Professional Documents

Culture Documents

Improved Fischer-Tropsch Economics Enabled by Microchannel Technology

Improved Fischer-Tropsch Economics Enabled by Microchannel Technology

Uploaded by

PAULINA CASTRUITA GARCIACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Improved Fischer-Tropsch Economics Enabled by Microchannel Technology

Improved Fischer-Tropsch Economics Enabled by Microchannel Technology

Uploaded by

PAULINA CASTRUITA GARCIACopyright:

Available Formats

Improved Fischer-Tropsch Economics Enabled

by Microchannel Technology

A.L. Tonkovich1, Terry Mazanec1, Kai Jarosch1, Sean Fitzgerald1, Bin Yang1, Rachid Taha1,

David Kilanowski1, Jan Lerou1, Jeff McDaniel1, Tad Dritz2

1. Velocys, Inc., 7950 Corporate Blvd., Plain City, Ohio 43064, USA

2. Shepherd Advisors, 58 E. South St., Worthington, Ohio 43085, USA

Microchannel process technology offers process intensification, in the form of enhanced heat and mass transfer, to a wide

range of chemical reactions. This paper describes the application of microchannel technology to the exothermic Fischer-Tropsch

(FT) process, which converts synthesis gas into a petroleum replacement – synthetic crude or fuels. Synthesis gas to feed the FT

unit can be derived from a variety of feedstock materials, including natural gas and biomass. By greatly reducing the size and

cost of chemical processing hardware, microchannel process technology enables cost effective production of synthetic fuels from

smaller scale facilities, appropriate for biomass and offshore natural gas resources.

Introduction hydrocarbons can be hydrocracked to produce distillate

Sustained high oil prices, concern about global products, notably diesel and jet fuels.[1]

climate change, and the drive for energy security have FT derived transportation fuels are typically

intensified attention on alternative fuels, including referred to as synthetic fuels. During the 20th century,

those produced from Fischer-Tropsch (FT) based these fuels were derived from coal in situations where

processes. Although some very large stranded natural petroleum was not readily available, such as Germany

gas and coal resources warrant the construction of in WWII and South Africa during Apartheid. However,

world-scale FT synthetic fuels facilities, many since the beginning of this decade, there has been a

applications call for smaller-scale plants, including renewed interest in synthetic fuels for four reasons.

offshore gas-to-liquids (GTL), biomass-to-liquids 1. World demand for petroleum is continually

(BTL) and waste-to-liquids opportunities. The concept increasing while the world oil production has

of producing synthetic fuels in compact units hinges on plateaued. Thus, there is a tremendous interest in

the ability to economically scale-down reaction alternative methods of liquid fuels production.

hardware while maintaining sufficient capacity. By 2. Synthetic fuels burn cleaner than petroleum-based

greatly reducing the size and cost of chemical diesel and jet fuels, because synthetics do not have

processing hardware, microchannel process technology soot-forming aromatics and other non-hydrocarbon

holds the potential to enable cost effective production contaminants.

of synthetic fuels in smaller scale facilities. 3. There are vast natural gas reserves considered

“stranded,” with no viable local uses or

Fischer-Tropsch Process and Products transportation means; these resources can be used

The FT process was first developed by Franz to produce liquid fuels in an FT process.

Fischer and Hanz Tropsch in Germany in the 1920s and 4. Concerns about greenhouse gas emissions have

1930s. The chemistry is based on making longer chain increased interest in fuels derived from renewable,

hydrocarbons from a mixture of carbon monoxide (CO) non-food biomass feedstocks.

and hydrogen (H2), referred to as “synthesis gas”, at an

elevated pressure and temperature and in the presence Microchannel Process Technology

of a catalyst. The excess heat generated from the Systems based on microchannel process

reaction has typically been removed by inserting boiler technology have the potential to transform the energy

tubes that carry water. In theory, any source of carbon and chemical processing industries by greatly reducing

can be used to generate the synthesis gas. the size of chemical reactor hardware. This technology

The majority of the products from FT synthesis are has many parallels with the microelectronics that

paraffinic waxes based on the following chemical revolutionized the computer industry because it can

equation. shrink processing hardware while improving

performance. Devices using microchannel technology

nCO + (2n+1)H2 → CnH2n+2 + H2O (1) are characterized by parallel arrays of microchannels,

with typical dimensions in the 0.1 to 5.0 mm range.

