Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsProperties of CRNO-BAOSTEEL-Products Brochure

Properties of CRNO-BAOSTEEL-Products Brochure

Uploaded by

Rui Gonzaga De AlmeidaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Properties and Characteristics of GraphiteDocument39 pagesProperties and Characteristics of GraphitePaden TranNo ratings yet

- Condon E. Scientific Study of UFO Vol1Document167 pagesCondon E. Scientific Study of UFO Vol1Igor KalytyukNo ratings yet

- Catch Basin ManholeDocument40 pagesCatch Basin Manholekalven marquezNo ratings yet

- Culvert Capacity Tables Pipe CulvertsDocument1 pageCulvert Capacity Tables Pipe CulvertsChristian NicolausNo ratings yet

- Connection Design MohapalDocument55 pagesConnection Design MohapalUMESH LAMICHHANENo ratings yet

- Design of Equal Angle For BridgingDocument7 pagesDesign of Equal Angle For BridgingjatinNo ratings yet

- WEB 6. Regresion Lineal Simple en Simulador 16-04 2018Document19 pagesWEB 6. Regresion Lineal Simple en Simulador 16-04 2018eglentine castrillonNo ratings yet

- XX Yy 4 Uu 4 VV 4 XX Yy Uu VV Xy 4 XX Yy XX Yy 2 XX Yy 3Document1 pageXX Yy 4 Uu 4 VV 4 XX Yy Uu VV Xy 4 XX Yy XX Yy 2 XX Yy 3shahsan2005No ratings yet

- STT Student ID Gender Condition Class Pre-Test 1 2 3 4 Student RecordDocument21 pagesSTT Student ID Gender Condition Class Pre-Test 1 2 3 4 Student RecordThanh TuongNo ratings yet

- Winkler SafeDocument1 pageWinkler SafeMañonMarianoMariaNo ratings yet

- @all in OneDocument268 pages@all in Onegerearegawi721No ratings yet

- Aprovechamiento Forestal Hato San MartínDocument55 pagesAprovechamiento Forestal Hato San MartínMoisesGuerreroNo ratings yet

- Modulo de Reaccion Del SueloDocument1 pageModulo de Reaccion Del SueloDaniel RabascallNo ratings yet

- Pipe SCDocument1 pagePipe SCJaganmatha BharanidharanNo ratings yet

- KV (NSPTmédio) - SAFE, MORRISON (1993)Document1 pageKV (NSPTmédio) - SAFE, MORRISON (1993)Naldinho MonteiroNo ratings yet

- CLASS 600 Weld Neck Flanges WeightDocument1 pageCLASS 600 Weld Neck Flanges WeightAwais IftikharNo ratings yet

- Es 10 A0910 Records 2009.10.26 - For PostingDocument12 pagesEs 10 A0910 Records 2009.10.26 - For Postingkarlajane03No ratings yet

- Altura Exposicion: Tabla 16-G Coeficiente CeDocument6 pagesAltura Exposicion: Tabla 16-G Coeficiente CeJUANCALABAZANo ratings yet

- Indian Standard Angle Sections 02Document1 pageIndian Standard Angle Sections 02CIVILNo ratings yet

- Retaining Rings MetricDocument18 pagesRetaining Rings MetricEmmanuelNo ratings yet

- Indian Standard Angle Sections 01Document1 pageIndian Standard Angle Sections 01CIVILNo ratings yet

- 000 215 1221 A02 31mar05Document2 pages000 215 1221 A02 31mar05Felipe FloresNo ratings yet

- Packing List CC2500 and CC2800-1Document15 pagesPacking List CC2500 and CC2800-1Duong Truong100% (1)

- 1991 Bookmatter CitrusProcessingDocument61 pages1991 Bookmatter CitrusProcessingSai Kiran PalikaNo ratings yet

- Itish Standard Welded Steel PipesDocument1 pageItish Standard Welded Steel PipesnelsonNo ratings yet

- Sugar Industry: Main Cane Carrier ChainDocument6 pagesSugar Industry: Main Cane Carrier ChainAlexander Arias VargasNo ratings yet

- حصر كمبات من مقاول الباطن جديدDocument10 pagesحصر كمبات من مقاول الباطن جديدSameh Salama MohamedNo ratings yet

- ANSI_16_5_300Rev1Document1 pageANSI_16_5_300Rev1nurulapriliashNo ratings yet

- ANSI_16_5_300Rev1Document1 pageANSI_16_5_300Rev1nurulapriliashNo ratings yet

- Single-Span Support: Negative PositionDocument1 pageSingle-Span Support: Negative PositionmikeshiiNo ratings yet

