Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsUnit6 Physic

Unit6 Physic

Uploaded by

Mahesh JoshiSppu unit 6 imp questions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- EEE3091F Test 1 Questions - 2022Document3 pagesEEE3091F Test 1 Questions - 2022Student 80No ratings yet

- PCN Ultrasonic Testing Material Level 2 MaterialDocument131 pagesPCN Ultrasonic Testing Material Level 2 Materialmohammed100% (2)

- WLC1 Q1Document7 pagesWLC1 Q1SeyahatNo ratings yet

- UT Course Material PDFDocument131 pagesUT Course Material PDFketasriNo ratings yet

- Phy (Unit 6) (Notes)Document12 pagesPhy (Unit 6) (Notes)pranjaliiis25No ratings yet

- NAME 345 Welding Technology Lecture - 13 Non-Destructive Testing (NDT)Document22 pagesNAME 345 Welding Technology Lecture - 13 Non-Destructive Testing (NDT)Bob SteinerNo ratings yet

- NDT Assignment: Q.1. Compare The Methods of Producing Radiations in Radiography? AnswerDocument20 pagesNDT Assignment: Q.1. Compare The Methods of Producing Radiations in Radiography? AnswerTanvir AhmedNo ratings yet

- Unit - 5 NDTDocument7 pagesUnit - 5 NDTRAJESH. RNo ratings yet

- SSRN Id2770922Document13 pagesSSRN Id2770922oelassal444No ratings yet

- X Ray Radiography Study MaterialDocument5 pagesX Ray Radiography Study MaterialManjukaviNo ratings yet

- A New Method For The Determination of Cluster Velocity and Size in A Circulating Fluidized BedDocument9 pagesA New Method For The Determination of Cluster Velocity and Size in A Circulating Fluidized Bedกะตั้ว คับNo ratings yet

- Neutron Scattering TechniqueDocument22 pagesNeutron Scattering TechniqueIshfaq AhmadNo ratings yet

- TPW (Final Copy) P SunilDocument6 pagesTPW (Final Copy) P SunilFierdy AkasyaNo ratings yet

- Unit 5 Nanomaterials and Its Characterization TechniquesDocument48 pagesUnit 5 Nanomaterials and Its Characterization TechniquesAditya SalunkheNo ratings yet

- NDT Module 5Document17 pagesNDT Module 5Abhishek DNo ratings yet

- Ultrasonic Technique For Detection and Measurement: of Fatigue CracksDocument25 pagesUltrasonic Technique For Detection and Measurement: of Fatigue Cracksbharathi_pmNo ratings yet

- MS Assignment Alms1Document5 pagesMS Assignment Alms1Aryan SharmaNo ratings yet

- Microelectronics ReliabilityDocument6 pagesMicroelectronics ReliabilityIndrawan AzizNo ratings yet

- DAVIDDocument12 pagesDAVIDhercheys aberteNo ratings yet

- Me 8 Mseme Module 20Document7 pagesMe 8 Mseme Module 20Kendrick RomeroNo ratings yet

- 1992 - Shalom Et Al. - A Micropipette Force Probe Suitable For Near-Field Scanning Optical Microscopy - Review of Scientific InstrumentsDocument6 pages1992 - Shalom Et Al. - A Micropipette Force Probe Suitable For Near-Field Scanning Optical Microscopy - Review of Scientific InstrumentsClaudio BiaginiNo ratings yet

- Scanning Tunneling Microscopy Transmission Electron MicroscopyDocument18 pagesScanning Tunneling Microscopy Transmission Electron MicroscopyAWMツ MØNARCHNo ratings yet

- Non-Destructive Testing of Capless Porcelain Line Post Insulators To Detect Internal DefectsDocument132 pagesNon-Destructive Testing of Capless Porcelain Line Post Insulators To Detect Internal Defectsmartin2502No ratings yet

- A Simple Method of Coil DesignDocument7 pagesA Simple Method of Coil DesignPAUL RODRIGUEZNo ratings yet

- Non Destructive Testing of High Volltage Cables by Non-Electrical MethodsDocument4 pagesNon Destructive Testing of High Volltage Cables by Non-Electrical MethodsRIDHO RISKI HADINo ratings yet

- Chapter 4 RTDocument24 pagesChapter 4 RTNurjihan Binti AimiNo ratings yet

- AFM Atomic Force MicroscopyDocument24 pagesAFM Atomic Force MicroscopyYogesh KhandelwalNo ratings yet

- RT SafetyDocument157 pagesRT SafetyYasser Abd El FattahNo ratings yet

- Introduction To Nanotechnology - History, Definition, Methodology, Applications, and ChallengesDocument35 pagesIntroduction To Nanotechnology - History, Definition, Methodology, Applications, and ChallengeschandruuncleNo ratings yet

- Unit 4NDTDocument9 pagesUnit 4NDTRAJESH. RNo ratings yet

- Studies On Feasibility of Ultrasonic Phased Array in Rail InspectionDocument4 pagesStudies On Feasibility of Ultrasonic Phased Array in Rail InspectionMartin Chimenti - ARO SANo ratings yet

