Professional Documents

Culture Documents

Hilo 02

Hilo 02

Uploaded by

한정욱Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hilo 02

Hilo 02

Uploaded by

한정욱Copyright:

Available Formats

HI-LO® FASTENERS

SCREWS FOR PLASTIC AND OTHER LOW DENSITY MATERIALS

THE HIGH PERFORMANCE FASTENER FOR PLASTICS, REDUCED CRACKING, SPLITTING AND

PARTICLE BOARD, MASONITE AND WOOD BOSS BREAKAGE

The Hi-Lo fastener, with its unique thread form, improves The superior performance of the Hi-Lo fastener

fastener performance in a broad range of low density mate- increases product quality and decreases costs. The

rials such as plastics, wood, masonite and particle board. 30° included angle of the high thread form reduces

This fastener is designed with a double lead, consisting of radial or bursting pressure to one-half of that gener-

a high and a low thread. The high thread is sharper than a ated by the conventional 60° included angle thread

conventional thread, having a 30° included angle. The form. Boss cracking in plastic is dramatically reduced

low thread has the 60° included angle and a height that and smaller diameter bosses can often be specified.

is 40% to 50% of the high thread height. In wood applications, even when driving close to the

edge, splitting is greatly reduced due to this lower

radial pressure.

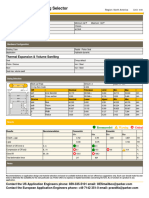

HI-LO FASTENER PHILLIPS PAN HEAD DIMENSIONS IN INCHES

INCREASED PULL-OUT STRENGTH SPECIFICATIONS 2 7 11 1/4

#8 TYPE B #8 HI-LO SCREW SIZE 3 4 5 6 8 10 12 13 9/32

SCREW FASTENER

G G HEAD MAX. .167 .193 .219 .254 .270 .322 .373 .425 .492

DIAMETER MIN. .155 .180 .205 .240 .258 .306 .357 .407 .473

MINOR MAJOR MINOR T H HEAD MAX. .062 .071 .080 .097 .097 .115 .133 .151 .175

DIA. DIA. DIA. H

HEIGHT MIN. .053 .062 .070 .087 .087 .105 .122 .139 .162

PENETRATION

PHILLIPS PAN HEAD

T GAGING MAX. .052 .061 .071 .072 .080 .097 .113 .124 .144

LARGER SHEAR AREA

DEPTH MIN. .034 .043 .053 .046 .055 .071 .089 .098 .118

The Hi-Lo screw thread configuration

has a smaller minor diameter than a con- INDENTED HEX WASHER HEAD DIMENSIONS IN INCHES

ventional screw. The high threads make 1/4

a deeper cut into the material between SCREW SIZE 2 3 5 7 10 12 9/32

the threads. There is also a greater 4 6 8 11 13 5/16

amount of material in contact with the L WASHER MAX. .167 .177 .260 .328 .348 .432 .520

L DIAMETER MIN. .154 .163 .240 .302 .322 .396 .480

high, sharp thread and the axial shear

G ACROSS

area is increased. All of this contributes G CORNERS MIN. .134 .134 .202 .272 .272 .340 .409

F

to greater resistance to pullout and ACROSS MAX. .125 .125 .187 .250 .250 .312 .375

H F

stronger fastening. FLATS MIN. .120 .120 .181 .244 .244 .305 .367

M HEAD MAX. .050 .055 .070 .093 .110 .155 .190

H HEIGHT MIN. .040 .044 .058 .080 .096 .139 .172

HEX WASHER HEAD

LOWER DRIVING, HIGHER WASHER MAX. .016 .016 .025 .025 .031 .039 .050

STRIPPING TORQUES M THICKNESS MIN. .010 .010 .015 .015 .019 .022 .030

AXIAL

SHEAR HI-LO FASTENERS DIMENSIONS IN INCHES

MATERIAL

SCREW HIGH THREAD LOW THREAD POINT RECOMMENDED

SIZE DIAMETER (D) DIAMETER DIAMETER PILOT HOLE

MAX. MIN. (P) (d) DIAMETER*

3-28 .105 .095 .078 .061 .078

TYPE B THREAD HI-LO THREAD

4-24 .115 .105 .086 .066 .086

5-20 .125 .119 .100 .078 .099

The 30° included angle of the high 6-19 .145 .135 .108 .085 .108

thread displaces less material when it is 7-19 .158 .148 .030 .095 .125

driven into plastic or wood and, there- 8-18 .170 .160 .130 .100 .128

fore, requires lower driving torques. A 10-16 .195 .185 .145 .105 .144

greater amount of material remains 11-16 .210 .198 .150 .119 .150

12-16 .220 .210 .176 .131 .166

between the high threads, increasing the

13-16 .230 .220 .180 .133 .180

stripping torque. Low driving torque

1/4-15 .260 .250 .200 .168 .200

and high stripping torque provide maxi- 5/16-14 .317 .307 .250 .206 .250

mum protection against stripping prob-

* These hole sizes are tentative and are provided as a guide only. Actual hole

lems. size could vary depending on type of plastic, boss diameter and length of

HI-LO FASTENERS

thread engagement.

