Professional Documents

Culture Documents

Tribology Module 01

Tribology Module 01

Uploaded by

raveshrathod0610 ratings0% found this document useful (0 votes)

2 views4 pagesshort note

Original Title

tribology module 01

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentshort note

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views4 pagesTribology Module 01

Tribology Module 01

Uploaded by

raveshrathod061short note

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

History Of Tribology: 1)September 1964: Conference On Contact Takes Place.

This Often Exists During The Starting And

Lubrication In Iron And Steel Works In Cardiff (UK). Realization Of Stopping Or When Heavy Load Rotates At Very Low Speeds Or

Considerable Losses Due To Lack Of Knowledge Related Friction At High Temperature When The Lubricant Tends To Squeeze

And Wear Of Machine Components. 2) After This Realization UK Out. The Co-Efficient Of Friction In Boundary Lubrication Varies

Minister Of State For Science Formed A Committee To Investigate From 0.08-0.2. 2)Mixed Film Lubrication When Under

The Education, Research And The Need Of Industry Related To Conditions Of Fluid Film Lubrication, The Viscosity Of The

Lubrication.3)Committee After Discussions Concluded That Only Lubricant Or The Relative Velocity Between The Surfaces

Lubrication Could Not Provide Complete Solution To Deal With Decreases Or If The Load Increases, The Lubricant Thins Out

Friction And Wear Of Machine Components.4)An Interdisciplinary And The Interacting Surfaces In Relative Motion Come Closer And

Approach Embracing Solid And Fluid Mechanics, Chemistry, And If Slight Asperities Comes In Contact With The Surface The

Material Science Is Essential. Since There Was No Word For Regime Of Lubrication Is Mixed Film Lubrication. 3)Fluid Film

Such New Concept, A New Name “Tribology” Was Coined In Lubrication Or Full Film Lubrication In This Regime The

1966.5)Major Breakthrough In Tribological Science Came In 1981 Lubricant Film Is Sufficiently Thick To Prevent The Opposing

With Development Of “Scanning Tunneling Microscope” (STM) Surfaces From Coming Into Contact And Provides Low Friction,

And Systematic Theory Based On “Contact Mechanics”. Such High Resistance To Wear, Good Damping Characteristics, Better

Developments Provided Tools To Predict And Estimate The Cooling And Minimum Chance Of Fatigue Failure Of Surfaces.

Behavior Of A Single Asperity Contact. PURPOSE OF The Viscosity Of The Lubricant Plays A Very Important Role In

LUBRICATION: Though Lubrication Was Basically Conceived This Type Of Lubrication Mechanism. Fluid Film Lubrication Can

With The Purpose Of Reducing Friction, Lubrication Also Performs Further Be Divided As: I. Hydrostatic Lubrication Ii. Hydrodynamic

Several Functions Such As: 1. Reduce Sliding And Rolling Lubrication Hydrostatic Lubrication: In Hydrostatic Lubrication,

Frictions For Prolonging The Life Of Parts And Components In A High Pressure Oil Is Supplied Over The Whole Range Of Load

Machine To Prevent Wear. 2. Protect Bearings And Other And Speed From External Pump Source To Separate The Two

Components From Rust And Corrosion. 3. To Work As A Coolant Surfaces (Journal And Bearing) By Thick Oil Film. The Friction Is

Thereby Absorbing Heat From The Components. 4. Act As A Nearly Zero And Co-Efficient Of Friction Is Nearly 0.0001 As The

Cleansing Agent By Carrying Away The Chips And Other Foreign Load Fully Floats And The Friction Depends Mainly On The

Matters. 5. Act As A Sealant By Preventing The Escaping Of Gas Viscosity Of The Oil. Hydrodynamic Lubrication: In

Or The Working Fluid 6. Reduce Vibration, Noise And Shock Hydrodynamic Lubrication Relative Velocity Between The Two

Between The Gear Teeth And Other Components. REGIME OF Surfaces Is Used To Generate Liquid Pressure Between Two

LUBRICATION: 1)Boundary Film Lubrication This Is The Thin Surfaces. The Load Is Transmitted On The Self-Renewing Film Of

Film Lubrication Where The Organic Film Is Physically Adsorbed The Lubricant. SELECTION OF LUBRICANTS :Other Criterion

Or Chemisorbed. The Film Of Lubrication Occasionally Breaks By For Selection Of The Lubricants Is Mainly Done On The Basis

The Asperities Of The Two Surfaces And Often Metal To Metal Of:1)Component Design And Life.2)Type Of Operation

(Continuous/Periodic/ Intermittent) And Machineb3) Longest Drain Products Derived Can Be Operated At Temperature Ranging

Interval.4) Operating Parameters Such As Power Consumption, From -70℃ To +300℃.Based On The Applications Lubricating Oils

Number Of Cycles, Type Of Tools Etc. 5)Easy Availability And Are Further Classified Into: I. Automotive Lubricating Oils Ii.

