Professional Documents

Culture Documents

EPA HQ OAR 2002 0037 0710 - Attachment - 1

EPA HQ OAR 2002 0037 0710 - Attachment - 1

Uploaded by

pmuhammad.r.y.2011Copyright:

Available Formats

You might also like

- Waukesha Gas Engines VHP Series Four P9394GSIDocument2 pagesWaukesha Gas Engines VHP Series Four P9394GSIrohizat0% (1)

- 2009 Ajax CatalogDocument88 pages2009 Ajax Cataloglemiis93No ratings yet

- Relief Systems - Introduction 2019Document16 pagesRelief Systems - Introduction 2019S M KumarNo ratings yet

- Jeffrey Ifft - Final Southerly GUS OWEA 20170612Document29 pagesJeffrey Ifft - Final Southerly GUS OWEA 20170612Felipe BrainNo ratings yet

- To Sec7 TOC: Recovery Sequence When TD Cleaning Brush Cleaning Sequences Are Suspended. TD Cleaning SequenceDocument1 pageTo Sec7 TOC: Recovery Sequence When TD Cleaning Brush Cleaning Sequences Are Suspended. TD Cleaning SequencePhong DoNo ratings yet

- Tt04-Sanitation - TIbarDocument22 pagesTt04-Sanitation - TIbarEmilia BeloNo ratings yet

- SATIP-K-001-05 - Chilled Water System Rev 7Document3 pagesSATIP-K-001-05 - Chilled Water System Rev 7RAMAKRISHNANo ratings yet

- Blue Baleen PreConditioner PC - PSST1301-UKDocument2 pagesBlue Baleen PreConditioner PC - PSST1301-UKvonksvenomNo ratings yet

- SATIP K 001 05 Chilled Water SystemDocument3 pagesSATIP K 001 05 Chilled Water Systemimrankhan220% (1)

- GS12 SPECIAL PROCESSES - JC01 RevisiDocument20 pagesGS12 SPECIAL PROCESSES - JC01 RevisiNathallyia InasNo ratings yet

- SATIP-P-116-03 Rev 1Document4 pagesSATIP-P-116-03 Rev 1Ahmed GamalNo ratings yet

- SATIP-P-113-03 Rev 7 FinalDocument5 pagesSATIP-P-113-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Major Work DoneDocument2 pagesMajor Work Donerabi4457No ratings yet

- Proses Bisnis RefineryDocument10 pagesProses Bisnis RefineryM. Fadhli Cesar KNo ratings yet

- BOQ 1x80 MW Dariba HZL Captive Power PlantDocument8 pagesBOQ 1x80 MW Dariba HZL Captive Power Plantm 418No ratings yet

- Instruction For HP-SCRDocument48 pagesInstruction For HP-SCRboris345678No ratings yet

- Dav PVC Tape Project Piping Testing & System Handover Schedule (Rev.0)Document1 pageDav PVC Tape Project Piping Testing & System Handover Schedule (Rev.0)PHAM PHI HUNGNo ratings yet

- HPHT Intern ReportDocument40 pagesHPHT Intern ReportSURYA VENKATA SAINADH50% (2)

- Fmea of Co Air Conditioning Systems: by Dr.-Ing. Ulrich Hussels Risa Sicherheitsanalysen GMBH, GermanyDocument13 pagesFmea of Co Air Conditioning Systems: by Dr.-Ing. Ulrich Hussels Risa Sicherheitsanalysen GMBH, GermanykaimanwatsoNNo ratings yet

- Big Orange DP Fmea Rev e PDFDocument62 pagesBig Orange DP Fmea Rev e PDFAndrzej StepienNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNo ratings yet

- Saep 327Document14 pagesSaep 327AbdullahNo ratings yet

- Karnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemDocument7 pagesKarnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemJahangir AlamNo ratings yet

- Storage Tank Hydrotest ProcedureDocument16 pagesStorage Tank Hydrotest ProcedureAhmad AltaieNo ratings yet

- Control Valves Data Sheet: K9 S.P.A. - ItalyDocument11 pagesControl Valves Data Sheet: K9 S.P.A. - ItalyAhmadNo ratings yet

