 780 2 0.9T 5

u4NiMo

NiMo:(Ni)24(Al, Mo, Ni)20(Mo)12:

8GNi:Al:Mo 2 128GbccMo 2

248Gfcc

Ni 2 208GAl

bcc

5 21,750,000 21,750,000

Ni3Mo:(Al, Mo, Ni)3(Al, Mo, Ni)1:

8GAl:Ni 2 8GbccAl 2 38GNi

fcc

5 2173,798 1 31.91T 2239,987 1 91.49T

AlMo:(Al, Mo, Ni)1(Al, Mo, Ni)1:

8GMo:Ni 2 8Gbcc fcc

Mo 2 8GNi 5

57,500 2 2.5T 57,500 2 2.5T

8GNi:Mo 2 8Gbcc fcc

Mo 2 8GNi 5

57,500 2 2.5T 57,500 2 2.5T

Al3Ni2:(Al)3(Al, Mo, Ni)2(Ni, Mo, Va)1:

8GAl:Mo:Ni 2 28GbccNi 2 38GAl 5

bcc

Fig. 17—Calculated isothermal section (thin lines) compared with experi-

230,000 230,000 mental data at 1553 K. I: fcc 1 NiMo 1 bcc; II: fcc 1 L12 1 bcc; and

8GAl:Ni:Mo 2 8GbccMo 2 28GNi 2

bcc

III: L12 1 B2 1 bcc.

38Gbcc

Al 5 230,000 230,000

Table VII. Invariant Reaction Temperatures (K)

the Ni3Mo phase. Figure 19 shows the work of Maslenkov

et al.[8] and a calculated one at 1153 K. Summarized by

Wakashima et Present

Henry[1] studied the precipitation of the L12 phase in fcc 1

Reaction al.[4] Calculations

bcc eutectics using the alloys AG34 (65.6 at. pct Ni, 14.4

at. pct Al, and 20.0 at. pct Mo) and AG8 (65.7 at. pct Ni, L Öfcc 1 L12 1 bcc 1573 1572

17.6 at. pct Al, and 16.7 at. pct Mo). The lower Al content Fcc 1 bcc ÖL12 1 NiMo 1403 1403

L ÖNiMo 1 bcc 1 fcc 1583 1577

alloy, AG34, yields a structure as-directionally solidified,

L 1 B2 ÖL12 1 bcc 1576 1577

consisting of primary Mo fibers surrounded by an L12 matrix

with fcc phase centered in the L12 phase, whereas, at 1260

8C, the L12 precipitate is dissolved and the matrix is almost

all back to the parent fcc phase. The calculated AG34 struc- from the fcc 1 bcc structure, and the fcc 1 L12 1 bcc

ture is fcc 1 L12 1 bcc at 1200 8C and fcc 1 bcc at 1260 structure could be kept at room temperature in an ordinary

8C. This can, approximately, be seen in Figure 20. As the furnace-cooling condition without undergoing the peritec-

temperature is lowered, the L12 phase precipitates readily toeutectoid reaction (fcc 1 bcc ÖL12 1 NiMo). The reason

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 30A, JULY 1999—1793

Fig. 18—Calculated isothermal section (thin lines) compared with experi-

mental data at 1473 K. I: fcc 1 NiMo 1 bcc; II: fcc 1 L12 1 bcc; and

III: L12 1 B2 1 bcc.

Fig. 20—Calculated isopleth section at 65 at. pct Ni of Ni-Al-Mo system.

