Professional Documents

Culture Documents

Allwailer

Allwailer

Uploaded by

mlodydrumm3rOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Allwailer

Allwailer

Uploaded by

mlodydrumm3rCopyright:

Available Formats

Series: AEB1F

Design: IE

Progressive cavity pumps

ALL-OPTIFLOW

Series AEB1F

IE close-coupled design

FEATURES OVERVIEW OF PERFORMANCE

Self-priming, single-stage, rotating progressive The exact operating limits can be found in the quotation

cavity pump and order confirmation.

Compact block design

Parameter Value

Horizontal or vertical installation

Flow rate Q to 3,800 l/min

Shaft sealing by stuffing box, single or double-acting

1)

mechanical seal Pumped liquid temperature t to 100 °C

The bearing of the drive/stub shaft is provided in the Discharge pressure single-stage Δ p to 6 bar

reinforced bearings of the gear motor Pump pressure Pd 3)

to 16 bar

Wide range of applications, including: Sewage and Attainable vacuum Ps 2) to 0.95 bar

environmental technology, chemical industry, food

Viscosity η2) to 300,000 mPa s

and beverage processing as well as agriculture and

2)

shipbuilding Permissible proportion of solids to 60 vol %

Suitable for viscous, abrasive and aggressive liquids 1) Dependent on the pumped liquid and the elastomers used.

2) Dependent on pump size/design, speed, pumped liquid.

and liquids carrying solids 3) Dependent on sense of rotation, inlet pressure.

228493 – 179-202/0 2021.02 en-US 1

Series: AEB1F

Design: IE

PERFORMANCE CURVE

For the approximate selection of the pump size and speed (n) depending on the desired flow rate (Q) and the type of

liquid to be pumped. Vg “m” = existing average sliding speed of the rotor in the stator.

7.000

6.000

0 3

5.000 3,0 55

4.000

2,0 03

30

3.000

1,5

03

16

/s]

2.000

[m 1,0 03

"m

" 10

Vg 3

70

0,7 3

1.000 55

900 3

800 0,5 40

700

600 3

20

500 0,3

400 3,0

0,2

300 3

10

200

Q [l/min] at p = 0 bar

0,1

2,0

1,5

100

90

80

70

60 1,0

50

7

40 0,

30 0,5

20

0,3

0,2

10

9

8

7

/s]

6

0,1 " [m

5 "m

Vg

4

2

10 20 30 40 50 60 70 80 90 100 200 300 400 500 600 700 800 900

9001.000

n [1/min] a c e g

b d f h

Explanation of abbreviations:

a very high viscosity c highly viscous e viscous g low viscosity Q Flow rate

b highly abrasive d relatively abrasive f slightly abrasive h not abrasive n Motor speed

More detailed performance data can be found in the separate individual performance curves.

2 2021.02 en-US 228493 – 179-202/0

Series: AEB1F

Design: IE

TYPE CODE

The type code is divided into 3 basic categories:

Category: Type series Geometry design Material version

AEB 1 F 203 IE 0 3 2 P 0 1 NY 1 1 2 A P 6230

Symbols:

AEB 1 F 703 IE 0 1 1 G 0 K D 1 Y 4 4 3 P P 5FV

Position: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Explanation of the Type series category:

Pos. Description Explanation

1 Product AEB Allweiler progressive cavity pump, block version

2 Stage number 1 single-stage up to discharge pressure Δp = 6 bar

3 Mechanics F designed for discharge pressure Δp = 6 bar

4 Size 103, 203, 403, 553, 703, 1003, 1603, 3003, 5503

The figures indicate the theoretical flow rate in l/min at n = 400 1/min and Δp = 0 bar.

5 Design IE Industrial version with external bearing

Explanation of the Geometry design category:

Pos. Description Explanation

6 Bearing version 0 External bearing in drive unit

7 Suction and 1 DIN flanges

discharge flange 3 ANSI flanges

design X Suction and/or discharge flanges in special design

8 Flange position 1, 2, 3, 4

For arrangement see illustration, page 10. Arrangement 3 not possible for size 103

9 Shaft seal type P Stuffing box or other non-mechanical shaft seal

G Mechanical seal (mechanical shaft seal)

10 Shaft seal design 0 Shaft without shaft protection sleeve

11 Shaft seal design Stuffing box (P…)

P01 Stuffing box in standard design (without lantern gland / without flushing ring)