Typical byproducts are liquefied petroleum gas Processes are accelerated 10 to 1,000 fold by reducing

(LPG) and naphtha. After the FT process, heavier heat and mass transfer distances, thus decreasing

Velocys © 2008 Page 1 of 7

transfer resistance between process fluids and channel microchannel reactors which commonly accommodate

walls as shown in Table 1. System volumes can be a complex suite of chemical unit operations in a single

reduced 10-fold or more compared with conventional device. Laminate construction involves forming many

hardware.[2] parallel microchannels by interleaving (stacking) thin

sheets of formed material (shims) with solid sheets

Table 1. Microchannel technology offers enhanced heat and (walls). This process is shown in Figure 1.

mass transfer

units Microchannel Conventional Feature

Heat Transfer Shim Creation Stacking

Convective W/cm2 1-20 <1

Boiling W/cm2 1-20 <1

Mass Transfer (contact time)

Gas Phase Sec 0.001-0.3 1-10

Microchannel technology is ideally suited for Bonding Machining

carrying out catalytic reactions that are either highly

exothermic, such as FT synthesis, or highly

endothermic, such as methane reforming. The heat

generated in exothermic reactions or required for

endothermic reactions must be efficiently transferred Figure 1. Laminate microchannel fabrication process

across reactor walls to maintain an optimal and uniform

temperature so as to achieve the highest catalytic Microchannel FT Reactor Technology

activity and the longest catalyst life. Conventional The microchannel FT reactor system is an example

reactor systems use massive hardware to manage the of “process intensification”, whereby the reactor

heat in such reactions. volume to produce a given amount of product is

reduced by an order of magnitude or more, by utilizing

Microchannel Fouling. Claims by microchannel enhanced heat and mass transfer capabilities of

practitioners are often met with skepticism from microchannel architecture. This increased productivity

industry. A common concern is the plugging or fouling is made possible with highly active cobalt-based

of the thousands of small channels inside each catalysts.[4,5] As shown in Figure 2, each reactor

microchannel devices. While this is an understandable block has thousands of process channels filled with FT

concern, experiments show that two interrelated catalyst interleaved with water filled coolant channels.

strategies mitigate the risk of microchannel plugging:

1) high wall shear, and 2) good flow distribution.

Long duration microchannel vaporizer experiments

were run with and without good flow distribution. For

the devices with good flow distribution, no pressure

drop increases were observed in runs ranging from

1,000 to 9,000 hours at both ambient and high pressure

(20.3 bar) conditions. The lack of pressure drop Water/Steam

increases held true even when the feed water was Water 0.2 – 5.0 mm

intentionally doped with high levels of dissolved solids.

This absence of fouling within individual CO + 2H2 0.2 – 5.0 mm

microchannels was verified by post operational -(CH2)n- + H2O

autopsies and attributed to high wall shear. Some

fouling was noted in the headers and footers, but they

were sufficiently large as not to affect pressure drop or

heat transfer performance.[3] Figure 2. Microchannel FT reactor schematic

Manufacturing Techniques. Microchannel Multiple microreactors are manifolded in parallel

development efforts have gone beyond the process to achieve commercially significant production

design methodology to include the manufacturing volumes. Figure 3 compares a 10 reactor assembly

techniques for devices that commonly operate at with a conventional technology reactor. From the

elevated temperatures and pressures. The selected outside, microchannel assemblies have a low profile,

process, known as laminate fabrication, provides cost with external dimensions of 1.5m diameter by 8m long.

effectiveness, tight tolerances and design flexibility for On the other hand, conventional FT reactors have a

diameter of 9m or more and are over 60m tall.

Velocys © 2008 Page 2 of 7

One of Sasol’s FT Reactors that was installed in Qatar Coolant Out - Vapor

Specifications

• Shell Diameter = 1.5m

61m

200 ft. • Shell Length = 7.6m

• Coolant flow length = 0.6m

Repeating

Units • Process flow length = 0.6m

• 360 bbl/day capacity

Process In

Coolant In

Coolant Out - Liquid

Process Out

(under shell - not shown)

Steam trace

Figure 3. Microchannel FT reactor assemblies are far smaller than conventional technology FT reactors

Experimental Results. The testing of an integrated that correlated to a single commercial scale reactor

microchannel FT pilot reactor, shown in Figure 4, capacity of 28 - 44 bpd. Multiple commercial

was first completed in January of 2007. This reactor reactors can operate in parallel to meet plant capacity

had 40 process and 425 coolant microchannels. requirements.

Process In Process Scale-up. While several R&D groups

Coolant In around the world have shown the potential of

Cross Flow Design microchannel reactors for process intensification,

Partial Boiling Water Coolant only Velocys has been successful in developing the

Process length ~ 0.6 m technology for industrial scale applications. This

Process microchannels = 40 effort, begun in 1998, spanned several key scale-up

Coolant Length ~ 0.3 m steps, and recently culminated in fabricating the

Coolant microchannels = 425

manufacturing test device shown in Figure 6. If

Nominal Capacity = ~ 7 lit/day

operated, this reactor would have a nominal capacity

Coolant Out

Process Out of 1,000 liters/day or 6 barrels/day (bpd). The key

scale-up steps are summarized in Table 2.

Figure 4. Pilot-scale microchannel FT reactor

Table 2. Microchannel FT process scale-up

The performance of a second pilot reactor is Type Units Size Year Hours

shown in Figure 5. The two key numbers are the Catalyst Catalyst N/A 1998- 1,200

conversion of CO, and selectivity to methane. The Development only 2003

steady state CO conversion was over 70%. The Commercial Reaction 24” 2003 600

reactor operated steadily and had minimal change in Length and oil long

conversion level during the 1,100 hour run. Reactor cooling

Integrated With partial 12”x 2006 1,200

100% 370

Pilot #1 boiling for 24”x

90% 350

cooling 0.5”

80% 330

Integrated With partial 6”x 2008 3,000

70% 310

Pilot #2 boiling 6”x

Conversion, Selectivity (%)

Temperature (°C)

60% 290

CO Conversion

2”

Commercial FT with 10”x 2007 mfg.