- AKW9 Instruction Manual PIM00364CDocument52 pagesAKW9 Instruction Manual PIM00364Cma7moud.3ttiaNo ratings yet

- 0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFDocument38 pages0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFMark InnesNo ratings yet

- Safia Reference ListDocument4 pagesSafia Reference Listxtrooz abi100% (1)

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 30-Apr-13 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SATIP-A-104-01 Rev 8high Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Ponds FinalDocument2 pagesSATIP-A-104-01 Rev 8high Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Ponds FinalTito GarciaNo ratings yet

- MAR-FO-141-EN-1 ODSC - Dry Dock - ToDoListDocument6 pagesMAR-FO-141-EN-1 ODSC - Dry Dock - ToDoListNarvalNo ratings yet

- 9 - CP22 - HSE LogDocument6 pages9 - CP22 - HSE Logfaisal nadeemNo ratings yet

- NMDC-WABAG-54-05-15-BE-1153-R2 - Process Design Basis - APPDocument31 pagesNMDC-WABAG-54-05-15-BE-1153-R2 - Process Design Basis - APPneeraj1mishraNo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument7 pagesSaudi Aramco Typical Inspection PlansajidNo ratings yet

- Tab For PrintingDocument2 pagesTab For PrintingRafunzel Pe BandoquilloNo ratings yet

- Jadwal PekerjaanDocument1 pageJadwal Pekerjaanwahyu hidayatNo ratings yet

- C04-E02 Rev 2 Dec 2014 Containment For Storage Tanks N PondsDocument18 pagesC04-E02 Rev 2 Dec 2014 Containment For Storage Tanks N Pondsryann mananquilNo ratings yet

- Satip D 100 01Document11 pagesSatip D 100 01Mirza BaigNo ratings yet

- Onepage QcstoryDocument1 pageOnepage QcstoryRS MANIKANDANNo ratings yet

- Report ViewerDocument13 pagesReport Viewertrivtt5096No ratings yet

- D0000 Asset Drawing Numbering SystemDocument70 pagesD0000 Asset Drawing Numbering SystemcoollhandNo ratings yet

- TQ - Technical Query Tracking ListDocument9 pagesTQ - Technical Query Tracking ListSyerifaizal Hj. MustaphaNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- Lars Wadsr #13 NewDocument2 pagesLars Wadsr #13 NewLarsen Verlo De CastroNo ratings yet

- Gac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDocument3 pagesGac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDipayan DasNo ratings yet

- Lecture 25 CANDU 9 Safety and LicensabilityDocument28 pagesLecture 25 CANDU 9 Safety and LicensabilityLazarescu ElenaNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet

- SATIP-A-104-01 High Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation PondsDocument10 pagesSATIP-A-104-01 High Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Pondsjohn ajitNo ratings yet

- Qav Observation Closer Sheet FormatDocument1 pageQav Observation Closer Sheet FormatDEVENDERNo ratings yet

- EDC DTS MV009 Surge ArrestersDocument18 pagesEDC DTS MV009 Surge ArrestersJoe bilouteNo ratings yet

- SATIP-P-104-02 Rev 7 FinalDocument3 pagesSATIP-P-104-02 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- GT L.O CCWP Flushing PPT r1Document23 pagesGT L.O CCWP Flushing PPT r1Deffous AbdelhadiNo ratings yet

- Atac 113 Pfmea R10 IatfDocument50 pagesAtac 113 Pfmea R10 IatfAzlan MustaphaNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalpravinNo ratings yet

- Satip X 600 02Document15 pagesSatip X 600 02spravin231No ratings yet

- Maintenance Harian ADVIA Ok PrintDocument2 pagesMaintenance Harian ADVIA Ok PrintBaiq MayaNo ratings yet

- 34 - Presentation For IAPWS Workshop - Gabriel NicolaidesDocument21 pages34 - Presentation For IAPWS Workshop - Gabriel NicolaidesNoumanIhsanNo ratings yet

- CV2024 EnglishDocument1 pageCV2024 Englishmamadou ndiaye mamboundouNo ratings yet

