Professional Documents

Culture Documents

Tbqm-Zamil-406-Coat-009

Tbqm-Zamil-406-Coat-009

Uploaded by

Muhammad RizwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tbqm-Zamil-406-Coat-009

Tbqm-Zamil-406-Coat-009

Uploaded by

Muhammad RizwanCopyright:

Available Formats

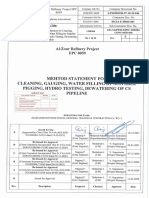

Zamilr 4~J wWJ =-- 1 '~_GJJ; =~

oth,hot<;tcor.•wucr.~ .. Z Al\1IL O FFSHORE SERVIC E S COMPANY

OFFSHORE HOOK UP, UPGRADE MODIFICATION, SCADA INSTALLATION

AND COMISSIONING SUPPORT

(CONTRACT: 6600044802)

TOOL BOX TALK

Location: Zamil-406 Date: 3 1-12-2020

Start Time: 08.00 AM TBT Log No: TBQM-ZAMIL-406-

COAT-009

M eeting Dur ation: 30 Minutes Number of Attendees: 02

Topics Discussed:

SAUDI ARAMCO REFERENCE STANDRAD: SAES-H-004

Health hazards and Coating Application

PARTICIPANTS

51. Zamil Emp. Aramco ID I Name of Attend ee Position Sig nature

No. # IQAMA

~~~

1

63185 2161136284 Jainul Rain Blaster /Painter

2

61922 8904114 Ronnie Centeno

Gen . Supervisor <v~~ .~~

~<--

3 r

4

QC Inspector : QC Supervisor

Name: ABDUR RAHMAN Name:

Discipline : QC COATING INSPECTOR Discipline :

Signature: Signature:

TBT Log No: TBOM-ZAMIL-406-COAT-009 Page 1

APPENDIX-I

Health hazards and Coating Application

1. If alkaline catalysts (such as used in many epoxy paints) come in contact with the skin, they

shall be immediately treated as per the safety recommendation given in the manufacturer' s

Safety data sheet. As immediate first aid action it shall be washed off with waterto avoid

chemical burns.

2. The appropriate personnel protection equipment shall be worn . In addition, safety belts and

lines shall always be used by personnel working from unguarded platforms or in confined spaces

where a manhole accessed by a ladder is the only exit.

3. Adequate washing facilities shall be frequently tested to ensure the proper function so that

paints and solvents splashed on the body or in the eyes can be immediately removed .

4. Safety shoes and coveralls shall always be worn and safety hats shall be worn as required by

proponent organizations .

5. Air hoses shall not be used by personnel for cleaning or cooling themselves.

6 Solvents shall not be used by personnel for cleaning or washing up.

7 Materials Safety Data Sheets for all coatings, solvents, and cleaners in use shall be readily

available on-site, in paint store and all work locations.

8. ASTM E1575 is the minimum safety requirement for pressure water jetting.

9. Any person required to operate or maintain pressure water-jetting equipment shall have

been trained and have demonstrated the ability and knowledge to do so in accordance with the

original equipment manufacturer's instructions, specifications, and training programs.

10. In case of multi-coat application; the primer, intermed iate coat, and topcoats shall be of

contrasting colors .

11 All paint materials for each coating system shall be supplied by same manufacturer. Only

proprietary thinner from same manufacturer shall be used .

12 Any oxide formation shall be removed by high pressure cleaning using sweet water (with

maximum chloride contents of 50 PPM and maximum TDS of 500 PPM), or by sweet water

hos ing followed by scrubbing with stiff brushes to remove zinc salts. The surface shall be

allowed to dry thoroughly prior to applying the topcoat. To avoid pinholes and bubbles

occurring in the intermediate coat of epoxy, a mist-coat thinned 10 to 20% should first be

applied .

13. The dry film thickness {OFT) shall be within the minimum and maximum limits per the