Note: Hi-Lo is a registered trademark of Illinois Tool Works Incorporated.

Page 16

WEST COAST LOCKWASHER, 16730 East Johnson Drive, P.O. Box 3588 Industry, California 91744 • www.wclco.com • Phone (800) 331-3816 • Fax (626) 369-9805

You might also like

- Tenarishydril-Premium-Connections-Catalog TSH Blue PDFDocument2 pagesTenarishydril-Premium-Connections-Catalog TSH Blue PDFGustavo Pérez100% (2)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- Socket Countersunk Screws Din7991Document2 pagesSocket Countersunk Screws Din7991Gökhan Anli100% (1)

- Socket Countersunk Screws Din7991Document2 pagesSocket Countersunk Screws Din7991Gökhan Anli100% (1)

- A Report On DrillDocument18 pagesA Report On DrillTITU NATH100% (1)

- Sltp-Standard Inch Pins UsDocument2 pagesSltp-Standard Inch Pins UsErick Frank Dueñas CudeñaNo ratings yet

- TFS BrochureDocument178 pagesTFS Brochureewqeq100% (1)

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsAlejandro MejíasNo ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- T 52 PG 69-70 PDFDocument2 pagesT 52 PG 69-70 PDFJossimar PerezNo ratings yet

- Rod Seals: Technical DetailsDocument2 pagesRod Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- T 714 PG 187-188 PDFDocument2 pagesT 714 PG 187-188 PDFJossimar PerezNo ratings yet

- Off-The-Road Tyres Series: Dump TrucksDocument2 pagesOff-The-Road Tyres Series: Dump TrucksJamal HabbasNo ratings yet

- 100sx LitDocument3 pages100sx LitismicicNo ratings yet

- ASME B18.8.2 PinsDocument2 pagesASME B18.8.2 Pinsvictor manuel flores martinezNo ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Rigid Cellulose MediaDocument4 pagesRigid Cellulose MediaEaster KongNo ratings yet

- Elephant Gypsum Boards Specification - Moistbloc BoardDocument1 pageElephant Gypsum Boards Specification - Moistbloc BoardDilon Fernando0% (1)

- Technical Details: Vee Pack SetsDocument2 pagesTechnical Details: Vee Pack SetsJossimar PerezNo ratings yet

- Mechanical Seals JohnCraneDocument6 pagesMechanical Seals JohnCranevalikka100% (3)

- PTFE, FEP and ETFE Convoluted TubingDocument4 pagesPTFE, FEP and ETFE Convoluted TubingYong-il KimNo ratings yet

- R&D Axial Flow Control ValvesDocument2 pagesR&D Axial Flow Control ValvesnandkishorNo ratings yet

- TEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low WeightDocument4 pagesTEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low Weightalexander_1985No ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- OringDocument1 pageOringA TMNo ratings yet

- T 56 PG 79-82 PDFDocument4 pagesT 56 PG 79-82 PDFJossimar PerezNo ratings yet

- 6093d9371fcc533e30f3b6cd - FRD FXJ SERIESDocument4 pages6093d9371fcc533e30f3b6cd - FRD FXJ SERIESjuanchis650No ratings yet

- Rod Seals: Technical DetailsDocument3 pagesRod Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- HD 242 Flexible HoseDocument4 pagesHD 242 Flexible HoseSelvakumar EkambaramNo ratings yet

- Technical Details: Vee Pack SetsDocument2 pagesTechnical Details: Vee Pack SetsRPINILLA (EICO S.A.)No ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- Sttype BDocument1 pageSttype BSean YangNo ratings yet

- Dry Seal Pressure PlugsDocument2 pagesDry Seal Pressure PlugsS DasNo ratings yet

- Expansion Contraction: Control JointsDocument4 pagesExpansion Contraction: Control JointsRezkyNo ratings yet