P02 Stuffing box with flushing ring

P03 Stuffing box with internal lantern gland

P04 Stuffing box with external lantern gland

P0X non-mechanical shaft seal in special design

Mechanical seal (G…)

Pump size 103 203 403 553 703 1003 1603 3003 5503

Shaft diameter in the area of the 25 30 35 43 43 53 53 60 75

shaft seal [mm]

G0K Single GLRD, DIN EN

12 756, K design, U X X X X X X X X X

form

G0N As above, but N design X X X X X X X X X

G0S Single GLRD, DIN EN

12 756, K design, U

form, rotating part with

X X X X X X X X X

integrated locking

device and throttle ring

on pump side

G0T As above, but N design X X X X – – X X X

G0Q Single GLRD, DIN EN

12 756, K design, U X X X X X X X X X

form with quench

G0D Double GLRD Seal design - consultation required

G0X GLRD in special design

12 Double casing D Double casing for heating/cooling, only available in stainless steel. Connections as

threaded nipple for liquid media. Max. heating/cooling liquid pressure 6 bar, max. heating

temperature + 100°C, max. cooling temperature -20°C (consultation required)

13 Double casing 1 Suction housing with double casing

design 2 Stuffing box housing for P01 with double casing

12 Suction and stuffing box housing P01 with double casing

X Special design for other double casings

14 Design variants Stators with uneven elastomer wall thickness (all qualities)

N, M, H, T Rotor with temperature clearance depending on the temperature of the pumped liquid

Y Rotor ductile, hard chrome plated W Winding protection on universal joint shaft

Z Rotor, metallically coated L Stator for thermal dry-running protection

S Worm on universal joint shaft X other designs

228493 – 179-202/0 2021.02 en-US 3

Series: AEB1F

Design: IE

Explanation of the Material version category:

Pos. Description Explanation

15 Suction and 1 EN-GJL-250 A 1.4462

discharge casing in 4 1.4408 X Special materials

contact with liquid,

Material

16 Stub shaft, universal 1 1.4021/1.1191 A 1.4462

joint shaft, in contact 4 1.4404/1.4571/1.4408/ X Special materials, e.g. also for articulated parts

with liquid, material 1.4462

17 Rotor material 2 1.4301 4 1.4404/1.4571 A 1.4462

3 1.2436/1.2379 X Special materials, e.g. other metals, plastic materials

18 Stator material P Perbunan N PA Perbunan A ALLDUR

HP Perbunan/hydrated E EPDM Y Hypalon

X Special materials

19 Joint sleeves P Perbunan N Y Hypalon X Special materials

Material V Viton B Butyl

20 Shaft seal Stuffing box:

Material 5846 Ramie fiber with PTFE impregnation, asbestos-free

6426 Aramid continuous fiber with PTFE impregnation, asbestos-free

6230 Graphite-incorporated PTFE with lubricant, asbestos-free

Mechanical seal:

1st position for single seal 2nd position 3rd position for single seal

1st + 4th position for double seal 3rd + 5th position for double seal

2 CrMo casting/hard F 1.4571/1.4404 E EP rubber

carbon

5 Hard metal/highly wear- X Special materials V Viton

resistant hard metal

X Special materials X Special materials

4 2021.02 en-US 228493 – 179-202/0

Series: AEB1F

Design: IE

USAGE Stator: The stator, which is vulcanized into a pipe, is

equipped with outer collars vulcanized on both sides,

Pumped liquids: For pumping slightly to highly which seal reliably against the suction casing and the

viscous, neutral or aggressive, pure or abrasive, discharge casing and protect the stator casing from

gaseous or foaming liquids, also with a proportion of corrosion.

fibrous and solid content.

Gasket: The replaceable stuffing box or mechanical

Application: Main applications in waste water, sewage seal housing is located between the suction casing and

and environmental technology, chemical and the lantern base.

petrochemical industry, pulp and paper industry, soap

and fat industry, paint and varnish industry, food and Power transmission: The drive torque is transmitted to

beverage industry, plastics industry, ceramics industry, the rotor via a stub shaft and the universal joint shaft.

agriculture, sugar industry and shipbuilding. The universal joint shaft ends on both sides in liquid-

encapsulated pin joints, which have a particularly

PUMPED LIQUIDS simple and robust design and enable the eccentric

movement of the rotor. The sense of rotation is

Increasing proportion of solids and increasing particle reversible.

size require a reduction in pump speed.