- A Hierarchy of Turing Degrees: A Transfinite Hierarchy of Lowness Notions in the Computably Enumerable Degrees, Unifying Classes, and Natural Definability (AMS-206)From EverandA Hierarchy of Turing Degrees: A Transfinite Hierarchy of Lowness Notions in the Computably Enumerable Degrees, Unifying Classes, and Natural Definability (AMS-206)No ratings yet

- Sim Power System 1Document70 pagesSim Power System 1Mahmoud ChihebNo ratings yet

- Gradually Varied Flow Equation IsDocument5 pagesGradually Varied Flow Equation IsRefisa JiruNo ratings yet

- Kriwan Overload Module - InT369-DiagnoseDocument2 pagesKriwan Overload Module - InT369-DiagnoseDaniel PertuzNo ratings yet

- Turbine WakeDocument19 pagesTurbine Wakeabraham_imam_muttaqinNo ratings yet

- ELBMT50 ch4 140907Document57 pagesELBMT50 ch4 140907Nilesh NarkhedeNo ratings yet

- ABB MV-LV TransformerDocument44 pagesABB MV-LV Transformeryarafat007No ratings yet

- Distillation PrinciplesDocument71 pagesDistillation PrinciplesRaghu Kohli100% (1)

- Automatic Power Factor Correction2Document40 pagesAutomatic Power Factor Correction2Lynn LucyNo ratings yet

- Vitodens 100 W Service InstructionsDocument100 pagesVitodens 100 W Service InstructionsbruatiNo ratings yet

- Photovoltaic Maximum Power Point Tracking Under Fast Varying of Solar RadiationDocument8 pagesPhotovoltaic Maximum Power Point Tracking Under Fast Varying of Solar Radiationvofemoj676No ratings yet

- Lanka Electicity Company Training Report Power DistributionDocument44 pagesLanka Electicity Company Training Report Power DistributionShashini MaldeniyaNo ratings yet

- Hantek 1008C USB 8CH Automotive Diagnostic Oscilloscope DAQ Program GeneratorDocument7 pagesHantek 1008C USB 8CH Automotive Diagnostic Oscilloscope DAQ Program GeneratorMohamed Wahieb100% (1)

- Operator'S Manual LP3001-1: Grease Pump System LP3001-1, LP3008-1Document2 pagesOperator'S Manual LP3001-1: Grease Pump System LP3001-1, LP3008-1jon fredyNo ratings yet

- Analisis Sootblower Terhadap Head TransferDocument5 pagesAnalisis Sootblower Terhadap Head TransferRDSetyawanNo ratings yet

- Wind Power OptimizationDocument9 pagesWind Power OptimizationRasmus JakobsenNo ratings yet

- 145 KV Sf6 Circuit Breaker H'Mu NDocument15 pages145 KV Sf6 Circuit Breaker H'Mu NQuang NguyenNo ratings yet

- Unit - IX - Impulse and Reaction TurbineDocument46 pagesUnit - IX - Impulse and Reaction TurbineRICHARD VALIENTENo ratings yet

- Preface: FR100L&FR200L For Wire Drawing MachineDocument28 pagesPreface: FR100L&FR200L For Wire Drawing MachineAch SyarifNo ratings yet

- Instructions:: Environmental Education and Awareness For ParentsDocument1 pageInstructions:: Environmental Education and Awareness For ParentsJea RodegerioNo ratings yet

- Greening Class Group Project PROPOSAL: Green ComputingDocument10 pagesGreening Class Group Project PROPOSAL: Green ComputingHappy RajputNo ratings yet

- Company Profile ORD CIPTA KREASIDocument7 pagesCompany Profile ORD CIPTA KREASIWijaya Kusuma SubrotoNo ratings yet

- 3 D 91654 Fed 96 C 76 ADocument7 pages3 D 91654 Fed 96 C 76 APhuriwat ChantraworawitNo ratings yet

- Rototherm PDFDocument2 pagesRototherm PDFcnaren67No ratings yet

- 01062020Document14 pages01062020Kishore KunduNo ratings yet

- Endo Vs Exothermic Assessment TaskDocument2 pagesEndo Vs Exothermic Assessment Taskapi-32133818No ratings yet

