Professional Documents

Culture Documents

Transolac Aluminium HR 5.11 - 1605177121

Transolac Aluminium HR 5.11 - 1605177121

Uploaded by

Tirumala PrasadCopyright:

Available Formats

You might also like

- Tds Paratherm 600Document2 pagesTds Paratherm 600yarth880% (1)

- Lumber Case ModelDocument6 pagesLumber Case ModeltheonlypaulNo ratings yet

- The Woman Speaks To The Man Who Has Employed Her SonDocument3 pagesThe Woman Speaks To The Man Who Has Employed Her SonSerena SulawammotNo ratings yet

- F F F F: Downloaded From Manuals Search EngineDocument2 pagesF F F F: Downloaded From Manuals Search EngineZsolt KántorNo ratings yet

- Introduction To Fluorescence Techniques: Fluorophores and Their Amine-Reactive DerivativesDocument8 pagesIntroduction To Fluorescence Techniques: Fluorophores and Their Amine-Reactive DerivativesManoj Kumar ChaurasiaNo ratings yet

- Case Study Julies BakeshopDocument3 pagesCase Study Julies BakeshopKristel Anne AquinoNo ratings yet

- Transolac Aluminium HR: Product DescriptionDocument3 pagesTransolac Aluminium HR: Product Descriptionshady yehiaNo ratings yet

- Product Data Sheet: Transocean Cold Zinc Primer 10.16Document3 pagesProduct Data Sheet: Transocean Cold Zinc Primer 10.16rimshadtpNo ratings yet

- Transolac Undercoat 321Document2 pagesTransolac Undercoat 321mido medoNo ratings yet

- Product Data Sheet: Transoplate Epoxy Primer 1.57Document2 pagesProduct Data Sheet: Transoplate Epoxy Primer 1.57Sachin NambiarNo ratings yet

- T.o.1.55 (Zinc Rich Epoxy Primer)Document2 pagesT.o.1.55 (Zinc Rich Epoxy Primer)Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Primer 1.16Document3 pagesProduct Data Sheet: Transpoxy Primer 1.16Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Masterbond 4.68Document2 pagesProduct Data Sheet: Transpoxy Masterbond 4.68rajeshNo ratings yet

- Transpoxy Primer 1.16Document2 pagesTranspoxy Primer 1.16thinesNo ratings yet

- Transoprene Primer 1.25Document2 pagesTransoprene Primer 1.25Tirumala PrasadNo ratings yet

- Product Data Sheet: Transozinc Silicate Solventborne 1.52Document2 pagesProduct Data Sheet: Transozinc Silicate Solventborne 1.52Sachin NambiarNo ratings yet

- Product Data Sheet: Transuniprene Finish 2.53Document2 pagesProduct Data Sheet: Transuniprene Finish 2.53Sachin NambiarNo ratings yet

- TO 1.58 Transozinc Silicate 158 ENDocument5 pagesTO 1.58 Transozinc Silicate 158 ENTirumala PrasadNo ratings yet

- Transpoxy Masterbond 4.67NDocument2 pagesTranspoxy Masterbond 4.67NAhmed FodaNo ratings yet

- Product Data Sheet: Transolac Finish 3.31Document2 pagesProduct Data Sheet: Transolac Finish 3.31Sachin NambiarNo ratings yet

- Product Data Sheet: Transunilac Finish 3.30Document2 pagesProduct Data Sheet: Transunilac Finish 3.30Sachin NambiarNo ratings yet

- Transpoxy Masterbond BT 4.68 ProDocument3 pagesTranspoxy Masterbond BT 4.68 ProMuhammad Asyraf MahatNo ratings yet

- Transozinc Epoxy Primer 175Document5 pagesTransozinc Epoxy Primer 175Tirumala PrasadNo ratings yet

- Transpoxy ShopprimerDocument5 pagesTranspoxy ShopprimerTirumala PrasadNo ratings yet

- Transunilac Finish 331Document4 pagesTransunilac Finish 331bhukyanaik02No ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Sam Epoxy Primer ZP - ECDocument3 pagesSam Epoxy Primer ZP - ECqcahmedsobhyNo ratings yet

- Product Data Sheet: Transpoxy Finish 4.60Document2 pagesProduct Data Sheet: Transpoxy Finish 4.60Sachin NambiarNo ratings yet

- Sam Epoxy Primer 50Document3 pagesSam Epoxy Primer 50qcahmedsobhyNo ratings yet