- Note: Density of Insulation Material Considered As 150 KG/CMDocument1 pageNote: Density of Insulation Material Considered As 150 KG/CMHarsh KhatriNo ratings yet

- Curvas IdtrDocument21 pagesCurvas IdtrOSCAR RENE DOMINGUEZ MONCLOVANo ratings yet

- SDD TW10Document1 pageSDD TW10Tera Water TechnologyNo ratings yet

- A12 MT OBLICON 2nd Sem AY 2022Document1 pageA12 MT OBLICON 2nd Sem AY 2022Mask HeheNo ratings yet

- Max Zs Values 17th - Sheet1Document1 pageMax Zs Values 17th - Sheet1Francisco M. RamosNo ratings yet

- Table 1 - 1Document11 pagesTable 1 - 1jessieNo ratings yet

- Pengujian Lentur Balok Beton Karet (Beam) VARIASI 1 (PSR 60%: KRT 40%)Document43 pagesPengujian Lentur Balok Beton Karet (Beam) VARIASI 1 (PSR 60%: KRT 40%)cristian jeremy jeremyNo ratings yet

- Manila Standard Today - Business Daily Stocks Review (June 14, 2012)Document1 pageManila Standard Today - Business Daily Stocks Review (June 14, 2012)Manila Standard TodayNo ratings yet

- SDD TW9Document1 pageSDD TW9Tera Water TechnologyNo ratings yet

- Pipe ScheduleDocument2 pagesPipe ScheduleRUDDY ALFAN SUBAKTINo ratings yet

- S.1 Parung BangkongDocument3 pagesS.1 Parung BangkongAde SetiawanNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012Thomas CalvinNo ratings yet

- All STD Material WeightDocument19 pagesAll STD Material WeightCoralPT WorldwideNo ratings yet

- Ansi - 600 - Norma de BridasDocument1 pageAnsi - 600 - Norma de BridasDaniel PorrasNo ratings yet

- 27.00 MM Jobthickness: A/l A/t A/l A/tDocument1 page27.00 MM Jobthickness: A/l A/t A/l A/tSatyabrata KunduNo ratings yet

- Angka KonvesiDocument23 pagesAngka Konvesisilvia akmaNo ratings yet

- Feed Cost For 1 Pangasius FishDocument7 pagesFeed Cost For 1 Pangasius FishkushNo ratings yet

- Astm A312Document5 pagesAstm A312Hưng PhùngNo ratings yet

- Cara Cepat LP Msuk Cad 4Document9 pagesCara Cepat LP Msuk Cad 4Audric GenterNo ratings yet

- Manila Standard Today - Business Daily Stocks Review (November 20, 2012)Document1 pageManila Standard Today - Business Daily Stocks Review (November 20, 2012)Manila Standard TodayNo ratings yet

- Wind LoadDocument4 pagesWind LoadAamir SuhailNo ratings yet

- Steel TableDocument2 pagesSteel TableManan ShahNo ratings yet

- Kathen ExcelDocument10 pagesKathen ExcelTarunNo ratings yet

- Kathen ExcelDocument10 pagesKathen ExcelTarunNo ratings yet

- Kathen ExcelDocument10 pagesKathen ExcelTarunNo ratings yet

- LFA Girls 0 2 Percentiles PDFDocument1 pageLFA Girls 0 2 Percentiles PDFprofundae2073No ratings yet

- 0 2 PercentilesDocument1 page0 2 PercentilesannisarachmaNo ratings yet

- Debt FundsDocument36 pagesDebt FundsArmstrong CapitalNo ratings yet

- Core Capcity & Turns Per VoltDocument1 pageCore Capcity & Turns Per VoltDeepak BainsNo ratings yet

- B Catalogo de Motores Asincronos Mayo 2020Document2 pagesB Catalogo de Motores Asincronos Mayo 2020MARLON RUIZ OCHOANo ratings yet

- 11a. Cuadro de Calculo Paso Aereo #1Document17 pages11a. Cuadro de Calculo Paso Aereo #1JOSE ALBERTO JEREZNo ratings yet

- Still Life Painting Lesson PlanDocument2 pagesStill Life Painting Lesson PlanGevy CamachoNo ratings yet

- ROCKAL FOAM (28: 30) KG/M: FlammabilityDocument9 pagesROCKAL FOAM (28: 30) KG/M: Flammabilityjustice judgeNo ratings yet