- Nanomaterials and Its Characterization TechniquesDocument16 pagesNanomaterials and Its Characterization TechniquesAditya SalunkheNo ratings yet

- Powder DiffractionDocument22 pagesPowder DiffractionTamara Silvana CárcamoNo ratings yet

- Seminar ON Non-Destructive Testing: Department of Automobile EngineeringDocument23 pagesSeminar ON Non-Destructive Testing: Department of Automobile EngineeringAjith K100% (1)

- Wa0000Document29 pagesWa0000মহিবুল আলম মানিকNo ratings yet

- Cui 2021Document8 pagesCui 2021mvssrajuNo ratings yet

- Shielded Metal Arc Welding (SMAW) NC II: Worksheet Week 2Document10 pagesShielded Metal Arc Welding (SMAW) NC II: Worksheet Week 2Tommy Dela CruzNo ratings yet

- PHY1003 - PHYSICS - ETH - 1.0 - 0 - PHY1003 Physics PDFDocument4 pagesPHY1003 - PHYSICS - ETH - 1.0 - 0 - PHY1003 Physics PDFChandreyi ChowdhuryNo ratings yet

- Non-Destructive Test Methods For Hollow-Core Composite InsulatorsDocument4 pagesNon-Destructive Test Methods For Hollow-Core Composite InsulatorsHendi AfriyanNo ratings yet

- Crystal Structure PPT4.2Document16 pagesCrystal Structure PPT4.2komalkajal804No ratings yet

- Non - Destructive TestingDocument28 pagesNon - Destructive TestingPhilip PanaNo ratings yet

- X-Ray DiffractometerDocument17 pagesX-Ray Diffractometerananyo sabujNo ratings yet

- Department of Chemical & Polymer Engineering University of Engineering & Technology Lahore (FSD Campus)Document42 pagesDepartment of Chemical & Polymer Engineering University of Engineering & Technology Lahore (FSD Campus)Muhammad Waqas AkbarNo ratings yet

- Lec 8Document26 pagesLec 8Amjed AL-KAHTEEBNo ratings yet

- Star NMRDocument20 pagesStar NMRstarskyhutch0000No ratings yet

- The Basics of Confocal MicrosDocument22 pagesThe Basics of Confocal MicrosViswanathan SundaramNo ratings yet

- Fast Single-Mode Characterization of Optical Fiber by Finite-Difference Time-Domain MethodDocument9 pagesFast Single-Mode Characterization of Optical Fiber by Finite-Difference Time-Domain MethodAnonymous c75J3yX33No ratings yet

- Inspection of Dissimilar Material Joints Using Ultrasonic Phased ArraysDocument6 pagesInspection of Dissimilar Material Joints Using Ultrasonic Phased ArraysBruno César LevitaNo ratings yet

- Damage Detection in Membrane Structures Using Non-Contact Laser Excitation and WaveletDocument16 pagesDamage Detection in Membrane Structures Using Non-Contact Laser Excitation and Wavelet3tarebitarafNo ratings yet

- Government Engineering College Gandhinagar: Long Range Ultrasonic TestingDocument21 pagesGovernment Engineering College Gandhinagar: Long Range Ultrasonic TestingJaynish IdhariyaNo ratings yet

- Non Destructive Testing QuizDocument5 pagesNon Destructive Testing QuizFuture HazeNo ratings yet

- Barc RT Level - 2Document160 pagesBarc RT Level - 2NavnitNo ratings yet

- TOM Question PaperDocument9 pagesTOM Question PaperPriyadharshan RNo ratings yet

- NDE TechniquesDocument25 pagesNDE TechniquesaseNo ratings yet

- 239 MookDocument8 pages239 MookAnurag SharmaNo ratings yet

- Hikmantiyah 2018 J. Phys. Conf. Ser. 1025 012010Document6 pagesHikmantiyah 2018 J. Phys. Conf. Ser. 1025 012010Argus SparkNo ratings yet

- Nano TechnologyDocument29 pagesNano TechnologyAdiNo ratings yet

- Nanomaterials and NanotechnologyDocument19 pagesNanomaterials and NanotechnologyIgor GomelNo ratings yet

- Tem 2final PDFDocument9 pagesTem 2final PDFSkuukzky baeNo ratings yet

- Bolotina 2015 IOP Conf. Ser. Mater. Sci. Eng. 81 012073Document8 pagesBolotina 2015 IOP Conf. Ser. Mater. Sci. Eng. 81 012073Titik SundariNo ratings yet

- Probing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsFrom EverandProbing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsRating: 2 out of 5 stars2/5 (1)

- BR - Bridge WorkDocument35 pagesBR - Bridge WorkMuthusamy ArumugamNo ratings yet

- Legacies Dispatches From An Uncertain WorldDocument9 pagesLegacies Dispatches From An Uncertain WorldlopxmnNo ratings yet