- 21 BSC Example Switch GearDocument5 pages21 BSC Example Switch GearjimmstellingNo ratings yet

- Design of An Atmospheric Water GeneratorDocument5 pagesDesign of An Atmospheric Water GeneratorBala Murali100% (1)

- Gas-Liquid Mass Transfer Influence of Sparger Location PDFDocument31 pagesGas-Liquid Mass Transfer Influence of Sparger Location PDFchetanudctNo ratings yet

EPA HQ OAR 2002 0037 0710 - Attachment - 1

EPA HQ OAR 2002 0037 0710 - Attachment - 1

Uploaded by

pmuhammad.r.y.2011Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EPA HQ OAR 2002 0037 0710 - Attachment - 1

EPA HQ OAR 2002 0037 0710 - Attachment - 1

Uploaded by

pmuhammad.r.y.2011Copyright:

Available Formats

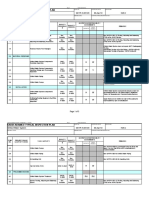

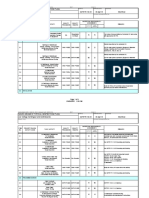

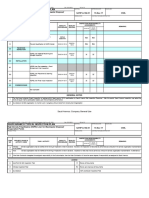

02/05/21 ver.

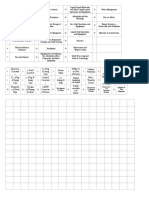

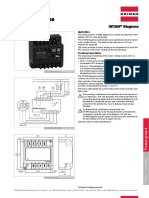

14 Attachment 6: Suspension and Dispersion PVC Processes Typical Flow Diagram

Process Vents Manifold from

Process Components to CVS

Waste gas line

SD3 off recovery

SD1 Knock-out VC Recovery devices

Holding Tank Polymerization Pot Devices (system) is

VC Batch PV Reactor Continuous Continuous Closed Vent

Storage Batch PV PV PV System

Storage

Vessel Vent SD5

SD2 Recovery Process

System Vent

Unloading Weighing “Table 1b”

Misc Vent Tank Polymer Limits

Batch PV Stripping To

Vessel Wastewater “

Batch or Stripper Control

Continuous Devices

Process Steps SD4

PV

SD1. VC Unloading and Storage

SD2. Mixing, Weighing and Holding

SD3. Polymerization Reaction Stripped

SD4. Resin Stripping Resin Caustic

SD6

SD5. Recovery System “Table 1b”

SD6. Blending Stripped Limits

SD7. Drying Resin Blend Thermal Water

SD8. PVC Storage Tanks Oxidizer &

SD9. “In Process” Wastewater Stripping Scrubber

SD10. Control Device System (e.g. Thermal

Oxidizer & Scrubber) SD10 To Wastewater

Nat. Gas Treatment

SD9 “In

Process” To Incinerator/

Scrubber and/or

“In Process” wastewater Wastewater

PVC Storage Cyclone & or Resin Drying Recovery

& Shipping Screening Centrifuge Continuous PV

1) Monomer Recovery System

2) H2O from Double Mechanical Seals Wastewater

SD8

Recovered Centrate Water: on all Pumps, Compressors and Stripper

SD7 used for Eq. washout, CW makeup, Agitators

or sent to bio treatment 3) H2O from Reactor Evacuating

1) Prior to Opening Steam

4) Knock-Out Pots

CVS starts where all waste gas streams are manifolded together 5) Gasholders

: VCM gas stream to/from VCM Recovery System 6) Other misc. process sources

: PVC MACT “Process Vent”

To Biological WW Treatment

Process Wastewater via sewers, pipes, open tanks,

Purple outline blocks are presumed to not be in HAP service

ponds, or closed conveyance

systems

You might also like

- Waukesha Gas Engines VHP Series Four P9394GSIDocument2 pagesWaukesha Gas Engines VHP Series Four P9394GSIrohizat0% (1)

- 2009 Ajax CatalogDocument88 pages2009 Ajax Cataloglemiis93No ratings yet

- Relief Systems - Introduction 2019Document16 pagesRelief Systems - Introduction 2019S M KumarNo ratings yet