applicable APCS. The dry film thickness shall be checked in accordance with SSPC-PA2.

14. The dry film shall be free of any application related defects such as but not limited to runs,

sags, drips, dry spray or foreign matter. The dry film shall have a uniform appearance.

15. Areas with blisters, cracks, porous or below minimum dry film thickness shall be repaired .

16. In case of brush application, the maximum brush size used shall be 125 mm.

17. Paints to be spray applied shall be filtered through a 30 to 60-mesh screen prior to use and

shall be continuously agitated with a low-speed stirrer during application .

18. Coating systems having glass flake, ceramic beads, and any other reinforcement additives

shall not be filtered as required in 9.1.7.

19. Adhesion strength of all coating systems shall not be less than that required in the

appropriate Saudi Aramco Materials System Specification .

TBT Log No: TBOM-ZAMIL-406-COAT-009 Page 2

w

u

2

w

c

>

w

0)

0

w 0

I

> ~

-<:

1-

u

w

0

u

--. I

(.0

a:l 0

0 ..,j'<

I

....:l

H

::E

~ I

::E

0

~

~

0

z

l:l(

0

....J

E-

CQ

E-

You might also like

- NS 2 PDFDocument187 pagesNS 2 PDFParviz Nasirov63% (8)

- Blasting & Painting Procedure For Structural Steel Rev.00Document16 pagesBlasting & Painting Procedure For Structural Steel Rev.00Hansel Francis67% (12)

- Hydro Blowers - OPM-002 - A - JetFan 70 Operators ManualDocument29 pagesHydro Blowers - OPM-002 - A - JetFan 70 Operators ManualvinodNo ratings yet

- Blasting and Painting ProcedureDocument9 pagesBlasting and Painting Procedureisukuru67% (12)

- Coat 011Document3 pagesCoat 011Muhammad RizwanNo ratings yet

- Tbqm-Zamil-406-Coat-010Document3 pagesTbqm-Zamil-406-Coat-010Muhammad RizwanNo ratings yet

- Tbqm-Zamil-406-Coat-013Document3 pagesTbqm-Zamil-406-Coat-013Muhammad RizwanNo ratings yet

- Tbqm-Zamil-406-Coat-014Document3 pagesTbqm-Zamil-406-Coat-014Muhammad RizwanNo ratings yet

- Tbqm-Zamil-406-Coat-008Document3 pagesTbqm-Zamil-406-Coat-008Muhammad RizwanNo ratings yet

- Tbqm-Zamil-406-Coat-005Document2 pagesTbqm-Zamil-406-Coat-005Muhammad RizwanNo ratings yet

- Tbqm-Zamil-37-Coat-004Document2 pagesTbqm-Zamil-37-Coat-004Muhammad RizwanNo ratings yet

- Tbqm-Zamil-406-Coat-006Document2 pagesTbqm-Zamil-406-Coat-006Muhammad RizwanNo ratings yet

- Tbqm-Zamil-37-Coat-002Document4 pagesTbqm-Zamil-37-Coat-002Muhammad RizwanNo ratings yet

- Ma Wi Rfi 016Document3 pagesMa Wi Rfi 016Jayan VKNo ratings yet

- Daman: Manufacturing CoatingDocument7 pagesDaman: Manufacturing CoatingPramod SingareNo ratings yet

- Tbqm-Zamil-406-Coat-003Document3 pagesTbqm-Zamil-406-Coat-003Muhammad RizwanNo ratings yet

- RT Procedure Asme 2001Document14 pagesRT Procedure Asme 2001கோகுல் இராNo ratings yet

- Document Transmittal: SAW-CWCO-TR149 15 January 2013Document8 pagesDocument Transmittal: SAW-CWCO-TR149 15 January 2013Budi IndraNo ratings yet

- Tbqm-Zamil-37-Coat-003Document2 pagesTbqm-Zamil-37-Coat-003Muhammad RizwanNo ratings yet

- Radiography StandardsDocument15 pagesRadiography Standardsjena_anshumanNo ratings yet

- IncineratorDocument211 pagesIncineratorThái Phan TrọngNo ratings yet

- New Complete Company Profile-2020Document88 pagesNew Complete Company Profile-2020OGTC Reports100% (1)

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Honing Procedure: Doc. No.: - Job No.: 26071Document10 pagesHoning Procedure: Doc. No.: - Job No.: 26071Muhammad GaneshaNo ratings yet

- TMT 035 Nde 04Document14 pagesTMT 035 Nde 04rameshqcNo ratings yet