- UNIT-6 Multivariable Calculus (DOC FILE)Document15 pagesUNIT-6 Multivariable Calculus (DOC FILE)chinoerageorge0No ratings yet

- AB1202 Week 5Document4 pagesAB1202 Week 5amos liewNo ratings yet

- Ys Us S S: BG3102 Control in Biosystems AssignmentDocument2 pagesYs Us S S: BG3102 Control in Biosystems AssignmenteliasNo ratings yet

- NanotechnologyDocument14 pagesNanotechnologymohan vamsi100% (1)

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Paulino, Paul Tyrone R. Assignment 3Document14 pagesPaulino, Paul Tyrone R. Assignment 3Tyrone PaulinoNo ratings yet

- 9A04603 Digital Signal Processing16Document4 pages9A04603 Digital Signal Processing16Mahaboob SubahanNo ratings yet

- Newton S Law of CoolingDocument9 pagesNewton S Law of CoolingJulian Mauricio Cuevas GalloNo ratings yet

- Wet Gas Sampling in The Upstream Area Rev Brazil - ISO TC193 - SC3 Chairman DocumentDocument13 pagesWet Gas Sampling in The Upstream Area Rev Brazil - ISO TC193 - SC3 Chairman DocumentPhilip A Lawrence C.Eng. F. Inst M.C.No ratings yet

- Rag663 SLR Paper - AmalinaDocument26 pagesRag663 SLR Paper - AmalinaSEVENSEA CLANNo ratings yet

- What and When ? Visual Electrophysiology in The Clinical PracticeDocument23 pagesWhat and When ? Visual Electrophysiology in The Clinical PracticeAlexandra BobaruNo ratings yet

- Lighting - Education - Science-ZumtobelDocument60 pagesLighting - Education - Science-ZumtobelManoj IllangasooriyaNo ratings yet

- 25 Feb Shift 1 JEE Main 2021Document64 pages25 Feb Shift 1 JEE Main 2021Devchand BothraNo ratings yet

- 2537 VD4G-50 Vacuum Circuit-Breaker GBDocument4 pages2537 VD4G-50 Vacuum Circuit-Breaker GBburvanov0% (1)

- Performance Specification: Hot Side Cold SideDocument2 pagesPerformance Specification: Hot Side Cold SideStevan KrstojevicNo ratings yet

- Asme PTC 38Document133 pagesAsme PTC 38Anonymous knICax100% (1)

- Effects of Tires and Tire Pressures On Road Pavements: Matti Huhtala,) Ari Pihlajamaki, and Markku PienimakiDocument8 pagesEffects of Tires and Tire Pressures On Road Pavements: Matti Huhtala,) Ari Pihlajamaki, and Markku Pienimakiศิวาเวช อบมาNo ratings yet

- Hand Biometrics: Erdem Yo Ru K, Helin Dutag Aci, Bu Lent SankurDocument15 pagesHand Biometrics: Erdem Yo Ru K, Helin Dutag Aci, Bu Lent Sankurjit_72No ratings yet

- Phase Transformation in AISI 410 Stainless Steel PDFDocument10 pagesPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiNo ratings yet

- IETE-Journal of Research Template PDFDocument7 pagesIETE-Journal of Research Template PDFMadan R HonnalagereNo ratings yet

- MechanicsOfCompliantMaterialsWk 04notesDocument15 pagesMechanicsOfCompliantMaterialsWk 04notesLorenzo MartinezNo ratings yet

- MMEN 226 - Worked Examples On Torsion, Set 7Document10 pagesMMEN 226 - Worked Examples On Torsion, Set 7nattydreadfathelahNo ratings yet

- NC590 - Construction Planning L2 QP Supp 2019Document8 pagesNC590 - Construction Planning L2 QP Supp 2019fanafisto04No ratings yet

- HHI Generator Manual-FINALDocument45 pagesHHI Generator Manual-FINALIgor CanabarroNo ratings yet

- Chemistry 311 Physical ChemistryDocument3 pagesChemistry 311 Physical ChemistryJosef CatiggayNo ratings yet

- I-Io) (National .I-Jiuuuutics " - : - (At'nYDocument116 pagesI-Io) (National .I-Jiuuuutics " - : - (At'nYLuis GianiNo ratings yet

Properties of CRNO-BAOSTEEL-Products Brochure

Properties of CRNO-BAOSTEEL-Products Brochure

Uploaded by

Rui Gonzaga De Almeida0 ratings0% found this document useful (0 votes)

4 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views6 pagesProperties of CRNO-BAOSTEEL-Products Brochure

Properties of CRNO-BAOSTEEL-Products Brochure

Uploaded by

Rui Gonzaga De AlmeidaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

THE SPECIFICATION

OF

COLD ROLLED NON-ORIENTED ELECTRICAL STEEL

PRODUCED BY

BAOSTEEL, CHINA

FOR

INTERNATIONAL MARKET

PRESENTED BY

M & M RESOURCES INTERNATIONAL INC.