Fig. 19—Calculated isothermal section (thin lines) compared with experi-

mental data at 1153 K. I: L12 1 NiMo 1 bcc; and II: L12 1 B2 1 bcc. Fig. 21—Calculated liquidus projection compared with experimental data.

for this has been proposed by Wakashima et al.,[4] by recog- eutectic reaction (L Ö fcc 1 bcc) occurring at about 1310

nizing that, when surrounded by thick L12-phase walls, the 8C and found the L12 solvus to be 1248 6 2 8C on heating

bcc phase would be prevented from reacting with the fcc and 1234 6 2 8C on cooling, at a heating/cooling rate of

phase. Alloy AG8, on the other hand, consists of primary 10 K per minute. Thus, they reported a bcc 1 fcc two-phase

Mo fibers in an essentially pure L12 matrix, and L12 progres- structure at 1260 8C. The calculated results, on the other

sively dissolves into fcc phase as the annealing temperature hand, are that the L12 solvus is 1234 8C and that the alloy

is raised from 1220 8C to 1280 8C. The present calculation with this composition is in bcc 1 fcc equilibrium at 1260

shows that AG8 has an L12 1 bcc two-phase structure at 8C (Figures 14 and 20). Also, simple simulation of the solidi-

1000 8C (or even lower) and an fcc 1 L12 1 bcc three-phase fication path is conducted using a Scheil model for example,

structure at 1280 8C, as seen, approximately, in Figure 20. (Reference 27) and an equilibrium model with the present

Yoshizawa et al.[2,3] studied the phase stability of a direc- thermodynamic parameters. They produce almost the same

tionally solidified eutectic alloy of composition 12.7 at. pct eutectic temperature, 1305.6 8C. The Scheil model neglects

Al, 21.6 at. pct Mo, and the balance Ni. They measured the back-diffusion in solid and assumes perfect mixing in liquid;

1794—VOLUME 30A, JULY 1999 METALLURGICAL AND MATERIALS TRANSACTIONS A

thus, it is often used to simulate solidification behavior with REFERENCES

extremely high cooling rates. The equilibrium model, on the

other hand, assumes that the equilibrium state is obtained 1. Michael F. Henry: Scripta Metall., 1976, vol. 10, pp. 955-57.

in the process of solidification, which corresponds to the 2. H. Yoshizawa, K. Wakashima, S. Umekawa, and T. Suzuki: Scripta

condition of extremely slow cooling rates. Since such models Metall., 1981, vol. 15, pp. 1091-96.

3. H. Yoshizawa, K. Wakashima, and S. Umekawa: J. Mater. Sci., 1982,

describe two limiting cases, all other solidification paths vol. 17, pp. 3484-90.

will go in between. So, the calculated eutectic temperature 4. K. Wakashima, K. Higuchi, T. Suzuki, and S. Umekawa: Acta Metall.,

agrees with the experimental one very well. 1983, vol. 31, pp. 1937-44.

The liquidus projection is plotted in Figure 21 using the 5. P. Nash, S. Fielding, and D.R.F. West: Met. Sci., 1983, vol. 17, pp.

experimental data by Svetlov et al.[28] The two alloys used 192-94.

6. D.B. Miracle, K.A. Lark, V. Srinivasan, and H.A. Lipsitt: Metall.

by them have different primary phases, and the eutectic Trans. A, 1984, vol. 15A, pp. 481-86.

trough must go between them. 7. S.B. Maslenkov, A.L. Udovski, N.N. Burova, and V.A. Rodimkina:

Izv. Akad. Nauk SSSR, Metally, 1986, No. 1, pp. 198-205.

8. S.B. Maslenkov, N.N. Burova, and V.A. Rodimkina: Izv. Akad. Nauk

IV. SUMMARY SSSR, Metally, 1988, No. 6, pp. 183-90.

9. L. Kaufman and H. Nesor: Metall. Trans., 1974, vol. 5, pp. 1623-29.

1. The isothermal section of the Ni-Al-Mo system at 1373 10. W. Huang and Y.A. Chang: Intermetallics, 1998, vol. 6, pp. 487-98.

