Professional Documents

Culture Documents

PS PC200-8

PS PC200-8

Uploaded by

asvdfmcbdiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PS PC200-8

PS PC200-8

Uploaded by

asvdfmcbdiCopyright:

Available Formats

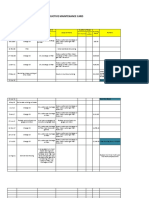

PERIODIC SERVICE SHEET Plan Date Day

PT UNITED TRACTORS

Bendili Site

KOMATSU EXCAVATOR PC 200 – 8

Unit

Unit No Date SMR

√ = Done Properly X = Not Yet Done Add = Add if needed (When Not In Servicing)

No Component & Item Service Job Goods No Qty 250 500 1000 2000 4000 5000 Type Of Service

Take the Following Oil Sample Before Carried Out Service

1 Engine Oil 799-801-1501 1

2 Hydraulic Oil 799-801-1501 1

3 Swing Machinery 799-801-1501 1

4 RH Final Drive Oil 799-801-1501 1

Fuel filter Engine Oil Filter

5 LH Final Drive Oil 799-801-1501 1

ENGINE GROUP

Hyd Oil Filter

1 Engine Oil Pan Change KGO EO SAE 30 DH 24 Liter

Refill Tube

2 Engine Oil Filter Change 6736 – 51 – 5142 1 Pcs

3 Engine Fuel Filter Change 6732 – 71 – 6111 1 Pcs

4 Engine Pre Fuel Filter Change 600 - 319 - 3610 1 Pcs

5 Corrosion Resistor Change 600 - 411- 1191 1 Pcs

6 Air Cleaner (Outer) Change Clean Clean Clean Drain Plug

7 Air Cleaner Assy Change 600 – 185 – 3100 1 Pcs Hyd Strainer

8 Water Separator Drain

9 Radiator , Oil Cooler , After Cooler & Condensor fin Clean

10 Radiator & Sub Tank Check/Refill If Required

Swing Pinion Grease Level

11 Turbocharger Play Check

12 Check Air intake & Exhaust piping clamp Retorque Hyd tank breather

13 Vibration Damper Check

14 Water Pump Check

15 Fan Pulley & Tention Pulley Check

Battery

16 AC V–Belt Adjust

17 Fan Belt tention Check / Adjust

18 Valve Clearance Adjust Initial Final Drive

19 Damper Oil Level Change Check Swing Oil

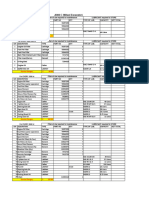

HYDRAULIC SYSTEM

1 Hydraulic Oil Change Komatsu HO46 135 Liter

2 Hydraulic Oil Filter Element Change 20Y – 60 – 71181 1 Pcs

3 Hydraulic Oil Filter Oring Change 07000 – 15195 1 Pcs

4 Hydraulic Tank Breather Change 20Y – 60 – 21470 1 Pcs Drain Plug

Swing Drain

5 Hydraulic Tank Strainer Clean

Swing System

1 Swing Machinery Oil Change KGO TO SAE 30 DH 7.1 Liter

2 Swing Pinion grease level Check NLGI – 2

AC Belt

3 Swing Circle Grease Lubricate NLGI – 2 Adjustment

Final Drive & Undercarriage

1 Final Drive Oil RH & LH Change KGO TO SAE 30 DH 3.3 Liter

2 Welding Structure of frame Check

3 Carrier Roller mounting bolt & condition Check

2 Track Roller mounting bolt & condition Check

4 Sprocket mounting bolt & condition Check

6 Front idler mounting bolt & condition Check Damper oil level

7 Track shoe & Track link condition Check

8 Track tention Check

THE OTHERS FLUID

1 Window Washer Refill Clean Water

2 AC Referigrant Check R 134 Filter AC

ELECTRIC SYSTEM & AC Radiator

1 Battery Electrolit Refill

2 Battery Terminal Check & Lub After Cooler

3 Electric Connector Check

4 AC Filter (Inside) Clean AC Condernsor

5 AC Filter (Outside) Clean

LUBRICATIONS

1 Boom cylinder foot pin ( 2 point ) Lubricate Grease

2 Boom foot pin ( 2 point ) Lubricate Grease

3 Boom cylinder rod end ( 2 point ) Lubricate Grease

4 Arm cylinder foot pin ( 1 point ) Lubricate Grease

5 Boom arm coupling pin ( 1 point ) Lubricate Grease

6 Arm cylinder rod end ( 1 point ) Lubricate Grease

7 Bucket cylinder foot pin ( 1 point ) Lubricate Grease

8 Arm & Link coupling pin ( 1 point ) Lubricate Grease

Service Man Approved

Mech UT Mech Custom SPV UT Kabag Custm SDH NFMC

You might also like

- Widmann Mig Tig Mma-160 ManualDocument24 pagesWidmann Mig Tig Mma-160 ManualCleive Santos100% (1)