- Technical Details: Piston SealsDocument2 pagesTechnical Details: Piston SealsRPINILLA (EICO S.A.)No ratings yet

- TF ENGcatalogo2016 TRS 2Document8 pagesTF ENGcatalogo2016 TRS 2James MckerrNo ratings yet

- Technical Details: Rod/ Piston SealsDocument2 pagesTechnical Details: Rod/ Piston SealsJosé HurtadoNo ratings yet

- Snap Bore Ring PDFDocument8 pagesSnap Bore Ring PDFlaaliNo ratings yet

- T 51 PG 67-68 PDFDocument2 pagesT 51 PG 67-68 PDFJossimar PerezNo ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Trevoli - Co.nz-Trevoli DSK Series Submersible Sewage Cutter PumpsDocument3 pagesTrevoli - Co.nz-Trevoli DSK Series Submersible Sewage Cutter Pumpsfaisal andreansyahNo ratings yet

- #3 Domed Head Plow Bolt: Earnest Technical BulletinDocument3 pages#3 Domed Head Plow Bolt: Earnest Technical BulletinNarvaxisNo ratings yet

- Fiche Technique DRBDocument2 pagesFiche Technique DRBJob EmploiNo ratings yet

- Screw Flat Head, TorxDocument1 pageScrew Flat Head, TorxDerekNo ratings yet

- Screw, ISO 10664-2014, Truss Head, Flat Head, 6-Lobe, TorxDocument1 pageScrew, ISO 10664-2014, Truss Head, Flat Head, 6-Lobe, TorxDerekNo ratings yet

- 高低牙Document4 pages高低牙Sean YangNo ratings yet

- Manguera C-Inc. Nitrilo Acop. Br. de 30MTS 300psi 5elem UlDocument1 pageManguera C-Inc. Nitrilo Acop. Br. de 30MTS 300psi 5elem UlComercial FirenoNo ratings yet

- Strenx 700 Brochure Square ENDocument6 pagesStrenx 700 Brochure Square ENEjang GutNo ratings yet

- T 14pg 37-38 PDFDocument2 pagesT 14pg 37-38 PDFJossimar PerezNo ratings yet

- Technical Details: Vee Pack SetsDocument2 pagesTechnical Details: Vee Pack SetsJosé HurtadoNo ratings yet

- Wire & Cable 202312261659586681900588413Document24 pagesWire & Cable 202312261659586681900588413Amir IqbalNo ratings yet

- GGB Wire MeshDocument1 pageGGB Wire Meshargometer tzarNo ratings yet

- 27 - Wire MeshDocument1 page27 - Wire MeshBagus Maulidika RoufiNo ratings yet

- 27 - Wire Mesh PDFDocument1 page27 - Wire Mesh PDFIdaa Saida RasmiNo ratings yet

- GGB Wire MeshDocument1 pageGGB Wire MeshNurul LailyahNo ratings yet

- Countersunk Socket Head Screws Inch Spec SheetDocument2 pagesCountersunk Socket Head Screws Inch Spec SheetMob PhoNo ratings yet

- Premium Free-Rolling Radial: Premium, Free-Rolling Axle Tire Designed For Long Haul, Over The Highway OperationsDocument1 pagePremium Free-Rolling Radial: Premium, Free-Rolling Axle Tire Designed For Long Haul, Over The Highway Operationseyya 007No ratings yet

- High Performance - Grade 90: Pretensioned Spun High Strength Concrete PilesDocument2 pagesHigh Performance - Grade 90: Pretensioned Spun High Strength Concrete PilesPete WongNo ratings yet

- Multi Rib Metal Roofing TileDocument1 pageMulti Rib Metal Roofing Tilevadivel415No ratings yet

- ROB - ComparisonDocument6 pagesROB - ComparisonvinoraamNo ratings yet

- Packing & Wiper RingsDocument1 pagePacking & Wiper Ringscontango O&GNo ratings yet

- Dicom - (MATLAB) 3D CT Image Reconstruction by 2DDocument2 pagesDicom - (MATLAB) 3D CT Image Reconstruction by 2DGökhan AnliNo ratings yet

- Deltapt ToleranslarDocument18 pagesDeltapt ToleranslarGökhan AnliNo ratings yet

- 001-Verb Tenses RevisionDocument14 pages001-Verb Tenses RevisionGökhan Anli100% (1)

- Standard BoltsDocument11 pagesStandard BoltsGökhan AnliNo ratings yet

- Internal Dimensions of Hexalobular Screws (DIN en ISO 10664)Document1 pageInternal Dimensions of Hexalobular Screws (DIN en ISO 10664)Purushothama Nanje GowdaNo ratings yet

