Professional Documents

Culture Documents

Ab 036262 002 - 05312022

Ab 036262 002 - 05312022

Uploaded by

JAWAHAR TOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ab 036262 002 - 05312022

Ab 036262 002 - 05312022

Uploaded by

JAWAHAR TCopyright:

Available Formats

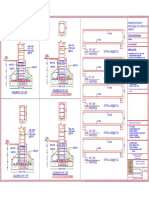

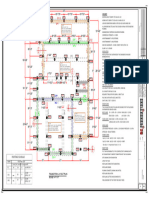

PIPE DIMENSION SLEEVE DIMENSION

NOTES:

NPS t ts R1 L

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

6" 12 14 88 296

1. SLEEVES SHALL BE MADE IN TWO HALVES. THE

8" 12.4 14 113 374

LONGITUDINAL WELD JOINT SIDES SHALL BE

10" 12.7 14 140 459 BEVELED TO 37 deg. +/- 2.5 deg., WITHOUT

"L" MEAN ARC LENGTH 12" 12.9 14 165 537 A LAND.

OF SLEEVE HALVE 14" 13 14 181 588 2. SLEEVE MATERIAL SHALL BE EQUIVALENT TO API 5L

13 GR. X-60 MATERIAL, HAVING A SPECIFIED MINIMUM YIELD

16" 14 207 669

C

STRENGTH (SMYS) OF NOT LESS THAN413.7 MPA.

18" 15 16 232 751

ASTM A537 CLASS 2 IS ACCEPTABLE. EXPANDED

20" 15 16 257 830 STEEL IS NOT ACCEPTABLE. NO SPECIAL

22" 16 911 IMPACT TEST REQUIREMENTS ARE NEEDED.

ts 15.1 283

SEE DETAIL "J"

24" 15.2 16 308 990 3. THE PIPE SIZE FOR WHICH THE SLEEVE IS

(TYP.)

1.6

1

1.6

R 26" 15.3 16 334 1072 INTENDED SHALL BE STENCILED ON THE OUTSIDE

3000 ( + 100 ) 28" 15.3 359 1150

SURFACE OF EACH SLEEVE HALF.

t ts - 16

30" 15.4 16 384 1229 4. ALL WELDING AND WELDER QUALIFICATIONS

SHALL BE IN ACCORDANCE WITH EITHER ASME

31" 15.4 16 397 1269

SECT. IX OR API 1104.

32" 15.4 16 410 1310

51 H 51 34" 15.4 16 435 1389

5. RUN-OUT TABS SHALL BE FABRICATED FROM LOW

CARBON STEEL MATERIAL. THEIR THICKNESS SHALL BE

36" 15.5 16 461 1472 EQUAL TO THE SLEEVE THICKNESS. THE WELD JOINT

38" 15.5 16 486 1549 SIDE SHALL BE BEVELED TO 37 deg. +/- 2.5 deg.,

C C

40" 15.5 16 512 1631 WITHOUT A LAND. RUN-OUT TABS SHALL BE TACK

WELDED INTO PLACE USING LOW HYDROGEN

42" 15.5 16 537 1709

SEE DETAIL "K" ELECTRODES.

46" 16.5 17 588 1871

H (TYP.) 6. BACKING STRIPS SHALL BE FABRICATED FROM LOW

48" 16.5 17 613 1950

1.6

1.6

CARBON STEEL MATERIAL, NOT TO EXCEED 1.6mm IN

56" 20.4 21 715 2276 THICKNESS x 25mm WIDE. BACKING STRIP LENGTH

60" SHALL EXTEND TO THE ENTIRE LENGTH OF SLEEVE

20.4 21 766 2437

AND RUN-OUT TABS. BACKING STRIPS SHALL BE

1 TACK WELDED INTO PLACE USING LOW HYDROGEN

PLAIN ENDS R

ELECTRODES.

(TYP.)

