Professional Documents

Culture Documents

Portable Power Tools Ra Sds Drill

Portable Power Tools Ra Sds Drill

Uploaded by

brent machelmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Portable Power Tools Ra Sds Drill

Portable Power Tools Ra Sds Drill

Uploaded by

brent machelmCopyright:

Available Formats

FORM: Safety, Health and Environment (SHE)

TITLE: DEWALT SDS DRILL RISK ASSESSMENT

NUMBER: FORM 005

Risk Assessment

Reference # A 0005

Work Area Contracting

Location of

Site generally

Plant/Equipment

Plant/Equipment # Dewalt SDS Drill

Date of Assessment 17 June 2015

Assessed by

Last reviewed (if

-

applicable)

Task and/or use of Plant/Equipment

Drilling

Reason for Assessment Comment

Review Existing Task

New Task Using portable power tools on construction sites

Change in task, or

legislation

Report of injury

Requested To establish safe methods of working

Is the task or use of the plant/ equipment a hazardous manual handling task? If any of the boxes have

been ticked/ checked a separate manual handling risk assessment requires be completed and

attached/referenced to this risk assessment.

Repetitive Sustained

High or Exposure

or or Repetitive

Task sustained

sudden

awkward movement

to

force vibrations

force postures

Hand held power tool in use

Manual Handling Risk Assessment Required Yes No Rx Number

Attached ( if no give reason) Yes No Reason for no

Uncontrolled when printed Page 1 of 4

Version: 001

Issued: June 2015

Review: 2017

Control

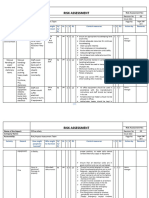

Rating

Rating

Ref

Post

Risk

Risk

Hazard Consequence Controls

#

Check condition of lead and plug before use.

Check for hidden/buried cables / nails before

LTI, business

Electricity causing drilling etc.

interruption;

1 electric shock H9 Do not work where water is present without L3

regulator

specialist advice.

involvement

Periodically test all portable electrical hand tools.

Do not use heat generating equipment

H9 without Hot Work Permit.

LTI, business

Fire or explosion risk Do not work near flammables, compressed

interruption;

2 in flammable gases, in explosive atmospheres or L3

regulator

atmosphere confined spaces without specialist advice.

involvement

Check with Supervisor before using

flammable fuel or gas driven equipment.

LTI, business L3

Loose clothing, jewellery and long hair to be kept

Entanglement in interruption; H9

3 clear of moving parts.

moving parts regulator

Use guards where appropriate.

involvement

Use protective eyewear or face shield. L3

LTI, business Use guards where appropriate.

Flying debris / swarf

interruption; H9 Wear protective gloves where appropriate.

4 etc causing eye, hand

regulator Advise nearby persons of hazard.

or facial injury

involvement Isolate area with barriers, tape etc. where

necessary.

Wear hearing protection if above 80dB(A) L4 / M6

LTI, business H9 or if uncomfortably loud (request

Noise causing interruption; assessment if in doubt).

5

hearing damage regulator Advise nearby persons of hazard.

involvement Supervisors should inform users of risks

from noise.

Select power tools with lowest vibration

levels.

Minimise the time individuals use the

equipment (e.g. job rotation).

Vibration causing

LTI, business Restrict use of vibration inducing tools to L4 / M6

Hand/Arm Vibration

interruption; H9 recommended times (see manufacturer’s

6 Syndrome (HAVS)

regulator information, local risk assessment or label

Carpal Tunnel

involvement on equipment/ box).

Syndrome

Supervisor should inform users of risks

from vibration.

Arrange health surveillance for those

identified at risk from vibration.

7 Tool ergonomics LTI, business Ensure there is adequate room to do the

H9

causing musculo- interruption; job. L4 / M6

Uncontrolled when printed Page 2 of 4

Version: 001

Issued: June 2015

Review: 2017

Minimise the time individuals use heavy

regulator

skeletal injury equipment (e.g. job rotation).

involvement

Wear safety footwear

Minor or major injury Ensure work area is free from trailing

LTI, business L4 / M6

or fatality arising from H9 cables, tools, materials, debris and spills.

interruption;

8 slips, trips or falls All work should be from a suitable and

regulator

stable work platform.

involvement

Do not work from ladders.