- Vehicle Dynamics Prof. R. Krishnakumar Department of Engineering Design Indian Institute of Technology - Madras Lecture - 12 Lateral Force GenerationDocument17 pagesVehicle Dynamics Prof. R. Krishnakumar Department of Engineering Design Indian Institute of Technology - Madras Lecture - 12 Lateral Force Generationgauraang singh baghelNo ratings yet

- Week 18 - Science 10Document6 pagesWeek 18 - Science 10Mira VeranoNo ratings yet

- Structural TheoryDocument9 pagesStructural TheoryVincent ParagasNo ratings yet

- Pib04 PDFDocument3 pagesPib04 PDFANGIE PAOLA RODELO PANZANo ratings yet

- Measuring Ultrashort Laser Pulses I: Autocorrelation: 1D Phase RetrievalDocument42 pagesMeasuring Ultrashort Laser Pulses I: Autocorrelation: 1D Phase RetrievalNadia Al-RoshdeeNo ratings yet

- Installation Manual: Sliding Gate SystemDocument14 pagesInstallation Manual: Sliding Gate SystemGloria Cecilia SanchezNo ratings yet

- CH - 4 The Adventure Answer KeyDocument3 pagesCH - 4 The Adventure Answer Keyhawrahaider52No ratings yet

- CE Board Nov 2021 - Hydraulics - Set 1Document2 pagesCE Board Nov 2021 - Hydraulics - Set 1Asif UsmanNo ratings yet

- 1.preliminary DESIGNDocument7 pages1.preliminary DESIGNSandip Paudel100% (1)

- AdmixtureDocument5 pagesAdmixtureMishra dtuNo ratings yet

- Synchronous Motor - InstruDocument12 pagesSynchronous Motor - InstruMohit IndurkarNo ratings yet

- Circuit Lab Introduction I ECE - Partial NotesDocument27 pagesCircuit Lab Introduction I ECE - Partial NotesDr.P. RAJASEKARNo ratings yet

- Circuit Construction: Assignment 3Document45 pagesCircuit Construction: Assignment 3ali morisyNo ratings yet

- "Simulation of Asynchronous Motor Using MATLAB": Submitted To: Prof. GOKULAKRISHNAN GDocument35 pages"Simulation of Asynchronous Motor Using MATLAB": Submitted To: Prof. GOKULAKRISHNAN GAditi DixitNo ratings yet

- RHM30-160 Installation GuideDocument30 pagesRHM30-160 Installation GuideJoseph FranciscoNo ratings yet

- Parts Catalog: Ir C3200 SeriesDocument178 pagesParts Catalog: Ir C3200 SeriesЕвгений100% (1)

- Scour Behaviour and Scour Protection For MonopileDocument15 pagesScour Behaviour and Scour Protection For MonopileWilliam HoNo ratings yet

- Thermodynamics 2 & Fluid MechanicsDocument18 pagesThermodynamics 2 & Fluid MechanicsNicole Mae AllosadaNo ratings yet

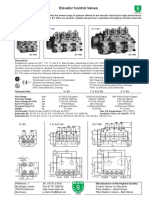

- Elevator Control Valves: EN ISO 9001Document6 pagesElevator Control Valves: EN ISO 9001Jibjab7No ratings yet

- STYLE AG-4911 4# Eva Closed Cell Foam: Typical Properties ofDocument2 pagesSTYLE AG-4911 4# Eva Closed Cell Foam: Typical Properties ofArrow LazarusNo ratings yet

- Boardworks 1 .PPT - LightDocument9 pagesBoardworks 1 .PPT - LightsrenNo ratings yet

- Mechanics of Materials Formulas and Problems Engineering Mechanics 2 by - by WWW - LearnEngineering.inDocument219 pagesMechanics of Materials Formulas and Problems Engineering Mechanics 2 by - by WWW - LearnEngineering.inHữu Danh Nguyễn100% (1)

- Quotation: Home Automation Price ListDocument2 pagesQuotation: Home Automation Price ListUsman khanNo ratings yet

- Lecture Magnetostatic DevicesDocument30 pagesLecture Magnetostatic DevicesBill WhiteNo ratings yet

- Wireline Works Tech-BulletinsDocument25 pagesWireline Works Tech-BulletinsGerardo LizardoNo ratings yet

- STEREOISOMERISMDocument11 pagesSTEREOISOMERISMSuresh KumarNo ratings yet

Unit6 Physic

Unit6 Physic

Uploaded by

Mahesh Joshi0 ratings0% found this document useful (0 votes)

1 views4 pagesSppu unit 6 imp questions

Original Title

UNIT6 PHYSIC

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSppu unit 6 imp questions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views4 pagesUnit6 Physic

Unit6 Physic

Uploaded by

Mahesh JoshiSppu unit 6 imp questions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

UNIT 6 also locate theirPosi on.5.