- Product Data Sheet: Transurethane Finish 3.43Document2 pagesProduct Data Sheet: Transurethane Finish 3.43Sachin NambiarNo ratings yet

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- Hempadur 15553Document2 pagesHempadur 15553EngTamerNo ratings yet

- Carbomastic 15 LT: Selection & Specification DataDocument3 pagesCarbomastic 15 LT: Selection & Specification Datasrinath vNo ratings yet

- PDS HEMPADUR 15553 en-GBDocument2 pagesPDS HEMPADUR 15553 en-GBachusanachuNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Marathon XHB (UG FW Line)Document5 pagesMarathon XHB (UG FW Line)mazharmehmood112233454No ratings yet

- Epoxy Red Oxide PrimerDocument2 pagesEpoxy Red Oxide PrimerBalakrishna ChowdaryNo ratings yet

- TDS-ANODESHIELD ICCP-EnglishDocument4 pagesTDS-ANODESHIELD ICCP-EnglishthirdNo ratings yet

- PC 1713 - Apcodur HB ZP PrimerDocument3 pagesPC 1713 - Apcodur HB ZP Primeronshore purchaseNo ratings yet

- Sam Epoxy Holding Primer 50Document4 pagesSam Epoxy Holding Primer 50qcahmedsobhyNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intercryl - 853 - Eng - A4 - 20150205Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intercryl - 853 - Eng - A4 - 20150205Antonio Diaz FeireNo ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- Penguard Primer: Technical DataDocument3 pagesPenguard Primer: Technical DataMohamed FarhanNo ratings yet

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- 312 UkDocument4 pages312 UkAhmed IbrahimNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- Durosan 03 Exterior Matt (I) : Technical Data SheetDocument3 pagesDurosan 03 Exterior Matt (I) : Technical Data Sheetمحمد عزتNo ratings yet

- Technical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionSyedFarhanNo ratings yet

- Apcodur 207Document3 pagesApcodur 207Md Irshad AhmadNo ratings yet

- Berger Royale Semi-Gloss EnamelDocument3 pagesBerger Royale Semi-Gloss Enamelbhima irabattiNo ratings yet

- Baltoflake: Technical DataDocument4 pagesBaltoflake: Technical DataMohamed FarhanNo ratings yet

- Durebild Ste Aug 2018Document4 pagesDurebild Ste Aug 2018Biju_PottayilNo ratings yet

- Marathon XHB - English (Uk) - Issued.06.12.2007Document3 pagesMarathon XHB - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Apcosil 605: Product DescriptionDocument3 pagesApcosil 605: Product DescriptionShravana PrasadNo ratings yet

- 2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Document3 pages2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Jafffar MahasnehNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Heat Resisting Silicone Aluminium PaintDocument3 pagesHeat Resisting Silicone Aluminium Paintrumi_2kNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- Jotashield ColourXtreme Matt (I)Document3 pagesJotashield ColourXtreme Matt (I)محمد عزتNo ratings yet

- THMT SCDocument2 pagesTHMT SCZaheer Ahmad RazaNo ratings yet

- Pilot QD Primer: Technical Data SheetDocument4 pagesPilot QD Primer: Technical Data SheetShreenivas ThakurNo ratings yet

- Aluflex: Technical Data SheetDocument4 pagesAluflex: Technical Data SheetNurmalinda Sihombing100% (1)

- Epilux 44 Enamel: Product Data Resistance GuideDocument2 pagesEpilux 44 Enamel: Product Data Resistance GuideKishore Nayak kNo ratings yet

- Nanoengineered Silica-Properties PDFDocument18 pagesNanoengineered Silica-Properties PDFkevinNo ratings yet

- Evaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialDocument6 pagesEvaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialGonzalo MendozaNo ratings yet

- Promotion Letter ShwetaDocument2 pagesPromotion Letter ShwetayogeshNo ratings yet

- Trane Xb13 Packaged Air Conditioner: Your Profit-AbilityDocument2 pagesTrane Xb13 Packaged Air Conditioner: Your Profit-AbilityJesus CantuNo ratings yet

- Mina NEGRA HUANUSHA 2 ParteDocument23 pagesMina NEGRA HUANUSHA 2 ParteRoberto VillegasNo ratings yet

- CAT MENTAL HEALTH FOR Community Health YEAR 4Document4 pagesCAT MENTAL HEALTH FOR Community Health YEAR 4Dennis ButtoNo ratings yet

