Professional Documents

Culture Documents

PRS XATS 68 - XAS 88 KD EN Antwerp 2960 2570 01

PRS XATS 68 - XAS 88 KD EN Antwerp 2960 2570 01

Uploaded by

Puji PawokoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRS XATS 68 - XAS 88 KD EN Antwerp 2960 2570 01

PRS XATS 68 - XAS 88 KD EN Antwerp 2960 2570 01

Uploaded by

Puji PawokoCopyright:

Available Formats

Product Reference

XATS 68 - XAS 88 KD APP

Standard Scope of Supply

The Atlas Copco XATS 68-XAS 88 KD is a single-stage, oil-injected, rotary screw type air compressor range, powered by a

liquid-cooled, four-cylinder Kubota diesel engine.

The unit hosts the new generation C67 Screw element in its air end, combined with a Kubota made diesel engine model

V1505 or V1505-T, complying with the EU Stage 3A emission standard.

Different pressure variants are available.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to

ensure best in class cost of ownership.

Features Benefits

• Compact, fuel-efficient engine • Saves up to 12% of fuel on typical applications in this range.

• Designed with environmental protection in • The unit comes with a Spillage Free frame as standard with 110% fluid

mind containment and EU Stage3A emission compliant engine, this makes the

compressor suitable for use in all areas of the EU.

• Compact, sound attenuated, corrosion • For OND compliance the unit is enclosed in a sound attenuated Zincor steel

resistant enclosure enclosure.

Compact and maneuverable, saving valuable space on your job site and

during transportation, weighing less than 750 kg.

• HardHatTM hood and 3-layer painting of metal • High residual value and low repair costs

