Professional Documents

Culture Documents

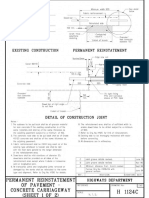

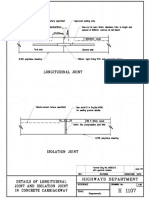

Det Ails of Expansion Joint in Concrete Carriagewa Y: Highways Department

Det Ails of Expansion Joint in Concrete Carriagewa Y: Highways Department

Uploaded by

cho673524Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Det Ails of Expansion Joint in Concrete Carriagewa Y: Highways Department

Det Ails of Expansion Joint in Concrete Carriagewa Y: Highways Department

Uploaded by

cho673524Copyright:

Available Formats

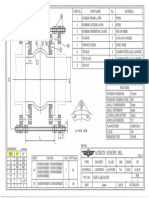

Holes <tilled in Ihe liler Seaing groove and

to give a dowel bar sleeve approved joint sedant

a "push fit" (see deloil C in Drg No.

~eilforcement

\

(where specified) \ r l d steel dowel bars sow cut at

both ends, at mid-depth and at

q; H'109)

1

300mm centres

~j-------~

300 :!: 50mm - 60 :!: IOmm cover

Wire ties~. .\'} :--I

~---'-------

1 .20

.". ~ ~ 1\ "

I

I 1\ I

J>O CompressiJle filer .". '-7

~6mm •

~

" ~

Cradle bent

6mm dio. 01

300rrm centres

~

Ilia.

tie bars

fI

Preformed PVC light

fillilg dowel sleeve

bed/ ~o.'25mm

I

liar tar Compressible joilt filer

t1 pert cement (2Onm Thick) polythene sheeting

to J parts sand)

over f"lwidlh

DIIENSIONS OF MlD STEEL DOWEL BARS

Slob Itickness Dowel bars Sleeve

(mm) Dio.tmm) Length(mm) Lenglh(mm)

• 150 ond over 25 650 400

Former Drg. No. H,003/3

• Dowel ben en not recommended for June 94

with general revision

slobs thinner thon 150mm

REF. REVISION SIGNATIJlE DATE

HIGHWAYS DEPARTMENT

DET AILS OF EXPANSION JOINT REFERENCE DRAWING No.

lE£.

IN CONCRETE CARRIAGEWA Y SCALE H 1105

Dia!rommotic

w:\stddrgs\h1105.dgn May. 04, 2000 15:00:1

You might also like

- Blue Boat ScoreDocument4 pagesBlue Boat ScorePhillip Morgan100% (2)

- Watch Me Soar Scott Alan PDFDocument10 pagesWatch Me Soar Scott Alan PDFBethany OverbaughNo ratings yet

- Canción MixtecaDocument3 pagesCanción MixtecaScher Holopainen100% (1)

- Manual Instructions For Sap Note 3167391 Edocument Mexico - Annex 20 V4.0: Full SolutionDocument4 pagesManual Instructions For Sap Note 3167391 Edocument Mexico - Annex 20 V4.0: Full SolutionDarioNo ratings yet

- N R 'B '" '" R : E::/ ,, ( - : ,,"'0"' 199","os"e, ,,,,, ,,,, ","00''''0' 'M," E, "0,,, """""Document2 pagesN R 'B '" '" R : E::/ ,, ( - : ,,"'0"' 199","os"e, ,,,,, ,,,, ","00''''0' 'M," E, "0,,, """""Véronique RacicotNo ratings yet

- Welding Procedure Specifica Tion (WPS) : I I I IDocument5 pagesWelding Procedure Specifica Tion (WPS) : I I I ITrinh DungNo ratings yet

- Watch Me SoarDocument10 pagesWatch Me SoarSevina T100% (2)

- Materi PPT Packaging and Material HandlingDocument54 pagesMateri PPT Packaging and Material HandlingAhmad Amirul Iman Haqh100% (2)

- LL Proved: Permanent Reinstatement of Pavement Concrete Carriageway (Sheet OFDocument1 pageLL Proved: Permanent Reinstatement of Pavement Concrete Carriageway (Sheet OFahtin618No ratings yet