SHAFT SEAL

Size Max. particle size Max. fiber length

[mm] [mm] Types:

103 3 42 Stuffing box – uncooled, cooled or heated.

203 3.8 48 Mechanical seal – single or double-acting, uncooled

403 5 60 or cooled, maintenance free, unbalanced

553 6.8 79 Materials: Material pairing and design are matched to

703 6.8 79 the respective operating conditions.

1003 9.5 98

Layout: Shaft seal housings with different designs are

1603 9.5 98 interchangeable within one size.

3003 14 130 The various mechanical seal housing parts form a

modular system and can be easily combined with each

5503 20 210

other in a conversion to a different GLRD design.

FUNCTION Installation: Installation spaces for mechanical seals

according to DIN EN 12756 (except double-acting

Pump type: Self-priming, single-stage, rotating mechanical seal).

displacement pump

BEARING

Operating procedure: The eccentric rotor rotates in

the fixed stator. The contents are moved axially and The bearing of the drive/stub shaft is provided in the

continuously from the suction to the discharge side of reinforced bearings of the electric motors, gear motors

the pump. or variable gears, which simultaneously absorb the axial

Extremely gentle, virtually pulsation-free pumping and forces that occur.

no turbulence during rotor rotation. Since all drives are delivered only with reinforced

bearings, this ensures that the assigned pumps can

DESIGN always be fully extended within their permissible

operating limits.

Block design: Pump and drive are flanged together via

a lantern base.

Housing: The discharge casing, stator and suction

casing are held together by external clamp bolts. The

suction casing has a particularly streamlined design.

Sizes 403…5503 are supplied in a gray cast iron design

with offset openings for cleaning.

228493 – 179-202/0 2021.02 en-US 5

Series: AEB1F

Design: IE

DRIVE

Drive types:

Three-phase motors, gear motors or variable gears

Use in potentially explosive area or normal area

Technical data and dimensions of the drives are

described in a separate sales document, sheet 19-00-

0000- 111- 3.

Connection:

Identical connection dimensions for all drive types

within one size

Conversion to another drive type or size is possible

INSTALLATION

Horizontal or vertical installation

Type of installation depends on the shaft seal. In the

case of a vertical arrangement, “shaft downwards” is

not permissible

REPLACEABILITY OF COMPONENTS

Production of components according to modular

system

Simple and inexpensive spare parts stock – even

when using pumps of different series and designs in

one system

6 2021.02 en-US 228493 – 179-202/0

Series: AEB1F

Design: IE

CROSS SECTIONS

Pump

Pump basic version Bearing 0 External bearing in drive unit

Shaft seal P01 Versatile due to particularly long packing length, permissible pressure at shaft seal p = -0.7 to 16 bar

Shaft seals

P02 Stuffing box with flushing ring P03 Stuffing box with internal lantern gland P04 Stuffing box with external lantern

Use with highly abrasive pumped liquids gland

with external flushing For use with pure pumped liquids with Used when the external flushing

p = -0.7 to 12 bar self-flushing or with abrasive pumped fluid is incompatible with the

liquids with external flushing pumped liquid or when the inflow

p = -0.8 to 6.0 bar of air is to be prevented.

p = -0.9 to 12 bar

G0K/ Single GLRD, G0S Single GLRD, G0Q Single GLRD, G0D Double GLRD, with flushing

G0N DIN EN 12756, K/N G0T DIN EN 12756, K/N design, DIN EN 12756, K fluid connection. Use after

design, U form. Use after U form, rotating part with design, U form, with consultation,

consultation, integrated locking device, quench. p = -0.95 to 16 bar

p = -0.5 to 16 bar with flushing fluid Use after consultation,

connection and throttle ring p = -0.5 to 16 bar

on pump side.