parts

Product Reference - 2960 2570 01 Page 1 of 8

XATS 68 - XAS 88 KD APP - Product Reference

Main data

Model XATS 68 KD XAS 78 KD XAS 88 KD

Minimum effective receiver pressure bar(g) 2 2 2

Maximum effective receiver pressure (Unloaded) bar(g) 12,5 8,8 8,8

Normal effective working pressure bar(g) 10,3 7 7

Actual free air delivery m³/min 3,5 4,5 5,0

Fuel consumption

at 100% FAD (full load) kg/h 8,17 8,17 8,17

at 75% FAD kg/h 6,83 6,83 6,83

at 50% FAD kg/h 5,3 5,3 5,3

at 25% FAD kg/h 2,93 2,93 2,93

Specific fuel consumption at 100% FAD g/m³ 39,81 30,83 30,83

Maximum typical oil content of compressed air mg/m³ 5 5 5

Max. sound power level (Lw @ 2000/14/EC) dB(A) 98 98 98

Max. sound pressure level (Lp @ ISO 2151) dB(A) 70 70 70

Compressed air temperature at outlet valve °C 78,5 83,2 83,2

Max. ambient temperature at sea level °C 50 50 50

Min. starting temperature with CS equipment °C -20 -20 -20

Min. starting temperature without CS equipment °C -10 -10 -10

Engine Kubota Kubota Kubota

Type V1505-T V1505-T V1505-T

Emission stage EU Stage3A EU Stage3A EU Stage3A

Coolant ParCool ParCool ParCool

Number of cylinders 4 4 4

Bore mm 78 78 78

Stroke mm 78,4 78,4 78,4

Swept volume l 1,498 1,498 1,498

Engine power at normal shaft speed @ ISO 9249G kW 33 33 33

Full Load rpm 3000 3000 3000

Unload rpm 1850 1850 1850

Capacity of oil sump: - Initial fill l 5,5 5,5 5,5

Capacity of oil sump: - Refill (max) l 5,35 5,35 5,35

Capacity of cooling system l 8,5 8,5 8,5

Capacity of compressor oil system l 8 8 8

Net capacity of air receiver l 12 12 12

Air volume at inlet grating (approx.) m³/s 0,93 0,93 0,93

Capacity of standard fuel tanks l 60 60 60

Safety valve - minimum opening pressure bar(g) 14,1 9,9 9,9

Product Reference - 2960 2570 01 Page 2 of 8

XATS 68 - XAS 88 KD APP - Product Reference

Model XAS 68 KDG 6kVA 110 V XAS 68 KDG 6kVA 400 V XAS 88 KDG 6,5kVA 110 V

Minimum effective receiver pressure bar(g) 2 2 2

Maximum effective receiver pressure (Unloaded) bar(g) 8,8 8,8 8,8

Normal effective working pressure bar(g) 7 7 7

Actual free air delivery m³/min 3,5 3,5 5,0

Fuel consumption

at 100% FAD (full load) kg/h 6,68 6,68 8,17

at 75% FAD kg/h 5,61 5,61 6,83

at 50% FAD kg/h 4,12 4,12 5,3

at 25% FAD kg/h 3,1 3,1 2,93

Specific fuel consumption at 100% FAD g/m³ 30,67 30,67 30,83

Maximum typical oil content of compressed air mg/m³ 5 5 5

Max. sound power level (Lw @ 2000/14/EC) dB(A) 98 98 98

Max. sound pressure level (Lp @ ISO 2151) dB(A) 70 70 70

Compressed air temperature at outlet valve °C 80,8 80,8 82

Max. ambient temperature at sea level °C 50 50 50

Min. starting temperature with CS equipment °C -20 -20 -20

Min. starting temperature without CS equipment °C -10 -10 -10

Engine Kubota Kubota Kubota

Type V1505-T V1505-T V1505-T

Emission stage EU Stage3A EU Stage3A EU Stage3A

Coolant ParCool ParCool ParCool

Number of cylinders 4 4 4

Bore mm 78 78 78

Stroke mm 78,4 78,4 78,4

Swept volume l 1,498 1,498 1,498

Engine power at normal shaft speed @ ISO 9249G kW 33 33 33

Full Load rpm 3000 3000 3000

Unload rpm 1850 1850 1850

Capacity of oil sump: - Initial fill l 5,5 5,5 5,5

Capacity of oil sump: - Refill (max) l 5,35 5,35 5,35

Capacity of cooling system l 8,5 8,5 8,5

Capacity of compressor oil system l 8 8 8

Net capacity of air receiver l 12 12 12

Air volume at inlet grating (approx.) m³/s 0,93 0,93 0,93

Capacity of standard fuel tanks l 60 60 60

Safety valve - minimum opening pressure bar(g) 9,9 9,9 9,9

Alternator MECC ALTE MECC ALTE MECC ALTE

Type S16F-150/A T16F-130A S16F-180/A

Insulation class H H H

Rated output, class H temp. rise kVA 6 6 6,5

Standard IEC 34-1 IEC 34-1 IEC 34-1

Number of phases 1 3 1

Fault current protection, residual current release, Idn A 0,03 10 0,03

Circuit-breaker 1ph: Number of poles 2 4 2

Circuit-breaker 1ph: Thermal release (lt) A 50 10 63

Circuit-breaker 1ph: Magnetic release %In 300-500 300-500 300-500

Circuit-breaker 1ph: Rated current (In) A 50 10 63

Air/Electricity operating mode* Simultaneous Simultaneous Semi-simultaneous

* Simultaneous: full FAD and full electric power available at the same time

Semi-simultaneous: air and electric power available at the same time, but not both at full load