50% CH4 Selectivity 270

Temperature

40% 250

Fabrication boiler 7.5” test

30% 230

7.5”

20% 210

Full-scale FT with 24”x 2008 mfg.

10% 190 Fabrication boiler 24”x6” test

0% 170

0 200 400 600 800 1000

Time on stream (hr)

Limited manufacturing scale-up is required

Figure 5. Microchannel FT reactor demonstrated beyond this stage, as the commercial scale reactor,

equivalent of 28 - 44 bpd for a full-scale reactor with a capacity to produce 36 bpd of FT products will

have microchannel shims that are the same size

Selectivity to methane, also known as methane (24”x24”, 0.61x0.61m) as the device shown in Figure

make, was approximately 9%. Methane production is 6, but a stack height of 24” (0.61m).

counterproductive and should be minimized. The 9%

methane is on par with competing fixed bed FT

technologies. The reactor was operated at conditions

Velocys © 2008 Page 3 of 7

100% 370

CO Conversion

90% CH4 Selectivity 350

Temperature

80% 330

70% 310

Conversion, Selectivity (%)

Regeneration

Temperature (°C)

60% 290

50% 270

40% 250

30% 230

20% 210

10% 190

0% 170

0 500 1000 2000 2500

Time on Stream (hr)

Figure 6. Commercial microchannel manufacturing

Figure 7. Microchannel FT in-situ regeneration shown

techniques validated

effective at recovering performance

Catalyst Integration. Placing catalyst in packed bed

reactors can be a challenge for any technology. As noted above, in the tubular fixed bed reactor,

Conventional FT reactors have as many as 29,000 the catalyst is packed in a large number of small

small (1”) diameter tubes 12m in length, which must diameter tubes with means to remove heat by boiling

be equally loaded and then unloaded after 2 to 5 years water outside the tubes. Like the microchannel FT,

of operation.[6] These high aspect ratio (over 500:1 all reaction products (light hydrocarbon gases,

length to diameter) tubes are hung in very large, naphtha, distillate, and wax) exit the reactor through

immobile reactors, but commercial integration one outlet, leaving the catalyst behind in the reactor.

techniques have been shown effective. Because The resulting products are segregated by sequential

microchannel technology has extremely small cooling.[7]

passages, many expect loading and unloading catalyst In the slurry-bubble reactors, a heavy

to be especially challenging, but this was found not to hydrocarbon liquid is used to suspend the catalyst and

be the case. the heavier products remain in the reactor while the

Catalyst loading, regeneration and unloading for light ones are removed from the top. A portion of the

microchannel FT reactors have been successfully liquid mixture is continuously removed to recover the

demonstrated. Multiple operating and non-operating heavy hydrocarbon products, while the carrier liquid

reactors with commercial length microchannels and majority of the catalyst are recycled to the

(aspect ratio 385:1 length to hydraulic diameter) have reactor.[8]

been repeatedly loaded and unloaded. A mechanical Microchannel FT reactor technology has

loading method is employed using commercially characteristics that provide substantial techno-

available material handling techniques and economic benefits over conventional FT technology.

equipment. The key benefits are as follows:

There are two types of catalyst deactivation in 1. Microchannel FT has thin (1-2 orders of

FT synthesis: 1) short-term deactivation caused by magnitude smaller characteristic dimension) reaction

wax build-up and/or partial oxidation of the cobalt channels which greatly improves heat and mass

catalyst particles, and 2) longer term deactivation, transfer. This allows optimal temperature control

which involves sintering, loss of pore structure and/or across the catalyst bed, which maximizes catalyst

poisoning. The first is reversible; the second requires activity and life. This leads to far higher reactor

replacing the catalyst. For short-term deactivation, in productivity, defined as barrels/day of FT product per

situ hydrotreating was shown to be effective at ton of reactor mass (Figure 8). It also leads to 10

restoring catalyst activity. Figure 7 displays reactor times higher catalyst productivity, defined as kg/hr of

performance data at the same condition before and synthesis gas processed per cubic meter of catalyst

after regeneration. volume. Both capital and operating costs are thus

reduced.

Comparison with Competing FT Technologies

Due to improved volumetric and catalytic

productivity, microchannel FT enables lower capital

and operating costs compared to the following classes

of conventional FT reactor systems: 1) tubular, fixed-

bed, with a cobalt catalyst, and 2) slurry-bubble with

cobalt or iron catalyst.