Use after consultation,

p = -0.5 to 16 bar

228493 – 179-202/0 2021.02 en-US 7

Series: AEB1F

Design: IE

Options

Winding protection on universal joint shaft Worm on universal joint shaft

Part numbers and designations

Part no. Designation Part no. Designation Part no. Designation

122 Lantern base 236 Lock washer 506 Suction casing cover

123 Clamping set 245 Hexagon head bolt 507 Gasket

125 Stub shaft 251 Sealing material 508 Stud bolt

201 Stud bolt 301 Joint pin 509 Nut

202 Self-locking nut 302 1) Joint bush 525 Washer

203 Stuffing box gland 303 Bush for joint pin 601 Type plate

204 Stuffing box casing 304 Joint sleeve 602 Round head grooved pin

207 Gland packing 305 Joint oil 603 Commissioning information plate

208 Flushing ring 306 Joint clamp 604 Suction information plate

209 Lantern gland 307 Universal joint shaft 605 Pressure information plate

212 Screw plug 308 Joint sleeve 606 Hexagon head bolt/stud bolt

213 Joint tape 401 Rotor 607 Hexagon nut

214 Mechanical seal housing 402 Stator 608 Serrated washer

215 Mechanical seal cover 403 Stator sealing on pressure side 609 Hexagon nut

218 O-ring 404 Stator sealing, suction side 610 Washer

219 Mechanical seal 501 Gasket for suction casing 611 Clamp bolt

220 Lock washer 502 Screw plug 612 Support

232 Shaft seal ring 503 Joint tape 613 Hexagon nut

234 Throttle ring 504 Discharge casing 627 Risk of injury information plate

235 O-ring 505 Suction casing

1) Not for size 103.

8 2021.02 en-US 228493 – 179-202/0

Series: AEB1F

Design: IE

DIMENSIONS*

Pump dimensions and weights

Pump dimensions Connection dimensions for

suction and discharge

connections

Size Pump dimensions max.

Dimen

sions

b c e f h m1 m2 n1 n2 o q 1) s L v [kg]

0103-IE 585 10 75 95 90 84 30 19 11 167 280 9 Rp ⅜ - 26

0203-IE 711 10 85 105 100 93 30 19 11 192 365 9 Rp ⅜ - 36

0403-IE 897 13 100 125 125 106 38 25 13 227 470 11.5 Rp ½ - 58

0553-IE 923 15 114 140 140 110 40 26 14 252 430 14 Rp ¾ - 78

0703-IE 1075 15 114 140 140 110 40 26 14 252 580 14 Rp ¾ - 91

1003-IE 1070.5 16 132 168 160 128 50 31 19 304 490 18 Rp ¾ - 125

1603-IE 1358.5 16 132 168 160 128 50 31 19 304 780 18 Rp ¾ - 153

3003-IE 1679.5 16 164 200 180 131 50 31 19 330 980 18 Rp ¾ 1079 252

5503-IE 2041.5 21 200 245 225 153 63 40 23 407.5 1195 22 Rp 1 1313 415

Size Connection dimensions for suction and discharge connections

Flanges DIN EN 1092, PN 16 3) Flanges ANSI B16.1, class 125 2) Flanges ANSI B16.5, class 150 2)

DN1 DN2 k p w g DN1 DN2 k p w g DN1 DN2 k p w g

0103-IE 50 50 696 529 43 175 2 2 692 525 39 171 2 2 696 529 43 175

0203-IE 65 65 834 642 46 190 2½ 2½ 833 641 45 189 2 ½ 2 ½ 838 646 50 194

0403-IE 80 80 1026 799 45 230 3 3 1024 797 43 228 3 3 1029 802 48 233

0553-IE 100 100 1054 802 43.5 260 4 4 1056 804 45.5 262 4 4 1056 804 45.5 262

0703-IE 100 100 1206 954 43.5 260 4 4 1208 956 45.5 262 4 4 1208 956 45.5 262

1003-IE 125 125 1216 912 44 300 5 5 1216 912 44 300 5 5 1216 912 44 300

1603-IE 125 125 1504 1200 44 300 5 5 1504 1200 44 300 5 5 1504 1200 44 300

3003-IE 150 150 1842 1512 59 350 6 6 1842 1512 59 350 6 6 1842 1512 59 350

5503-IE 200 200 2222.5 1815 64 425 8 8 2222.5 1815 64 425 8 8 2222.5 1815 64 425

*) Dimensions in mm, nominal widths of ANSI flanges (DN) in inches. Subject to change without notice.

Sense of rotation: Normal left as seen from the drive end, in this case DN1 = discharge flange, DN2 = suction branch, sense of direction of rotation possible, then DN1 =

suction branch, DN2 = discharge flange.