Product Reference - 2960 2570 01 Page 3 of 8

XATS 68 - XAS 88 KD APP - Product Reference

Model XAS 48 KDG 12kVA 400 V XAS 68 KDG 12kVA 400 V XAS 88 KDG 9kVA 400 V

Minimum effective receiver pressure bar(g) 2 2 2

Maximum effective receiver pressure (Unloaded) bar(g) 8,8 8,8 8,8

Normal effective working pressure bar(g) 7 7 7

Actual free air delivery m³/min 2,5 3,5 5,0

Fuel consumption

at 100% FAD (full load) kg/h 4,89 6,68 8,17

at 75% FAD kg/h 3,96 5,61 6,83

at 50% FAD kg/h 3,12 4,12 5,3

at 25% FAD kg/h 2,29 3,1 2,93

Specific fuel consumption at 100% FAD g/m³ 36,51 30,67 30,83

Maximum typical oil content of compressed air mg/m³ 5 5 5

Max. sound power level (Lw @ 2000/14/EC) dB(A) 98 98 98

Max. sound pressure level (Lp @ ISO 2151) dB(A) 70 70 70

Compressed air temperature at outlet valve °C 76 80,8 83,2

Max. ambient temperature at sea level °C 50 50 50

Min. starting temperature with CS equipment °C -20 -20 -20

Min. starting temperature without CS equipment °C -10 -10 -10

Engine Kubota Kubota Kubota

Type V1505-T V1505-T V1505-T

Emission stage EU Stage3A EU Stage3A EU Stage3A

Coolant ParCool ParCool ParCool

Number of cylinders 4 4 4

Bore mm 78 78 78

Stroke mm 78,4 78,4 78,4

Swept volume l 1,498 1,498 1,498

Engine power at normal shaft speed @ ISO 9249G kW 33 33 33

Full Load rpm 3000 3000 3000

Unload rpm 1850 1850 1850

Capacity of oil sump: - Initial fill l 5,5 5,5 5,5

Capacity of oil sump: - Refill (max) l 5,35 5,35 5,35

Capacity of cooling system l 8,5 8,5 8,5

Capacity of compressor oil system l 8 8 8

Net capacity of air receiver l 12 12 12

Air volume at inlet grating (approx.) m³/s 0,93 0,93 0,93

Capacity of standard fuel tanks l 60 60 60

Safety valve - minimum opening pressure bar(g) 9,9 9,9 11,6

Alternator MECC ALTE MECC ALTE MECC ALTE

Type T20FS-160/A T20FS-160/A T20FS-160/A

Insulation class H H H

Rated output, class H temp. rise kVA 12,5 12,5 12,5**

Standard IEC 34-1 IEC 34-1 IEC 34-1

Number of phases 3 3 3

Fault current protection, Insulation resistance kOhm 10 10 10

Circuit-breaker 3ph: Number of poles 4 4 4

Circuit-breaker 3ph: Thermal release (lt) A 16 16 13

Circuit-breaker 3ph: Magnetic release %In 300-500 300-500 300-500

Circuit-breaker 3ph: Rated current (In) A 16 16 13

Air/Electricity operating mode* Simultaneous Semi-simultaneous Semi-simultaneous

* Simultaneous: full FAD and full electric power available at the same time

Semi-simultaneous: air and electric power available at the same time, but not both at full load

** limited to 9 kVA by main circuit breaker

Product Reference - 2960 2570 01 Page 4 of 8

XATS 68 - XAS 88 KD APP - Product Reference

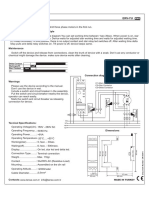

Dimensions

See dimension drawing

Principle Data

Compressor Element

The quality of a compressor can be measured through the reliability, efficiency and durability of the compressor element used. Through

decades of expertise in the design of compressor elements, the result is the production of most efficient and reliable compressors in the

market. When the screw element is efficient durability excels, maintenance intervals decrease and fuel consumption goes down.

The XATS 68 - XAS 88 KD compressors utilize an Atlas Copco C67 element which is driven from the diesel engine. Inlet air

is filtered through a heavy duty two stage air filter.

Air/Oil Separator

Air and oil separation is achieved through a centrifugal oil separator combined with a filter element. The vessel is either CE or

ASME/CRN/MOM/AS1210 approved, and stamped accordingly.

Designed for a higher maximum working pressure, the separator is equipped with a high pressure sealed and certified safety

relief valve (automatic blow-down valve).

Cooling System

The cooling system consists of integrated side-by-side aluminum coolers with an axial fan to ensure optimum cooling. The fan is

protected by a guard for operator safety. There is an access port for easy cleaning of coolers.

The cooling system is suitably designed for continuous operation in ambient conditions up to 50°C, with canopy doors closed.

Engine

A Kubota V1505 naturally aspirated or V1505-T turbocharged, four-cylinder, liquid-cooled diesel engine provides ample power

to operate the compressor continuously at full load.