- Utility Duct Drawings From BCL Joydebpur-Mymensing 4 Lane Project - OptDocument1 pageUtility Duct Drawings From BCL Joydebpur-Mymensing 4 Lane Project - OptParvez Syed RafiNo ratings yet

- IMG - 0165 PSME Code 2008 157Document1 pageIMG - 0165 PSME Code 2008 157bnqr584bNo ratings yet

- Fu L - Q0 .... : Upper TubeDocument2 pagesFu L - Q0 .... : Upper TubeolsiNo ratings yet

- House DesignDocument12 pagesHouse DesignMadusha TisseraNo ratings yet

- Single Open-End Spanner Open Combination SpannerDocument8 pagesSingle Open-End Spanner Open Combination SpannerNicholas KumarNo ratings yet

- Strand Century Lighting 4273 18-Inch Scoop Floodlight Spec Sheet 6-77Document2 pagesStrand Century Lighting 4273 18-Inch Scoop Floodlight Spec Sheet 6-77Alan MastersNo ratings yet

- Sheelng : SheelingDocument1 pageSheelng : Sheelingcho673524No ratings yet

- 3.1 Sample General NotesDocument6 pages3.1 Sample General NotesMaMoh MohNo ratings yet

- New Equipment & Systems Approval - Strail Rubber Level CrossingDocument4 pagesNew Equipment & Systems Approval - Strail Rubber Level CrossingLulu IluNo ratings yet

- STEP Product OverviewDocument7 pagesSTEP Product OverviewTran Nguyen BaNo ratings yet

- Rigid To Flexible Pavement JointDocument1 pageRigid To Flexible Pavement JointFrederick TanNo ratings yet

- H3107ADocument1 pageH3107AExile PeachNo ratings yet

- WORK-Workshop Practice Series 23 - Workshop ConstructionDocument72 pagesWORK-Workshop Practice Series 23 - Workshop ConstructionpeterNo ratings yet

- Guard Rail CP-BP Tebal 4,5 MM (Tipe B)Document1 pageGuard Rail CP-BP Tebal 4,5 MM (Tipe B)rani wulansariNo ratings yet

- Plastering AccessoriesDocument45 pagesPlastering AccessoriesisrarNo ratings yet

- 20db0064 New Plan Part 3Document4 pages20db0064 New Plan Part 3geraldiglesia121No ratings yet

- Mir Ou: Phenol' With R Fly Proof Ventilat Top Dome 125mm ThickDocument1 pageMir Ou: Phenol' With R Fly Proof Ventilat Top Dome 125mm ThickanilNo ratings yet

- Highway Structure Drawings 3Document1 pageHighway Structure Drawings 3Martin ScottNo ratings yet

- Tieng Anh Chuyen Nganh MayDocument7 pagesTieng Anh Chuyen Nganh Maykieunguyen70No ratings yet

- Rubber Expansion JointsDocument1 pageRubber Expansion JointsBaqar RazaNo ratings yet

- LandisDocument23 pagesLandisGustavo Brea MalavéNo ratings yet

- TO Metal Transmission LinesDocument6 pagesTO Metal Transmission Linesluis albertoNo ratings yet

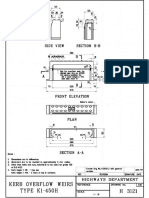

- Lif-I.1: Kerb Overflow Weirs Type K1-450H H 3121Document1 pageLif-I.1: Kerb Overflow Weirs Type K1-450H H 3121Ahmed ProlicNo ratings yet

- Slewing Crane Schematic Diagram PDFDocument3 pagesSlewing Crane Schematic Diagram PDFachmadihinNo ratings yet

- HeatExc PDFDocument1 pageHeatExc PDFraja raniNo ratings yet

- Heat Exchanger TYPESDocument1 pageHeat Exchanger TYPESSiva baalanNo ratings yet

- ED ED: Ed For ONS RUDocument2 pagesED ED: Ed For ONS RUQazi NoorNo ratings yet

- R:::RRR B Rti!Itri : I I I I I "'Document1 pageR:::RRR B Rti!Itri : I I I I I "'Prashant MaliNo ratings yet