This method gives real

me data on development of cracks and breaking of

Q.1 Compare destruc ve and non-destruc ve

fibres within the structure.6.This method is used in

tes ng.ANS:-Destruc ve Tes ng 1.The component is

bridges, dams and aerospace

destroyed2.All components cannot be tested3.Tests

structures.Advantages: 1) Gives real me data

are more me consuming.4.Tes ng during opera on

during opera on of the structure.2) This method is

is not possible.5.Test results are quan ta ve

highly sensi ve. 3) Leads to early detec on of

.NonDestruc ve Tes ng1.The component Is not

flaws.4) Cost is less. Disadvantages: 1) Requires the

destroyed.2.All components can be tested.3.Tes ng

loading to be sufficiently high to produce a

is rapid.4.Tes ng during opera on is possible.5.Test

significant signal. 2) Requires sensors to be

results are generally qualita ve.

permanently mounted on the structure.

(Q.2) List the objec ves of non-destruc ve

(Q.5)) Describe X-ray radiography method for non-

tes ng.Ans:- The objec ves of non-destruc ve

destruc ve tes ng of engineering components.

tes ng are as follows: 1) To detect flaws during the

State its advantages and disadvantages:- 1.X-ray

manufacturing of components so that defec ve

have high penetra on power. The smaller the

components can be detected at an early stage of

wavelength, larger is the penetra on power.2.When

produc on. This saves me and money.2) To detect

x-rays are passed through metals, the intensity

flaws of finished components which will enhance

decreases due to absorp on.3.Larger the distance

their performance and reliability.3) To detect flaws

travelled by xrays in the metal, larger is the decrease

which may develop during opera on which will

in intensity and smaller is the transmi ed

ensure that there is no reduc on in the rate of

intensity.4.The decrease in intensity also depends on

produc on4) To increase the safety by ensuring that

the density of the material.5.The x-ray film kept

the defec ve components are replaced during

behind the object will become darker in the region

periodic checks.

of the flaw 6 .This method is able to reveal the flaws

(Q.3) List the methods of non-destruc ve tes ng:- hidden in the interior of the component.7.If x-ray

The following methods are used for image is taken for only one posi on of the source,

nondestruc veTes ng:1.Liquid/dye penetrant test the flaw can be detected but its posi on cannot be

2.Radiography methods: a) x-ray radiography and b) located.8.To locate posi on of the flaw, the image is

y-ray radiography. 3.Ultrasonic inspec on taken for two posi ons of the source 9. f Distance

4.Magne c par cle inspec on. 5.Visual inspec on between source and film,10. p = Distance between

6.Eddy current inspec on.7.Thermography two posi ons of source 11.s = Distance between the

two image,12.The depth d of the flaw from the

(Q4)Describe acous c emission tes ng. State its

upper surface is given by d= fs/s+p 13.A similar

advantages and disadvantage:- 1.The stress waves

approach is used in x-ray fluoroscopy except that the

propagate to the surface of the structure and can be

x-ray film is replaced by a fluorescent screen.14.This

detected by sensors. 2. Such acous c emission is

method gives live images of the components.

also observed when iron, n or ceramics are cooled

15.Instead of x-rays, yrays can also be used to form

from high temperatures.3.Acous c emission also

images.•Advantages:1) Hidden flaws can be

takes place due to development of cracks and

detected.2) Inspec on takes very li le me.3) A

breaking of fibres in a stressed material. Hence,

wide variety of materials can be

these canAlso be detected by sensors.4.The sensors

tested.•Disadvantages:1) It is expensive compared

are piezoelectric crystals which are placed in

to other methods.2) Inspec on has to be carried out

arrays.They can defect the presence of defects and

in an isolated place as long exposure to x-rays is

harmful to beings.3) Very small flaws cannot be between atoms.2.Imperfec ons in the crystal

detected. structure and impuri es result in changes in these

proper es.3.As the nanopar cles are highly pure

(Q 6) What are nano-par cles:- Explain. 1. The radii

and free from imperfec ons, they show different

of atoms and most of the molecules are less thana

mechanical proper es than the bulk material. 4.it

nanometer.2. Nanopar cles are generally

has been observed that the Young's modulus

considered to have radius in the range of 1 nm to 100

decreases in metallic nanocrystals with decrease in

nm which can have 25 to 106 atoms.3. The

par cle size.5.The yield stress has been observed to

nanopar cles show unique proper es that change

increase with the decrease in grain size in bulk

with their size.4. Classical mechanics is able to

materials with nanosized grains.6.Hence stronger

explain proper es of bulk materials but is unable to

materials can be produced by making materials with

explain proper es of nanopar cles.5.Quantum

nanosized grains.7. The carbon nanotubes are

mechanical principles have to be used to explain

es mated to be about 20 mes stronger

proper es of the nanopar cles.6.The state of ma er

around the nanosize is known as mesoscopic state. (Q8)Explain applica ons of nanopar cles.1.