Cold start options are available for temperatures down to -20°C.

The 60-liter fuel tank is sufficiently sized to allow full shift autonomy (8 hours).

Product Reference - 2960 2570 01 Page 5 of 8

XATS 68 - XAS 88 KD APP - Product Reference

For the curve of XAS78, please refer to XAS88.

Electrical System

The XATS 68 - XAS 88 KD is equipped with a 12 Volt negative ground electrical starting system.

Instrumentation

The instrument control panel is located at the rear of the compressor canopy with easy access.

The standard instrument package includes an operating pressure gauge, a starter switch, a running hour counter, and 2 warning lamps.

The starter switch has an integrated lockout mechanism to prevent starter motor damage.

Product Reference - 2960 2570 01 Page 6 of 8

XATS 68 - XAS 88 KD APP - Product Reference

Bodywork

The compressor’s frame comes standard with ASTM A653 Zincor steel platework with powder coat paint finish providing excellent corrosion

protection. The canopy is sound attenuated to meet the most current legal noise requirements.

Undercarriage

The XATS 68 - XAS 88 KD compressors are available with a choice of undercarriages, providing utmost flexibility in installation or

towing requirements.

All undercarriage types can be partially disassembled and/or adjusted vertically upwards, to allow for sideways truck loading, up to

9 units per truck.

With the Fixed without brakes undercarriage type, even sideways container loading is also possible, allowing up to 8 units per

container.

Options

The following options are available:

• Undercarriage • Pressure vessel

o Adjustable without brakes o CE approved

o Adjustable with brakes o Multi-approved

o Fixed without brakes (ASME/CRN/MOM/AS1210)

o Fixed with brakes • Anti-theft device

o DoT approved • Additional fuelfilter

o Support mounted • Safety cartridge

o Extended support mounted • Toolbox

• Towing eyes • Cold weather equipment (thermostatic

o AC bypass valve and synthetic oil)

o Ball coupling • Hose reel

o DIN • Refinery equipment

o GB o Spark arrester

o ITA o Inlet shutdown valve

o NATO • Customized appearance

• Towbar supports o Special labelling

o Support leg o Special coloured hood

o Jockey wheel o Special coloured frame

• Road light systems o Special coloured bumper

o Normal • Connectivity

o LED o FleetlinkTM

o DoT approved non-LED

o Reflectors only

• Quality air equipment

o Aftercooler with optional bypass

valve

o Lubricator

o Reheater

o Non return valve

Product Reference - 2960 2570 01 Page 7 of 8

XATS 68 - XAS 88 KD APP - Product Reference

Supplied Documentation

The unit is delivered with documentation regarding:

• Hard copies of the Atlas Copco Operators Safety and Instruction Manual, Atlas Copco Parts Book, Kubota Engine Manual and Parts book,

as well as electronic copies available on request.

• Warranty Registration card for engine and Atlas Copco Compressor (Units must be registered upon receipt).

• Certificate for air/oil separator vessel and safety valve approval (Upon request only).

Warranty Coverage

Please refer to product presentation for warranty info

Extended Warranty Programs are available; please contact your local sales representative for more info.

Product Reference - 2960 2570 01 Page 8 of 8

You might also like

- S12A2-Y1PTA-1 Mitsubishi Diesel Generator EngineDocument3 pagesS12A2-Y1PTA-1 Mitsubishi Diesel Generator Enginejabed habib100% (1)

- Air Compressor XAS 186 CDocument2 pagesAir Compressor XAS 186 CAsad Aijaz100% (1)

- Mitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFDocument3 pagesMitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFSalvador Millán EstradaNo ratings yet

- Electrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsJose luis ConsuegraNo ratings yet

- AXS98Document7 pagesAXS98van javNo ratings yet

- PRS XAS 48-7 G 6 kVA KD S5 EN Antwerp 2960 7180 00Document5 pagesPRS XAS 48-7 G 6 kVA KD S5 EN Antwerp 2960 7180 00duroux.thibaultNo ratings yet