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiNo ratings yet

- Air Compressor and ReceiverDocument17 pagesAir Compressor and ReceiverRafeeq Ur RahmanNo ratings yet

- Sipl - MCP-12-18Document2 pagesSipl - MCP-12-18p.v.v.satyanarayana MurthyNo ratings yet

- MS (TP-50002)Document13 pagesMS (TP-50002)Benasher IbrahimNo ratings yet

- Surface Treatment ProcedureDocument5 pagesSurface Treatment Proceduredeepan85No ratings yet

- 186 Soldering Flux Data SheetDocument2 pages186 Soldering Flux Data SheetBéla BődiNo ratings yet

- C.1.3 Method Statement For Sand BlastingDocument7 pagesC.1.3 Method Statement For Sand Blastingagbon johnNo ratings yet

- P-28 Cargo Pumping System (1-4)Document281 pagesP-28 Cargo Pumping System (1-4)Raúl Oscar Ledesma100% (7)

- LL TL TTLTLT: I ' J.: 'IlDocument3 pagesLL TL TTLTLT: I ' J.: 'IlVaibhav ShrivastavNo ratings yet

- Radiography Testing: Larsen & Toubro LimitedDocument15 pagesRadiography Testing: Larsen & Toubro Limitedகோகுல் இராNo ratings yet

- Enkon PresentationDocument115 pagesEnkon PresentationSalimNo ratings yet

- TANALLOY Z 4.00X450MM-gazproDocument1 pageTANALLOY Z 4.00X450MM-gazprogauravNo ratings yet

- Procedure Painting Mps Epoxcy - Final - PT KhiDocument12 pagesProcedure Painting Mps Epoxcy - Final - PT KhisinambeladavidNo ratings yet

- Test ReportDocument5 pagesTest ReportNavneet YaduvanshiNo ratings yet

- Chemical CleaningDocument40 pagesChemical CleaningPiyush Singh100% (1)

- Bada Heavy Industries Co., LTDDocument50 pagesBada Heavy Industries Co., LTDCleverson SchmidtNo ratings yet

- STD 130Document29 pagesSTD 130Subash Gold KingNo ratings yet

- OISD STD Inspection of Pipes, Valves & FittingsDocument25 pagesOISD STD Inspection of Pipes, Valves & FittingsNanu PatelNo ratings yet

- Method Statement For Sonic Tube GroutingDocument22 pagesMethod Statement For Sonic Tube GroutingKaushalye Mahanama DissanayakeNo ratings yet

- Blasting Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting Coating Procedure For Fabricated Steel StructureSalman Alfarisi100% (1)

- Lampiran Pengecatan Struktur BajaDocument6 pagesLampiran Pengecatan Struktur BajaBalimbukNo ratings yet

- Seawage Treatment PDFDocument96 pagesSeawage Treatment PDFaung koko100% (1)

- AMNIT-CU-100-PRC-1016-A0-Leak Test ProcedureDocument9 pagesAMNIT-CU-100-PRC-1016-A0-Leak Test Procedurenailulfalah17No ratings yet

- 11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureDocument8 pages11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureAvak NishanNo ratings yet

- 00 Za e 05046 001Document66 pages00 Za e 05046 001Antonio100% (1)

- Arandela Plana Galv Cal 58Document1 pageArandela Plana Galv Cal 58knery684No ratings yet

- Procedure of Apcs-113cDocument8 pagesProcedure of Apcs-113cNoman AhmedNo ratings yet

- Incr-Zamil-403-Coat-004 .. H..Document6 pagesIncr-Zamil-403-Coat-004 .. H..Muhammad RizwanNo ratings yet

- EA-VIS-23-001 (Test Separator)Document17 pagesEA-VIS-23-001 (Test Separator)Ahmed El GehaniNo ratings yet

- Tbqm-Zamil-37-Coat-001.Document2 pagesTbqm-Zamil-37-Coat-001.Muhammad RizwanNo ratings yet

- Sheet & PurlinDocument14 pagesSheet & PurlinStructures ProductionNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Tbqm-Zamil-406-Coat-010Document3 pagesTbqm-Zamil-406-Coat-010Muhammad RizwanNo ratings yet

- Mir - 914 Date Nov-26 Grit Blast Abrasive Slag Type 100 3-Ply Paper BagDocument7 pagesMir - 914 Date Nov-26 Grit Blast Abrasive Slag Type 100 3-Ply Paper BagMuhammad RizwanNo ratings yet

- 19.02.28 Test Report - QG19000646-JS Abrasives SB-Sibelco VasilgritDocument5 pages19.02.28 Test Report - QG19000646-JS Abrasives SB-Sibelco VasilgritMuhammad RizwanNo ratings yet