155 Pleasant Ave. Dundas, ON. L9H 3T9, Canada

Tel: 001-905-627-2473 Fax: 001-905-627-2473

Email: mmresources@gmail.com

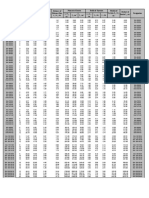

SPECIFICATION OF COLD ROLLED NON-ORIENTED ELECTRICAL STEEL

Guaranteed Core Loss and induction

Min.

Thickness Density Max. Core Loss Min. Induction Lamination

Grade Factor

(mm) (kg/dm3) w/kg (1.5T, 50HZ) T (B50) (%)

35A230 7.60 2.30 1.62 95.0

35A250 7.60 2.50 1.62 95.0

35A270 7.65 2.70 1.62 95.0

35A300 0.35 7.65 3.00 1.62 95.0

35A360 7.65 3.60 1.63 95.0

35A440 7.70 4.40 1.63 95.0

35A550 7.75 5.50 1.64 95.0

50A250 7.60 2.50 1.62 96.0

50A270 7.60 2.70 1.62 96.0

50A290 7.60 2.90 1.62 96.0

50A310 7.65 3.10 1.62 96.0

50A350 7.65 3.50 1.62 96.0

50A400 7.65 4.00 1.63 96.0

0.50

50A470 7.70 4.70 1.64 96.0

50A600 7.75 6.00 1.66 96.0

50A700 7.80 7.00 1.70 96.0

50A800 7.80 8.00 1.70 96.0

50A1000 7.85 10.00 1.70 96.0

50A1300 7.85 13.00 1.70 96.0

65A470 7.65 4.70 1.70 97.0

65A600 7.75 6.00 1.70 97.0

65A700 7.75 7.00 1.71 97.0

0.65

65A800 7.80 8.00 1.70 97.0

65A1000 7.80 10.00 1.70 97.0

65A1300 7.85 13.00 1.70 97.0

Typical Core Loss and Induction

Thickness Density Typical Core Loss (w/kg) Induction (T)