7. ALL DIMENSIONS SHALL BE IN MILLIMETERS (mm),

UNLESS NOTED OTHERWISE. EXCEPT FOR THE

LEGEND :

ts SLEEVE AND BACKING STRIP THICKNESS, ALL OTHER

t s

= THICKNESS OF SLEEVE DIMENSIONAL TOLERANCES SHALL BE +/- 2mm.

t = THICKNESS OF PIPE

"L" MEAN ARC LENGTH

OF SLEEVE HALVE

1.6

37°

REFERENCE DRAWINGS

PACKING DETAILS FOR P/L

DETAIL "J" REPAIR SLEEVES AB-036262 SHT. 003

( PRESSURE CONTAINING )

TYPICAL BEVEL W/O LAND

FOR LONGITUDINAL SEAMS INSTALLATION OF PIPELINE

REPAIR SLEEVES AB-036262 SHT. 001

( PRESSURE CONTAINING )

t

s

1 FORMERLY DWG. AD-036786 SHT. 001

5

1.6 x 25mm BACK-UP STRIP

(LOW CARBON STEEL) SLEEVE

(SEE NOTE 6)

|

RUN-OUT TABS

C (LOW CARBON STEEL)

CUT WIDTH TO SUIT.

BEVEL 37° + 2.5° SCALE:

-

( SEE NOTE 5 )

R1

REVISION VALIDATION

THIS REVISION NO. 03 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

TACK WELD TO BACKING STRIP TO SLEEVE REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

RUN-OUT THE ENTIRE 30027516-0522-013

LOWER HALF

LENGTH OF TABS

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

( SEE NOTE 6 ) (DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

MSK KMM MSK KMM

TACK WELDS 05/24/22 05/24/22 05/24/22 05/24/22

(TYP.) REV.NO. DATE REVISION DESCRIPTION

03 05/22/22 REVISION UPDATE

SECTION H-H JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

30027516 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

FABRICATION OF PIPELINE REPAIR SLEEVES STD

DETAIL "K" ( PRESSURE CONTAINING )

RUN-OUT TABS (TYP.) STANDARD DRAWING

(SEE NOTE 5) STD.DWG SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

990 L AB-036262 002 03

Saudi Aramco 2634 ENG. (05/05)

RESTRICTED VECTOR CADD-05

You might also like

- Low-Relaxation, Seven-Wire Steel Strand For Prestressed ConcreteDocument5 pagesLow-Relaxation, Seven-Wire Steel Strand For Prestressed Concreteist93993100% (5)

- DT4 (88 98)Document41 pagesDT4 (88 98)cristicozma76100% (1)

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- Vernacular Architecture of The Himalayan Region in NepalDocument55 pagesVernacular Architecture of The Himalayan Region in NepalSwastika Regmi53% (15)

- Arnes Paccar mx13 2017Document10 pagesArnes Paccar mx13 2017Adderly Chinchero Torres100% (3)

- Pilot Operations Handbook C182 (1970-182N)Document44 pagesPilot Operations Handbook C182 (1970-182N)Fabrício Torres PeixotoNo ratings yet

- SN047a - Simplified Approach To The Selection of Equivalent Horizontal ForcesDocument10 pagesSN047a - Simplified Approach To The Selection of Equivalent Horizontal ForcesJohn WoodsNo ratings yet

- Fatigue AssessmentDocument142 pagesFatigue AssessmentRamchandraNo ratings yet

- T'boli HouseDocument18 pagesT'boli HouseRojun Aranas75% (4)

- PlanoDocument1 pagePlanoYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- Hra Construction SDN BHD: A5, Tingkat 1B, Lorong Tun Ismail 6, Sri Dagangan 25000 Kuantan Pahang Darul MakmurDocument1 pageHra Construction SDN BHD: A5, Tingkat 1B, Lorong Tun Ismail 6, Sri Dagangan 25000 Kuantan Pahang Darul MakmurAnas SuhaibNo ratings yet