Low Cost.6) Effect On Environmental Conditions Selection Industrial Lubricating Oils Iii. Metal Working Oils Iv. Industrial

Stages Of Lubricants: Considerations At The Following Three Specialty Oils V. Marine Lubricating Oils. B. GREASES: Derived

Levels Of A Machine Development Is Vital For Choosing A From The Greek Word ‘Crassus’ Meaning Fat As Initially Animal

Lubricant. 1)Design Level Based On Design Parameters Fats Were Used As Grease. Grease Form The Semi-Solid Class

Particularly The Pressure And Speed A Designer Can Suggest Of The Lubricants And Were Developed For Applications Where

The Appropriate Lubricant. If The Machine Is A Conventional Oil Would Run-Out Of The Lubricating Zones. It’s A Semi Fluid

Type, Then For A Given Viscosity Different Grades Of Lubricant Product Of Dispersion Of Thickening Agents In Liquid Lubricants.

Oils Might Be Used Based On The Input From The Manufacturers Some Amount Of Fatty Acids And Other Ingredients Are Added

Guide Book.2)Manufacturers Level Based On The Designer’s For Imparting Special Properties. C. SOLID LUBRICANTS The

Recommendations The Manufacturer Can Review The Additive Limitations Of Lubricating Oils And Greases Such As Physical

Package Or Develop A New Package Conducting Physio- And Chemical Degradation Dueto High Operating Temperature,

Chemical And Field Tests. The Lubricant Type Is Then Chosen As Low Volatility Of The Lubricating Oils And Undesirability For

Per The Standards Set By The Organizations Like Prolonged Storage Like In Missile Components, Requirement For

ISO/SAE/AGMA/ASTM. 3)Selection At User Level The End User Regular Re-Lubrication Led To The Development Of Solid

Can Choose The Lubricant Based On The Catalogues Of The Lubricants. Graphite And Molybdenum Di-Sulphide (Mos2) Are

Machine And The Lubricants Specified For Different Operations. The Best Known Lamellar Solids Which Work As Excellent

The User Adopts Some Stringent Analysis Such As Spectroscopic Lubricants. Their High Thermal And Oxidation Stabilities At

Analysis Of The Lubricant Oil To Predict The Possible State Of Temperatures Of 500 To 6000℃ Enable Use Of This Solid

Replenishment Of The Lubricant. TYPES OF LUBRICANTS Lubricant At High Temperatures And High Sliding Speeds. D.

Lubricants Can Be Broadly Classified Under Four Categories GASEOUS LUBRICANTS Gas (I.E., Air, Nitrogen, And Helium)

Namely: A. Lubricating Oils B. Greases (Semi-Solid Lubrication Is Used For Ultra-Thin Film Thickness(Separation)

Lubricants) C. Solid Lubricants D. Gaseous Lubricants A. Between Tribo-Pairs. Gas Lubricated Bearings Have Numerous

LUBRICATING OILS: The Lubricating Oils Used Are Mostly The Advantages Over Liquid And Solid Lubricated Bearings For A

Mineral Oils Produced By Petroleum Refining. They Are Wide Range Of Applications. A Gas Bearing Is Virtually

Composed Of Hydrocarbons And Other Aromatic Compounds. Frictionless, Silent, Clean And Vibration Free. Gas Bearings Can

However, Some Amount Of Fattyoils And Fatty Acids Like Be Used For Extremely Large Surface Velocities. A Gas Bearing

Vegetable Oils, Fish Oil Etc. Are Used To Increase The Oiliness Can Eliminate The Risk Of Contaminating A Process With

Of The Mineral Oils. Synthetic Lubricant Oils Are Produced By Lubricant.Effect Of Viscosity With Temperature : Temp Strongly

Synthesizing Different Constituents Of Hydrocarbons So That The Influences A Fluid Viscosity A Substance Viscosity Decreases