- The Ready To Go Range: The 8 Series. What Do You Tow?Document8 pagesThe Ready To Go Range: The 8 Series. What Do You Tow?Mohamad NasserNo ratings yet

- Compresor Mobil Atlas Copco XAVS 287 MDDocument4 pagesCompresor Mobil Atlas Copco XAVS 287 MDdiconNo ratings yet

- Atlas Copco: Small Portable Air CompressorsDocument2 pagesAtlas Copco: Small Portable Air CompressorsAsad AijazNo ratings yet

- Product Specifications PDFDocument8 pagesProduct Specifications PDFDave WallaceNo ratings yet

- Product Ref Sheet U 75-110 PACE KD WUX 2960 1910 00 ENDocument5 pagesProduct Ref Sheet U 75-110 PACE KD WUX 2960 1910 00 ENduroux.thibaultNo ratings yet

- Atlas Copco U 110 KD WUX Product Reference SheetDocument4 pagesAtlas Copco U 110 KD WUX Product Reference SheetYanNo ratings yet

- Product Reference Sheet CPS350-400 2954 4550 00 ENDocument4 pagesProduct Reference Sheet CPS350-400 2954 4550 00 ENyoucef alimNo ratings yet

- 6btaa5 9G2Document3 pages6btaa5 9G2Budi Nais100% (2)

- T0221 0013E-Rev.5 S16R2 PTAW2 E-50HzDocument5 pagesT0221 0013E-Rev.5 S16R2 PTAW2 E-50HzParinyaNo ratings yet

- Multi V Air Conditioner: SVC MANUAL (Exploded View)Document21 pagesMulti V Air Conditioner: SVC MANUAL (Exploded View)José ArgüelloNo ratings yet

- Ficha Técnica Compresora Compair C76Document1 pageFicha Técnica Compresora Compair C76Percy CárdenasNo ratings yet

- S12A2 Y2PTAW 2 Rev1 Spec SheetDocument5 pagesS12A2 Y2PTAW 2 Rev1 Spec Sheetivan1989104100% (1)

- Atlas Copco Xats350-450Document2 pagesAtlas Copco Xats350-450bruno le briereNo ratings yet

- Magnum Literature Trash Pumps Dry Wet Priming Pump BrochureDocument4 pagesMagnum Literature Trash Pumps Dry Wet Priming Pump BrochureAzzam NashrullahNo ratings yet

- ), 1$/ DRAWINGS FOR Centrifugal SeparatorDocument2,113 pages), 1$/ DRAWINGS FOR Centrifugal SeparatorCvetelin TodorovNo ratings yet

- Operation 490BDocument60 pagesOperation 490BYe Min Htike100% (1)

- Kta 38 G7Document3 pagesKta 38 G7ophar100% (1)

- Cummins Engine Co - LTD: General Engine Data CPL 1519 CPL 6BT5.9G1 6BT5.9G2Document3 pagesCummins Engine Co - LTD: General Engine Data CPL 1519 CPL 6BT5.9G1 6BT5.9G2mardalan nabisukNo ratings yet

- Doosan Engine de 12 Maintenance ManualDocument10 pagesDoosan Engine de 12 Maintenance ManualJoseph100% (59)

- Compresor Mobil Atlas Copco XAMS 287 MDDocument4 pagesCompresor Mobil Atlas Copco XAMS 287 MDdicon100% (1)

- HTTP Mitsubishi-Engine - Ru Assets Files PDF SR S16R-PTA-S (MGS1500B)Document3 pagesHTTP Mitsubishi-Engine - Ru Assets Files PDF SR S16R-PTA-S (MGS1500B)NOELGREGORIONo ratings yet

- Cirkulac Pumpe BUHLER De370001Document8 pagesCirkulac Pumpe BUHLER De370001sealion72100% (1)

- Product Reference Sheet XAHTS 350 400 T3 XAHS 400 PACE WUX 2960 1970 01 EN PDFDocument5 pagesProduct Reference Sheet XAHTS 350 400 T3 XAHS 400 PACE WUX 2960 1970 01 EN PDFwayan mardanaNo ratings yet