11. Ibrahim Ansara, Nathalie Dupin, Hans Leo Lukas, and Bo Sundman:

K has been studied by means of the diffusion triple tech- J. Alloys Compounds, 1997, vol. 247, pp. 20-30.

nique. Equilibrium tie-lines have been measured and 12. N. Saunders: “Thermodynamic Database for Light Metal Alloys,”

phase relations have been established. There is good COST507, European Commission, Brussels, 1997.

agreement between the present work and other 13. Yuwen Cui and Zhanpeng Jin: Central South University of Technology,

Changsha, Hunan, China, unpublished research, 1998.

experiments.

14. R.W. Guard and E.A. Smith: J. Inst. Met., 1960, vol. 88, pp. 283-87.

2. Thermodynamic parameters of the Ni-Al-Mo ternary sys- 15. A.V. Virkar and A. Raman: Z. Metallkd., 1969, vol. 60, pp. 594-600.

tem have been evaluated from the present experimental 16. V.Y. Markiv, V.V. Burnashova, L.I. Pryakhina, and K.P. Myasnikova:

data and from those available in the literature. Two sets Izv. Akad. Nauk SSSR, Metally, 1969, No. 5, pp. 117-19.

of thermodynamic parameters have been optimized, and 17. R.E.W. Casselton and W. Hume-Rothery: J. Less-Common Met., 1964,

vol. 7, pp. 212-21.

assessment 1 is thought to be the better one. The compari- 18. C.P. Heijwegen and G.D. Rieck: Z. Metallkd., 1973, vol. 64, pp. 450-53.

sons between experimental data and the calculated equi- 19. Karin Frisk: CALPHAD, 1990, vol. 14, pp. 311-20.

librium phase diagrams were made, and experimental 20. A.T. Dinsdale: CALPHAD, 1991, vol. 15, pp. 317-425.

facts have been explained. They show that, thermody- 21. Y.M. Muggianu, M. Gambino, and J.P. Bros: J. Chim. Phys., 1975,

namically, this ternary system has been satisfactorily vol. 72, pp. 83-88.

22. M. Hillert and M. Jarl: CALPHAD, 1978, vol. 2, pp. 227-38.

described.

23. M. Hillert and L.-I. Staffanson: Acta Chem. Scand., 1970, vol. 24,

pp. 3618-26.

24. N. Dupin: Ph.D. Thesis, Institut National Polytechnique de Grenoble,

ACKNOWLEDGMENTS Grenoble, France, 1995.

25. B. Sundman, B. Jansson, and J.O. Andersson: CALPHAD, 1985, vol.

This work is financially supported by the General Electric 9, pp. 153-90.

Company, under Research Contract No. 9622031. The 26. Yong Myong Hong, Hitoshi Nakajima, Yoshinao Mishima, and Tomoo

authors thank Dr. J.-C. Zhao, GE Company, for his invalu- Suzuki: Iron Steel Inst. Jpn. Int., 1989, vol. 29, pp. 78-84.

able help during the work. We are indebted to Mrs. Xiulin 27. D.A. Porter and K.E. Easterling: Phase Transformation in Metals

Han (The Geology Institute, Chinese Academy of Science), and Alloys, 1st ed., Van Nostrand Reinhold Co. Ltd., Wokingham,

Berkshire, England, 1981, pp. 209-13.

who performed the EPMA measurements reported in the 28. I.L. Svetlov, A.L. Udovskii, E.V. Monastyrskaya, I.V. Oldakovskii,

present work. We also thank Mr. Zhongyi Liu for valuable and M.P. Nazarova: Izv. Akad. Nauk SSSR, Metally, 1987, No. 6, pp.

comments on the manuscript. 183-89.