1) Stator removal dimension

2) Sealing surface stock finish

3) Connection dimensions according to DIN EN1092 up to DN 100 sealing strip B form, larger than DN 100 sealing strip A form

228493 – 179-202/0 2021.02 en-US 9

Series: AEB1F

Design: IE

Flange dimensions

DIN EN 1092, PN 16 2) ANSI B16.1/16.5, class 125/150 1)

DN1/DN2 k1 d1 z DN1/DN2 k1 d1 z

50 125 18 4 2 120.6 19 4

65 145 18 4 2½ 139.7 19 4

80 160 18 8 3 152.4 19 4

100 180 18 8 4 190.5 19 8

125 210 18 8 5 215.9 22.2 8

150 240 22 8 6 241.3 22.2 8

Possible flange positions as seen from the 200 295 22 12 8 298.4 22.2 8

drive (3 not for size 103)

1) Sealing surface stock finish

2) Connection dimensions according to DIN EN1092 up to DN 100 sealing strip B form, larger than DN 100

sealing strip A form

Permissible minimum flange load according to ISO 14847.

Arrangement of auxiliary connections for shaft seals

P02 with flushing ring G0Q with quench connection

P03 with internal lantern gland G0S/G0T with flushing connection

P04 with internal lantern gland G0D with flushing connection

10 2021.02 en-US 228493 – 179-202/0

Series: AEB1F

Design: IE

Size Connection dimensions Auxiliary connections for shaft seals (P…)

P02 with flushing ring P03 with internal P04 with external

Lantern gland Lantern gland

S1 1) u1 x1 t1 S2 1) u2 x2 t2 S3 1) u3 x3

103-IE M8x1 84 28 42˚ M8x1 77 30 20˚ M8x1 69 30.5

203-IE M8x1 93 31.5 40˚ M8x1 87 32 20˚ M8x1 78.5 33.5

403-IE Rp ⅛ 104.5 38 42˚ Rp ⅛ 97 40 17˚ Rp ⅛ 85 39.5

553-IE

Rp ⅛ 109.5 42 42˚ Rp ⅛ 102 44 17˚ Rp ⅛ 91.5 43.5

703-IE

1003-IE

Rp ⅛ 128.5 52 42˚ Rp ⅛ 119.5 54 17˚ Rp ⅛ 105 54.5

1603-IE

3003-IE Rp ⅛ 133 56 35˚ Rp ⅛ 122.5 57 13˚ Rp ⅛ 106 58

5503-IE Rp ¼ 155 67 35˚ Rp ¼ 142 68.5 13˚ Rp ¼ 122 69.5

Size Connection dimensions Auxiliary connections for shaft seals (G…)

G0S/G0T with flushing G0Q with quench G0D with flushing connection

connection connection

S5 1) u5 x5 S4 1) u4 x4 S6 1) S7 u6 u7 x6 x7 t7

103-IE Rp ¼ 46.5 34 Rp ⅛ 56 30.5 Rp ¼ Rp ¼ 46.5 71.5 34 33 15°

203-IE Rp ¼ 55 38 Rp ⅛ 63.5 30.5 Rp ¼ Rp ¼ 55 79 38 36.5 15°

403-IE Rp ¼ 69.5 41.5 Rp ⅛ 74 33.5 Rp ¼ Rp ¼ 69.5 95 41.5 40 15°

553-IE

Rp ⅜ 71.5 48.5 Rp ⅛ 79 41 Rp ⅜ Rp ⅜ 71.5 96.5 48.5 47 15°

703-IE

1003-IE

Rp ⅜ 92.5 56 Rp ⅛ 99.5 54 Rp ⅜ Rp ⅜ 92.5 118 56 53.5 20°

1603-IE

3003-IE Rp ⅜ 80.5 61 Rp ⅛ 99 57.5 Rp ⅜ Rp ⅜ 80.5 121 61 58.5 20°

5503-IE Rp ⅜ 103 71.5 Rp ¼ 106.5 68.5 Rp ⅜ Rp ⅜ 103 145 71.5 69 22°

1) Screw-in hole DIN 3852, Z form

► Control supply

▻ Possible supply, for this purpose the seal housing must be rotated for the P02, G0S, G0T, G0Q, G0D designs

Drive options

AEB-IE with electric motor AEB-IE with gear motor AEB-IE with infinitely variable gear box

Optional:

Gear motor with frequency converter

IEC gear boxes with and without motor

228493 – 179-202/0 2021.02 en-US 11

Series: AEB1F

Design: IE

We reserve the right to make technical changes.