With Increasing Temp And Vice Versa This Inversely Proportional Classification Is Based On Viscosity Values At 210 ⁰F. The Suffix

Relation Applies To All Substance Any Change In Temp ‘W’ Indicates Winter Grades, I.E. These Grades Have Good Cold

Influences Viscosity But For Different Fluid The Size Of This Start-Up Characteristics. These Characteristics Mean Lubricant

Influences Certain Fluid React With A 10% Increases In Viscosity Retaining Fluidity At Low Temperatures And Are Easily

If Temp Decreases By 1 C A Fluid Viscosity Strongly Depend On Pumped.3) AGMA (American Gear Manufacturers Association)

Its Temp Even 1K Temp Increase Can Decrease The Viscosity By Viscosity Grades AGMA Grades Standardize Gear Oils Based On

10%. Effect Of Viscosity With Pressure: Normally An Increase Additives Used. These Are Rust And Oxidation Inhibited Gear Oil,

In Pressure Causes A Fluid Viscosity To Increase Too However Extreme Pressure Gear Lubricant AndCompoundOil.VISCOSITY

Fluid Are Not Dramatically Affected If The Pressure Is Low R MEASUREMENT:1)ROTATIONAL VISCOMETER: Rotational

Medium Liquid Is Almost Non Compressible In This Pressure Viscometers Use The Idea That The Torque Required To Turn An

Range Most Liquid React To A Significantly Altered Pressure Object In A Fluid Is A Function Of The Viscosity Of That Fluid.

(From 0.1 MPA To 30MAP) With A Viscosity Change Of About They Measure The Torque Required To Rotate A Disk Or Bob In

10% In Case The Pressure Goes Up From 0.1MPA To 200 Mpa A Fluid At A Known Speed. This Is Perhaps The Only Viscometer

The Viscosity Can Rise T 3to 7 Time The Original Value . This That Measure The Absolute Viscosity Of The Oil. It Is In The Form

Applied To Most Low Molecular Liquid Higher Viscous Mineral Oil Of Two Concentric Cylinders Of Which One Rotates In The Oil

React With Viscosity Increase To Time 20000, For Example Whose Viscosity Is To Be Measured. The Absolute Viscosity Is

Lubrication In Cogwheels Or Gear Can Be Submitted To Pressure Measured By Measuring The Frictional Drag Due To Viscous

Of 1 Gpa And Higher In Most Liquid, Pressure Reduces The Free Shear On The Inner Cylinder At A Particular Velocity. This

Volume In The Internal Structure. LIBRICANT GRADES OR Viscometer Is Suitable For Measuring The Viscosities Of Oils

GRADES VISCOSITY :1)ISO (International Standards Having Higher Viscosity. 2)U-TUBE VISCOMETER: These

Organization) Viscosity Grades: Features Of ISO Grades Of Viscometers Are Also Known As Glass Capillary Viscometers Or

Viscosity Are: I. Consists Of 18 Viscosity Grades In The Range Of Ostwald Viscometer. IT Consists Of A U-Shaped Glass Tube Held

2cst1500cst At 40℃Summarized In The Table Below. Ii. Viscosity Vertically In A Controlled Temperature Bath. In One Arm Of The U

Grade Indicates The Mid-Point Kinematic Viscosity In Cst At 40℃. Is A Vertical Section Of Precise Narrow Bore (The Capillary).

Iii. The Classification Is Silent About Any Aspect On Viscosity Above There Is A Bulb, With It Is Another Bulb Lower Down On

Temperature Or Other Behavioral Characteristics, Quality, Type The Other Arm. In Use, Liquid Is Drawn Into The Upper Bulb By

Of Hydrocarbon And Application Of Lubricant. Iv. The Graduation Suction, Then Allowed To Flow Down Through The Capillary Into

Is Based On The Principle That The Mid-Point Kinematic Viscosity The Lower Bulb. Two Marks (One Above And One Below The

Of Each Grade Is Nearly 50% Greater Than The Preceding Upper Bulb) Indicate A Known Volume. 3)CAPILLARY

One.2)SAE (Society Of Automotive Engineers) Viscosity VISCOMETER: The earliest method for measuring viscosity were

Grades. SAE GRADES SAE Viscosity Grades Are Categorized based n using capillary tubes and measuring the time it took for a