- Adobe Scan 09 Jun 2021Document3 pagesAdobe Scan 09 Jun 2021digiprepareNo ratings yet

- Math PDFDocument66 pagesMath PDFBenjamin Benicarlo Juanillo IIINo ratings yet

- 4" G.I Pipe: TB G 620 V16KDocument1 page4" G.I Pipe: TB G 620 V16KAdnan Rahman SouravNo ratings yet

- Ito 1996Document16 pagesIto 1996Bridge&StructureNo ratings yet

- Accu LocationDocument1 pageAccu LocationEdsel SiababaNo ratings yet

- CH 8Document4 pagesCH 8Anish ChakrabortiNo ratings yet

- CL of Girder: Top of Bridge Deck SlabDocument1 pageCL of Girder: Top of Bridge Deck SlabBenjamin Benicarlo Juanillo IIINo ratings yet

- SN SeriesDocument49 pagesSN SeriesSam WangNo ratings yet

- Indoor Termination Kit Tent Able 1 X 240 MM KV (Three 40 SMOE 60641Document2 pagesIndoor Termination Kit Tent Able 1 X 240 MM KV (Three 40 SMOE 60641manafNo ratings yet

- PT Manual CalculationDocument4 pagesPT Manual CalculationrishiNo ratings yet

- Adobe Scan 12 Jan 2024Document6 pagesAdobe Scan 12 Jan 2024rstgycsn4mNo ratings yet

- Part 4 Tubing Sizing and Well Performance New PDFDocument93 pagesPart 4 Tubing Sizing and Well Performance New PDFRanim HishamNo ratings yet

- Kelmo Electric Actuator Driven Compact Ball Valves: MAS Sakti EmailDocument2 pagesKelmo Electric Actuator Driven Compact Ball Valves: MAS Sakti EmailJohnIbanesNo ratings yet

- KSH International Paper Insulated Copper Rectangular BrochureDocument2 pagesKSH International Paper Insulated Copper Rectangular BrochurekshintlNo ratings yet

- Transmit Measured Data XXX Receive Measured Data Receive No. IDocument3 pagesTransmit Measured Data XXX Receive Measured Data Receive No. ISuneelkrishna RallabhandiNo ratings yet

- CODEG-16 - 0-: JGC Arabia L TDDocument19 pagesCODEG-16 - 0-: JGC Arabia L TDElezer BatchoNo ratings yet

- Fig 9.7 of Irc 84Document1 pageFig 9.7 of Irc 84Aalap DarjiNo ratings yet

- Nortronics Magnetic Tape Heads SpecificationsDocument6 pagesNortronics Magnetic Tape Heads SpecificationspsychpostersNo ratings yet

- 05-23 WBI WBD Series Thrust RestraintsDocument2 pages05-23 WBI WBD Series Thrust Restraintsjonathan watsonNo ratings yet

- Wire Line ch-2Document35 pagesWire Line ch-2Ammar HrzNo ratings yet

- Sheetr.g : Longitudinal JointDocument1 pageSheetr.g : Longitudinal JointpeakNo ratings yet

- Wi 701 Stddwgs 021920finalDocument32 pagesWi 701 Stddwgs 021920finalRafael SalazarNo ratings yet

- OF OF: Reinst Atement of Expansion JointDocument1 pageOF OF: Reinst Atement of Expansion JointMartin ScottNo ratings yet

- Raag Notes ChayanatDocument1 pageRaag Notes ChayanatPratham DesaiNo ratings yet

- Growing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyFrom EverandGrowing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyNo ratings yet

- Absolute Deed of Sale - Mini VanDocument2 pagesAbsolute Deed of Sale - Mini VanAlly ClenistaNo ratings yet

- Knott V Cottee (1852) 51 ER 705Document3 pagesKnott V Cottee (1852) 51 ER 705schoolemailsdumpNo ratings yet

- Test Bank For Introduction To Management Accounting 16th Edition Charles T HorngrenDocument24 pagesTest Bank For Introduction To Management Accounting 16th Edition Charles T HorngrenRebeccaMillerbtmq100% (47)