- Jeffrey Ifft - Final Southerly GUS OWEA 20170612Document29 pagesJeffrey Ifft - Final Southerly GUS OWEA 20170612Felipe BrainNo ratings yet

- To Sec7 TOC: Recovery Sequence When TD Cleaning Brush Cleaning Sequences Are Suspended. TD Cleaning SequenceDocument1 pageTo Sec7 TOC: Recovery Sequence When TD Cleaning Brush Cleaning Sequences Are Suspended. TD Cleaning SequencePhong DoNo ratings yet

- Tt04-Sanitation - TIbarDocument22 pagesTt04-Sanitation - TIbarEmilia BeloNo ratings yet

- SATIP-K-001-05 - Chilled Water System Rev 7Document3 pagesSATIP-K-001-05 - Chilled Water System Rev 7RAMAKRISHNANo ratings yet

- Blue Baleen PreConditioner PC - PSST1301-UKDocument2 pagesBlue Baleen PreConditioner PC - PSST1301-UKvonksvenomNo ratings yet

- SATIP K 001 05 Chilled Water SystemDocument3 pagesSATIP K 001 05 Chilled Water Systemimrankhan220% (1)

- GS12 SPECIAL PROCESSES - JC01 RevisiDocument20 pagesGS12 SPECIAL PROCESSES - JC01 RevisiNathallyia InasNo ratings yet

- SATIP-P-116-03 Rev 1Document4 pagesSATIP-P-116-03 Rev 1Ahmed GamalNo ratings yet

- SATIP-P-113-03 Rev 7 FinalDocument5 pagesSATIP-P-113-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Major Work DoneDocument2 pagesMajor Work Donerabi4457No ratings yet

- Proses Bisnis RefineryDocument10 pagesProses Bisnis RefineryM. Fadhli Cesar KNo ratings yet

- BOQ 1x80 MW Dariba HZL Captive Power PlantDocument8 pagesBOQ 1x80 MW Dariba HZL Captive Power Plantm 418No ratings yet

- Instruction For HP-SCRDocument48 pagesInstruction For HP-SCRboris345678No ratings yet

- Dav PVC Tape Project Piping Testing & System Handover Schedule (Rev.0)Document1 pageDav PVC Tape Project Piping Testing & System Handover Schedule (Rev.0)PHAM PHI HUNGNo ratings yet

- HPHT Intern ReportDocument40 pagesHPHT Intern ReportSURYA VENKATA SAINADH50% (2)

- Fmea of Co Air Conditioning Systems: by Dr.-Ing. Ulrich Hussels Risa Sicherheitsanalysen GMBH, GermanyDocument13 pagesFmea of Co Air Conditioning Systems: by Dr.-Ing. Ulrich Hussels Risa Sicherheitsanalysen GMBH, GermanykaimanwatsoNNo ratings yet

- Big Orange DP Fmea Rev e PDFDocument62 pagesBig Orange DP Fmea Rev e PDFAndrzej StepienNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNo ratings yet

- Saep 327Document14 pagesSaep 327AbdullahNo ratings yet

- Karnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemDocument7 pagesKarnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemJahangir AlamNo ratings yet

- Storage Tank Hydrotest ProcedureDocument16 pagesStorage Tank Hydrotest ProcedureAhmad AltaieNo ratings yet

- Control Valves Data Sheet: K9 S.P.A. - ItalyDocument11 pagesControl Valves Data Sheet: K9 S.P.A. - ItalyAhmadNo ratings yet

- AKW9 Instruction Manual PIM00364CDocument52 pagesAKW9 Instruction Manual PIM00364Cma7moud.3ttiaNo ratings yet

- 0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFDocument38 pages0013-nd Rev 8.1 28-Jun-16 Guidelines For Load-Outs PDFMark InnesNo ratings yet

- Safia Reference ListDocument4 pagesSafia Reference Listxtrooz abi100% (1)

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 30-Apr-13 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SATIP-A-104-01 Rev 8high Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Ponds FinalDocument2 pagesSATIP-A-104-01 Rev 8high Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Ponds FinalTito GarciaNo ratings yet