ALLWEILER GmbH

P.O. Box 200123 • 46223 Bottrop

Kirchhellener Ring 77–79 • 46244 Bottrop

Germany

Phone +49 (0)2045 966-60

Fax +49 (0)2045 966-679

E-mail: service-ge@allweiler.de

Internet: http://www.allweiler.com

12 2021.02 en-US 228493 – 179-202/0

You might also like

- Pipeline Calculations - ASAB Gas Lift LinesDocument11 pagesPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqNo ratings yet

- Load Chart Gr-500exl L S GDocument16 pagesLoad Chart Gr-500exl L S GChan RizkyNo ratings yet

- GR-130EX: Hydraulic Rough Terrain CraneDocument16 pagesGR-130EX: Hydraulic Rough Terrain CraneDenny AjaNo ratings yet

- Crushing - GrindingDocument118 pagesCrushing - GrindingHarrison Antonio Mira NiloNo ratings yet

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Prof. MurugaiyanDocument13 pagesProf. MurugaiyanilasundaramNo ratings yet

- PRS Var 3-140 D 2960138000 - LDocument4 pagesPRS Var 3-140 D 2960138000 - LBJ AbelaNo ratings yet

- Oprema Oprema: Staircase Swirl Diffuser, Type IRDocument3 pagesOprema Oprema: Staircase Swirl Diffuser, Type IRAnonymous KB3AksTpBNo ratings yet

- Ac-Var 6-250Document4 pagesAc-Var 6-250Mota Guine InformaçõesNo ratings yet

- Gr-500exs-3 Lng-En Gen S 202111 PDFDocument12 pagesGr-500exs-3 Lng-En Gen S 202111 PDFanh tranNo ratings yet

- Carrier Tabela6 DuctDimensionsDocument5 pagesCarrier Tabela6 DuctDimensionsLuciano Lopes SimõesNo ratings yet

- Pump Curve 250x350Document1 pagePump Curve 250x350reiNo ratings yet

- Ficha Tecnica WMD-05SDocument1 pageFicha Tecnica WMD-05SjatsocaNo ratings yet

- SP - 5A17 Deep Well PumpDocument8 pagesSP - 5A17 Deep Well PumpGita SaputraNo ratings yet

- Datasheet (Métrico) - 2BH1900Document2 pagesDatasheet (Métrico) - 2BH1900Rafael BalakNo ratings yet

- Design and Characteristic Analysis of Vibration FeDocument7 pagesDesign and Characteristic Analysis of Vibration FeĐăng Điệp NguyễnNo ratings yet

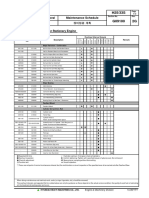

- Hyundai Maintenance ScheduleDocument3 pagesHyundai Maintenance ScheduleAsim RehmanNo ratings yet

- Air Operated Diaphragm Pumps: Catalogue 2011 Rev 1Document23 pagesAir Operated Diaphragm Pumps: Catalogue 2011 Rev 1TrungGVNo ratings yet

- Media Type Effect On Ginding EfficiencyDocument9 pagesMedia Type Effect On Ginding EfficiencyLuis BNo ratings yet

- Eaton LVBreakers 70 C1446Document1 pageEaton LVBreakers 70 C1446Al JoNo ratings yet

- Screw Pump Catalogue EnDocument17 pagesScrew Pump Catalogue Enmuhammad.kamranNo ratings yet

- Bulk HP: Achieve MoreDocument4 pagesBulk HP: Achieve MoreTangguh JayaNo ratings yet

- LFWP Training R1Document27 pagesLFWP Training R1lemuel bacsaNo ratings yet

- 4 - V112-3.0MW - VestasDocument26 pages4 - V112-3.0MW - Vestasvasile78No ratings yet

- Basic SaunaDocument6 pagesBasic SaunaDavid LussiNo ratings yet

- ITM Nterruptor 400 EATONDocument1 pageITM Nterruptor 400 EATONjosseNo ratings yet

- AHLSTAR End-Suction Single-Stage Centrifugal PumpsDocument24 pagesAHLSTAR End-Suction Single-Stage Centrifugal PumpsDoanh VoNo ratings yet

- Pneumatic Pump Range Letter Rev13Document1 pagePneumatic Pump Range Letter Rev13mari villalobosNo ratings yet