Electronics:- Nanosized electronic components

(Q7) Explain op cal, electrical and mechanical

show unique proper es which are different from the

proper es of nanopar cles :- (1) Op cal proper es

larger semiconductor components. The

::1.The colour of nanopar cles is different from the

semiconductor devices are based on the concept of

bulk material. 2.Atomic clusters of different sizes will

charge transport only whereas the nanosized

have different energy level separa ons.3.Hence the

components work on the concept of charge as well

size of the cluster can be altered to change the

as spin transport of electrons. This has been used in

colour of a material.4.For example, gold in bulk form

devices like spin FET, spin LED etc 2.Automobiles:

appears yellow but gold nanopar cles appear bright

Nanotube composites have be er mechanical

red in colour.5.Due to these metal nanopar cles, the

strength compared to steel but are costly at present.

glasses appear coloured.(2)Electrical

Efforts are being made to develop cheaper nanotube

proper es::1.The resis vity in bulk ma er is mainly

composites that can replace steel which is used to

due to sca ering of electrons by ions and crystal

construct the body structure of automobiles. Use of

defects.2. Thus smaller par cle size increases the

nanopar cles in paints provides thin and smooth

resis vity.3. The situa on changes when one or

coa ngs. 3. Tex les: The use of nanotechnology in

more dimensions of the conductor are made very

tex le industry has led to the development of water

small.4.In a quantum well, the electron will be

repellent and wrinkle free clothes.4. Cosme cs: Zinc

confined along one dimension but will move freely

oxide and tanium oxide nanopar cles are used in

along the remaining two dimensions 5. Confinement

sunscreen lo ons which protect the skin from the

of electrons to small dimensions leads to

ultraviolet radia ons. These nanopar cles absorb

quan za on of energy.6.The level of doping in

ultraviolet radia ons. Nanopar cle based dyes and

semiconductors gives rise to another important

colours are harmless to the skin and hence are used

phenomenon.7.In other words, on an average, one

in hair creams, gels and hair dyes.2).Medical:

quantum dot in 10 will have a free electron.8.These

Nanopar cles can be used for detec on and

result in the phenomena of single-electron tunneling

treatment of cancers and tumours. The

and coulomb blockade.9.This phenomenon is called

nanopar cles are injected into the body and guided

coulomb blockade.(3) Mechanical

towards a specific part. Drugs can be encapsulated

proper es::1.Mechanical proper es like hardness,

in nanocapsuleser. 3)Space and defence: Aerogels

elas city and duc lity depend upon the bonds

are porous materials with nanosized pores. They

have very low density and are poor conductors of component needs to be smooth.2.Very thin

heat. They can be used in spacecra s, light weight specimens cannot be tasted.3.Specimen must have

suits and jackets. homogeneous composi on.4.Defects very close to

the surface are not detected.

.Q.(9) Describe the ultrasonic tes ng method of

flow detec on. State advantages and (Q10)Explain applica ons of nanopar cles

disadvantages.:- Ultrasonic flaw detec on :2)opening the capsule at a desired rate using

technique uses the property of ultrasonic waves that magne c fields or infrared light. This targeted drug

they get par ally reflected from any boundary delivery does not affect the healthy organs.

separa ng two media having different densi es.The Nanotechnology based tests developed for fast

me interval between the transmission of an detec on of viruses and an bodies 2.Polymer

ultrasonic pulse and the arrival of an echo is composites using silica fibers and nanopar cles have

propor onal to the distance of the boundary larger mechanical strength and low temperature

separa ng the two media from the transducer. An coefficient of expansion. They can be used in

ultrasonic pulse is transmi ed into the specimen spacecra s which have to withstand high

from one end by an ultrasonic transducer like quartz temperature and stress condi ons during launching

crystal which also performs the func on of a and re-entry into the earth’s atmosphere.

receiver. In absence of any flaw, the pulse is reflected 3.Satellites and spacecra s use solar energy. 4.The

from the other end of the specimen and the two efficiency of solar cells can be increased using

pulses are displayed on a C.R.O.The distance nanopar cles. The use of nanopar cles will also

between the two pulses on the C.R.O. screen can be make the solar cells smaller in size and light weight.

calibrated in terms of the distance travelled by the

Q.What is echo sounding :-Echo sounding or depth

ultrasonic waves in the specimen If there is a flaw, an

sounding is the use of sonar for ranging, normally to

addi onal peak will be seen between the determine the depth of water (bathymetry). It

transmi ed pulse and the pulse reflected from the involves transmi ng acous c waves into water and

other end asFrom the distance between transmi ed recording the me interval between emission and

pulse and the pulse corresponding to the flaw on the return of a pulse; the resul ng me of flight, along

CRO screen, the distance of the flaw from the with knowledge of the speed of sound in water,

surface through which ultrasonic wave was allows determining the distance between sonar and

transmi ed can be obtainedThe posi on and target. This informa on is then typically used for

dimensions of the flaw can be obtained by moving naviga on purposes or in order to obtain depths for

the transducer on the specimen surface and finding char ng purposes. Echo sounding can also be used

the distance of the flaw from different loca ons on for ranging to other targets, such as fish schools.

the specimen surface.The ultrasonic flaw detec on Hydroacous c assessments have tradi onally

method is used in automobile, aircra , railway and employed mobile surveys from boats to evaluate fish

biomass and spa al distribu ons. Conversely, fixed-

shipping industries to test machine parts and rails for

loca on techniques use sta onary transducers to

flaws.Three types of visual display units are used in

monitor passing fish. The word sounding is used for

ultrasonic inspec on. They are known as A-scan

all types of depth measurements, including those

display, B-scan display and C-scan display ..