- Data Sheet - CompressorDocument2 pagesData Sheet - CompressorShanu kumarNo ratings yet

- DS338-CPGK Data SheetDocument3 pagesDS338-CPGK Data SheetMoh NezNo ratings yet

- Compressor 135wir-260wirDocument3 pagesCompressor 135wir-260wirdffxnlkfnNo ratings yet

- Catalogue Mitsubishi S12A2 PTADocument5 pagesCatalogue Mitsubishi S12A2 PTAmoris.wahyuNo ratings yet

- S12R-Y1PTA-2 Mitsubishi Diesel Generator EngineDocument3 pagesS12R-Y1PTA-2 Mitsubishi Diesel Generator EnginealstomNo ratings yet

- Ingersollrand P260WIRDocument2 pagesIngersollrand P260WIROjik OnlineNo ratings yet

- Technical Data:-: Diesel Generator Set C SeriesDocument2 pagesTechnical Data:-: Diesel Generator Set C Seriesmozes tamarapalliNo ratings yet

- The Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMDocument6 pagesThe Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMSiding BarroNo ratings yet

- 110 CFM To 260 CFM QXD - ENDocument2 pages110 CFM To 260 CFM QXD - ENJamal HabbasNo ratings yet

- The 8 Series Utility Range: What Do You Integrate?Document4 pagesThe 8 Series Utility Range: What Do You Integrate?Asad AijazNo ratings yet

- S12H-engine - PDF SPECSDocument3 pagesS12H-engine - PDF SPECSMarcos Vinicio StizzioliNo ratings yet

- PUSH 400CTL K38热平衡表Document1 pagePUSH 400CTL K38热平衡表周庆卓No ratings yet

- Specification S16R2 PTAWDocument4 pagesSpecification S16R2 PTAWMuhammad rizki100% (1)

- The Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMDocument6 pagesThe Engine For Construction Equipment.: 60 - 155 KW at 1500 - 2500 RPMAinal MuchlisNo ratings yet

- C35 10 C76 - EnglishDocument6 pagesC35 10 C76 - EnglishLyuben BoyadzhievNo ratings yet

- Model: C1500 D6 Frequency: 60 HZ Fuel Type: Diesel: Generator Set Data SheetDocument3 pagesModel: C1500 D6 Frequency: 60 HZ Fuel Type: Diesel: Generator Set Data SheetJose VarelaNo ratings yet

- Bolaite (Atlas Copco) Screw Air CompressorDocument11 pagesBolaite (Atlas Copco) Screw Air CompressorJafarov VuqarNo ratings yet

- Sullivan Palatek M SeriesDocument2 pagesSullivan Palatek M SeriesLeonardo BarrancoNo ratings yet

- VacPumpReq TSB007Document6 pagesVacPumpReq TSB007zosuryantoNo ratings yet

- S16R-PTA: Specification SheetDocument4 pagesS16R-PTA: Specification Sheetzona amrulloh100% (1)

- CompressorDocument8 pagesCompressorzahid_497No ratings yet

- S12A2-PTA: Specifcation SheetDocument3 pagesS12A2-PTA: Specifcation Sheetjabed habib100% (1)

- GMP60PXSDocument7 pagesGMP60PXSDevilNo ratings yet

- Model: C60D6R (B3.3 Rental Product) Frequency: 60 HZ Fuel Type: DieselDocument3 pagesModel: C60D6R (B3.3 Rental Product) Frequency: 60 HZ Fuel Type: DieselMarco BernalNo ratings yet

- EcoDocument2 pagesEcoAsad KhanNo ratings yet

- S12H PtaDocument4 pagesS12H PtaThanh Trúc Đặng HuỳnhNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Appendix3 25113Document189 pagesAppendix3 25113iezohreNo ratings yet

- Standby 200 KW Prime 180 KW: Diesel Generator SetsDocument4 pagesStandby 200 KW Prime 180 KW: Diesel Generator SetsJaimecolina2004No ratings yet