- MAR-FO-141-EN-1 ODSC - Dry Dock - ToDoListDocument6 pagesMAR-FO-141-EN-1 ODSC - Dry Dock - ToDoListNarvalNo ratings yet

- 9 - CP22 - HSE LogDocument6 pages9 - CP22 - HSE Logfaisal nadeemNo ratings yet

- NMDC-WABAG-54-05-15-BE-1153-R2 - Process Design Basis - APPDocument31 pagesNMDC-WABAG-54-05-15-BE-1153-R2 - Process Design Basis - APPneeraj1mishraNo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument7 pagesSaudi Aramco Typical Inspection PlansajidNo ratings yet

- Tab For PrintingDocument2 pagesTab For PrintingRafunzel Pe BandoquilloNo ratings yet

- Jadwal PekerjaanDocument1 pageJadwal Pekerjaanwahyu hidayatNo ratings yet

- C04-E02 Rev 2 Dec 2014 Containment For Storage Tanks N PondsDocument18 pagesC04-E02 Rev 2 Dec 2014 Containment For Storage Tanks N Pondsryann mananquilNo ratings yet

- Satip D 100 01Document11 pagesSatip D 100 01Mirza BaigNo ratings yet

- Onepage QcstoryDocument1 pageOnepage QcstoryRS MANIKANDANNo ratings yet

- Report ViewerDocument13 pagesReport Viewertrivtt5096No ratings yet

- D0000 Asset Drawing Numbering SystemDocument70 pagesD0000 Asset Drawing Numbering SystemcoollhandNo ratings yet

- TQ - Technical Query Tracking ListDocument9 pagesTQ - Technical Query Tracking ListSyerifaizal Hj. MustaphaNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- Lars Wadsr #13 NewDocument2 pagesLars Wadsr #13 NewLarsen Verlo De CastroNo ratings yet

- Gac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDocument3 pagesGac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDipayan DasNo ratings yet

- Lecture 25 CANDU 9 Safety and LicensabilityDocument28 pagesLecture 25 CANDU 9 Safety and LicensabilityLazarescu ElenaNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet

- SATIP-A-104-01 High Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation PondsDocument10 pagesSATIP-A-104-01 High Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Pondsjohn ajitNo ratings yet

- Qav Observation Closer Sheet FormatDocument1 pageQav Observation Closer Sheet FormatDEVENDERNo ratings yet

- EDC DTS MV009 Surge ArrestersDocument18 pagesEDC DTS MV009 Surge ArrestersJoe bilouteNo ratings yet

- SATIP-P-104-02 Rev 7 FinalDocument3 pagesSATIP-P-104-02 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- GT L.O CCWP Flushing PPT r1Document23 pagesGT L.O CCWP Flushing PPT r1Deffous AbdelhadiNo ratings yet

- Atac 113 Pfmea R10 IatfDocument50 pagesAtac 113 Pfmea R10 IatfAzlan MustaphaNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalpravinNo ratings yet

- Satip X 600 02Document15 pagesSatip X 600 02spravin231No ratings yet

- Maintenance Harian ADVIA Ok PrintDocument2 pagesMaintenance Harian ADVIA Ok PrintBaiq MayaNo ratings yet

- 34 - Presentation For IAPWS Workshop - Gabriel NicolaidesDocument21 pages34 - Presentation For IAPWS Workshop - Gabriel NicolaidesNoumanIhsanNo ratings yet

- CV2024 EnglishDocument1 pageCV2024 Englishmamadou ndiaye mamboundouNo ratings yet

- A Hierarchy of Turing Degrees: A Transfinite Hierarchy of Lowness Notions in the Computably Enumerable Degrees, Unifying Classes, and Natural Definability (AMS-206)From EverandA Hierarchy of Turing Degrees: A Transfinite Hierarchy of Lowness Notions in the Computably Enumerable Degrees, Unifying Classes, and Natural Definability (AMS-206)No ratings yet

- Sim Power System 1Document70 pagesSim Power System 1Mahmoud ChihebNo ratings yet