METALLURGICAL AND MATERIALS TRANSACTIONS A VOLUME 30A, JULY 1999—1795

You might also like

- Solvent Extraction Lab ReportDocument11 pagesSolvent Extraction Lab ReportFaiz Farhan80% (5)

- Tube To Tube SheetDocument59 pagesTube To Tube Sheet0101100175% (12)

- J.C. Zhao, V. Ravikumar, A.M. Beltran, Met. Trans. A. Phase Precipitation and Phase Stability in Nimonic 263Document2 pagesJ.C. Zhao, V. Ravikumar, A.M. Beltran, Met. Trans. A. Phase Precipitation and Phase Stability in Nimonic 263Henry León HenaoNo ratings yet

- Experimental Study and Thermodynamic Assessment of The Ni-Mo-Ta Ternary SystemDocument10 pagesExperimental Study and Thermodynamic Assessment of The Ni-Mo-Ta Ternary Systemapi-3804910No ratings yet

- Efectul AluminiuluiDocument15 pagesEfectul AluminiuluiGhermeniNo ratings yet

- ZnO MNDocument8 pagesZnO MNmohapatra.manojNo ratings yet

- Nanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsDocument5 pagesNanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsMohamed KhalifaNo ratings yet

- Aluminetos de TitânioDocument7 pagesAluminetos de TitânioMarcionilo NeriNo ratings yet

- 2015-TransNonferrousMetSocChina-Formation Mechanism of Ni-Al Intermetallics During Heat Treatment of Ni Coating On Al SusbtrateDocument8 pages2015-TransNonferrousMetSocChina-Formation Mechanism of Ni-Al Intermetallics During Heat Treatment of Ni Coating On Al SusbtrateSIVAJI TADISETTYNo ratings yet

- Kleppa 1951Document3 pagesKleppa 1951Fred Duarte CaldeiraNo ratings yet

- Optics and Laser Technology: Full Length ArticleDocument9 pagesOptics and Laser Technology: Full Length Articlesrinathgudur11No ratings yet

- Magnetic Properties of Iron-Oxide and (Iron, Cobalt) - Oxide Nanoparticles Synthesized in Polystyrene Resin MatrixDocument3 pagesMagnetic Properties of Iron-Oxide and (Iron, Cobalt) - Oxide Nanoparticles Synthesized in Polystyrene Resin MatrixPpa Gpat AmitNo ratings yet

- The Development of Highly Magnetostrictive Rare Earth-Iron AlloysDocument12 pagesThe Development of Highly Magnetostrictive Rare Earth-Iron AlloysYASHANSHU DIXITNo ratings yet

- FKNJNDocument6 pagesFKNJNIlham Mahrojan SulaimanNo ratings yet

- Mehra J 2015Document9 pagesMehra J 2015hussanmuhammadNo ratings yet

- Thermodynamic Calculation of The In-Sn-Zn Ternary SystemDocument8 pagesThermodynamic Calculation of The In-Sn-Zn Ternary Systemapi-3804910No ratings yet

- A Three Dimensional Finite Element Analysis of The Temperature Field During Laser Melting of Metal Powders in Additive Layer ManufacturingDocument8 pagesA Three Dimensional Finite Element Analysis of The Temperature Field During Laser Melting of Metal Powders in Additive Layer Manufacturingsahilnagula0504No ratings yet

- Thermodynamic Reassessment of Au-Ni-Sn Ternary System: Calphad December 2013Document11 pagesThermodynamic Reassessment of Au-Ni-Sn Ternary System: Calphad December 2013Pei-YuChenNo ratings yet

- 2004wu - JMMM - A Study On The Role of NB in Melt-Spun NanocrystallineDocument9 pages2004wu - JMMM - A Study On The Role of NB in Melt-Spun NanocrystallinePatrícia CanazartNo ratings yet

- MTIPROFEDocument9 pagesMTIPROFEMar Cerda SilvaNo ratings yet

- The Microstructure and PrecipitationDocument4 pagesThe Microstructure and PrecipitationDACAMOGO DCMGNo ratings yet

- Shi 1999Document6 pagesShi 1999Tatiane NascimentoNo ratings yet

- Fe-Nb-Ni (Iron-Niobium-Nickel) : Binary SystemsDocument4 pagesFe-Nb-Ni (Iron-Niobium-Nickel) : Binary Systemsabdul basitNo ratings yet