that don't use sound, and is unrelated in origin to the

Advantages: 1) Components with larger thicknesses word sound in the sense of noise or tones. Echo

can be tested compared to x-ray radiography. 2) This sounding is a more rapid method of measuring depth

method is more accurate.3) Low cost 4) High speed than the previous technique of lowering a sounding

5) Small flaws can also be line un l it touched bo om. The required precision

detected..Disadvantages:1.Surface of the and accuracy of the hydrographic echo sounder is

defined by the requirements of the Interna onal

Hydrographic Organiza on (IHO) for surveys that are

to be undertaken to IHO standards.[7] These values

are contained within IHO publica on S44. In order to

meet these standards, the surveyor must consider

not only the ver cal and horizontal accuracy of the

echo sounder and transducer, but the survey system

as a whole. A mo on sensor may be used, specifically

the heave component (in single beam echosounding)

to reduce soundings for the mo on of the vessel

experienced on the water's surface.

You might also like

- EEE3091F Test 1 Questions - 2022Document3 pagesEEE3091F Test 1 Questions - 2022Student 80No ratings yet

- PCN Ultrasonic Testing Material Level 2 MaterialDocument131 pagesPCN Ultrasonic Testing Material Level 2 Materialmohammed100% (2)

- WLC1 Q1Document7 pagesWLC1 Q1SeyahatNo ratings yet

- UT Course Material PDFDocument131 pagesUT Course Material PDFketasriNo ratings yet

- Phy (Unit 6) (Notes)Document12 pagesPhy (Unit 6) (Notes)pranjaliiis25No ratings yet

- NAME 345 Welding Technology Lecture - 13 Non-Destructive Testing (NDT)Document22 pagesNAME 345 Welding Technology Lecture - 13 Non-Destructive Testing (NDT)Bob SteinerNo ratings yet

- NDT Assignment: Q.1. Compare The Methods of Producing Radiations in Radiography? AnswerDocument20 pagesNDT Assignment: Q.1. Compare The Methods of Producing Radiations in Radiography? AnswerTanvir AhmedNo ratings yet

- Unit - 5 NDTDocument7 pagesUnit - 5 NDTRAJESH. RNo ratings yet

- SSRN Id2770922Document13 pagesSSRN Id2770922oelassal444No ratings yet

- X Ray Radiography Study MaterialDocument5 pagesX Ray Radiography Study MaterialManjukaviNo ratings yet

- A New Method For The Determination of Cluster Velocity and Size in A Circulating Fluidized BedDocument9 pagesA New Method For The Determination of Cluster Velocity and Size in A Circulating Fluidized Bedกะตั้ว คับNo ratings yet

- Neutron Scattering TechniqueDocument22 pagesNeutron Scattering TechniqueIshfaq AhmadNo ratings yet

- TPW (Final Copy) P SunilDocument6 pagesTPW (Final Copy) P SunilFierdy AkasyaNo ratings yet

- Unit 5 Nanomaterials and Its Characterization TechniquesDocument48 pagesUnit 5 Nanomaterials and Its Characterization TechniquesAditya SalunkheNo ratings yet

- NDT Module 5Document17 pagesNDT Module 5Abhishek DNo ratings yet

- Ultrasonic Technique For Detection and Measurement: of Fatigue CracksDocument25 pagesUltrasonic Technique For Detection and Measurement: of Fatigue Cracksbharathi_pmNo ratings yet

- MS Assignment Alms1Document5 pagesMS Assignment Alms1Aryan SharmaNo ratings yet

- Microelectronics ReliabilityDocument6 pagesMicroelectronics ReliabilityIndrawan AzizNo ratings yet

- DAVIDDocument12 pagesDAVIDhercheys aberteNo ratings yet

- Me 8 Mseme Module 20Document7 pagesMe 8 Mseme Module 20Kendrick RomeroNo ratings yet

- 1992 - Shalom Et Al. - A Micropipette Force Probe Suitable For Near-Field Scanning Optical Microscopy - Review of Scientific InstrumentsDocument6 pages1992 - Shalom Et Al. - A Micropipette Force Probe Suitable For Near-Field Scanning Optical Microscopy - Review of Scientific InstrumentsClaudio BiaginiNo ratings yet

- Scanning Tunneling Microscopy Transmission Electron MicroscopyDocument18 pagesScanning Tunneling Microscopy Transmission Electron MicroscopyAWMツ MØNARCHNo ratings yet

- Non-Destructive Testing of Capless Porcelain Line Post Insulators To Detect Internal DefectsDocument132 pagesNon-Destructive Testing of Capless Porcelain Line Post Insulators To Detect Internal Defectsmartin2502No ratings yet

- A Simple Method of Coil DesignDocument7 pagesA Simple Method of Coil DesignPAUL RODRIGUEZNo ratings yet

- Non Destructive Testing of High Volltage Cables by Non-Electrical MethodsDocument4 pagesNon Destructive Testing of High Volltage Cables by Non-Electrical MethodsRIDHO RISKI HADINo ratings yet