- Vinra Group PortfolioDocument40 pagesVinra Group PortfolioDerlyn RichardNo ratings yet

- Ijcs 2016 0303013 PDFDocument4 pagesIjcs 2016 0303013 PDFeditorinchiefijcsNo ratings yet

- Prova de Inglês Terceiro Ano Interpretação INFLUENCERS VERSÃO 3Document3 pagesProva de Inglês Terceiro Ano Interpretação INFLUENCERS VERSÃO 3jane.aparecida.andradeNo ratings yet

- Glass Lined PipingDocument6 pagesGlass Lined PipingPawel MielnikNo ratings yet

- Semence Bonane Resume 2Document5 pagesSemence Bonane Resume 2api-240351783No ratings yet

- Complete Tablet Protection 2yr-10-1500.0Document18 pagesComplete Tablet Protection 2yr-10-1500.0dibakarthakur2023No ratings yet

- Mimf MDG ClaimDocument2 pagesMimf MDG ClaimDeanna HazierraNo ratings yet

- ARDIENTE-Research QuestionnaireDocument6 pagesARDIENTE-Research QuestionnaireHennessy Shania Gallera ArdienteNo ratings yet

- Mobilink ProjectDocument46 pagesMobilink ProjectAnamMushtaqNo ratings yet

- Blue Dart Annual Report 2008Document112 pagesBlue Dart Annual Report 2008Jr. ScientistNo ratings yet

- EQT AB Year-End Report 2023Document33 pagesEQT AB Year-End Report 2023Ftu NGUYỄN THỊ NGỌC MINHNo ratings yet

- ASTM D97 and 2500 SolutionDocument10 pagesASTM D97 and 2500 SolutionKamruzaman MiahNo ratings yet

- Network Marketing Business Techniques 1Document7 pagesNetwork Marketing Business Techniques 1usman saleemNo ratings yet

- Garnier - Sustainability Progress Report - 2020 Final LDDocument29 pagesGarnier - Sustainability Progress Report - 2020 Final LDSimaSenNo ratings yet

- End Term - Corporate FinanceDocument3 pagesEnd Term - Corporate FinanceDEBAPRIYA SARKARNo ratings yet

- Introductory Microeconomics Class 11 NCERTDocument8 pagesIntroductory Microeconomics Class 11 NCERTVansh AgrwalNo ratings yet

- EI 1550 Handbook On Equipment Used For The Maintenance and Delivery of Clean Aviation FuelDocument125 pagesEI 1550 Handbook On Equipment Used For The Maintenance and Delivery of Clean Aviation FuelAbdullah AnarNo ratings yet

- Chapter 1 - Marketing - Creating Customer Value and Engagement PDFDocument25 pagesChapter 1 - Marketing - Creating Customer Value and Engagement PDFmaalouf nicolasNo ratings yet

- Strategy, Value Innovation, Knowledge Economy ReviewDocument3 pagesStrategy, Value Innovation, Knowledge Economy ReviewDiana Leonita FajriNo ratings yet

- Kuala Lumpur: Answer Sheets: GBHDHFH: 23525: ABMC2054 Cost & Management Accounting IDocument30 pagesKuala Lumpur: Answer Sheets: GBHDHFH: 23525: ABMC2054 Cost & Management Accounting IJUN XIANG NGNo ratings yet

- Dela Cruz, Jumar James BDocument2 pagesDela Cruz, Jumar James BSantiago Buladaco100% (1)

- Papers by C K PrahladDocument2 pagesPapers by C K PrahladSabyasachi SinhaNo ratings yet

- JayseearrDocument1 pageJayseearrBeantickNo ratings yet

- Buying Behaviour of Consumers of Edible Oil - A Study of Tiruchirappalli CityDocument5 pagesBuying Behaviour of Consumers of Edible Oil - A Study of Tiruchirappalli CityNishma LigalNo ratings yet

- E-Commerce Project (D)Document5 pagesE-Commerce Project (D)TAHER AL-NEMERNo ratings yet