Grade

(mm) (kg/dm3) P10/50 P15/50 P10/60 P15/60 B10 B25 B50 B100

35A230 7.60 0.92 2.15 1.15 2.67 1.47 1.57 1.66 1.78

35A250 7.60 0.98 2.25 1.22 2.78 1.48 1.57 1.66 1.78

35A270 7.65 1.00 2.40 1.24 2.82 1.48 1.58 1.67 1.79

35A300 0.35 7.65 1.14 2.55 1.42 3.13 1.51 1.59 1.68 1.80

35A360 7.65 1.25 2.80 1.55 3.41 1.51 1.60 1.68 1.80

35A440 7.70 1.35 3.00 1.66 3.69 1.53 1.62 1.70 1.82

35A550 7.75 1.55 3.50 1.92 4.34 1.53 1.61 1.69 1.82

50A250 7.60 1.05 2.39 1.34 3.03 1.48 1.57 1.67 1.79

50A270 7.60 1.08 2.50 1.40 3.18 1.48 1.57 1.67 1.80

50A290 7.60 1.10 2.60 1.41 3.25 1.49 1.58 1.67 1.79

50A310 7.65 1.18 2.70 1.57 3.38 1.50 1.59 1.68 1.80

50A350 7.65 1.30 2.85 1.65 3.60 1.50 1.60 1.68 1.80

50A400 7.65 1.45 3.15 1.84 4.01 1.52 1.61 1.69 1.81

0.50

50A470 7.70 1.76 4.00 2.22 5.01 1.52 1.60 1.69 1.80

50A600 7.75 1.93 4.30 2.43 5.37 1.53 1.62 1.71 1.82

50A700 7.80 2.42 5.20 3.01 6.47 1.56 1.65 1.73 1.84

50A800 7.80 2.67 5.70 3.34 7.11 1.57 1.66 1.74 1.84

50A1000 7.85 2.82 6.20 3.57 7.80 1.59 1.68 1.76 1.87

50A1300 7.85 3.32 7.20 4.20 9.12 1.59 1.68 1.76 1.88

65A470 7.65 1.69 3.70 2.19 4.75 1.52 1.62 1.71 1.82

65A600 7.75 2.11 4.70 2.71 5.97 1.52 1.62 1.71 1.82

65A700 7.75 2.19 4.90 2.84 6.25 1.53 1.63 1.72 1.83

0.65

65A800 7.80 2.69 5.90 3.42 7.52 1.56 1.66 1.74 1.85

65A100 7.80 2.85 6.40 3.67 8.17 1.57 1.67 1.75 1.86

65A1300 7.85 3.25 7.40 4.22 8.52 1.59 1.68 1.77 1.88

Typical Mechanical Properties

Thickness Density Tensile Strength Yield Strength Elongation Hardness Bending

Grade

mm (kg/dm3) (N/mm2) (N/mm2) (%) (HV1) Number

35A230 7.60 548 431 19 221 >5

35A250 7.60 549 429 20 217 >5

35A270 7.65 537 412 21 212 >10

35A300 0.35 7.65 516 378 26 197 >11

35A360 7.65 497 350 29 186 >15

35A440 7.70 444 289 32 162 >15

35A550 7.75 400 234 36 133 >15

50A250 7.60 550 432 19 227 >4

50A270 7.60 555 435 20 220 >4

50A290 7.60 538 405 20 211 >5

50A310 7.65 538 405 24 207 >12

50A350 7.65 516 376 26 197 >14

50A400 7.65 454 302 32 170 >15

0.50

50A470 7.70 407 241 37 137 >15

50A600 7.75 407 253 37 133 >15

50A700 7.80 382 247 38 120 >15

50A800 7.80 397 266 38 126 >15

50A1000 7.85 366 241 40 113 >15

50A1300 7.85 352 239 41 108 >15

65A470 7.65 450 298 32 171 >15

65A600 7.75 408 248 37 138 >15

65A700 7.75 402 241 38 133 >15

0.65

65A800 7.80 387 251 39 124 >15

65A1000 7.80 391 257 39 124 >15

65A1300 7.85 357 231 41 110 >15

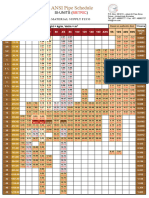

Available Size

Thickness: 0.35mm 0.50mm 0.65mm

Width: 900mm-1290mm

Inner Dia. 508mm

Outer Dia. 700-1550mm

Size and Shape Tolerance

Tolerance (mm)

Width (mm) Thick (mm)

Thickness Camberness Width Linear Measure Shear Burr

0.35 (+/-)0.04 <=0.02

<=150 0.5 (+/-)0.04 <=0.03 (+) 0.3-0

0.65 (+/-)0.05 <=0.03

0.35 (+/-)0.04 <=0.02

>150-500 0.5 (+/-)0.04 <=0.03 (+) 0.5-0

0.65 (+/-)0.05 <=0.03

<=1.0 <=0.05

0.35 (+/-)0.04 <=0.02

>500-1000 0.5 (+/-)0.04 <=0.03 (+) 1.5-0

0.65 (+/-)0.05 <=0.04

0.35 (+/-)0.04 <=0.03

>1000 0.5 (+/-)0.04 <=0.04 (+) 1.5-0

0.65 (+/-)0.05 <=0.04

Surface Insulation Coating

We provide Type A, H and D of Coatings. Users may select a qualified coating type from them in accordance with

interlamination resistance, sheet punching ability, from resistance, heat resistance and other characteristics.

Coating A: Coating A is a semi-organic thin coating with excellent sheet-punching ability, corrosion resistance, from

Resistance and high lamination resistance. It has extraordinarily excellent weld ability and is suitable for medium and

Small size electric motors and motors for household appliances. It is equivalent to the coat A1of KSC and coating T4

of Wuhan Steel

Coating H: Coating H is a semi-organic thick coating with excellent sheet-punching ability, corrosion resistance, freon

resistance and high lamination resistance. It has extraordinarily excellent weldability and is suitable for medium and

small size electric motors and motors for household appliances which requires higher sheet punching ability It is

equivalent to A1 of KSC and T4 of Wuhan Steel

Coating D: Coating D is an inorganic coating with excellent weldability and heat resistance. It is suitable for medium

and small size electrical motors and especially fit in the application of stress-relief annealing at a high temperature.