Into SAE Engine Oil And SAE Transmission Lubricants. The volume of liquid to pass through the length of the tube 4)Zahn cup

similar to this method is Zahn cup which is a small container with

handle and a small hole in the bottom the time take to empty the

cup through the hole is correlated to viscosity it is used in the paint

industry.5) falling sphere viscometer : anther technique is (fsp)

in which a sphere of known density is dropped into the fluid

sample and the time it take for the sphere to fall ta a specified

point is recorded. 6) saybolt and redwood : saybolt – has a

vertical cylindrical chamber filled with liquid whose viscosity is to b

measured. It is surrounded by a constant temp bath and a

capillary tube (length 12mm and dia 1.75mm ) is attached

vertically at the bottom of the chamber for measuring of viscosity

the stopper at bottom of the tube is removed and time for 6ml of

liquid to flow is noted which is named as saybolt second.

Redwood – it is another type viscometer that work on the same

principle of saybolt here the sopper is replace with an orifice and

redwood second is define for collection of 50ml of liquid to flow

out of orifice . in general both the viscometer are used to compare

the viscosities of different liquid so the value of viscosity of the

liquid may be obtained by comparison with valve of the for the

liquid of known viscosity .

You might also like

- Bell B50D Parts ManualDocument2 pagesBell B50D Parts ManualAfandiquokkaNo ratings yet

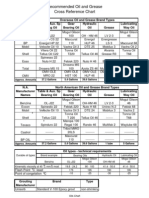

- Recommended Oil and Grease Cross Reference ChartDocument1 pageRecommended Oil and Grease Cross Reference Chartnanjay33% (3)

- Codes For Lubricants Acc. DIN 51502Document5 pagesCodes For Lubricants Acc. DIN 51502Anonymous alQXB11EgQ80% (10)

- 1.2. BTR - Lubrication NotesDocument17 pages1.2. BTR - Lubrication Notesvishnu vishnu G.T.No ratings yet

- Lubrication Types and GradesDocument6 pagesLubrication Types and Gradesroopa mNo ratings yet

- Plain Bearing ReportDocument15 pagesPlain Bearing Reportpresident fishrollNo ratings yet

- Unit7 Lubricants7Document5 pagesUnit7 Lubricants7engineeringchemistryNo ratings yet

- Oil Viscosity Analys On Gearbox Performance: Compiled By: Group 2: 2 Year of Mechanical BDocument9 pagesOil Viscosity Analys On Gearbox Performance: Compiled By: Group 2: 2 Year of Mechanical Bwildan amaludinNo ratings yet

- Lubricants 7Document4 pagesLubricants 7chemistrymaster100% (3)

- Dewangan 2019 IOP Conf. Ser. Mater. Sci. Eng. 624 012011Document7 pagesDewangan 2019 IOP Conf. Ser. Mater. Sci. Eng. 624 012011Nagesh DewanganNo ratings yet

- Lubricants FinalDocument18 pagesLubricants FinalRonak GandhiNo ratings yet

- Lubricants and LubricationDocument17 pagesLubricants and Lubricationry3745654100% (1)

- Effect of Additives On Lubricating OilDocument4 pagesEffect of Additives On Lubricating OilGilson Furtado SouzaNo ratings yet

- Lubs, Properties & TeatingDocument33 pagesLubs, Properties & Teatingjamesv52_743942786No ratings yet

- Best Practice 6.grease Construction and FunctionDocument7 pagesBest Practice 6.grease Construction and FunctionJorge ZegarraNo ratings yet

- Lubrication Principles: Learning OutcomeDocument12 pagesLubrication Principles: Learning OutcomeMandeep MalikNo ratings yet

- Introduction and LubricationDocument9 pagesIntroduction and LubricationslchemNo ratings yet

- Lubricants and Lubrication PDFDocument18 pagesLubricants and Lubrication PDFAtul Gautam100% (1)

- Grease Construction and FunctionDocument7 pagesGrease Construction and FunctionProphx BliziceNo ratings yet

- UNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015Document46 pagesUNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015anjali sharmaNo ratings yet

- Engineering Chemistry: LubricantsDocument7 pagesEngineering Chemistry: LubricantsbhanuNo ratings yet

- Engineering Chemistry: LubricantsDocument7 pagesEngineering Chemistry: LubricantsSavita ChemistryNo ratings yet

- M4 LUBRICATION PRINCIPLES and BEARING CONSTRUCTIONSDocument45 pagesM4 LUBRICATION PRINCIPLES and BEARING CONSTRUCTIONSnaresh100% (1)