Velocys © 2008 Page 4 of 7

14

360 bpd Microchannel

Reactor Assembly

12

10

Reactor Productivity (bpd/tonne)

Sasol - Oryx

8

Shell - Pearl

4

Shell - Bintulu FT Reactor

2

0

0 2,000 4,000 6,000 8,000 10,000 12,000

Scale of Single Reactor (bpd) FT Reactor

Figure 8. Microchannel FT improves reactor productivity

and achieves economy of scale at far lower capacity

2. The basic building blocks of the microchannel

FT reactor design are components with parallel

microchannels. These reactor components, which

have fixed production capabilities, can be added or Figure 9. Small size and low profile eases installation and

removed to match throughput requirements. When operation in offshore environments

this modular design approach is combined with

process intensification benefits discussed in item 1

above, two advantages are realized: Coal-to-Liquid Challenges. Several Coal-to-Liquid

a. Microchannel FT realizes economies of scale (CTL) projects are underway in China, but the

at much smaller size (500 bpd) than conventional prospects are different in the U.S. In late 2006 and

technology (10,000 bpd). This advantage allows early 2007, several coal-based fuel facilities were

microchannel FT to be feasible for BTL applications announced, ranging in size from 6,400 to 80,000 bpd,

since it is not practical to transport the required using 4,000 to 50,000 tons per day (tpd) of coal.[9]

biomass feedstock of 10,000 tons/day for a 10,000 However, to date, none of the U.S. facilities have

bpd facility. The smaller economy of scale also entered the construction phase and a number have

permits feasibility for offshore GTL. been cancelled.

b. Since the basic reactor modules are small, There are two primary hurdles for coal-to-liquid

reactor fabrication can take place at indoor shops, (CTL) facilities. First, the life cycle carbon

which speeds field installation. On the other hand, (greenhouse gas) emissions for fuels from a CTL

conventional reactors must be ‘stick built’ and the facility are 30% to 80% higher than petroleum-based

time to field construct these facilities is long. fuels. This carbon footprint is clearly unacceptable to

3. The modular approach of microchannel FT environmental groups and more importantly, key

helps minimize downtime due to individual modules customers. The Energy Independence and Security

needing components or catalysts to be replaced. The Act of 2007 prevents federal agencies, including

conventional systems require the entire system to Department of Defense, from purchasing fuels with

shutdown to make changes or repairs. more greenhouse gas emissions than petroleum-

4. The microchannel FT not only has a smaller derived fuels and thereby will require CTL operators

footprint, it also has a lower profile. Microchannel to sequester the carbon dioxide (CO2) emissions.[10]

reactor assemblies are relatively small at 1.5m in In some cases, operators will be able to capture the

diameter and sit horizontally versus conventional FT CO2 and use that stream for enhanced oil recovery

reactors that are situated vertically and can be more (EOR) projects. This approach is well proven but in

than 60m tall. This is a critical advantage for mobile many cases, EOR is not a viable option due to the

and offshore installations (Figure 9). location and/or size of the CTL project. Therefore,

CTL promoters are evaluating the option of

Commercial Applications sequestering CO2 in deep saline aquifers. While the

Since conventional FT technologies are not Department of Energy (DOE) is funding a number of

economically viable at small scale, below 10,000 bpd, sequestration research and demonstration projects,

the current focus for FT planning and installation this route has not been proven and is expected to be

projects are coal-based facilities, in U.S. and China, costly. In contrast, BTL facilities can reduce

or large land-based natural gas fields, such as those in greenhouse gas (GHG) emissions by up to 90% when

Qatar. compared to petroleum-based fuels. For this reason,

many domestic CTL developers are now planning to

blend biomass to reduce carbon emissions.

Velocys © 2008 Page 5 of 7

Second, the proposed CTL projects have multi- not possible without venting, flaring or reinjection of

billion dollar price tags and are based on processes this gas back into the reservoir. Venting is not

that are not yet commercially proven in the U.S. Due allowed as the global warming potential of methane is

to the size of these investments and the technical risk 21 times that of CO2. Flaring is also effectively

of sequestration, U.S. CTL developers have not been banned in many countries due to GHG emissions and

able to secure financing for their projects. Once the other issues. Finally, reinjection currently cost up to

sequestration, financing and technical questions have $13 per equivalent barrel of petroleum, and these

been resolved, CTL projects will likely begin costs are highest offshore. A better solution is to

occurring at a substantial pace. However, some convert this gas into liquid fuels in a FT process.

industry experts anticipate these questions might not Unfortunately, GTL plants based on

be answered for a decade or more. conventional FT technology require very large

reserves. For example, only about 6% of the world’s

Biomass-to-Liquids. Biomass feedstock materials gas fields are large enough to sustain a 10,000+ bpd

are not easily aggregated and transportation costs to GTL plant. Reducing the production rate to 2,000

large BTL plants are high. Microchannel FT can bpd makes approximately 40% of gas fields viable

overcome these challenges by economically operating sources. Microchannel FT permits economic

small (500-2,000 bpd) plants that require about 500- production at this smaller scale.[14]

2,000 tpd of biomass. These synthesis gas generation Another advantage of microchannel FT

plus FT synthesis facilities can then be located near technology is that it enables facilities to be placed on

low-cost, biomass sources. The heavy hydrocarbon offshore structures. A conceptual sketch of such a

products can then be economically shipped to central plant is shown in Figure 11.

upgrading (refining) facilities since the FT product

density is much higher than that of biomass.