- Tensile Behaviour of As Deposited and Heat-Treated Electroless Ni-P DepositsDocument14 pagesTensile Behaviour of As Deposited and Heat-Treated Electroless Ni-P DepositslinNo ratings yet

- TMP 37 E9Document9 pagesTMP 37 E9FrontiersNo ratings yet

- 49 6 BeronskaDocument10 pages49 6 BeronskasaifbenNo ratings yet

- Mno2 Apl 1Document3 pagesMno2 Apl 1CHEMISTRYNo ratings yet

- Large Negative Thermal Expansion in The Cubic Phase of Camn ODocument6 pagesLarge Negative Thermal Expansion in The Cubic Phase of Camn OKamini GautamNo ratings yet

- Low-Density, Refractory Multi-Principal Element AlloysDocument13 pagesLow-Density, Refractory Multi-Principal Element AlloysMauricio RosasNo ratings yet

- ZnSwire-ribbon-JPCBDocument6 pagesZnSwire-ribbon-JPCBKrishnendu metiaNo ratings yet

- Generation of Copper, Nickel, and Cuni Alloy Nanoparticles by Spark DischargeDocument9 pagesGeneration of Copper, Nickel, and Cuni Alloy Nanoparticles by Spark DischargeThanh DinhNo ratings yet

- The Influence of Cooling Rate On The Microstructure and Phase Fraction of Gas Atomized NiAl3 Alloy Powders During Rapid SolidificationDocument7 pagesThe Influence of Cooling Rate On The Microstructure and Phase Fraction of Gas Atomized NiAl3 Alloy Powders During Rapid SolidificationJotaNo ratings yet

- Role of Sintering Temperature On The Phase Stability and Electrical Properties of 0.94 (K Na Nbo) - 0.06 (Lisbo) CeramicsDocument5 pagesRole of Sintering Temperature On The Phase Stability and Electrical Properties of 0.94 (K Na Nbo) - 0.06 (Lisbo) CeramicsprakashpaleiNo ratings yet

- Molecular Dynamic Study For Ultrathin Ni Fe Alloy: 3 M. D. Starostenkov M. M. AishDocument7 pagesMolecular Dynamic Study For Ultrathin Ni Fe Alloy: 3 M. D. Starostenkov M. M. AishIbrahim HasanNo ratings yet

- Temperature Changes of Copper Nanoparticle in 2014 Journal of Materials ProcDocument9 pagesTemperature Changes of Copper Nanoparticle in 2014 Journal of Materials ProcEdipo SantosNo ratings yet

- Thermal Conductivity of Zinc Oxide Micro - and NanoDocument4 pagesThermal Conductivity of Zinc Oxide Micro - and NanoMiki MikicNo ratings yet

- Thermo-Mechanical Analysis of Carbon Nanotube Based Functionally Graded Timoshenko BeamDocument44 pagesThermo-Mechanical Analysis of Carbon Nanotube Based Functionally Graded Timoshenko BeamajayNo ratings yet

- Mechanocaloric Materials For Solid-State Cooling 2015Document8 pagesMechanocaloric Materials For Solid-State Cooling 2015Jose MatutesNo ratings yet

- Articulo AlnicoDocument5 pagesArticulo Alnicojose baenaNo ratings yet

- Haruyama Etal 1993 SolarHeating OrtDocument12 pagesHaruyama Etal 1993 SolarHeating OrtLuciano del ValleNo ratings yet

- Materials Science & Engineering A: F. Mokdad, D.L. Chen, Z.Y. Liu, D.R. Ni, B.L. Xiao, Z.Y. MaDocument10 pagesMaterials Science & Engineering A: F. Mokdad, D.L. Chen, Z.Y. Liu, D.R. Ni, B.L. Xiao, Z.Y. Maפּואַ פּוגאַNo ratings yet

- Structural Transformation of Moo Nanobelts Into Mos NanotubesDocument7 pagesStructural Transformation of Moo Nanobelts Into Mos NanotubesSHUO SUNNo ratings yet