- Equipments CatalogueDocument26 pagesEquipments CatalogueBenfil ViernezNo ratings yet

- Aversa DP Cat RO EN PDFDocument16 pagesAversa DP Cat RO EN PDFmatache temelieNo ratings yet

- Aversa DP Cat RO EN PDFDocument16 pagesAversa DP Cat RO EN PDFmatache temelieNo ratings yet

- Framo Ballast Operation Manual PDFDocument13 pagesFramo Ballast Operation Manual PDFkokiNo ratings yet

- KSB MDXDocument3 pagesKSB MDXLuis VelazcoNo ratings yet

- Mix Design of Self ConsolidatingDocument21 pagesMix Design of Self ConsolidatingMohamed BukhamsinNo ratings yet

- 3rd Option -Technical AGRA (Dragged)Document1 page3rd Option -Technical AGRA (Dragged)saurabhNo ratings yet

- Ecler Dla600 Dual Line Adaptor Service ManualDocument11 pagesEcler Dla600 Dual Line Adaptor Service ManualDSV InnovationsNo ratings yet

- BHR 35 - 30 4 Stg.Document3 pagesBHR 35 - 30 4 Stg.Maknan SteelNo ratings yet

- 131197.BSC 01.HW - Piazza.dessie - Ner Eno PPT 20200107 2232Document29 pages131197.BSC 01.HW - Piazza.dessie - Ner Eno PPT 20200107 2232MikatechNo ratings yet

- Hydraulic Crawler Crane: Model: CKL1000iDocument4 pagesHydraulic Crawler Crane: Model: CKL1000iRameshkumararya RameshkumararyaNo ratings yet

- 02 Monograma de Casa GrandeDocument1 page02 Monograma de Casa GrandeQC A NoelNo ratings yet

- 07 Electrical Res LogDocument44 pages07 Electrical Res LogAhmed BubakerNo ratings yet

- Myers: HR Series Convertible Jet PumpsDocument2 pagesMyers: HR Series Convertible Jet PumpsDiana AguayoNo ratings yet

- Bomba 600 MDX-KSBDocument2 pagesBomba 600 MDX-KSBP. Ernesto C. GutierrezNo ratings yet

- Truck-Mounted UNIC Crane UR-V500 Series For Heavy-Duty TruckDocument3 pagesTruck-Mounted UNIC Crane UR-V500 Series For Heavy-Duty TruckXUAN LUUNo ratings yet

- M28N-2 Series: DC Mini-MotorsDocument1 pageM28N-2 Series: DC Mini-MotorsYacine MARICHENo ratings yet

- 2xK3G450PB29L1 17820m3h 325pa 14-5-2024 11-08-09 enDocument3 pages2xK3G450PB29L1 17820m3h 325pa 14-5-2024 11-08-09 enMJNo ratings yet

- As Staked 22FB0280 Layout6Document1 pageAs Staked 22FB0280 Layout6ber gularNo ratings yet

- S800nf-S800rf-Cat1 - MCCB TerasakiDocument2 pagesS800nf-S800rf-Cat1 - MCCB Terasakihakiman.irecNo ratings yet

- Pump GAD For Vertical TurbineDocument9 pagesPump GAD For Vertical TurbineVijay Rama RajuNo ratings yet

- Purgadoras de AireDocument15 pagesPurgadoras de AireAlberto DiazNo ratings yet

- Kripsol - KAPDocument9 pagesKripsol - KAPThọ Đỗ ĐứcNo ratings yet

- Rod Shaped Proppant PsDocument2 pagesRod Shaped Proppant PsbayuNo ratings yet

- 3.2 ECB Guardrail 40mmDocument1 page3.2 ECB Guardrail 40mmSyed Nizam ElahiNo ratings yet

- Extruder Design and ScalingDocument2 pagesExtruder Design and ScalingasdfesddNo ratings yet

- Pavement JointDocument1 pagePavement Jointnazam eubNo ratings yet

- Jig SHS5004 004 000Document2 pagesJig SHS5004 004 000Luong LeNo ratings yet

- ModelDocument1 pageModelShady RainNo ratings yet

- Sketch Struktur D6-06Document7 pagesSketch Struktur D6-06David WenzNo ratings yet

- Emerson Flow CalculationsDocument10 pagesEmerson Flow Calculationsalpim54No ratings yet