- Chapter 4 RTDocument24 pagesChapter 4 RTNurjihan Binti AimiNo ratings yet

- AFM Atomic Force MicroscopyDocument24 pagesAFM Atomic Force MicroscopyYogesh KhandelwalNo ratings yet

- RT SafetyDocument157 pagesRT SafetyYasser Abd El FattahNo ratings yet

- Introduction To Nanotechnology - History, Definition, Methodology, Applications, and ChallengesDocument35 pagesIntroduction To Nanotechnology - History, Definition, Methodology, Applications, and ChallengeschandruuncleNo ratings yet

- Unit 4NDTDocument9 pagesUnit 4NDTRAJESH. RNo ratings yet

- Studies On Feasibility of Ultrasonic Phased Array in Rail InspectionDocument4 pagesStudies On Feasibility of Ultrasonic Phased Array in Rail InspectionMartin Chimenti - ARO SANo ratings yet

- Nanomaterials and Its Characterization TechniquesDocument16 pagesNanomaterials and Its Characterization TechniquesAditya SalunkheNo ratings yet

- Powder DiffractionDocument22 pagesPowder DiffractionTamara Silvana CárcamoNo ratings yet

- Seminar ON Non-Destructive Testing: Department of Automobile EngineeringDocument23 pagesSeminar ON Non-Destructive Testing: Department of Automobile EngineeringAjith K100% (1)

- Wa0000Document29 pagesWa0000মহিবুল আলম মানিকNo ratings yet

- Cui 2021Document8 pagesCui 2021mvssrajuNo ratings yet

- Shielded Metal Arc Welding (SMAW) NC II: Worksheet Week 2Document10 pagesShielded Metal Arc Welding (SMAW) NC II: Worksheet Week 2Tommy Dela CruzNo ratings yet

- PHY1003 - PHYSICS - ETH - 1.0 - 0 - PHY1003 Physics PDFDocument4 pagesPHY1003 - PHYSICS - ETH - 1.0 - 0 - PHY1003 Physics PDFChandreyi ChowdhuryNo ratings yet

- Non-Destructive Test Methods For Hollow-Core Composite InsulatorsDocument4 pagesNon-Destructive Test Methods For Hollow-Core Composite InsulatorsHendi AfriyanNo ratings yet

- Crystal Structure PPT4.2Document16 pagesCrystal Structure PPT4.2komalkajal804No ratings yet

- Non - Destructive TestingDocument28 pagesNon - Destructive TestingPhilip PanaNo ratings yet

- X-Ray DiffractometerDocument17 pagesX-Ray Diffractometerananyo sabujNo ratings yet

- Department of Chemical & Polymer Engineering University of Engineering & Technology Lahore (FSD Campus)Document42 pagesDepartment of Chemical & Polymer Engineering University of Engineering & Technology Lahore (FSD Campus)Muhammad Waqas AkbarNo ratings yet

- Lec 8Document26 pagesLec 8Amjed AL-KAHTEEBNo ratings yet

- Star NMRDocument20 pagesStar NMRstarskyhutch0000No ratings yet

- The Basics of Confocal MicrosDocument22 pagesThe Basics of Confocal MicrosViswanathan SundaramNo ratings yet

- Fast Single-Mode Characterization of Optical Fiber by Finite-Difference Time-Domain MethodDocument9 pagesFast Single-Mode Characterization of Optical Fiber by Finite-Difference Time-Domain MethodAnonymous c75J3yX33No ratings yet

- Inspection of Dissimilar Material Joints Using Ultrasonic Phased ArraysDocument6 pagesInspection of Dissimilar Material Joints Using Ultrasonic Phased ArraysBruno César LevitaNo ratings yet

- Damage Detection in Membrane Structures Using Non-Contact Laser Excitation and WaveletDocument16 pagesDamage Detection in Membrane Structures Using Non-Contact Laser Excitation and Wavelet3tarebitarafNo ratings yet

- Government Engineering College Gandhinagar: Long Range Ultrasonic TestingDocument21 pagesGovernment Engineering College Gandhinagar: Long Range Ultrasonic TestingJaynish IdhariyaNo ratings yet

- Non Destructive Testing QuizDocument5 pagesNon Destructive Testing QuizFuture HazeNo ratings yet

- Barc RT Level - 2Document160 pagesBarc RT Level - 2NavnitNo ratings yet

- TOM Question PaperDocument9 pagesTOM Question PaperPriyadharshan RNo ratings yet

- NDE TechniquesDocument25 pagesNDE TechniquesaseNo ratings yet

- 239 MookDocument8 pages239 MookAnurag SharmaNo ratings yet

- Hikmantiyah 2018 J. Phys. Conf. Ser. 1025 012010Document6 pagesHikmantiyah 2018 J. Phys. Conf. Ser. 1025 012010Argus SparkNo ratings yet

- Nano TechnologyDocument29 pagesNano TechnologyAdiNo ratings yet

- Nanomaterials and NanotechnologyDocument19 pagesNanomaterials and NanotechnologyIgor GomelNo ratings yet