- Cisco ASA 5510, ASA 5520, ASA 5540, and ASA 5550 Hardware Installation GuideDocument70 pagesCisco ASA 5510, ASA 5520, ASA 5540, and ASA 5550 Hardware Installation Guideroben parsieNo ratings yet

- The Problem of Arcing Faults in Low-Voltage Power Distribution SystemsDocument11 pagesThe Problem of Arcing Faults in Low-Voltage Power Distribution SystemsRogelio RevettiNo ratings yet

- Coordination Tables: 1SDC007004D0204Document110 pagesCoordination Tables: 1SDC007004D0204Nitesh KumarNo ratings yet

- @?????????????????? Modern Selectivity Techniques For LV SystemDocument47 pages@?????????????????? Modern Selectivity Techniques For LV SystemudayakumartNo ratings yet

- Guidelines For Schematic DiagramDocument19 pagesGuidelines For Schematic DiagramRaphael HoNo ratings yet

- OVRHT3 - Installation, Operation and Maintenance ManualDocument4 pagesOVRHT3 - Installation, Operation and Maintenance ManualIvan HerreraNo ratings yet

- Installation: Melody Technical ManualDocument22 pagesInstallation: Melody Technical ManualNassima BELILNo ratings yet

- Check List For Acdb: Document NoDocument2 pagesCheck List For Acdb: Document NoJaswant SutharNo ratings yet

- Rotating Rectifier - TestDocument10 pagesRotating Rectifier - TestDjebali Mourad100% (1)

- Acti9 iPRF1 - PRD1 - 16363Document2 pagesActi9 iPRF1 - PRD1 - 16363Fadi Mohd ShaherNo ratings yet

- ABB High Voltage ProductsDocument255 pagesABB High Voltage Productsemre kabatas100% (2)

- Calingasan CJ M Laboratory ActDocument24 pagesCalingasan CJ M Laboratory ActCharles CalibreNo ratings yet

- 1049 tc544cDocument6 pages1049 tc544cThủy NguyễnNo ratings yet

- Micrologic P User ManualDocument92 pagesMicrologic P User Manual322399mk7086No ratings yet

- 06-A3 APS6 APS12 Series Installation Guide-SC300Document116 pages06-A3 APS6 APS12 Series Installation Guide-SC300Abel Armando Erazo UmañaNo ratings yet

- Type CV Voltage RelayDocument28 pagesType CV Voltage Relayหนุ่ม วัยทองNo ratings yet

- 3WL11122CB381AA2 Datasheet enDocument7 pages3WL11122CB381AA2 Datasheet enRafael GarceteNo ratings yet

- C3controls Understanding Trip Curves PDFDocument8 pagesC3controls Understanding Trip Curves PDFAditya GizerNo ratings yet

- Inrush Current Reduction in Three Phase Power Transformer by Using Prefluxing TechniqueDocument10 pagesInrush Current Reduction in Three Phase Power Transformer by Using Prefluxing TechniqueIAEME Publication100% (1)

- Spec Sheet Woodward 2301A Load Sharing PDFDocument4 pagesSpec Sheet Woodward 2301A Load Sharing PDFahmedhassankhanNo ratings yet

- Sebp6163 11 02 AllcdDocument547 pagesSebp6163 11 02 AllcdMahmoodNo ratings yet

- Erv-Yu Star Delta Relay: GeneralDocument1 pageErv-Yu Star Delta Relay: GeneralMai Văn BáchNo ratings yet

- KVM-524RG ENG ManualDocument8 pagesKVM-524RG ENG ManualadlonusNo ratings yet

- BUILDING SERVICES Protection DevicesDocument8 pagesBUILDING SERVICES Protection DevicesASHFAQNo ratings yet

- 18ARC53 Building Services - MCB - Session3Document11 pages18ARC53 Building Services - MCB - Session3Pranav Pradyumna Gurulinga murthyNo ratings yet

- Introduction To Transformer Turns Ratio TestingDocument13 pagesIntroduction To Transformer Turns Ratio Testingridho kusumaNo ratings yet

- Schneider Electric - Acti-9 - A9HPGD12Document3 pagesSchneider Electric - Acti-9 - A9HPGD12pradeepNo ratings yet