It is equivalent to coating C4 of AISI and the coating of T3 of Wuhan Steel

Unless there are specific descriptions, the surface insulation coatings designed for steel grade are all coating A

You might also like

- Properties and Characteristics of GraphiteDocument39 pagesProperties and Characteristics of GraphitePaden TranNo ratings yet

- Condon E. Scientific Study of UFO Vol1Document167 pagesCondon E. Scientific Study of UFO Vol1Igor KalytyukNo ratings yet

- Catch Basin ManholeDocument40 pagesCatch Basin Manholekalven marquezNo ratings yet

- Culvert Capacity Tables Pipe CulvertsDocument1 pageCulvert Capacity Tables Pipe CulvertsChristian NicolausNo ratings yet

- Connection Design MohapalDocument55 pagesConnection Design MohapalUMESH LAMICHHANENo ratings yet

- Design of Equal Angle For BridgingDocument7 pagesDesign of Equal Angle For BridgingjatinNo ratings yet

- WEB 6. Regresion Lineal Simple en Simulador 16-04 2018Document19 pagesWEB 6. Regresion Lineal Simple en Simulador 16-04 2018eglentine castrillonNo ratings yet

- XX Yy 4 Uu 4 VV 4 XX Yy Uu VV Xy 4 XX Yy XX Yy 2 XX Yy 3Document1 pageXX Yy 4 Uu 4 VV 4 XX Yy Uu VV Xy 4 XX Yy XX Yy 2 XX Yy 3shahsan2005No ratings yet

- STT Student ID Gender Condition Class Pre-Test 1 2 3 4 Student RecordDocument21 pagesSTT Student ID Gender Condition Class Pre-Test 1 2 3 4 Student RecordThanh TuongNo ratings yet

- Winkler SafeDocument1 pageWinkler SafeMañonMarianoMariaNo ratings yet

- @all in OneDocument268 pages@all in Onegerearegawi721No ratings yet

- Aprovechamiento Forestal Hato San MartínDocument55 pagesAprovechamiento Forestal Hato San MartínMoisesGuerreroNo ratings yet

- Modulo de Reaccion Del SueloDocument1 pageModulo de Reaccion Del SueloDaniel RabascallNo ratings yet

- Pipe SCDocument1 pagePipe SCJaganmatha BharanidharanNo ratings yet

- KV (NSPTmédio) - SAFE, MORRISON (1993)Document1 pageKV (NSPTmédio) - SAFE, MORRISON (1993)Naldinho MonteiroNo ratings yet

- CLASS 600 Weld Neck Flanges WeightDocument1 pageCLASS 600 Weld Neck Flanges WeightAwais IftikharNo ratings yet

- Es 10 A0910 Records 2009.10.26 - For PostingDocument12 pagesEs 10 A0910 Records 2009.10.26 - For Postingkarlajane03No ratings yet

- Altura Exposicion: Tabla 16-G Coeficiente CeDocument6 pagesAltura Exposicion: Tabla 16-G Coeficiente CeJUANCALABAZANo ratings yet

- Indian Standard Angle Sections 02Document1 pageIndian Standard Angle Sections 02CIVILNo ratings yet

- Retaining Rings MetricDocument18 pagesRetaining Rings MetricEmmanuelNo ratings yet

- Indian Standard Angle Sections 01Document1 pageIndian Standard Angle Sections 01CIVILNo ratings yet

- 000 215 1221 A02 31mar05Document2 pages000 215 1221 A02 31mar05Felipe FloresNo ratings yet

- Packing List CC2500 and CC2800-1Document15 pagesPacking List CC2500 and CC2800-1Duong Truong100% (1)

- 1991 Bookmatter CitrusProcessingDocument61 pages1991 Bookmatter CitrusProcessingSai Kiran PalikaNo ratings yet

- Itish Standard Welded Steel PipesDocument1 pageItish Standard Welded Steel PipesnelsonNo ratings yet

- Sugar Industry: Main Cane Carrier ChainDocument6 pagesSugar Industry: Main Cane Carrier ChainAlexander Arias VargasNo ratings yet

- حصر كمبات من مقاول الباطن جديدDocument10 pagesحصر كمبات من مقاول الباطن جديدSameh Salama MohamedNo ratings yet