- Tem 2final PDFDocument9 pagesTem 2final PDFSkuukzky baeNo ratings yet

- Bolotina 2015 IOP Conf. Ser. Mater. Sci. Eng. 81 012073Document8 pagesBolotina 2015 IOP Conf. Ser. Mater. Sci. Eng. 81 012073Titik SundariNo ratings yet

- Probing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsFrom EverandProbing the Atom: Interactions of Coupled States, Fast Beams, and Loose ElectronsRating: 2 out of 5 stars2/5 (1)

- BR - Bridge WorkDocument35 pagesBR - Bridge WorkMuthusamy ArumugamNo ratings yet

- Legacies Dispatches From An Uncertain WorldDocument9 pagesLegacies Dispatches From An Uncertain WorldlopxmnNo ratings yet

- Vehicle Dynamics Prof. R. Krishnakumar Department of Engineering Design Indian Institute of Technology - Madras Lecture - 12 Lateral Force GenerationDocument17 pagesVehicle Dynamics Prof. R. Krishnakumar Department of Engineering Design Indian Institute of Technology - Madras Lecture - 12 Lateral Force Generationgauraang singh baghelNo ratings yet

- Week 18 - Science 10Document6 pagesWeek 18 - Science 10Mira VeranoNo ratings yet

- Structural TheoryDocument9 pagesStructural TheoryVincent ParagasNo ratings yet

- Pib04 PDFDocument3 pagesPib04 PDFANGIE PAOLA RODELO PANZANo ratings yet

- Measuring Ultrashort Laser Pulses I: Autocorrelation: 1D Phase RetrievalDocument42 pagesMeasuring Ultrashort Laser Pulses I: Autocorrelation: 1D Phase RetrievalNadia Al-RoshdeeNo ratings yet

- Installation Manual: Sliding Gate SystemDocument14 pagesInstallation Manual: Sliding Gate SystemGloria Cecilia SanchezNo ratings yet

- CH - 4 The Adventure Answer KeyDocument3 pagesCH - 4 The Adventure Answer Keyhawrahaider52No ratings yet

- CE Board Nov 2021 - Hydraulics - Set 1Document2 pagesCE Board Nov 2021 - Hydraulics - Set 1Asif UsmanNo ratings yet

- 1.preliminary DESIGNDocument7 pages1.preliminary DESIGNSandip Paudel100% (1)

- AdmixtureDocument5 pagesAdmixtureMishra dtuNo ratings yet

- Synchronous Motor - InstruDocument12 pagesSynchronous Motor - InstruMohit IndurkarNo ratings yet

- Circuit Lab Introduction I ECE - Partial NotesDocument27 pagesCircuit Lab Introduction I ECE - Partial NotesDr.P. RAJASEKARNo ratings yet

- Circuit Construction: Assignment 3Document45 pagesCircuit Construction: Assignment 3ali morisyNo ratings yet

- "Simulation of Asynchronous Motor Using MATLAB": Submitted To: Prof. GOKULAKRISHNAN GDocument35 pages"Simulation of Asynchronous Motor Using MATLAB": Submitted To: Prof. GOKULAKRISHNAN GAditi DixitNo ratings yet

- RHM30-160 Installation GuideDocument30 pagesRHM30-160 Installation GuideJoseph FranciscoNo ratings yet

- Parts Catalog: Ir C3200 SeriesDocument178 pagesParts Catalog: Ir C3200 SeriesЕвгений100% (1)

- Scour Behaviour and Scour Protection For MonopileDocument15 pagesScour Behaviour and Scour Protection For MonopileWilliam HoNo ratings yet

- Thermodynamics 2 & Fluid MechanicsDocument18 pagesThermodynamics 2 & Fluid MechanicsNicole Mae AllosadaNo ratings yet

- Elevator Control Valves: EN ISO 9001Document6 pagesElevator Control Valves: EN ISO 9001Jibjab7No ratings yet

- STYLE AG-4911 4# Eva Closed Cell Foam: Typical Properties ofDocument2 pagesSTYLE AG-4911 4# Eva Closed Cell Foam: Typical Properties ofArrow LazarusNo ratings yet

- Boardworks 1 .PPT - LightDocument9 pagesBoardworks 1 .PPT - LightsrenNo ratings yet

- Mechanics of Materials Formulas and Problems Engineering Mechanics 2 by - by WWW - LearnEngineering.inDocument219 pagesMechanics of Materials Formulas and Problems Engineering Mechanics 2 by - by WWW - LearnEngineering.inHữu Danh Nguyễn100% (1)

- Quotation: Home Automation Price ListDocument2 pagesQuotation: Home Automation Price ListUsman khanNo ratings yet

- Lecture Magnetostatic DevicesDocument30 pagesLecture Magnetostatic DevicesBill WhiteNo ratings yet

- Wireline Works Tech-BulletinsDocument25 pagesWireline Works Tech-BulletinsGerardo LizardoNo ratings yet

- STEREOISOMERISMDocument11 pagesSTEREOISOMERISMSuresh KumarNo ratings yet