- Packing List # C#66238-07-St00wh-00-Fr-032937-Falcon PearlDocument1 pagePacking List # C#66238-07-St00wh-00-Fr-032937-Falcon PearlMuhammad RizwanNo ratings yet

- 1656 - LNT RPM1656Document1 page1656 - LNT RPM1656Muhammad RizwanNo ratings yet

- Garnet Arabia Batch No. 6230-1481-C MIR NO.21-090 With Different P.O.#Document1 pageGarnet Arabia Batch No. 6230-1481-C MIR NO.21-090 With Different P.O.#Muhammad RizwanNo ratings yet

- Aug26 ConcreteWeb2Document4 pagesAug26 ConcreteWeb2Muhammad RizwanNo ratings yet

- MSDS Gta 220 ThinnerDocument10 pagesMSDS Gta 220 ThinnerMuhammad RizwanNo ratings yet

- MSDS Carboguard 893 SG Part BDocument10 pagesMSDS Carboguard 893 SG Part BMuhammad RizwanNo ratings yet

- Garnet Packing List #3006014419-003 With Different P.O.#Document1 pageGarnet Packing List #3006014419-003 With Different P.O.#Muhammad RizwanNo ratings yet

- Carboline 3630 Finish PDS EngDocument2 pagesCarboline 3630 Finish PDS EngMuhammad RizwanNo ratings yet

- Carbocholor 3630 FinishDocument2 pagesCarbocholor 3630 FinishMuhammad RizwanNo ratings yet

- Carbocholor 3630 Primer-HBDocument2 pagesCarbocholor 3630 Primer-HBMuhammad RizwanNo ratings yet

- MSDS Bitumastic 300M Part ADocument10 pagesMSDS Bitumastic 300M Part AMuhammad RizwanNo ratings yet

- Transmittal No.7 Old Airless MachineDocument1 pageTransmittal No.7 Old Airless MachineMuhammad RizwanNo ratings yet

- Carboline 3630 HB Aluminum PDS EngDocument2 pagesCarboline 3630 HB Aluminum PDS EngMuhammad RizwanNo ratings yet

- Falcon Pearl Transmittal-38-2022Document1 pageFalcon Pearl Transmittal-38-2022Muhammad RizwanNo ratings yet

- 001Document1 page001Muhammad RizwanNo ratings yet

- FP Transmittal #002Document1 pageFP Transmittal #002Muhammad RizwanNo ratings yet

- 04 Jan 2022Document2 pages04 Jan 2022Muhammad RizwanNo ratings yet

- NR Hempathane 55219 Safety Red (RAL 3020) 57200 - 831050604-TDocument1 pageNR Hempathane 55219 Safety Red (RAL 3020) 57200 - 831050604-TMuhammad RizwanNo ratings yet

- IFC Drawing For Zuluf-5 Drain Line Drg. No. RB-600625, Sht. No. 001, Rev. No. 00Document3 pagesIFC Drawing For Zuluf-5 Drain Line Drg. No. RB-600625, Sht. No. 001, Rev. No. 00Muhammad RizwanNo ratings yet

- Blasted Surface Code ComparisonDocument1 pageBlasted Surface Code ComparisonMuhammad RizwanNo ratings yet

- CHOKE VALVE Data SheetDocument4 pagesCHOKE VALVE Data SheetMuhammad RizwanNo ratings yet

- CSD Response To CRM-ESR No. 4043464386 Dated Jan 07, 2021 Proposal To Apply APCS-22A On Inconel 625 (Recd Jan 10, 2021)Document4 pagesCSD Response To CRM-ESR No. 4043464386 Dated Jan 07, 2021 Proposal To Apply APCS-22A On Inconel 625 (Recd Jan 10, 2021)Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-14-05 BBB-2020-03-06 BBB-2020-18-06 BBB-2020-01-07 BBB-2020-03-07 BBB-2020-06-07Document1 pageEb70 BBB-2020-14-05 BBB-2020-03-06 BBB-2020-18-06 BBB-2020-01-07 BBB-2020-03-07 BBB-2020-06-07Muhammad RizwanNo ratings yet

- Ecoblast EB70 B# EW38 (405MT)Document1 pageEcoblast EB70 B# EW38 (405MT)Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-01-14 3780. 3784, 3792 & 3795Document1 pageEb70 BBB-2020-01-14 3780. 3784, 3792 & 3795Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-01-27 4004 & 4008Document1 pageEb70 BBB-2020-01-27 4004 & 4008Muhammad RizwanNo ratings yet

- Eb70 BBB-2020-06-05 BBB-2020-06-08 BBB-2020-06-30 BBB-2020-07-03 2020-07-12Document1 pageEb70 BBB-2020-06-05 BBB-2020-06-08 BBB-2020-06-30 BBB-2020-07-03 2020-07-12Muhammad RizwanNo ratings yet