- MPT ProjectDocument10 pagesMPT ProjectTina SanghaviNo ratings yet

- Ethics in HRMDocument7 pagesEthics in HRMVinay RamaneNo ratings yet

- Brochure DM96Document12 pagesBrochure DM96Paul Avelino CallupeNo ratings yet

- Building An Effective Safety Management System For Airlines: James J.H. Liou, Leon Yen, Gwo-Hshiung TzengDocument7 pagesBuilding An Effective Safety Management System For Airlines: James J.H. Liou, Leon Yen, Gwo-Hshiung Tzengzatul hasniNo ratings yet

- Whirlpool BIWDWG861484uk enDocument4 pagesWhirlpool BIWDWG861484uk ennadaljoachim77No ratings yet

- Astm C 592Document9 pagesAstm C 592hoseinNo ratings yet

- BWT - HandbookDocument16 pagesBWT - HandbookDarko DuiloNo ratings yet

- General Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Document1 pageGeneral Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Kashima KotaroNo ratings yet

- Basic Symbals P&ID PDFDocument736 pagesBasic Symbals P&ID PDFPavar RavitejaNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Material HPLCDocument19 pagesMaterial HPLCIsmil ImamaNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Cognitive Chapter 6 Cornell NotesDocument10 pagesCognitive Chapter 6 Cornell Notesvalcobacl.681.studNo ratings yet

- S100X220YAJ Panduit Datasheet 5314981Document2 pagesS100X220YAJ Panduit Datasheet 5314981Ilham MaurizaNo ratings yet

- Soil Acidity and LimingDocument12 pagesSoil Acidity and LimingEloi Carlos GoveNo ratings yet

- Agrochem Cals Agrochem Cals: Conference OnDocument43 pagesAgrochem Cals Agrochem Cals: Conference OnGnanendraKumarNo ratings yet

- Stress and Coping Strategies Among Distance Education Students at The University of Cape Coast, GhanaDocument15 pagesStress and Coping Strategies Among Distance Education Students at The University of Cape Coast, GhanaReign EvansNo ratings yet

- Dokumen - Tips - Diagnostic Test Mapeh 10Document4 pagesDokumen - Tips - Diagnostic Test Mapeh 10charry ruayaNo ratings yet

Transolac Aluminium HR 5.11 - 1605177121

Transolac Aluminium HR 5.11 - 1605177121

Uploaded by

Tirumala PrasadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transolac Aluminium HR 5.11 - 1605177121

Transolac Aluminium HR 5.11 - 1605177121

Uploaded by

Tirumala PrasadCopyright:

Available Formats

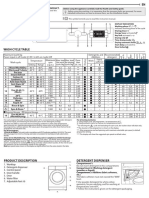

Product Data Sheet

Transolac Aluminium HR 5.11

Product description.

Aluminium based finish suitable for interior and exterior application for steel substrates where heat

resistance up to 200 °C is required. The product can be applied on Transogard priming system but for

maximum temperature resistance Transolac Aluminium HR must be applied directly to the steel.

Physical properties.

Colour/Texture Silver/Glossy

Volume Solids 33%

Specific gravity 1.01 gr/ml

VOC 585 gr/liter

Flashpoint >25°C

Dry film thickness per Wet film thickness per Theoretical spreading

coat (µ) coat (µ) rate (m2/l)

Range 20 – 40 60 – 120 16.5 – 8.2

Recommended 30 90 11.0

Application data.

Guiding data Airless spray Pressure at nozzle: 120 –150 bar. Nozzle size: 0.38 - 0.53 mm.

Spray angle: 60 - 80 degrees.

Volume of thinner: Not advised

Guiding data Air spray Pressure: 3 – 4 bar. Nozzle size: 1.2 - 1.5 mm.

Volume of thinner: 0 – 5%.

Brush/Roller Suitable.

Volume of thinner: 0 – 5%.

Thinner/Cleaner Transocean Alkyd Thinner 6.00.

Conditions Humidity: below 90% RH.

Temperature of the paint before application: min: 10°C, max: 30°C.

Substrate temperature: min: 1°C, max: 35°C.

The temperature of the substrate should be at least 3°C above the dew point

of the air. Air temperatures and relative humidity must be measured in the

vicinity of the substrate.

Drying and recoating times.

Substrate Touch dry Hard dry Dry to recoat

temperature Minimum Maximum (1)

10 °C 4 hours 2 days 16 hours Indefinite

23 °C 2 hours 1 day 10 hours Indefinite

30 °C 1 hour 1 day 8 hours Indefinite

(1) The surface should be dry and free from salts and other contaminants prior to overcoating. After

prolonged exposure times it may be necessary to roughen the surface to ensure intercoat adhesion.