- PM. Dozer D155A-6Document20 pagesPM. Dozer D155A-6Iqmal WahabNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamNo ratings yet

- CIS016 2 Assignment One 2016 17Document7 pagesCIS016 2 Assignment One 2016 17ProiectulTauNo ratings yet

- Andritz Decanter Centrifuges - BrochureDocument3 pagesAndritz Decanter Centrifuges - BrochureCentrifugal SeparatorNo ratings yet

- Service Sheet ScaniaDocument2 pagesService Sheet Scaniamiswansabani86No ratings yet

- WO Manual DZ-041 30-12-22Document1 pageWO Manual DZ-041 30-12-22Taufiq SetyaNo ratings yet

- Masterlist FiltersDocument17 pagesMasterlist FiltersncthanhckNo ratings yet

- Partes ServiciosDocument2 pagesPartes ServiciosAlejandro ValenzuelaNo ratings yet

- PM Kit Part Service KomatsuDocument3 pagesPM Kit Part Service KomatsuAndiNo ratings yet

- 140H GraderDocument1 page140H GraderMohamed SaiedNo ratings yet

- HINO FM 1000 HR Service SheetDocument7 pagesHINO FM 1000 HR Service SheetYudi AriantoNo ratings yet

- Maintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursDocument3 pagesMaintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursAsim Ghosh100% (1)

- PM Checklist ReportDocument3 pagesPM Checklist ReportSteven PanyalNo ratings yet

- RECOMENDED PART PS ALL UNIT Terbaru (Revisi)Document72 pagesRECOMENDED PART PS ALL UNIT Terbaru (Revisi)Abdul RohimNo ratings yet

- Productive Maintenance Card: Parts Replaced Time Reported Time FinishedDocument110 pagesProductive Maintenance Card: Parts Replaced Time Reported Time FinishedNestor LejarsoNo ratings yet

- R934 B (Hydraulic Excavator)Document2 pagesR934 B (Hydraulic Excavator)Saw LalsayNo ratings yet

- 14H GraderDocument1 page14H GraderMohamed SaiedNo ratings yet

- Double Drum Bomag BW 161 Ad 50Document4 pagesDouble Drum Bomag BW 161 Ad 50Mohamed SaiedNo ratings yet

- PMChecklist ReportDocument3 pagesPMChecklist Reportfauzi.i.simanjuntakNo ratings yet

- A944 C (Wheel Excavator) : Service Charges $ 60.00Document2 pagesA944 C (Wheel Excavator) : Service Charges $ 60.00sawbat880No ratings yet

- Maintenance Schedule: S.No. Items of Work KM MonthDocument1 pageMaintenance Schedule: S.No. Items of Work KM MonthErnan ConisllaNo ratings yet

- PM 2 (500 HOUR Interval) : ChecklistDocument2 pagesPM 2 (500 HOUR Interval) : ChecklistEdwin juanito gamarra serranoNo ratings yet

- PS PC300-8Document1 pagePS PC300-8asvdfmcbdiNo ratings yet

- PM 4 (2000 HOUR Interval) : ChecklistDocument3 pagesPM 4 (2000 HOUR Interval) : ChecklistWilliams ArayaNo ratings yet

- Pm. Dozer d85ssDocument20 pagesPm. Dozer d85ssIqmal WahabNo ratings yet

- Contoh Jadwal ServiceDocument4 pagesContoh Jadwal Serviceanwar.transportkpnNo ratings yet

- Daily Check ListDocument3 pagesDaily Check ListlehibyardNo ratings yet

- Draft Maintenance Record (Historical)Document1 pageDraft Maintenance Record (Historical)JohnNo ratings yet

- Bobcat S630Document5 pagesBobcat S630Mohamed SaiedNo ratings yet

- A900 C (Wheel Excavator) : Service Charges $ 60.00Document2 pagesA900 C (Wheel Excavator) : Service Charges $ 60.00yyewin491No ratings yet