The feedstock choices for FT are non-food

biomass, such as forest residues, agricultural residue,

municipal solid waste (MSW), and construction and

demolition waste (CDW). Based on the DOE

estimates and data on waste sent to landfills, the

biomass supply is large enough to replace more than

half of petroleum-based distillate fuel demand [11] as

shown in Figure 10.

100

Current Demand

90

80

Figure 11. Microchannel FT concept floating production

70 storage and offloading (FPSO)

Billions of Gallons/Year

60

Conclusion

50 Due to a number of factors, including sustained

40

MSW/CDW high oil prices, concern about global climate change,

Forest

and the drive for energy security, alternative fuels are

30 receiving an unprecedented level of attention. These

20

include FT based synthetic fuel processes that can

Agricultural convert a wide variety of feedstock materials, such as

10 coal, natural gas and biomass, into ultra-clean

0

transportation fuels. Of the potential raw materials

used for alternative fuels, biomass and stranded

Figure 10. U.S. demand for distillate fuel versus biomass

available for conversion to FT fuels natural gas are seen as the most attractive due to their

abundance and potential for low life cycle carbon

Offshore Gas to Liquids. Natural gas without emissions. Furthermore, the application of

access to the world market is known as “stranded microchannel technology to FT enables cost effective

gas.” This includes large reserves in remote places production at the smaller-scales appropriate for BTL

and associated gas that is co-produced with oil. The and offshore GTL facilities.

quantity of stranded gas is estimated to be between First generation biofuels, including corn ethanol

900 and 9,000 trillion cubic feet in volume,[12,13] and biodiesel, are prevalent today, but are seen as

which is sufficient to supply current level of U.S. only an interim solution due to their use of food crops

distillate fuels demand for more than 300 years. for raw material. Next generation biofuels, ones that

As noted above, natural gas is either co-produced use non-food biomass, are a more sustainable choice.

with petroleum or sits on top of petroleum reservoirs. Systems based on microchannel FT produce high

With no local market for this gas, oil production is quality, energy dense fuel from a wide variety of

Velocys © 2008 Page 6 of 7

resources, including waste wood, energy crops and [13] Agee, M., "Taking GTL conversion offshore,"

municipal solid waste. Furthermore, they permit OTC 10762, Offshore Technology Conference,

favorable economics for smaller-scale facilities, May 3-6, 1999.

suitable for next generation biofuels. [14] N. Jones, T. Tveitnes, “The M-flex LNG Carrier

Due to ever stricter flaring regulations, Design”

associated natural gas is typically seen as a cost of oil

exploration and production because of the capital

equipment and energy required to re-inject the gas

back into the reservoir. The cost of associated gas is

highest offshore, where drilling wells and installing

equipment are more expensive, and deck space is at a

premium. The opportunity lies in the ability to

monetize the natural gas through a FT based GTL

process enabled by microchannel technology;

thereby, transforming the burden of associated gas

into a valuable resource that increases revenues and

stretches reserves. The process intensification

possible with microchannel FT improves volumetric

productivity and efficiency, reducing capital cost and

shrinking facility footprints, which is essential for

offshore facilities.

References

[1] Strange, A. M.; AIChE 2003 Spring National

Meeting, New Orleans, LA, 2003.

[2] K. T. Jarosch, A. L. Tonkovich, S. T. Perry, D.

Kuhlmann, Y. Wang, Reactors for Intensifying

Gas-to-Liquid Technology, in Microreactor

Technology and Process Intensification, ACS

Symposium Series n 914, September 2005.

[3] M. Lamont, A. Y. Tonkovich, S. Fitzgerald, P.

Neagle, Microchannel Fouling Mitigation: Flow

Distribution and Wall Shear Effects, AIChE

Spring 2006

[4] Y. Wang, D. P. Vanderwiel, A. Y. Tonkovich, Y.

Gao E. G. Baker, US 6,451,864 2002.

[5] Y. Wang, D. P. Vanderwiel, A. Y. Tonkovich, Y.

Gao, E. G. Baker, US 6,558,634 2003.

[6] B. Altemühl, Svetsaren: ESAB Welding and

Cutting Journal, Vol. 63, No. 1 (2008), p. 51-55

[7] R.L. Espinoza, A.P. Steynberg, B. Jager, A.C.

Vosloo, Applied Catalysis A: General 186 (1999)

13–26

[8] Font Freide, Joep J. H. M.; Collins, John P.; Nay,

Barry; Sharp, Chris, American Chemical Society,

Division of Petroleum Chemistry, Preprints, v

50, n 2, March, 2005, p 149-151

[9] J. Bereznicki, Alter NRG Analyst Report,

Paradigm Capital, April 15, 2007

[10] Energy Independence and Security Act of 2007,

Public Law 110-140, 110th Congress, Signed

December 19, 2007

[11] L. Wright, B. Boundy, B. Perlack, S. Davis, B.