Use a dust mask (check for fit).

H9 Increase ventilation to work area (e.g. open L3

windows, temporary extract etc.)

Respiratory illness, LTI, business Wear close-fitting safety goggles.

reduced visibility or interruption; Stop working if visibility is noticeably

9

skin irritation caused regulator reduced.

by dust involvement Wear suitable protective clothing

(especially gloves).

Clean work area regularly (e.g. sweep,

vacuum, wash down).

Check tool is appropriate for the job and

H9 used in accordance with manufacturer’s L4 / M6

LTI, business instructions. Ensure material being worked

Wrist or hand injury

interruption; upon is free from nails and the like.

10 from tool binding or

regulator Trained operators only (or under strict

jamming

involvement supervision).

Ensure tools are maintained according to

manufacturer’s instructions.

Check tool is appropriate for the job and

H9 used in accordance with manufacturer’s L4 / M6

instructions.

LTI, business

All of the above Users shall be trained in the correct use of

interruption;

11 caused by portable tools.

regulator

inappropriate use Inexperienced power tools users should be

involvement

supervised or observed when first using an

unfamiliar item of equipment or in an

unfamiliar environment.

Action Plan Developed Yes No Ref Number AP 0005

Attached ( if no give reason) Yes No Reason for no

Examples Risk Assessment: Measures of Consequence (or Impact)

Level HSE Environment

Uncontrolled when printed Page 3 of 4

Version: 001

Issued: June 2015

Review: 2017

No significant injuries. Minor breach of environmental policy / practices.

1. Insignificant

No significant impact on personnel. Negligible impact on the environment.

Small number of injuries; first aid or out-patients treatment

Minor localised impact; one-off situation easily

2. Minor required.

remedied.

Some inconvenience to personnel.

A number of injuries requiring hospitalisation and long-term Moderate impact on the environment; no long term or

3. Moderate treatment. irreversible damage. May incur cautionary notice or

Moderate disruption to work routines and schedules. infringement notice

Major disruption to work routines and practices. Additional

Severe impact requiring remedial action and review of

resources may be required.

4. Major processes to prevent reoccurrence. Penalties and / or

Significant number of serious injuries requiring hospitalisation

direction or compliance order incurred.

and long-term treatment. Small number of fatalities.

Long-term, large-scale damage to habitat or

Long-term disruption to work practices and routines. Impact on environmental.

5. Catastrophic well-being of personnel. Extensive, life-threatening impact; Serious / repeated breach of legislation / licence

potentially large numbers of serious injuries and fatalities. conditions.

Cancellation of licence and / or prosecution.

Risk Assessment: Measures of Likelihood

Level Description (As per AS/NZS 4360) Examples

Almost certain The event is expected to occur in most conditions Expected frequency range: Greater than one or more per annum

Expected frequency range: Between one in 5 years and one per

Likely The event will probably occur in most conditions

annum

Expected frequency range: Between one in 10 years and one in 5

Possible The event should happen at some time

years

Expected frequency range: Between one in a 100 years and one in

Unlikely The event could happen at some time

10 years

The event may only occur in exceptional

Rare Expected frequency range: Less than one in a hundred years

circumstances

Consequence/Severity

Likelihood

Catastrophic Major Moderate Minor Insignificant

Rating

5 4 3 2 1

Almost certain 5 Extreme (25) Extreme (20) High (15) High (10) Medium (5)

Likely 4 Extreme (20) Extreme (16) High (12) Medium (8) Medium (4)

Possible 3 High (15) High (12) High (9) Medium (6) Low (3)

Unlikely 2 High (10) Medium (8) Medium (6) Low (4) Low (2)

Rare 1 Medium (5) Medium (4) Low (3) Low (2) Low (1)