- ITEM 1 - TBV-600LB-2in-WCB-SS316-RF-Lever - PTFEDocument1 pageITEM 1 - TBV-600LB-2in-WCB-SS316-RF-Lever - PTFEsatphoenixNo ratings yet

- DS 14NHG28Document2 pagesDS 14NHG28M Ferry AnwarNo ratings yet

- 11 ShopDocument1 page11 ShopKundan SinghNo ratings yet

- KORME Atyrau 2023Document1 pageKORME Atyrau 202364y27f4wwtNo ratings yet

- Planos de Sistema MultiplexadoDocument7 pagesPlanos de Sistema MultiplexadoElver Tintaya MamaniNo ratings yet

- Pump Skid (With Boiler) - Rev-1 - Apr-15-2016Document3 pagesPump Skid (With Boiler) - Rev-1 - Apr-15-2016Carlos EafNo ratings yet

- Pulido Marina Ar 2Document1 pagePulido Marina Ar 2kira ribetNo ratings yet

- 1967 C150G Owners Manual PDFDocument28 pages1967 C150G Owners Manual PDFalexred89No ratings yet

- Construction of Proposed D.M. Office at Panipat: STPS 4L-8Ø@6"C/C 18" X 30" InvertedDocument1 pageConstruction of Proposed D.M. Office at Panipat: STPS 4L-8Ø@6"C/C 18" X 30" InvertedAshwin RamNo ratings yet

- MOUNTING STRAINER JAMUR Rev1Document1 pageMOUNTING STRAINER JAMUR Rev1Ranggi WandhikaNo ratings yet

- 37 Valley DetailDocument1 page37 Valley DetailAhmed Saber NassarNo ratings yet

- E - TBV-600LB-6in To 12in-WCB-SS316-RF-GearDocument1 pageE - TBV-600LB-6in To 12in-WCB-SS316-RF-Gearrashid kNo ratings yet

- Adobe Scan 16-Jul-2022Document1 pageAdobe Scan 16-Jul-2022Sai RamNo ratings yet

- CB150 RFQ002Document20 pagesCB150 RFQ002downloadgame151993No ratings yet

- Parts List: Replacement Parts Steerable Suspension Systems ST and PriorDocument20 pagesParts List: Replacement Parts Steerable Suspension Systems ST and PriorFilip FaustNo ratings yet

- Ac 036660 003 - 05312022Document1 pageAc 036660 003 - 05312022JAWAHAR TNo ratings yet

- Detail Center Line PlanDocument1 pageDetail Center Line Planibrahim shadabNo ratings yet

- Accuron 7200Document8 pagesAccuron 7200von_WerraNo ratings yet

- Pages From Hs 6097 Shop Order Rev eDocument1 pagePages From Hs 6097 Shop Order Rev ekennymagallanesNo ratings yet

- Tolerances: RWP SCO .X .XX .XXX ANGLE 0 30' Fractions 1/4" Third Angle ProjectionDocument1 pageTolerances: RWP SCO .X .XX .XXX ANGLE 0 30' Fractions 1/4" Third Angle ProjectionJorge OrihuelaNo ratings yet

- J. H. Fletcher & Co.: Cj151E Face DrillDocument2 pagesJ. H. Fletcher & Co.: Cj151E Face DrilljiaozhongxingNo ratings yet

- Hig Lower 38 WestDocument4 pagesHig Lower 38 WestShivani SoniNo ratings yet

- Kapasia Technical MargedDocument7 pagesKapasia Technical MargedJobair AlamNo ratings yet

- Weld Map of Well 32 FLDocument13 pagesWeld Map of Well 32 FLArfanAliNo ratings yet

- 300 - Three Phase - 14-inch Spacer Cable Tangent Bracket, Tangent and Angles Up to 5°Document2 pages300 - Three Phase - 14-inch Spacer Cable Tangent Bracket, Tangent and Angles Up to 5°hugo arroyoNo ratings yet