When in doubt, consult your nearest Transocean office.

Transolac Aluminium HR 5.11, Page 1 of 2.

Surface preparation.

Steel Oil and grease should be removed by solvent cleaning according to SSPC-SP1.

Remove weld spatter and smooth weld seams and sharp edges as applicable.

Abrasive blasting: min. Sa2,5 – ISO 8501:1.

Apply Transolac Aluminium HR immediately after the steel has been blasted

and the quality of preparation has been approved.

Coated substrates The surface must be dry and free salts, grease and other contaminants prior to

overcoating. Corroded areas should be power tool cleaned to ISO-St2 or blast

cleaned to ISO-Sa2 or better.

Recommended paint system.

A typical system is shown below.

Transogard Zincphosphate 1.24 2 x 35 µ dft.

Transolac Aluminium HR 5.11 2 x 30 µ dft.

Worldwide availability

The product is part of the common Transocean product range but local availability is subject to

confirmation. Although we strive to supply the same product through the world, slight modifications of the

product in some cases may be necessary in order to comply with local conditions and/or national

regulations. In such cases an alternative datasheet will be issued.

Health and safety.

Observe the precautionary notices on the label of the container. A material safety data sheet is available

upon request and national or local safety regulations should be followed. This product is intended for use

by professional applicators.

As a general rule, avoid skin- and eye contact by wearing overalls, gloves, goggles, mask, etc. Spillage on

the skin should immediately be removed by thorough washing with lukewarm water and soap or a suitable

industrial cleaner. Eyes should be flushed with fresh water and medical attention sought immediately.

Spraying should be carried out under well-ventilated conditions. Avoid inhalation of solvent vapours and

paint mist by wearing an air mask.

This product contains flammable materials and should be kept away from sparks and open flames.

Smoking in the area should not be permitted.

Disclaimer

The information in this data sheet is provided to the best of our knowledge. However, we have no control

over either quality or condition of the substrate and other factors affecting the use and application of this

product.

Therefore, we cannot accept any liability whatsoever or howsoever arising from the performance of the

product or for any loss or damage arising from the use of this product.

We reserve the right to change the product without notice.

Date of issue: August, 08.

Transolac Aluminium HR 5.11, Page 2 of 2.

You might also like

- Tds Paratherm 600Document2 pagesTds Paratherm 600yarth880% (1)

- Lumber Case ModelDocument6 pagesLumber Case ModeltheonlypaulNo ratings yet

- The Woman Speaks To The Man Who Has Employed Her SonDocument3 pagesThe Woman Speaks To The Man Who Has Employed Her SonSerena SulawammotNo ratings yet

- F F F F: Downloaded From Manuals Search EngineDocument2 pagesF F F F: Downloaded From Manuals Search EngineZsolt KántorNo ratings yet

- Introduction To Fluorescence Techniques: Fluorophores and Their Amine-Reactive DerivativesDocument8 pagesIntroduction To Fluorescence Techniques: Fluorophores and Their Amine-Reactive DerivativesManoj Kumar ChaurasiaNo ratings yet

- Case Study Julies BakeshopDocument3 pagesCase Study Julies BakeshopKristel Anne AquinoNo ratings yet

- Transolac Aluminium HR: Product DescriptionDocument3 pagesTransolac Aluminium HR: Product Descriptionshady yehiaNo ratings yet

- Product Data Sheet: Transocean Cold Zinc Primer 10.16Document3 pagesProduct Data Sheet: Transocean Cold Zinc Primer 10.16rimshadtpNo ratings yet

- Transolac Undercoat 321Document2 pagesTransolac Undercoat 321mido medoNo ratings yet

- Product Data Sheet: Transoplate Epoxy Primer 1.57Document2 pagesProduct Data Sheet: Transoplate Epoxy Primer 1.57Sachin NambiarNo ratings yet

- T.o.1.55 (Zinc Rich Epoxy Primer)Document2 pagesT.o.1.55 (Zinc Rich Epoxy Primer)Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Primer 1.16Document3 pagesProduct Data Sheet: Transpoxy Primer 1.16Sachin NambiarNo ratings yet

- Product Data Sheet: Transpoxy Masterbond 4.68Document2 pagesProduct Data Sheet: Transpoxy Masterbond 4.68rajeshNo ratings yet

- Transpoxy Primer 1.16Document2 pagesTranspoxy Primer 1.16thinesNo ratings yet

- Transoprene Primer 1.25Document2 pagesTransoprene Primer 1.25Tirumala PrasadNo ratings yet