- ANSI_16_5_300Rev1Document1 pageANSI_16_5_300Rev1nurulapriliashNo ratings yet

- ANSI_16_5_300Rev1Document1 pageANSI_16_5_300Rev1nurulapriliashNo ratings yet

- Single-Span Support: Negative PositionDocument1 pageSingle-Span Support: Negative PositionmikeshiiNo ratings yet

- Note: Density of Insulation Material Considered As 150 KG/CMDocument1 pageNote: Density of Insulation Material Considered As 150 KG/CMHarsh KhatriNo ratings yet

- Curvas IdtrDocument21 pagesCurvas IdtrOSCAR RENE DOMINGUEZ MONCLOVANo ratings yet

- SDD TW10Document1 pageSDD TW10Tera Water TechnologyNo ratings yet

- A12 MT OBLICON 2nd Sem AY 2022Document1 pageA12 MT OBLICON 2nd Sem AY 2022Mask HeheNo ratings yet

- Max Zs Values 17th - Sheet1Document1 pageMax Zs Values 17th - Sheet1Francisco M. RamosNo ratings yet

- Table 1 - 1Document11 pagesTable 1 - 1jessieNo ratings yet

- Pengujian Lentur Balok Beton Karet (Beam) VARIASI 1 (PSR 60%: KRT 40%)Document43 pagesPengujian Lentur Balok Beton Karet (Beam) VARIASI 1 (PSR 60%: KRT 40%)cristian jeremy jeremyNo ratings yet

- Manila Standard Today - Business Daily Stocks Review (June 14, 2012)Document1 pageManila Standard Today - Business Daily Stocks Review (June 14, 2012)Manila Standard TodayNo ratings yet

- SDD TW9Document1 pageSDD TW9Tera Water TechnologyNo ratings yet

- Pipe ScheduleDocument2 pagesPipe ScheduleRUDDY ALFAN SUBAKTINo ratings yet

- S.1 Parung BangkongDocument3 pagesS.1 Parung BangkongAde SetiawanNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012Thomas CalvinNo ratings yet

- All STD Material WeightDocument19 pagesAll STD Material WeightCoralPT WorldwideNo ratings yet

- Ansi - 600 - Norma de BridasDocument1 pageAnsi - 600 - Norma de BridasDaniel PorrasNo ratings yet

- 27.00 MM Jobthickness: A/l A/t A/l A/tDocument1 page27.00 MM Jobthickness: A/l A/t A/l A/tSatyabrata KunduNo ratings yet

- Angka KonvesiDocument23 pagesAngka Konvesisilvia akmaNo ratings yet

- Feed Cost For 1 Pangasius FishDocument7 pagesFeed Cost For 1 Pangasius FishkushNo ratings yet

- Astm A312Document5 pagesAstm A312Hưng PhùngNo ratings yet

- Cara Cepat LP Msuk Cad 4Document9 pagesCara Cepat LP Msuk Cad 4Audric GenterNo ratings yet

- Manila Standard Today - Business Daily Stocks Review (November 20, 2012)Document1 pageManila Standard Today - Business Daily Stocks Review (November 20, 2012)Manila Standard TodayNo ratings yet

- Wind LoadDocument4 pagesWind LoadAamir SuhailNo ratings yet

- Steel TableDocument2 pagesSteel TableManan ShahNo ratings yet

- Kathen ExcelDocument10 pagesKathen ExcelTarunNo ratings yet

- Kathen ExcelDocument10 pagesKathen ExcelTarunNo ratings yet

- Kathen ExcelDocument10 pagesKathen ExcelTarunNo ratings yet

- LFA Girls 0 2 Percentiles PDFDocument1 pageLFA Girls 0 2 Percentiles PDFprofundae2073No ratings yet

- 0 2 PercentilesDocument1 page0 2 PercentilesannisarachmaNo ratings yet

- Debt FundsDocument36 pagesDebt FundsArmstrong CapitalNo ratings yet

- Core Capcity & Turns Per VoltDocument1 pageCore Capcity & Turns Per VoltDeepak BainsNo ratings yet

- B Catalogo de Motores Asincronos Mayo 2020Document2 pagesB Catalogo de Motores Asincronos Mayo 2020MARLON RUIZ OCHOANo ratings yet

- 11a. Cuadro de Calculo Paso Aereo #1Document17 pages11a. Cuadro de Calculo Paso Aereo #1JOSE ALBERTO JEREZNo ratings yet

- Still Life Painting Lesson PlanDocument2 pagesStill Life Painting Lesson PlanGevy CamachoNo ratings yet