- Fmo Oh1168Document3 pagesFmo Oh1168venkatesh.gandhi91No ratings yet

- Witt (BTJ) - Sultan Iskandar MudaDocument11 pagesWitt (BTJ) - Sultan Iskandar MudaSmart TvNo ratings yet

- 145 KV Sf6 Circuit Breaker H'Mu NDocument15 pages145 KV Sf6 Circuit Breaker H'Mu NQuang NguyenNo ratings yet

- Typ 10 concrete Base (002)Document2 pagesTyp 10 concrete Base (002)Mohamed SitayebNo ratings yet

- Ad 036023 001Document1 pageAd 036023 001Abu Anas M.SalaheldinNo ratings yet

- Train 1 - PGADocument1 pageTrain 1 - PGAToniNo ratings yet

- ABSto BrakeDocument3 pagesABSto BrakeManuel MoralesNo ratings yet

- ANNAVARAM FLOOR PLAN - RevDocument1 pageANNAVARAM FLOOR PLAN - RevakshayatejomurthulaNo ratings yet

- R 140 Antenna Tuner Schema f1frv Rev 2d 918Document6 pagesR 140 Antenna Tuner Schema f1frv Rev 2d 918alibob78No ratings yet

- Singl Line Diagram Inline Shredder Motor (Rev.2) 19-10-2012-Fiberizer MotorDocument1 pageSingl Line Diagram Inline Shredder Motor (Rev.2) 19-10-2012-Fiberizer MotorBabiker ElrasheedNo ratings yet

- Powermax 1650 MTBDocument2 pagesPowermax 1650 MTBSahin CncNo ratings yet

- Model 3Document1 pageModel 3Bocah KampusNo ratings yet

- Adobe Scan 02-Aug-2023Document3 pagesAdobe Scan 02-Aug-2023PrincE ZarTasHNo ratings yet

- Renold Chain Flightbar Assy Ecm-20226Document1 pageRenold Chain Flightbar Assy Ecm-20226tajudin tajudinNo ratings yet

- SK-106-00 10inch 150lbs Reva02 PDFDocument3 pagesSK-106-00 10inch 150lbs Reva02 PDFBruno GonçalvesNo ratings yet

- Footing Plan FDocument1 pageFooting Plan Fsujan pokhrelNo ratings yet

- Regulator Valve Pressure KoomeyDocument2 pagesRegulator Valve Pressure KoomeyJuan Sebastian Diaz CuadrosNo ratings yet

- Aero-1000-5204-P (Tokheim)Document1 pageAero-1000-5204-P (Tokheim)Nikhil KeniNo ratings yet

- MH - Ad-2.mhlm Iac Rwy22 Ils ZDocument2 pagesMH - Ad-2.mhlm Iac Rwy22 Ils ZNelson HernandezNo ratings yet

- Harn - Allison 4th Gen, Dash P92-3018 - 01: VAR Option Omit Connectors Omit WiresDocument3 pagesHarn - Allison 4th Gen, Dash P92-3018 - 01: VAR Option Omit Connectors Omit WiresMohanad MHPSNo ratings yet

- Double and Single Barrel Box CulvertDocument10 pagesDouble and Single Barrel Box Culvertronulfo fabulaNo ratings yet

- Electrical Schematic NXG Tls PF2 St3a 130HP ENGINE 15 July 2016Document21 pagesElectrical Schematic NXG Tls PF2 St3a 130HP ENGINE 15 July 2016Carlos veraNo ratings yet

- Air Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerDocument1 pageAir Flow Accumulator Granulator Drum Granulator Hose Ammonia SpargerBharathiNo ratings yet

- Ldjsij V Si Ds Fy, Ekud Fofunszó RVH : Standard Specification For Scraper Traps (Onshore)Document8 pagesLdjsij V Si Ds Fy, Ekud Fofunszó RVH : Standard Specification For Scraper Traps (Onshore)resp-ectNo ratings yet