- Mi-20Kve: User'S GuideDocument15 pagesMi-20Kve: User'S GuideAhmad TaufikNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- E70 PDFDocument900 pagesE70 PDFАлексей100% (1)

- 6SL3210-1PB13-0UL0 Datasheet enDocument2 pages6SL3210-1PB13-0UL0 Datasheet enCintexNo ratings yet

- 7495 Electric Rope Shovel Electrical System CAT MPTS ™Document108 pages7495 Electric Rope Shovel Electrical System CAT MPTS ™Javier100% (1)

- Design, Modeling and Simulation of An Electric Vehicle SystemDocument12 pagesDesign, Modeling and Simulation of An Electric Vehicle SystemsushruthanNo ratings yet

- Rish Split Current TransformerDocument6 pagesRish Split Current TransformerluisNo ratings yet

- HW 3Document3 pagesHW 3JeeveshNo ratings yet

- Measurement of The Acoustic Absorption CoefficientDocument8 pagesMeasurement of The Acoustic Absorption CoefficientmahirtorsunNo ratings yet

- Chemistry Lab e Content Updated 2Document35 pagesChemistry Lab e Content Updated 2Debarghya DuttaNo ratings yet

- Series EHDW/Pendant Hand-Held: FeaturesDocument2 pagesSeries EHDW/Pendant Hand-Held: FeaturesBejo JacobNo ratings yet

- R19 Mw&oc Lab Manuals ModifiedDocument84 pagesR19 Mw&oc Lab Manuals ModifiedSUPRIYA TELUGUNo ratings yet

- Hot Box BasicsDocument12 pagesHot Box BasicsAhsen NasimNo ratings yet

- Studies On LightDocument8 pagesStudies On LightLora Angel MartinNo ratings yet

- EC 252:signals and Systems Laboratory: Generating Signals Using Matlab SimulatorDocument11 pagesEC 252:signals and Systems Laboratory: Generating Signals Using Matlab SimulatorSHOAIB WARJRINo ratings yet

- Optimization Design of Colpitts Oscillator For Active INDUCTION BALANCE METAL DETECTIONDocument6 pagesOptimization Design of Colpitts Oscillator For Active INDUCTION BALANCE METAL DETECTIONLAKIS PAVNo ratings yet

- Sany SSP80C-8H Paver - 101722Document2 pagesSany SSP80C-8H Paver - 101722Alex MazaNo ratings yet

- TVS Diode - ApplicationDocument6 pagesTVS Diode - ApplicationntchtdNo ratings yet

- 5.1-Bond energy-Calculations-Set-1-qp-msDocument10 pages5.1-Bond energy-Calculations-Set-1-qp-msrashmeen2007No ratings yet

- Master Notice BETM - ENDocument60 pagesMaster Notice BETM - ENBerat DeğirmenciNo ratings yet

- Application Note Metallography of WeldsDocument8 pagesApplication Note Metallography of WeldsLorena Grijalba LeónNo ratings yet

- J S University Diploma 5th Elect Assignment 1Document8 pagesJ S University Diploma 5th Elect Assignment 1Microsoft RewardNo ratings yet

- Thermostat AB-E 31-32: Adjustment Range 5 To 100°CDocument2 pagesThermostat AB-E 31-32: Adjustment Range 5 To 100°ChaggNo ratings yet

- Net Force WorksheetDocument2 pagesNet Force WorksheetJayson SisorNo ratings yet

- Construction Materials - Chemical AdmixturesDocument46 pagesConstruction Materials - Chemical AdmixturesWelday TsegayNo ratings yet

- Lighting Document 5.9.2020Document109 pagesLighting Document 5.9.2020VKNo ratings yet

- Hardness Test: NO: 3 Supervised By: Dr. OsmanDocument9 pagesHardness Test: NO: 3 Supervised By: Dr. Osmanwrya hussainNo ratings yet

- HUGGINS Geometrical OpticsDocument61 pagesHUGGINS Geometrical Opticst6wtdpbg92No ratings yet

- YTS-09 (XI Maths Sample Paper - O.P. GUPTA)Document5 pagesYTS-09 (XI Maths Sample Paper - O.P. GUPTA)SahilNo ratings yet

- Electrical Motors - Frame Sizes PDFDocument5 pagesElectrical Motors - Frame Sizes PDFGustavo CuatzoNo ratings yet