- Roy 2020Document7 pagesRoy 2020Agen KolarNo ratings yet

- Mössbauer Study On Martensite Phase in Ni 50 MN 36.5 Fe 0.5 57 SN 13 Metamagnetic Shape Memory AlloyDocument4 pagesMössbauer Study On Martensite Phase in Ni 50 MN 36.5 Fe 0.5 57 SN 13 Metamagnetic Shape Memory AlloyRicardo AlvesNo ratings yet

- Formation Structure and Magnetic Properties of PolDocument10 pagesFormation Structure and Magnetic Properties of Pol087Ervan PratamaNo ratings yet

- Article CIS 2021 21 pp.43-46Document4 pagesArticle CIS 2021 21 pp.43-46Maroš BobulaNo ratings yet

- Fe Ni Ti Alloy SystemsDocument14 pagesFe Ni Ti Alloy Systemssajjad moattarNo ratings yet

- 1.AirOxidationofFeCoNi BaseEqui MolarAlloysDocument24 pages1.AirOxidationofFeCoNi BaseEqui MolarAlloysWL JangNo ratings yet

- Hydrogen Storage in Solar Produced Single-Walled Carbon NanotubesDocument6 pagesHydrogen Storage in Solar Produced Single-Walled Carbon NanotubesMohammad Javad TavakkoliNo ratings yet

- Study of Ferromagnetic and Ferroelectric Properties of Nanocrystalline Bi MN ODocument11 pagesStudy of Ferromagnetic and Ferroelectric Properties of Nanocrystalline Bi MN ODeym GómezNo ratings yet

- Journal of The American Ceramic Society - November 1960 - LEE - Radiation Energy Transfer and Thermal Conductivity ofDocument14 pagesJournal of The American Ceramic Society - November 1960 - LEE - Radiation Energy Transfer and Thermal Conductivity ofamannigam19940914No ratings yet

- 1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 ParticlesDocument6 pages1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 Particlesyaswanth1992No ratings yet

- Biswas2011 Article Thermo-mechanicalAndExperimentDocument9 pagesBiswas2011 Article Thermo-mechanicalAndExperimentPardeepNo ratings yet

- Phase Diagram PMN PZ PTDocument6 pagesPhase Diagram PMN PZ PTAnaghaNo ratings yet

- Nickel and Iron Nano-Particles in Natural Rubber CompositesDocument6 pagesNickel and Iron Nano-Particles in Natural Rubber Compositeshoneywell123No ratings yet

- Kim2017 ODGREVANJEDocument23 pagesKim2017 ODGREVANJEAMS Lab.No ratings yet

- 10.1515 - MSP 2016 0027Document8 pages10.1515 - MSP 2016 0027G.L.R StudiosNo ratings yet

- Nickel Base Reformer TubesDocument8 pagesNickel Base Reformer TubesOwais MalikNo ratings yet

- Comparison of Experimental and Modelling Results of Thermal Properties in Cu-Aln Composite MaterialsDocument8 pagesComparison of Experimental and Modelling Results of Thermal Properties in Cu-Aln Composite MaterialsKamel FedaouiNo ratings yet

- 1 2960551 PDFDocument4 pages1 2960551 PDFRicardo AlvesNo ratings yet

- Hen - Effect of HeatDocument5 pagesHen - Effect of HeatGustavo FagundesNo ratings yet

- Ceramics Science and Technology, Volume 1: StructuresFrom EverandCeramics Science and Technology, Volume 1: StructuresRalf RiedelNo ratings yet

- Periodic Table of Elements W Atomic Mass PubChemDocument1 pagePeriodic Table of Elements W Atomic Mass PubChemImmaculada AcantoNo ratings yet

- W6 - Distillation UnitDocument36 pagesW6 - Distillation UnitRoza SavitriNo ratings yet