- Gradually Varied Flow Equation IsDocument5 pagesGradually Varied Flow Equation IsRefisa JiruNo ratings yet

- Kriwan Overload Module - InT369-DiagnoseDocument2 pagesKriwan Overload Module - InT369-DiagnoseDaniel PertuzNo ratings yet

- Turbine WakeDocument19 pagesTurbine Wakeabraham_imam_muttaqinNo ratings yet

- ELBMT50 ch4 140907Document57 pagesELBMT50 ch4 140907Nilesh NarkhedeNo ratings yet

- ABB MV-LV TransformerDocument44 pagesABB MV-LV Transformeryarafat007No ratings yet

- Distillation PrinciplesDocument71 pagesDistillation PrinciplesRaghu Kohli100% (1)

- Automatic Power Factor Correction2Document40 pagesAutomatic Power Factor Correction2Lynn LucyNo ratings yet

- Vitodens 100 W Service InstructionsDocument100 pagesVitodens 100 W Service InstructionsbruatiNo ratings yet

- Photovoltaic Maximum Power Point Tracking Under Fast Varying of Solar RadiationDocument8 pagesPhotovoltaic Maximum Power Point Tracking Under Fast Varying of Solar Radiationvofemoj676No ratings yet

- Lanka Electicity Company Training Report Power DistributionDocument44 pagesLanka Electicity Company Training Report Power DistributionShashini MaldeniyaNo ratings yet

- Hantek 1008C USB 8CH Automotive Diagnostic Oscilloscope DAQ Program GeneratorDocument7 pagesHantek 1008C USB 8CH Automotive Diagnostic Oscilloscope DAQ Program GeneratorMohamed Wahieb100% (1)

- Operator'S Manual LP3001-1: Grease Pump System LP3001-1, LP3008-1Document2 pagesOperator'S Manual LP3001-1: Grease Pump System LP3001-1, LP3008-1jon fredyNo ratings yet

- Analisis Sootblower Terhadap Head TransferDocument5 pagesAnalisis Sootblower Terhadap Head TransferRDSetyawanNo ratings yet

- Wind Power OptimizationDocument9 pagesWind Power OptimizationRasmus JakobsenNo ratings yet

- 145 KV Sf6 Circuit Breaker H'Mu NDocument15 pages145 KV Sf6 Circuit Breaker H'Mu NQuang NguyenNo ratings yet

- Unit - IX - Impulse and Reaction TurbineDocument46 pagesUnit - IX - Impulse and Reaction TurbineRICHARD VALIENTENo ratings yet

- Preface: FR100L&FR200L For Wire Drawing MachineDocument28 pagesPreface: FR100L&FR200L For Wire Drawing MachineAch SyarifNo ratings yet

- Instructions:: Environmental Education and Awareness For ParentsDocument1 pageInstructions:: Environmental Education and Awareness For ParentsJea RodegerioNo ratings yet

- Greening Class Group Project PROPOSAL: Green ComputingDocument10 pagesGreening Class Group Project PROPOSAL: Green ComputingHappy RajputNo ratings yet

- Company Profile ORD CIPTA KREASIDocument7 pagesCompany Profile ORD CIPTA KREASIWijaya Kusuma SubrotoNo ratings yet

- 3 D 91654 Fed 96 C 76 ADocument7 pages3 D 91654 Fed 96 C 76 APhuriwat ChantraworawitNo ratings yet

- Rototherm PDFDocument2 pagesRototherm PDFcnaren67No ratings yet

- 01062020Document14 pages01062020Kishore KunduNo ratings yet

- Endo Vs Exothermic Assessment TaskDocument2 pagesEndo Vs Exothermic Assessment Taskapi-32133818No ratings yet

- 21 BSC Example Switch GearDocument5 pages21 BSC Example Switch GearjimmstellingNo ratings yet

- Design of An Atmospheric Water GeneratorDocument5 pagesDesign of An Atmospheric Water GeneratorBala Murali100% (1)

- Gas-Liquid Mass Transfer Influence of Sparger Location PDFDocument31 pagesGas-Liquid Mass Transfer Influence of Sparger Location PDFchetanudctNo ratings yet