- Need For Lubrication in An I.C. EngineDocument6 pagesNeed For Lubrication in An I.C. EngineDrChandrakant KothareNo ratings yet

- MCE321 - Lubrication and LubricantsDocument9 pagesMCE321 - Lubrication and LubricantsVanina VaniniNo ratings yet

- Report On Engine LubricationDocument9 pagesReport On Engine LubricationJitesh MhatreNo ratings yet

- He Surface of Platinum (STM) : LubricantsDocument13 pagesHe Surface of Platinum (STM) : Lubricantswood_ksd3251No ratings yet

- Natural Refrigerants WhitepaperDocument10 pagesNatural Refrigerants WhitepaperDiptarghya KunduNo ratings yet

- LubricationsDocument80 pagesLubricationsVANSH BHATI100% (1)

- Amity - Lubricants - Why So DumbDocument17 pagesAmity - Lubricants - Why So DumbAbhimanyu Singhal100% (2)

- Chapter 2 - LubricationDocument22 pagesChapter 2 - LubricationMr Mickey83% (6)

- Term Paper of FluidDocument16 pagesTerm Paper of FluidRatnesh Raman PathakNo ratings yet

- LubricantsDocument6 pagesLubricantsVrajNo ratings yet

- Types of Lubrication: BoundaryDocument20 pagesTypes of Lubrication: BoundaryAbishek Abi100% (1)

- 06 WDD012 Tribology (2020)Document31 pages06 WDD012 Tribology (2020)Varun Mahulikar100% (1)

- Tribology in Marine ApplicationsDocument19 pagesTribology in Marine ApplicationsNeeraj RajpalNo ratings yet

- Chemistry Notes On LubricantsDocument4 pagesChemistry Notes On LubricantsSohamDixit67% (3)

- Lubricants Fundamental Article - Sergio Nicolas Cardenas ZipaDocument3 pagesLubricants Fundamental Article - Sergio Nicolas Cardenas ZipaLaura PinillaNo ratings yet

- LubricantsDocument5 pagesLubricantsengineeringchemistry100% (2)

- Understanding Oil AnalysisDocument8 pagesUnderstanding Oil AnalysisTim ku100% (1)

- What You Need To Know When Selecting Gear OilsDocument5 pagesWhat You Need To Know When Selecting Gear OilsmarciofelipessantosNo ratings yet

- S-Flow Houillon Viscometer - UpdatedDocument31 pagesS-Flow Houillon Viscometer - UpdatedAlamin Saj EngineeringNo ratings yet

- CHY1005 Module 02 - TRIBOLOGY Class NotesDocument77 pagesCHY1005 Module 02 - TRIBOLOGY Class Notessrikar princeNo ratings yet

- Lubrication For Journal BearingDocument25 pagesLubrication For Journal BearingNguyễn Thanh SơnNo ratings yet

- PresentationDocument27 pagesPresentationVishal SalveNo ratings yet

- Lubricants Final 1Document32 pagesLubricants Final 1onkar nikamNo ratings yet

- Engineering Chemistry Unit 3 Lubricants Notes PDFDocument11 pagesEngineering Chemistry Unit 3 Lubricants Notes PDFbhanu100% (1)

- Engineering Chemistry Unit 3 Lubricants Notes PDFDocument11 pagesEngineering Chemistry Unit 3 Lubricants Notes PDFbhanuNo ratings yet

- Lu Bri CtionDocument5 pagesLu Bri Ctionme1901932No ratings yet

- Industrial Lubrication and TribologyDocument16 pagesIndustrial Lubrication and TribologyBonifacio Bagual JrNo ratings yet

- Lubricant GlossaryDocument8 pagesLubricant GlossaryAli KhanNo ratings yet

- LubricantsDocument21 pagesLubricantsGourav KumarNo ratings yet

- Lubricating OilDocument24 pagesLubricating OilShyam YadavNo ratings yet

- Module 4Document32 pagesModule 4sandhrarosechackochan.b20me1136No ratings yet

- LubricationDocument22 pagesLubricationYasir MukhtarNo ratings yet

- Lubricating OilsDocument22 pagesLubricating OilsShweta PatilNo ratings yet

- Assignment LubricantDocument8 pagesAssignment LubricantNiten FlamelNo ratings yet

- Lubricating Your Bearings: A. Basic Lubricant FunctionsDocument48 pagesLubricating Your Bearings: A. Basic Lubricant Functionsamir8100No ratings yet