- ROCKAL FOAM (28: 30) KG/M: FlammabilityDocument9 pagesROCKAL FOAM (28: 30) KG/M: Flammabilityjustice judgeNo ratings yet

- UNIT-6 Multivariable Calculus (DOC FILE)Document15 pagesUNIT-6 Multivariable Calculus (DOC FILE)chinoerageorge0No ratings yet

- AB1202 Week 5Document4 pagesAB1202 Week 5amos liewNo ratings yet

- Ys Us S S: BG3102 Control in Biosystems AssignmentDocument2 pagesYs Us S S: BG3102 Control in Biosystems AssignmenteliasNo ratings yet

- NanotechnologyDocument14 pagesNanotechnologymohan vamsi100% (1)

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Paulino, Paul Tyrone R. Assignment 3Document14 pagesPaulino, Paul Tyrone R. Assignment 3Tyrone PaulinoNo ratings yet

- 9A04603 Digital Signal Processing16Document4 pages9A04603 Digital Signal Processing16Mahaboob SubahanNo ratings yet

- Newton S Law of CoolingDocument9 pagesNewton S Law of CoolingJulian Mauricio Cuevas GalloNo ratings yet

- Wet Gas Sampling in The Upstream Area Rev Brazil - ISO TC193 - SC3 Chairman DocumentDocument13 pagesWet Gas Sampling in The Upstream Area Rev Brazil - ISO TC193 - SC3 Chairman DocumentPhilip A Lawrence C.Eng. F. Inst M.C.No ratings yet

- Rag663 SLR Paper - AmalinaDocument26 pagesRag663 SLR Paper - AmalinaSEVENSEA CLANNo ratings yet

- What and When ? Visual Electrophysiology in The Clinical PracticeDocument23 pagesWhat and When ? Visual Electrophysiology in The Clinical PracticeAlexandra BobaruNo ratings yet

- Lighting - Education - Science-ZumtobelDocument60 pagesLighting - Education - Science-ZumtobelManoj IllangasooriyaNo ratings yet

- 25 Feb Shift 1 JEE Main 2021Document64 pages25 Feb Shift 1 JEE Main 2021Devchand BothraNo ratings yet

- 2537 VD4G-50 Vacuum Circuit-Breaker GBDocument4 pages2537 VD4G-50 Vacuum Circuit-Breaker GBburvanov0% (1)

- Performance Specification: Hot Side Cold SideDocument2 pagesPerformance Specification: Hot Side Cold SideStevan KrstojevicNo ratings yet

- Asme PTC 38Document133 pagesAsme PTC 38Anonymous knICax100% (1)

- Effects of Tires and Tire Pressures On Road Pavements: Matti Huhtala,) Ari Pihlajamaki, and Markku PienimakiDocument8 pagesEffects of Tires and Tire Pressures On Road Pavements: Matti Huhtala,) Ari Pihlajamaki, and Markku Pienimakiศิวาเวช อบมาNo ratings yet

- Hand Biometrics: Erdem Yo Ru K, Helin Dutag Aci, Bu Lent SankurDocument15 pagesHand Biometrics: Erdem Yo Ru K, Helin Dutag Aci, Bu Lent Sankurjit_72No ratings yet

- Phase Transformation in AISI 410 Stainless Steel PDFDocument10 pagesPhase Transformation in AISI 410 Stainless Steel PDFirajfarjiNo ratings yet

- IETE-Journal of Research Template PDFDocument7 pagesIETE-Journal of Research Template PDFMadan R HonnalagereNo ratings yet

- MechanicsOfCompliantMaterialsWk 04notesDocument15 pagesMechanicsOfCompliantMaterialsWk 04notesLorenzo MartinezNo ratings yet

- MMEN 226 - Worked Examples On Torsion, Set 7Document10 pagesMMEN 226 - Worked Examples On Torsion, Set 7nattydreadfathelahNo ratings yet

- NC590 - Construction Planning L2 QP Supp 2019Document8 pagesNC590 - Construction Planning L2 QP Supp 2019fanafisto04No ratings yet

- HHI Generator Manual-FINALDocument45 pagesHHI Generator Manual-FINALIgor CanabarroNo ratings yet

- Chemistry 311 Physical ChemistryDocument3 pagesChemistry 311 Physical ChemistryJosef CatiggayNo ratings yet

- I-Io) (National .I-Jiuuuutics " - : - (At'nYDocument116 pagesI-Io) (National .I-Jiuuuutics " - : - (At'nYLuis GianiNo ratings yet