Risk Rating Timeframe Whom

Extreme Immediate action senior management required Construction Manager

High Within 2 to 3 days senior management attention needed Construction Manager

Within one week management responsibility must be

Moderate Construction Manager

specified

Low Within 14 days manage by routine process Supervisor

Uncontrolled when printed Page 4 of 4

Version: 001

Issued: June 2015

Review: 2017

You might also like

- Risk Assessment For Hot WorkDocument4 pagesRisk Assessment For Hot WorkLu Min Han90% (60)

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (2)

- Code of Practice LTADocument177 pagesCode of Practice LTATay Khwang0% (1)

- Shashi Sir Iosh AssessementDocument3 pagesShashi Sir Iosh AssessementKumar Kush100% (2)

- Basic Occupational Safety and Health (40 Hour) Bosh Invitation Ger EnterpriseDocument2 pagesBasic Occupational Safety and Health (40 Hour) Bosh Invitation Ger EnterpriseAviects Avie Jaro100% (1)

- JSA HEMP Well Services Pg36-40Document5 pagesJSA HEMP Well Services Pg36-40Ashok Suresh100% (1)

- Jsa Functional Testing of Facility AlarmDocument4 pagesJsa Functional Testing of Facility AlarmASLAM MULANINo ratings yet

- 17-Using Portable Power ToolsDocument2 pages17-Using Portable Power Toolshsse.maltaNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- 11kV Switchgerar PD MeasurementDocument3 pages11kV Switchgerar PD MeasurementMohammadAsif ThakorNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo Rajan100% (1)

- Jsa Functional Testing of Fire DetectorDocument4 pagesJsa Functional Testing of Fire DetectorASLAM MULANINo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- Fire Risk Assessment For Site Office and SiteDocument11 pagesFire Risk Assessment For Site Office and SiteSajid Shah100% (1)

- STARRT CardDocument2 pagesSTARRT Cardsanny100% (1)

- Concrete ChippingDocument3 pagesConcrete ChippingAbhijit ParasharNo ratings yet

- TRA CylindersDocument2 pagesTRA Cylindersaparna_losariNo ratings yet

- Activities / Processes: Oh&S Risk & OpportunitiesDocument3 pagesActivities / Processes: Oh&S Risk & OpportunitiesAbdul MueedNo ratings yet

- Pre-Job Safety Meeting Form: Netcore Management SystemDocument10 pagesPre-Job Safety Meeting Form: Netcore Management SystemAniekan AkpaidiokNo ratings yet

- Work at Height Ref. No.: Confined Space Ref No.: Excavation Ref NoDocument2 pagesWork at Height Ref. No.: Confined Space Ref No.: Excavation Ref NoAshish JainNo ratings yet

- Ra - Floor Box Ins - QCSD - Rev 0Document7 pagesRa - Floor Box Ins - QCSD - Rev 0irfan vpNo ratings yet

- JSA HEMP Well Services Pg25-30Document5 pagesJSA HEMP Well Services Pg25-30Ashok SureshNo ratings yet

- Run Diesel Driven Fishing Unit Risk AssesmentDocument2 pagesRun Diesel Driven Fishing Unit Risk Assesmentmikewebster76No ratings yet

- Risk Assesment @ro, WTP & STP PremDocument6 pagesRisk Assesment @ro, WTP & STP PremvarunthalariNo ratings yet

- 16 Risk Assessment ManagementDocument5 pages16 Risk Assessment ManagementBasit HaswareNo ratings yet

- World Teachers Day I Consuelo PavillionDocument12 pagesWorld Teachers Day I Consuelo PavillionAlexis AlbosNo ratings yet

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 pagesJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNo ratings yet

- Ben Rinnes Activity Risk Assessment Worksheet: Activity ARA 224 Date: 22/12/07 Assessment Team: S Patterson, J MunizDocument2 pagesBen Rinnes Activity Risk Assessment Worksheet: Activity ARA 224 Date: 22/12/07 Assessment Team: S Patterson, J MunizAvinash MathewNo ratings yet