- Column & Foundation DetailsDocument1 pageColumn & Foundation DetailsSURAJ SINHANo ratings yet

- CombinepdfDocument3 pagesCombinepdfNesreen Ahmed NaoumNo ratings yet

- 1Document1 page1Nesreen Ahmed NaoumNo ratings yet

- 4 Left EleDocument1 page4 Left ElemdNo ratings yet

- Site PlanDocument1 pageSite Planengr jaleelNo ratings yet

- Valves AssignmentDocument16 pagesValves AssignmentAdil Jutt GNo ratings yet

- Torts Digests 2Document30 pagesTorts Digests 2D De LeonNo ratings yet

- Structural Steel Load and Resistance Factor Design Short VersionDocument8 pagesStructural Steel Load and Resistance Factor Design Short Versionjack.simpson.changNo ratings yet

- Design of Columns To EurocodeDocument19 pagesDesign of Columns To EurocodeKasun Karunaratne92% (13)

- Overview of Heat Pump TechnologiesDocument59 pagesOverview of Heat Pump Technologiesslobo187100% (1)

- Link-Belt: Cylindrical Roller BearingsDocument32 pagesLink-Belt: Cylindrical Roller BearingsHendra GunawanNo ratings yet

- Concrete Morter Cube QC 452 - 2, 7, 28 D - Strength 15-10-2020 PDFDocument1 pageConcrete Morter Cube QC 452 - 2, 7, 28 D - Strength 15-10-2020 PDFjajajajNo ratings yet

- The Bank of China TowerDocument4 pagesThe Bank of China TowerTasneem BarhamNo ratings yet

- Prefabricated Structures PDFDocument51 pagesPrefabricated Structures PDFAlex Christopher64% (14)

- Borehole InstallationDocument1 pageBorehole InstallationthomasNo ratings yet

- Manning's N ValuesDocument4 pagesManning's N ValuesMark Jayson PortarcosNo ratings yet

- Precast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingDocument4 pagesPrecast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingGan Chin PhangNo ratings yet

- Bidder'S Work Plan: Al-Janadriyah Exhibition Facility, Ar-RiyadhDocument16 pagesBidder'S Work Plan: Al-Janadriyah Exhibition Facility, Ar-RiyadhJonald DagsaNo ratings yet

- For Rooms Below 32F Site Conditions 3x5x3.5: Load Calculation FormDocument4 pagesFor Rooms Below 32F Site Conditions 3x5x3.5: Load Calculation FormKarthik HegdeNo ratings yet

- Nanawall HSWDocument15 pagesNanawall HSWAli SahibzadaNo ratings yet

- SyllabusDocument1 pageSyllabusKausalya PurushothamanNo ratings yet

- Roofing ShinglesDocument4 pagesRoofing ShinglesFaizal HaziziNo ratings yet

- Syllabus - PGDIDCDocument38 pagesSyllabus - PGDIDCAFNA HASEEBNo ratings yet

- Koh Pich Construction Company Cambodia-China Polytechnic University Daily Activities ReportDocument7 pagesKoh Pich Construction Company Cambodia-China Polytechnic University Daily Activities ReportNhoek RenNo ratings yet

- Preheater DesignDocument6 pagesPreheater DesignAlejandroPáramoFandiñoNo ratings yet

- BWappendix A1Document9 pagesBWappendix A1Ahmed KhanNo ratings yet

- Chem Tech - 300 400 450 500 - DatasheetDocument4 pagesChem Tech - 300 400 450 500 - DatasheetDony IPNo ratings yet

- A Project Report ON: Mr. Pravin Patil Mr. Amol Chavan Mr. Shrikant UbareDocument84 pagesA Project Report ON: Mr. Pravin Patil Mr. Amol Chavan Mr. Shrikant UbarePradeepLokhandeNo ratings yet

- WSI BS Stuffing BoxesDocument1 pageWSI BS Stuffing Boxeshenry mataNo ratings yet