- D 50 Lubrication - Fluid Maintenance ChartDocument2 pagesD 50 Lubrication - Fluid Maintenance Chartneymerjunior91No ratings yet

- PSCS Syz323 PDFDocument3 pagesPSCS Syz323 PDFTheo anggara kusumaNo ratings yet

- MEGA Series 16K-20K PMchartDocument1 pageMEGA Series 16K-20K PMchartJose GuerraNo ratings yet

- Double Drum Com hd110Document4 pagesDouble Drum Com hd110Mohamed SaiedNo ratings yet

- R944 B (Hydraulic Excavator)Document1 pageR944 B (Hydraulic Excavator)Saw LalsayNo ratings yet

- Periodical Service Scania P380: Maintenance SheetDocument2 pagesPeriodical Service Scania P380: Maintenance SheetWanda Panggih KurniawanNo ratings yet

- Perkin 2806 Mechanical Workshop ManualsDocument123 pagesPerkin 2806 Mechanical Workshop ManualsHarris Rao0% (1)

- PM Excavator 320D2Document2 pagesPM Excavator 320D2adinugroho100% (1)

- Double Drum Bomag BW 202 AD-4Document3 pagesDouble Drum Bomag BW 202 AD-4Mohamed SaiedNo ratings yet

- 7 Series Tractors 7715 and 7815 S N 070001 Brazil Replacement Parts GuideDocument3 pages7 Series Tractors 7715 and 7815 S N 070001 Brazil Replacement Parts GuidePinheiro WelintonNo ratings yet

- CAT - Recommended Spare PartsDocument1 pageCAT - Recommended Spare PartsregaraajaNo ratings yet

- ZX270-3 Maintenance PlannerDocument2 pagesZX270-3 Maintenance PlannerGee K ToubulukwaNo ratings yet

- Maintenance IntervalsDocument6 pagesMaintenance Intervalsuuganaa ugiNo ratings yet

- Rolls-Royce': Record of Temporary RevisionsDocument5 pagesRolls-Royce': Record of Temporary RevisionsAnonymous 298xlo3uUNo ratings yet

- Checklist All Free Service Kuzer E4Document1 pageChecklist All Free Service Kuzer E4ardians.bagusNo ratings yet

- Commercial N67 220 132 KWDocument2 pagesCommercial N67 220 132 KWEnzo SovittiNo ratings yet

- NH B90B, B90BLR - Fluids Specification & Maintenance ChartDocument5 pagesNH B90B, B90BLR - Fluids Specification & Maintenance ChartKristomiDerMarine-IngenieurNo ratings yet

- SP15Document5 pagesSP15mohitmishra9210No ratings yet

- R800LC-9 MaintananceDocument33 pagesR800LC-9 MaintananceJorge RojasNo ratings yet

- Water Pump 250 Hrs Service No Unit: Date: HM: ShiftDocument8 pagesWater Pump 250 Hrs Service No Unit: Date: HM: ShiftTLK ChannelNo ratings yet

- PM Vermeer T1255Document1 pagePM Vermeer T1255Rizal M. IqbalNo ratings yet

- Part Service & Urutan Service: Excavator @500 HMDocument1 pagePart Service & Urutan Service: Excavator @500 HMSutrisno PeralatanNo ratings yet

- 310G, 310SG and 315SG: As RequiredDocument2 pages310G, 310SG and 315SG: As Requiredp0t2g047No ratings yet

- Recommendation of Genuine Filter & Lubricants: LubricantDocument1 pageRecommendation of Genuine Filter & Lubricants: LubricantCucuk RajaNo ratings yet

- Inspection DT Scania 21633Document8 pagesInspection DT Scania 21633Sarohman RohmanNo ratings yet

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- CAT 725B Daily Service SheetDocument1 pageCAT 725B Daily Service SheetJayantha parakrama ThennakoonNo ratings yet

- Xrvs 1000 Service PDFDocument10 pagesXrvs 1000 Service PDFpowermanagerNo ratings yet

- Service & Maintenance Doosan Dl420: Consumable PartsDocument1 pageService & Maintenance Doosan Dl420: Consumable PartsMahmmod Al-Qawasmeh0% (1)

- Service DOOSAN DL420Document1 pageService DOOSAN DL420Mahmmod Al-QawasmehNo ratings yet

- Service DOOSAN DL420Document1 pageService DOOSAN DL420Mahmmod Al-QawasmehNo ratings yet