- STA ElectricalDocument3 pagesSTA ElectricalimranNo ratings yet

- JSA ELETRICAL MaintenanceDocument17 pagesJSA ELETRICAL MaintenanceWeru MorrisNo ratings yet

- Task Risk Assessment (TRA) : Project Name: Area On Site: Task Description: BTD InstallationDocument6 pagesTask Risk Assessment (TRA) : Project Name: Area On Site: Task Description: BTD InstallationADEEL SHAHZADNo ratings yet

- Cable Dray ATRDocument3 pagesCable Dray ATRferielvpkNo ratings yet

- Assessment Task: AWE: WHSSIM - Individual Risk AnalysisDocument4 pagesAssessment Task: AWE: WHSSIM - Individual Risk AnalysisSuraj NeupaneNo ratings yet

- Job Hazard Analysis: How To Use This FormDocument4 pagesJob Hazard Analysis: How To Use This FormZul Atfi100% (1)

- CUTTING Wood PROJECT AREA RAFIKDocument2 pagesCUTTING Wood PROJECT AREA RAFIKferielvpkNo ratings yet

- (BONDING CABLE-CONFINED SPACE ACTIVITYDocument4 pages(BONDING CABLE-CONFINED SPACE ACTIVITYborneocemerlangservicesNo ratings yet

- 2 RA - Storm Water Drainage Works (Revised)Document19 pages2 RA - Storm Water Drainage Works (Revised)Muhammad Shahid Iqbal100% (3)

- Risk Assessement For AAES ProductsDocument4 pagesRisk Assessement For AAES ProductsAzhar Shaikh100% (1)

- Job Safety Analysis: Arc WeldingDocument50 pagesJob Safety Analysis: Arc Weldingmurasolimaran100% (1)

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- JSA Trunks InstallationDocument9 pagesJSA Trunks InstallationWeru MorrisNo ratings yet

- ABRA For E-HouseDocument10 pagesABRA For E-HouseSatish SharmaNo ratings yet

- Transportation of Hazardous ChemicalsDocument2 pagesTransportation of Hazardous ChemicalsShannon MooreNo ratings yet

- JSA For RCC, Foundation & Generator Installation (R-00)Document14 pagesJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- SMO Blank ChecklistDocument2 pagesSMO Blank ChecklistPaeto KsdNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- Condenser Hotwell Conductivity HIRACDocument1 pageCondenser Hotwell Conductivity HIRACKent Martin D. CartagenaNo ratings yet

- Reinforcement Work: Project: Amar Pristine It Patk, Wagholi, PuneDocument9 pagesReinforcement Work: Project: Amar Pristine It Patk, Wagholi, Punesandip patilNo ratings yet

- Risk Assessment For Shifting of Truss by Double HydraDocument1 pageRisk Assessment For Shifting of Truss by Double HydraDanang Santoso100% (2)

- JSA For Station PipingDocument4 pagesJSA For Station PipingR Sahadeo ReddyNo ratings yet

- Final Job Safety Analysis Pre Assembly 1Document1 pageFinal Job Safety Analysis Pre Assembly 1Md Danish RazaNo ratings yet

- Risk Assessment RevisionDocument6 pagesRisk Assessment RevisionAneesh100% (1)

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro Campomar100% (1)

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document3 pagesRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- Crane JHA OKDocument4 pagesCrane JHA OKSyed Ali HassanNo ratings yet

- RG04-KPC1901-JHA-DOC-004-16 - Epoxy Mixing - Chemical HandlingDocument8 pagesRG04-KPC1901-JHA-DOC-004-16 - Epoxy Mixing - Chemical Handlingsaravana prabuNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- RA-Cleanig and Painting, Cladding1Document6 pagesRA-Cleanig and Painting, Cladding1usman khalidNo ratings yet

- Field Service Jsa: Prepare Yes / No / NADocument2 pagesField Service Jsa: Prepare Yes / No / NADeba RinaNo ratings yet

- JRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampDocument4 pagesJRA No 10-109 Replacement of Warning Lights For Guyed Tower at DEL CampAijaz AhmedNo ratings yet