Saulsbury, Biomass Energy Data Book: Edition

1, September 2006

[12] Petroconsultants-MIA and Zeus International,

Remote Gas Development Strategies, HIS

Energy Services, September 1999.

Velocys © 2008 Page 7 of 7

You might also like

- Full Download Advanced Financial Accounting 12th Edition Christensen Solutions ManualDocument35 pagesFull Download Advanced Financial Accounting 12th Edition Christensen Solutions Manuallienanayalaag100% (33)

- Protools Keyboard ShortcutsDocument27 pagesProtools Keyboard Shortcutsprettycool2No ratings yet

- Chapter 6 TransportationDocument25 pagesChapter 6 Transportationmamun gaziNo ratings yet

- Technical Paper PresentationDocument27 pagesTechnical Paper PresentationBhagyashree BachhavNo ratings yet

- Dariusz Bogdal and Aleksander Prociak - Microwave Synthesis of Polymeric Materials: Scale Up and Commercial AspectsDocument3 pagesDariusz Bogdal and Aleksander Prociak - Microwave Synthesis of Polymeric Materials: Scale Up and Commercial AspectsNstm3No ratings yet

- Crudo 2016Document6 pagesCrudo 2016bcherejiNo ratings yet

- Radial Microfluidic Fuel GeneratorDocument12 pagesRadial Microfluidic Fuel GeneratormmornelasNo ratings yet

- Paper 8, David Bond, Manchester UniversityDocument9 pagesPaper 8, David Bond, Manchester UniversityPrasanna KumarNo ratings yet

- 348 CourseprojectDocument19 pages348 CourseprojectJenish JainNo ratings yet

- Reff5 PDFDocument5 pagesReff5 PDFJuneeNo ratings yet

- A Comprehensive Review On Pool Boiling of Nanof - 2015 - Applied Thermal EngineeDocument19 pagesA Comprehensive Review On Pool Boiling of Nanof - 2015 - Applied Thermal EngineeANGIE JIMENEZ BOHORQUEZNo ratings yet

- Electric Power For Industrial Processes Using Dielectric HeatingDocument9 pagesElectric Power For Industrial Processes Using Dielectric Heatingharit_ecNo ratings yet

- Microfabricated ReactorDocument9 pagesMicrofabricated Reactorilyas savierNo ratings yet

- Energies 15 04580 v2Document16 pagesEnergies 15 04580 v2ฉัตรประภา แวววงศ์No ratings yet

- Kinetic Models For Fischer-Tropsch Synthesis For The Production of Clean FuelsDocument14 pagesKinetic Models For Fischer-Tropsch Synthesis For The Production of Clean FuelsbhiracityNo ratings yet

- Chapter 6 Process Intensification - NewDocument57 pagesChapter 6 Process Intensification - NewHOÀNG LÊ PHẠMNo ratings yet

- A Review of Multiscale Modelling Approaches For Understanding Catalytic Ammonia Synthesis and DecompositionDocument12 pagesA Review of Multiscale Modelling Approaches For Understanding Catalytic Ammonia Synthesis and DecompositionElias ChiquiarNo ratings yet

- Pyrolysis Using Microwave Heating: A Sustainable Process For Recycling Used Car Engine OilDocument7 pagesPyrolysis Using Microwave Heating: A Sustainable Process For Recycling Used Car Engine OilSalman Raza NaqviNo ratings yet

- Performance and Exergy Analysis of Biomass-To-Fuel Plants Producing Methanol, Dimethylether or HydrogenDocument10 pagesPerformance and Exergy Analysis of Biomass-To-Fuel Plants Producing Methanol, Dimethylether or HydrogenYanan CamarazaNo ratings yet

- Feasibility of SNG Production by Biomass Hydrogasification: August 2002Document8 pagesFeasibility of SNG Production by Biomass Hydrogasification: August 2002Robin ZwartNo ratings yet

- Energy Science Engineering - 2018 - ThunmanDocument29 pagesEnergy Science Engineering - 2018 - ThunmanClayer PaperNo ratings yet

- Fine Coal Drying and Plant Profitability: October 2012Document15 pagesFine Coal Drying and Plant Profitability: October 2012Adi Gunawan PrasetiaNo ratings yet

- Skripsi UI Fischer TropschDocument17 pagesSkripsi UI Fischer Tropschaisyahzafira26No ratings yet

- Processes 09 00234 v3Document18 pagesProcesses 09 00234 v3Elbanhawy4EverNo ratings yet

- Recuperacion de Granos Abrasivos PaperDocument5 pagesRecuperacion de Granos Abrasivos PaperALEJANDRO SALDARRIAGANo ratings yet

- A Microreactor For In-Situ Hydrogen Production by Catalytic Methanol ReformingDocument11 pagesA Microreactor For In-Situ Hydrogen Production by Catalytic Methanol ReformingramahtamahNo ratings yet

- The Mechanical Vapor Compression 38 Years of Experience PDFDocument10 pagesThe Mechanical Vapor Compression 38 Years of Experience PDFzamburittiNo ratings yet