- Product Data Sheet: Transozinc Silicate Solventborne 1.52Document2 pagesProduct Data Sheet: Transozinc Silicate Solventborne 1.52Sachin NambiarNo ratings yet

- Product Data Sheet: Transuniprene Finish 2.53Document2 pagesProduct Data Sheet: Transuniprene Finish 2.53Sachin NambiarNo ratings yet

- TO 1.58 Transozinc Silicate 158 ENDocument5 pagesTO 1.58 Transozinc Silicate 158 ENTirumala PrasadNo ratings yet

- Transpoxy Masterbond 4.67NDocument2 pagesTranspoxy Masterbond 4.67NAhmed FodaNo ratings yet

- Product Data Sheet: Transolac Finish 3.31Document2 pagesProduct Data Sheet: Transolac Finish 3.31Sachin NambiarNo ratings yet

- Product Data Sheet: Transunilac Finish 3.30Document2 pagesProduct Data Sheet: Transunilac Finish 3.30Sachin NambiarNo ratings yet

- Transpoxy Masterbond BT 4.68 ProDocument3 pagesTranspoxy Masterbond BT 4.68 ProMuhammad Asyraf MahatNo ratings yet

- Transozinc Epoxy Primer 175Document5 pagesTransozinc Epoxy Primer 175Tirumala PrasadNo ratings yet

- Transpoxy ShopprimerDocument5 pagesTranspoxy ShopprimerTirumala PrasadNo ratings yet

- Transunilac Finish 331Document4 pagesTransunilac Finish 331bhukyanaik02No ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Sam Epoxy Primer ZP - ECDocument3 pagesSam Epoxy Primer ZP - ECqcahmedsobhyNo ratings yet

- Product Data Sheet: Transpoxy Finish 4.60Document2 pagesProduct Data Sheet: Transpoxy Finish 4.60Sachin NambiarNo ratings yet

- Sam Epoxy Primer 50Document3 pagesSam Epoxy Primer 50qcahmedsobhyNo ratings yet

- Product Data Sheet: Transurethane Finish 3.43Document2 pagesProduct Data Sheet: Transurethane Finish 3.43Sachin NambiarNo ratings yet

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Sam Classic FinishDocument2 pagesSam Classic FinishMo MosadNo ratings yet

- Hempadur 15553Document2 pagesHempadur 15553EngTamerNo ratings yet

- Carbomastic 15 LT: Selection & Specification DataDocument3 pagesCarbomastic 15 LT: Selection & Specification Datasrinath vNo ratings yet

- PDS HEMPADUR 15553 en-GBDocument2 pagesPDS HEMPADUR 15553 en-GBachusanachuNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Marathon XHB (UG FW Line)Document5 pagesMarathon XHB (UG FW Line)mazharmehmood112233454No ratings yet

- Epoxy Red Oxide PrimerDocument2 pagesEpoxy Red Oxide PrimerBalakrishna ChowdaryNo ratings yet

- TDS-ANODESHIELD ICCP-EnglishDocument4 pagesTDS-ANODESHIELD ICCP-EnglishthirdNo ratings yet

- PC 1713 - Apcodur HB ZP PrimerDocument3 pagesPC 1713 - Apcodur HB ZP Primeronshore purchaseNo ratings yet

- Sam Epoxy Holding Primer 50Document4 pagesSam Epoxy Holding Primer 50qcahmedsobhyNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intercryl - 853 - Eng - A4 - 20150205Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Intercryl - 853 - Eng - A4 - 20150205Antonio Diaz FeireNo ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- Penguard Primer: Technical DataDocument3 pagesPenguard Primer: Technical DataMohamed FarhanNo ratings yet

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- 312 UkDocument4 pages312 UkAhmed IbrahimNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- Durosan 03 Exterior Matt (I) : Technical Data SheetDocument3 pagesDurosan 03 Exterior Matt (I) : Technical Data Sheetمحمد عزتNo ratings yet

- Technical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Epo-Rich Primer 90 JI-61031: DescriptionSyedFarhanNo ratings yet

- Apcodur 207Document3 pagesApcodur 207Md Irshad AhmadNo ratings yet

- Berger Royale Semi-Gloss EnamelDocument3 pagesBerger Royale Semi-Gloss Enamelbhima irabattiNo ratings yet

- Baltoflake: Technical DataDocument4 pagesBaltoflake: Technical DataMohamed FarhanNo ratings yet