- Principles of LubricationDocument109 pagesPrinciples of LubricationFaraj Mohamed100% (3)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Model of Friction Wear and ContactDocument10 pagesModel of Friction Wear and Contactadriano_rodsNo ratings yet

- 11 Rolling: ContactbearingsDocument29 pages11 Rolling: ContactbearingsAndres Alberto Osorio YupanquiNo ratings yet

- Project PPT 03032020Document16 pagesProject PPT 03032020Prateek100% (1)

- Victrex Properties-Guide en MetricDocument25 pagesVictrex Properties-Guide en MetricmlombardiTONo ratings yet

- Dr. Edward J. BergerDocument25 pagesDr. Edward J. BergerEdward BergerNo ratings yet

- Measuring Wear and Friction Using TribometerDocument25 pagesMeasuring Wear and Friction Using TribometerPriyank SharmaNo ratings yet

- ZKL MRP Pricelist 2011Document55 pagesZKL MRP Pricelist 2011Mahesh Daxini Thakker100% (4)

- NSK Precision Machine Component General PDFDocument1,067 pagesNSK Precision Machine Component General PDFSergio Trujillo CerroNo ratings yet

- UG 3-2 R19 Mech SyllabusDocument25 pagesUG 3-2 R19 Mech SyllabusSarath KumarNo ratings yet

- Part BDocument64 pagesPart Bvandv printsNo ratings yet

- Cat. Gral MercomarveDocument43 pagesCat. Gral Mercomarvewillys8No ratings yet

- 125marra 3Document6 pages125marra 3Djm AlgNo ratings yet

- Lubricants 07 00017 PDFDocument14 pagesLubricants 07 00017 PDFGabriel Ivan AviñaNo ratings yet

- Simulative Friction and Wear Testing: Peter J. BlauDocument12 pagesSimulative Friction and Wear Testing: Peter J. BlauGhania Nashwa FairuzaNo ratings yet

- Bachem High Lub l474 2Document1 pageBachem High Lub l474 2FitriRamayantiNo ratings yet

- Analysis of Hydrodynamic Journal Bearing: A Review: Priyanka Tiwari and Veerendra KumarDocument7 pagesAnalysis of Hydrodynamic Journal Bearing: A Review: Priyanka Tiwari and Veerendra KumarSridharan SekarNo ratings yet

- NSK Bearings-General CatalogsDocument512 pagesNSK Bearings-General Catalogsapi-3812573100% (5)

- Box Color Guide: Motorcycle Engine OilDocument2 pagesBox Color Guide: Motorcycle Engine OilAndi Septian Eka SetiawanNo ratings yet

- Sinopec Grease: SINOPEC Moly-Lithium Grease SINOPEC Heavy Duty LC Mining GreaseDocument2 pagesSinopec Grease: SINOPEC Moly-Lithium Grease SINOPEC Heavy Duty LC Mining GreaseSumaya AkterNo ratings yet

- LubricationDocument21 pagesLubricationmojiryhamid100% (1)

- 1 s2.0 S0261306905002827 MainDocument5 pages1 s2.0 S0261306905002827 MainMR GOKCHENNo ratings yet

- Tribological Behaviour of Aluminium Hybrid Metal Matrix CompositeDocument19 pagesTribological Behaviour of Aluminium Hybrid Metal Matrix CompositenisargaNo ratings yet

- Radial Gate Cylinder Technology: First Selection Civil Engineering First Selection Civil EngineeringDocument16 pagesRadial Gate Cylinder Technology: First Selection Civil Engineering First Selection Civil Engineerings_waqarNo ratings yet

- Influence of Micropolar Lubricant On Bearings Performance A ReviewDocument11 pagesInfluence of Micropolar Lubricant On Bearings Performance A ReviewDjamel DjamNo ratings yet

- Velocity Effects in Metal Forming and Machining ProcessesDocument24 pagesVelocity Effects in Metal Forming and Machining ProcessesMarcos WernerNo ratings yet

- Characterization of Al-7075 Metal Matrix Composites: A ReviewDocument10 pagesCharacterization of Al-7075 Metal Matrix Composites: A ReviewkalyanamanoharNo ratings yet

- Lista VALVOLINE 51 NOVIEMBRE 2023Document4 pagesLista VALVOLINE 51 NOVIEMBRE 2023Miguel Angel MedinaNo ratings yet