- Phosgene Micro Reactor A I CheDocument9 pagesPhosgene Micro Reactor A I CheJorge RamirezNo ratings yet

- Desmoke System p.155-173Document19 pagesDesmoke System p.155-173Just RysdanNo ratings yet

- Influence of Different Pretreatment Methods On Biomass Gasification and Production of Fischer-Tropsch Crude Integrated With A Pulp and Paper MillDocument6 pagesInfluence of Different Pretreatment Methods On Biomass Gasification and Production of Fischer-Tropsch Crude Integrated With A Pulp and Paper MillMUHAMMED HAFIS N PNo ratings yet

- Aerogel-Based Thermal Superinsulation An OverviewDocument25 pagesAerogel-Based Thermal Superinsulation An OverviewLin YangNo ratings yet

- Tonkovich 2004Document6 pagesTonkovich 2004Huỳnh Diễm QuyNo ratings yet

- Case Study of Wte and Gasification PDFDocument8 pagesCase Study of Wte and Gasification PDFreal_2b_realNo ratings yet

- Fluidized Bed Combustion For Clean EnergyDocument19 pagesFluidized Bed Combustion For Clean EnergyashameensNo ratings yet

- Sciencedirect1dfbd151 9117 20140518010953Document7 pagesSciencedirect1dfbd151 9117 20140518010953amirlove206No ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument41 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsdevendra meenaNo ratings yet

- What Is Process Intensification?: RamshawDocument17 pagesWhat Is Process Intensification?: RamshawVRUSHABHNo ratings yet

- Chapter 1 2 RaisDocument9 pagesChapter 1 2 RaisirviirviNo ratings yet

- Thermal Conversion of Biomass and Waste, The StatusDocument25 pagesThermal Conversion of Biomass and Waste, The StatusCamilo Augusto Ramírez L.100% (1)

- 1 OnlineDocument6 pages1 OnlineJenish JainNo ratings yet

- Yang Et Al. - 2020 - Experimental Study On Single-Phase Hybrid MicrochaDocument11 pagesYang Et Al. - 2020 - Experimental Study On Single-Phase Hybrid Microchamosab.backkupNo ratings yet

- Investigation of Thermal Conductivity of Multi Walled Carbon Nanotube Dispersed in Hydrogenated Oil Based Drilling FluidsDocument7 pagesInvestigation of Thermal Conductivity of Multi Walled Carbon Nanotube Dispersed in Hydrogenated Oil Based Drilling FluidschokvuisoonNo ratings yet

- An Integrated Approach For The HCL and Metals Recovery From Waste Pickling Solutions Pilot Plant and Design OperationsDocument14 pagesAn Integrated Approach For The HCL and Metals Recovery From Waste Pickling Solutions Pilot Plant and Design OperationssunhaolanNo ratings yet

- 1 s2.0 S0017931022005361 MainDocument39 pages1 s2.0 S0017931022005361 Mainmosab.backkupNo ratings yet

- 1 s2.0 S0196890421006671 MainDocument10 pages1 s2.0 S0196890421006671 MainWei WangNo ratings yet

- First PaperDocument10 pagesFirst PaperakhilNo ratings yet

- Production of Synthetic Natural Gas From Industrial Carbon DioxideDocument26 pagesProduction of Synthetic Natural Gas From Industrial Carbon Dioxidecv.macochapiNo ratings yet

- Refractory Failure Investigation in CFBC BoilerDocument9 pagesRefractory Failure Investigation in CFBC BoilerchoksNo ratings yet

- Price 1998Document11 pagesPrice 1998LỢI NGUYỄN CÔNGNo ratings yet

- 36 TCC WWsolidsDocument10 pages36 TCC WWsolidsSupatmono NAINo ratings yet

- Process Simulation of PowertoX SystemsModeling and Simulation of Biological Methanation 2023 MDPIDocument30 pagesProcess Simulation of PowertoX SystemsModeling and Simulation of Biological Methanation 2023 MDPIJOHAN SEBASTIAN OCHOA MU�OZNo ratings yet

- Biomass Gasification Integrated With Pyrolysis in A Circulating Uidised BedDocument5 pagesBiomass Gasification Integrated With Pyrolysis in A Circulating Uidised BedAnil KunworNo ratings yet

- Hydrogen Technology An OverviewDocument7 pagesHydrogen Technology An Overviewlili_eqNo ratings yet

- Chemical Cleaning of Oil Refinery Heat ExchangersDocument3 pagesChemical Cleaning of Oil Refinery Heat ExchangersAbdul JabbarNo ratings yet

- 1 s2.0 S0016236112007764 MainDocument7 pages1 s2.0 S0016236112007764 MainhoseiNo ratings yet

- 1 s2.0 S0960148121017900 MainDocument12 pages1 s2.0 S0960148121017900 MainSt cyr EdenNo ratings yet

- Pgweg: Recycling of Lead/Acid Batteries in A Small PlantDocument3 pagesPgweg: Recycling of Lead/Acid Batteries in A Small PlantCarolina SalcedoNo ratings yet