- Durebild Ste Aug 2018Document4 pagesDurebild Ste Aug 2018Biju_PottayilNo ratings yet

- Marathon XHB - English (Uk) - Issued.06.12.2007Document3 pagesMarathon XHB - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Apcosil 605: Product DescriptionDocument3 pagesApcosil 605: Product DescriptionShravana PrasadNo ratings yet

- 2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Document3 pages2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Jafffar MahasnehNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Heat Resisting Silicone Aluminium PaintDocument3 pagesHeat Resisting Silicone Aluminium Paintrumi_2kNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- Jotashield ColourXtreme Matt (I)Document3 pagesJotashield ColourXtreme Matt (I)محمد عزتNo ratings yet

- THMT SCDocument2 pagesTHMT SCZaheer Ahmad RazaNo ratings yet

- Pilot QD Primer: Technical Data SheetDocument4 pagesPilot QD Primer: Technical Data SheetShreenivas ThakurNo ratings yet

- Aluflex: Technical Data SheetDocument4 pagesAluflex: Technical Data SheetNurmalinda Sihombing100% (1)

- Epilux 44 Enamel: Product Data Resistance GuideDocument2 pagesEpilux 44 Enamel: Product Data Resistance GuideKishore Nayak kNo ratings yet

- Nanoengineered Silica-Properties PDFDocument18 pagesNanoengineered Silica-Properties PDFkevinNo ratings yet

- Evaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialDocument6 pagesEvaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialGonzalo MendozaNo ratings yet

- Promotion Letter ShwetaDocument2 pagesPromotion Letter ShwetayogeshNo ratings yet

- Trane Xb13 Packaged Air Conditioner: Your Profit-AbilityDocument2 pagesTrane Xb13 Packaged Air Conditioner: Your Profit-AbilityJesus CantuNo ratings yet

- Mina NEGRA HUANUSHA 2 ParteDocument23 pagesMina NEGRA HUANUSHA 2 ParteRoberto VillegasNo ratings yet

- CAT MENTAL HEALTH FOR Community Health YEAR 4Document4 pagesCAT MENTAL HEALTH FOR Community Health YEAR 4Dennis ButtoNo ratings yet

- MPT ProjectDocument10 pagesMPT ProjectTina SanghaviNo ratings yet

- Ethics in HRMDocument7 pagesEthics in HRMVinay RamaneNo ratings yet

- Brochure DM96Document12 pagesBrochure DM96Paul Avelino CallupeNo ratings yet

- Building An Effective Safety Management System For Airlines: James J.H. Liou, Leon Yen, Gwo-Hshiung TzengDocument7 pagesBuilding An Effective Safety Management System For Airlines: James J.H. Liou, Leon Yen, Gwo-Hshiung Tzengzatul hasniNo ratings yet

- Whirlpool BIWDWG861484uk enDocument4 pagesWhirlpool BIWDWG861484uk ennadaljoachim77No ratings yet

- Astm C 592Document9 pagesAstm C 592hoseinNo ratings yet

- BWT - HandbookDocument16 pagesBWT - HandbookDarko DuiloNo ratings yet

- General Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Document1 pageGeneral Physics 1: ACTIVITY/ANSWER SHEET: Quarter 2Kashima KotaroNo ratings yet

- Basic Symbals P&ID PDFDocument736 pagesBasic Symbals P&ID PDFPavar RavitejaNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Material HPLCDocument19 pagesMaterial HPLCIsmil ImamaNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Cognitive Chapter 6 Cornell NotesDocument10 pagesCognitive Chapter 6 Cornell Notesvalcobacl.681.studNo ratings yet

- S100X220YAJ Panduit Datasheet 5314981Document2 pagesS100X220YAJ Panduit Datasheet 5314981Ilham MaurizaNo ratings yet

- Soil Acidity and LimingDocument12 pagesSoil Acidity and LimingEloi Carlos GoveNo ratings yet

- Agrochem Cals Agrochem Cals: Conference OnDocument43 pagesAgrochem Cals Agrochem Cals: Conference OnGnanendraKumarNo ratings yet

- Stress and Coping Strategies Among Distance Education Students at The University of Cape Coast, GhanaDocument15 pagesStress and Coping Strategies Among Distance Education Students at The University of Cape Coast, GhanaReign EvansNo ratings yet

- Dokumen - Tips - Diagnostic Test Mapeh 10Document4 pagesDokumen - Tips - Diagnostic Test Mapeh 10charry ruayaNo ratings yet