- Internal Dimensions of Hexalobular Screws (DIN en ISO 10664)Document1 pageInternal Dimensions of Hexalobular Screws (DIN en ISO 10664)Purushothama Nanje GowdaNo ratings yet

- ms6015 ms7025 ms9025 b275b 20220330Document28 pagesms6015 ms7025 ms9025 b275b 20220330mooninjaNo ratings yet

- Oval Head Semi Tubular RivetsDocument1 pageOval Head Semi Tubular RivetstrandangbkNo ratings yet

- G-Code Cheat Sheet + MDI - Your CNC Secret WeaponDocument25 pagesG-Code Cheat Sheet + MDI - Your CNC Secret Weaponpatterson nji mbakwa100% (1)

- Et Atc1630 PDFDocument1 pageEt Atc1630 PDFwissam.alnaser6332No ratings yet

- Datasheet 19892 Rotary Shaft Lip Seals DIN 3760 - enDocument9 pagesDatasheet 19892 Rotary Shaft Lip Seals DIN 3760 - enSarath KumarNo ratings yet

- 570 950mpa High Tensile Strength SteelDocument32 pages570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNo ratings yet

- Temperature Dependant Properties of Excothermic Riser SleevesDocument4 pagesTemperature Dependant Properties of Excothermic Riser SleevesCorneNo ratings yet

- Teclumos Screwed Sight Glass Fitting SDDocument1 pageTeclumos Screwed Sight Glass Fitting SDKasraNo ratings yet

- ForgingDocument2 pagesForgingvelavansuNo ratings yet

- 19-PM-2015-16 Gripcoat Coating On Rewinder NR VapiDocument2 pages19-PM-2015-16 Gripcoat Coating On Rewinder NR VapiPankaj PandeyNo ratings yet

- F 492 - 95 - RJQ5MGDocument5 pagesF 492 - 95 - RJQ5MGCeratita ClarkNo ratings yet

- Materials Selection For Wear ResistanceDocument28 pagesMaterials Selection For Wear ResistanceRECEP ÇETİNKAYANo ratings yet

- Uhlfbert ReactionDocument1 pageUhlfbert ReactionCarl Aldrin SulamNo ratings yet

- 220 V2a MFMS 00274Document1 page220 V2a MFMS 00274Carlos GustavoNo ratings yet

- Products Techniques, Inc.: Aircraft Paint Application ManualDocument42 pagesProducts Techniques, Inc.: Aircraft Paint Application ManualOscar Cueva100% (2)

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNo ratings yet

- 2nd Year Wood ProjectDocument20 pages2nd Year Wood Projectapi-606257698No ratings yet

- ASME BPVC 2023 Sect IX - FigurasDocument39 pagesASME BPVC 2023 Sect IX - FigurasJose Adrian Hernandez HernandezNo ratings yet

- Output Per Operator TRANS Desember 20211Document2,505 pagesOutput Per Operator TRANS Desember 20211Muhammad Taufiek AkbarNo ratings yet

- Diagram Alir Paper Machine 3Document3 pagesDiagram Alir Paper Machine 3raiNo ratings yet

- Welding ProcedureDocument2 pagesWelding ProcedureAndrey GyrychNo ratings yet

- Practice Questionnaire For New Omani QAQC Staff - DLQ DeptDocument7 pagesPractice Questionnaire For New Omani QAQC Staff - DLQ DeptSuliman Al RuheiliNo ratings yet

- Preheater Calciner SystemsDocument8 pagesPreheater Calciner SystemsPaknubkNo ratings yet

- Sept E: Bleaching Agent Containing ChlorineDocument3 pagesSept E: Bleaching Agent Containing ChlorinemayNo ratings yet

- Emka Gasket Edge Protection and Window Rubber Ger 116116Document23 pagesEmka Gasket Edge Protection and Window Rubber Ger 116116Erikas KulpinasNo ratings yet

- New Microsoft Office Excel WorksheetDocument11 pagesNew Microsoft Office Excel WorksheetUmar NazarNo ratings yet

- DGS 0000 002 Rev 2Document71 pagesDGS 0000 002 Rev 2Anoop NairNo ratings yet

- 2c1 Seam WeldingDocument57 pages2c1 Seam WeldingBasavarajBusnurNo ratings yet

- Friction Stir WeldingDocument26 pagesFriction Stir WeldingMahaManthra0% (1)