- Composite Carbon Dioxide Sorbent: BackgroundDocument2 pagesComposite Carbon Dioxide Sorbent: Backgroundmercer KevinNo ratings yet

- Molecules 20 04998Document26 pagesMolecules 20 04998Carlos Rivera MontesNo ratings yet

- Analysis of A Bayonet Tube Heat Exchanger: T. O'Doherty, A.J. Jolly, C.J. BatesDocument18 pagesAnalysis of A Bayonet Tube Heat Exchanger: T. O'Doherty, A.J. Jolly, C.J. BatesMelanie PooleNo ratings yet

- FenrgDocument12 pagesFenrgcailiiiNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- Performance Analysis Between RunC and Kata Container RuntimeDocument4 pagesPerformance Analysis Between RunC and Kata Container RuntimeClyde MarNo ratings yet

- Denodo8 - Metadata Management OverviewDocument28 pagesDenodo8 - Metadata Management OverviewVincent HarcqNo ratings yet

- Data Privacy Candidate Consent FormDocument2 pagesData Privacy Candidate Consent FormENG 1B - Tabing - Melanie AngelNo ratings yet

- EHAQ 4th Cycle Audit Tool Final Feb.10-2022Document51 pagesEHAQ 4th Cycle Audit Tool Final Feb.10-2022Michael Gebreamlak100% (1)

- It Assignment 2014Document143 pagesIt Assignment 2014Preeti GahlotNo ratings yet

- Dataflex 6320 PDFDocument222 pagesDataflex 6320 PDFJardas Fernandes100% (1)

- 4-Port - RFS (Antenna) - Multi Ret - ScriptDocument2 pages4-Port - RFS (Antenna) - Multi Ret - Scriptyou are awesomeNo ratings yet

- Referencia M PDFDocument1,008 pagesReferencia M PDFrobertocarlosricciNo ratings yet

- Tender Jalahalli LandDocument3 pagesTender Jalahalli Landudupiganesh3069No ratings yet

- United States Court of Appeals For The Fifth Circuit: FiledDocument8 pagesUnited States Court of Appeals For The Fifth Circuit: FiledRHTNo ratings yet

- NG160 - 16 To 160A Modular Incoming Circuit BrakersDocument27 pagesNG160 - 16 To 160A Modular Incoming Circuit BrakerssomeontorrenteNo ratings yet

- TheodoliteDocument26 pagesTheodoliteNishant Sarraf100% (1)

- Kuliah Materi Budaya OrganisasiDocument19 pagesKuliah Materi Budaya OrganisasiTito YustiawanNo ratings yet

- Airflex® Air Cooled Disc Clutches and Brakes: Section EDocument22 pagesAirflex® Air Cooled Disc Clutches and Brakes: Section Erony adonay sandovalNo ratings yet

- Bpas 186 Solved AssignmentDocument7 pagesBpas 186 Solved AssignmentDivyansh Bajpai0% (1)

- 2009 Cardinal RV Model From Forest RiverDocument20 pages2009 Cardinal RV Model From Forest RiverDaly RV100% (3)

- Acquisition and Disposition of Property, Plant and EquipmentDocument63 pagesAcquisition and Disposition of Property, Plant and EquipmentKashif Raheem100% (1)

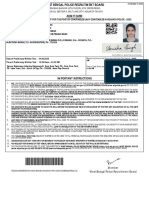

- Admit Card: Araksha Bhavan (5Th Floor), 6Th Cross Road, Block-Dj, Sector-Ii, Salt Lake City, Kolkata-700 091Document1 pageAdmit Card: Araksha Bhavan (5Th Floor), 6Th Cross Road, Block-Dj, Sector-Ii, Salt Lake City, Kolkata-700 091Ayesha HignisNo ratings yet

- Creating Cust Specific POWL Query PDFDocument3 pagesCreating Cust Specific POWL Query PDFvictorSNo ratings yet

- Hammond V. Odoi and Another: Supreme Court Dec. 20, 1982 GhanaDocument70 pagesHammond V. Odoi and Another: Supreme Court Dec. 20, 1982 GhanaJenaNo ratings yet

- Ai Finance 1Document10 pagesAi Finance 1Purnachandrarao SudaNo ratings yet

- UCM Notes PDFDocument92 pagesUCM Notes PDFTIRUPATHI KARTIKEYANo ratings yet

- PHM and Value AdditionDocument3 pagesPHM and Value AdditionNikhil GourNo ratings yet

- Sách Listening Basic Bản MớiDocument172 pagesSách Listening Basic Bản MớiThảo ChiantiNo ratings yet

- Developing Living Cities From Analysis To Action PDFDocument314 pagesDeveloping Living Cities From Analysis To Action PDFKien VuNo ratings yet

- AFM Case Study Q1,2Document3 pagesAFM Case Study Q1,2lim hui mengNo ratings yet

- Bildprospekt HolzumschlagDocument48 pagesBildprospekt HolzumschlagFirman ArifinNo ratings yet