- Parts and Service Interval DD90HF M@SH PDFDocument2 pagesParts and Service Interval DD90HF M@SH PDFjrincon26No ratings yet

- Chap 1-5 PDFDocument29 pagesChap 1-5 PDFKatana Jijtsu100% (1)

- Pre Feasibility Report For Welspun Iron & Steel Pvt. LimitedDocument25 pagesPre Feasibility Report For Welspun Iron & Steel Pvt. LimitedkalaiNo ratings yet

- Trenchless Technologies ManualDocument186 pagesTrenchless Technologies ManualLuis Fernando Leon Lecca100% (1)

- Chapter 3 - Water Transport KeralaDocument27 pagesChapter 3 - Water Transport KeralaReshma GeorgiNo ratings yet

- Polygonal ModelingDocument12 pagesPolygonal ModelingRex Shadnie LiuNo ratings yet

- Infocus 930 920 900 PDFDocument85 pagesInfocus 930 920 900 PDFspeedyeduNo ratings yet

- vnx.su дачия 1304-1305-1307 пикап ENGINE-F8QDocument620 pagesvnx.su дачия 1304-1305-1307 пикап ENGINE-F8Qcvn2No ratings yet

- Catalizzatore Pasta 11768Document6 pagesCatalizzatore Pasta 11768sachinvijanNo ratings yet

- 5-LCC Mineria PDFDocument19 pages5-LCC Mineria PDFCatalina GrimaldosNo ratings yet

- 2089-WAOC AD 2-1 SD AD 2-6Document6 pages2089-WAOC AD 2-1 SD AD 2-6Verdy TariganNo ratings yet

- Encryption and Decryption Process Using Quaternion and Farey Fractions For Secure TransmissionDocument9 pagesEncryption and Decryption Process Using Quaternion and Farey Fractions For Secure TransmissionIRJCS-INTERNATIONAL RESEARCH JOURNAL OF COMPUTER SCIENCENo ratings yet

- 11 TFS Toyofood-S EngDocument2 pages11 TFS Toyofood-S EngHalimNo ratings yet

- ECE UGC Approved Journal ListDocument74 pagesECE UGC Approved Journal Listautopsy_14No ratings yet

- Literature Supplement: Form No.: 160.00-M1 (LS03) 801Document2 pagesLiterature Supplement: Form No.: 160.00-M1 (LS03) 801Azar TajNo ratings yet

- Data Onboarding Cheat Sheet v2Document2 pagesData Onboarding Cheat Sheet v2bobwillmoreNo ratings yet

- ZGM ARMA 2 Map Making Tutorial PART 1&2Document27 pagesZGM ARMA 2 Map Making Tutorial PART 1&2James ChambersNo ratings yet

- Chapter 27 Well CompeletionDocument7 pagesChapter 27 Well CompeletionMustapha BouregaaNo ratings yet

- Typical Slab DetailsDocument1 pageTypical Slab DetailsSrigopi Chand RamineniNo ratings yet

- Hotel Management Database ProjectDocument45 pagesHotel Management Database ProjectFarrukh Tahir100% (1)

- Pamphlet - SO2 and ScrubbersDocument2 pagesPamphlet - SO2 and ScrubberssandyNo ratings yet

- 3M Filter Requirement - 3064 MisfahDocument3 pages3M Filter Requirement - 3064 MisfahHari Hara SuthanNo ratings yet

- Ginga Saker (IMO 9258155) PSC Inspection at Antwerp, Belgium On 09 February 2024Document3 pagesGinga Saker (IMO 9258155) PSC Inspection at Antwerp, Belgium On 09 February 2024cicilhar89No ratings yet

- PTB-2 Edtn 2009 PDFDocument244 pagesPTB-2 Edtn 2009 PDFHenry Javier Ríos100% (6)

- Agreed Site Measurement RecordDocument40 pagesAgreed Site Measurement Recordලහිරු විතානාච්චිNo ratings yet

- Worksheet On Kinetic Particle Theory G8Document4 pagesWorksheet On Kinetic Particle Theory G8sultanaNo ratings yet

- S+G+4-Footing and Column ScheduleDocument1 pageS+G+4-Footing and Column ScheduleAbhishek ChappaNo ratings yet

- 6 Evaluation of Slope StabilityDocument17 pages6 Evaluation of Slope StabilitytsuakNo ratings yet