- 7 Corona: 7.1. Effect of Corona On Transmission LineDocument5 pages7 Corona: 7.1. Effect of Corona On Transmission LineParimal PatelNo ratings yet

- Pressure MeterDocument17 pagesPressure MeterRakesh7770No ratings yet

- 68 Multiple Choice Questions: No Answer GivenDocument18 pages68 Multiple Choice Questions: No Answer GivenAkram AlhaddadNo ratings yet

- Linear Viscoelastic BehaviorDocument2 pagesLinear Viscoelastic BehaviorKaustubh BhaveNo ratings yet

- 03 - Ans To Gaseous State Supplemtary QN - 2012Document4 pages03 - Ans To Gaseous State Supplemtary QN - 2012caspersoongNo ratings yet

- Section 1 - Reading Comprehension Read The Text Carefully and Answer The Questions That Follow. Choose The Most Appropriate AnswerDocument3 pagesSection 1 - Reading Comprehension Read The Text Carefully and Answer The Questions That Follow. Choose The Most Appropriate AnswerlenakaNo ratings yet

- Self-Reading - Fatigue Rainflow CountingDocument106 pagesSelf-Reading - Fatigue Rainflow CountingMilkiNo ratings yet

- Material Removal ProcessDocument25 pagesMaterial Removal ProcessisharaNo ratings yet

- Equinox International LTD - Stainless Steel - ST ST Corrosion Resistance - 106 PDFDocument2 pagesEquinox International LTD - Stainless Steel - ST ST Corrosion Resistance - 106 PDFeugenio.gutenbertNo ratings yet

- Questions of CEM PDFDocument2 pagesQuestions of CEM PDFAnonymous Anzt6fAeM100% (1)

- Sample Final Intern ReportDocument56 pagesSample Final Intern ReportBirhan SeteNo ratings yet

- Week 3-Design of One Way SlabDocument4 pagesWeek 3-Design of One Way SlabMAYHAY, ADRIAN PAULNo ratings yet

- Combined Use of Calcium Chloride and Fly Ash in Road Base StabilizationDocument10 pagesCombined Use of Calcium Chloride and Fly Ash in Road Base StabilizationGeorge SorosNo ratings yet

- Experiment 7 Chemistry IndicatorsDocument3 pagesExperiment 7 Chemistry IndicatorsNova MattisonNo ratings yet

- Aci sp-219-2004Document174 pagesAci sp-219-2004Abigael Valles RamirezNo ratings yet

- Catalogs: Material (Articles)Document3 pagesCatalogs: Material (Articles)NishanthanNo ratings yet

- A-Sub Structure: Work Shop Group-4Document19 pagesA-Sub Structure: Work Shop Group-4Ermiyas EndashawNo ratings yet

- Importat Question of Building ConstructionDocument19 pagesImportat Question of Building Constructionamol bardeNo ratings yet

- CH 3 - AE Analysis and Design of Two-Way SlabsDocument111 pagesCH 3 - AE Analysis and Design of Two-Way Slabsephrem100% (3)

- Siaran Khas 2 (SM) Dis 14Document32 pagesSiaran Khas 2 (SM) Dis 14Tengku Jalal Tengku Abu BakarNo ratings yet

- Fyp LatestDocument18 pagesFyp Latestnaveen vmaNo ratings yet

- SPC Company BrochureDocument22 pagesSPC Company BrochureDaivasigamaniNo ratings yet

- Acids and BasesDocument44 pagesAcids and BasesSai Sasivardhan GampaNo ratings yet

- On Bending, Drawing, Forming & Fine Blanking.Document145 pagesOn Bending, Drawing, Forming & Fine Blanking.Rasadnya SirNo ratings yet

- Study and Experimental Analysis On BitumenDocument7 pagesStudy and Experimental Analysis On BitumenIJRASETPublicationsNo ratings yet

- Ww15 Act Sludge 1 AkDocument5 pagesWw15 Act Sludge 1 AkDAHBIA AMROUCHENo ratings yet