- RA-05-Office SafetyDocument5 pagesRA-05-Office Safetyamritha n krishnaNo ratings yet

- SPC-PTSI-HSE-001-E-R02 HSE Requirements For Vendor or Subcontractor Working at Karimun YardDocument11 pagesSPC-PTSI-HSE-001-E-R02 HSE Requirements For Vendor or Subcontractor Working at Karimun YardTuahNo ratings yet

- RR Icon DP2 User ManDocument226 pagesRR Icon DP2 User ManCindyNo ratings yet

- Vasanth ResumeDocument6 pagesVasanth ResumeVasanth PrabhuNo ratings yet

- Werner Ladder Safety ManualDocument32 pagesWerner Ladder Safety ManualMohd Shareen Ezzry Mohd SomNo ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- GN - HSE.0 1 AADC System Safety RulesDocument53 pagesGN - HSE.0 1 AADC System Safety RuleskhalidNo ratings yet

- Job Safety Analysis: Burning UnderwaterDocument2 pagesJob Safety Analysis: Burning UnderwaterEarl alboNo ratings yet

- Mining Science and Technology (China) : Wu Lirong, Jiang Zhongan, Cheng Weimin, Zuo Xiuwei, LV Dawei, Yao YujingDocument7 pagesMining Science and Technology (China) : Wu Lirong, Jiang Zhongan, Cheng Weimin, Zuo Xiuwei, LV Dawei, Yao YujingAnand sharmaNo ratings yet

- Practice Occupational Safety and Health ProceduresDocument33 pagesPractice Occupational Safety and Health ProceduresGeraldineNo ratings yet

- MSC 1-Circ 1447-GuidelinesForTheDevelopmentOfPlansAndProceduresForRecoveryOfPersonsFromTheWater (Secretariat) PDFDocument4 pagesMSC 1-Circ 1447-GuidelinesForTheDevelopmentOfPlansAndProceduresForRecoveryOfPersonsFromTheWater (Secretariat) PDFFaris HarunNo ratings yet

- IOG1 Element 2Document12 pagesIOG1 Element 2kaveh100% (2)

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Sieps80000066e 4 0 PDFDocument318 pagesSieps80000066e 4 0 PDFnew587No ratings yet

- Development of Basis of Design For Projects in Fertilizer Industry Document GuidanceDocument9 pagesDevelopment of Basis of Design For Projects in Fertilizer Industry Document GuidanceJak AshishNo ratings yet

- New Risk Assessment MatrixDocument1 pageNew Risk Assessment MatrixRiyadh SalehNo ratings yet

- Msds Diaseton AlkoholDocument5 pagesMsds Diaseton AlkoholtakenoveraccountNo ratings yet

- CBV 100Document4 pagesCBV 100Chemtech-tupt EF ClassNo ratings yet

- Recommended Reading ListDocument12 pagesRecommended Reading ListHITESH50% (2)

- 06 She Sop Consultation and Participation of WorkersDocument7 pages06 She Sop Consultation and Participation of WorkersHADWAN YUSOFNo ratings yet

- HS 065 Objectives and ProgrammesDocument14 pagesHS 065 Objectives and ProgrammesgrantNo ratings yet

- Contractor Project SHE Specifications - Cover LetterDocument1 pageContractor Project SHE Specifications - Cover LetterrendaninNo ratings yet

- Enoc Strata Marine Hydraulic Hvi 46Document7 pagesEnoc Strata Marine Hydraulic Hvi 46Jonathan HansenNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationVishal GoswamiNo ratings yet

- 566 AaDocument56 pages566 AatorbenchrNo ratings yet

- Assa Abloy RP300 Machine Protection Door - enDocument10 pagesAssa Abloy RP300 Machine Protection Door - enjonathansierraeNo ratings yet

- BP Unit 3Document19 pagesBP Unit 3Rakhi NainNo ratings yet

- (SOP09) LUS-HSE-SP2-442-001.02 - HSE Training ProcedureDocument8 pages(SOP09) LUS-HSE-SP2-442-001.02 - HSE Training ProceduregiovadiNo ratings yet