Professional Documents

Culture Documents

MAK RR Grease 3

MAK RR Grease 3

Uploaded by

chetanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAK RR Grease 3

MAK RR Grease 3

Uploaded by

chetanCopyright:

Available Formats

MAK RR GREASE 3

Description

This is Premium quality, multi purpose lithium soap base grease having excellent thermal and shear

stability. This grease has good resistance against water washout too and hence is suitable for

wheel bearing applications

This is an NLGI 3 grease and has higher consistency making it suitable for use in heavy duty bearing

applications

Application

It is recommended for use in the Wheel Bearings of Heavy Duty Vehicles for longer service life. It is

specially formulated for cylindrical roller bearings of axle boxes of diesel / electric locomotives &

freight stock

It is approved by RDSO for use in cylindrical bearing axle box for freight stock, spherical roller

bearing axle box for coaching stock and all the application on diesel / electric locomotives

Benefits

• High Drop point-With a high drop point, it is well suited to lubricate components efficiently under

high temperature conditions also

• Good Oxidation Stability- Gives enhanced life to the grease lubricant and minimum changing

intervals

• Excellent water resistance- Does not wash away due to water sprays over bearings and greases,

hence grease consumption also reduces

• Good Shear Stability- Provides grease with extra ability to resist early shear and work longer

during harsh working conditions

Performance Level

• RDSO’s WD. 17-MISC-92 specifications for Axle Box Grease

Technical Specifications

Characteristics Test Method MAK RR GREASE 3

Consistency of the Worked Grease at 25°C

ASTM D 217 235

@ 60 double strokes

Drop Point, °C ASTM D 2265 185

Free Organic Acidity (as oleic acid), % by mass IS 1448 P:53 Nil

Free Alkanity (as LiOH), % by mass IS 1448 P:53 0.08

Copper Strip Corrosion Test @ 100°C for 24 hrs. ASTM D 4048 Negative

All the mentioned values are typical which may vary from batch to batch

Storage and Handling

• Indoor Storage is always preferable

• Barrels should be kept vertically and should be kept away from dusty or heated areas.

• Lid should not be left open and during handling any contact with dust must be avoided

• Containers used for grease transport should be clean and exclusive

Health & Safety

This grade is not hazardous under normal conditions of use. For further guidance Material Safety

Data Sheet (MSDS) may be referred

Advice

For any further advice on applications or otherwise, please contact the nearest Bharat Petroleum

territory office or Technical Services department at the address given below.

Bharat Petroleum Corporation Ltd.

Product and Application Development Dept.

BPCL ‘A’ Installation, Sewree Fort Road, Sewree (East)

Mumbai -400015

E-mail: MAKcustomercare2@bharatpetroleum.in

Tel No.: 022-24176351

You might also like

- Shell Argina X 40 - TDSDocument2 pagesShell Argina X 40 - TDSHUM CIREBON DFLTS100% (1)

- Sae J1344 Marking of Plastic Parts 070197 PDFDocument25 pagesSae J1344 Marking of Plastic Parts 070197 PDFmpedraza-1100% (2)

- Lamborghini AventadorSVJRoadster AC37EZ 19.05.17Document16 pagesLamborghini AventadorSVJRoadster AC37EZ 19.05.17Lucian NicolaeNo ratings yet

- Clinical PharmacyDocument4 pagesClinical PharmacyLi LizNo ratings yet

- Model: Frequency: Fuel Type: C1000 D6B 60 Diesel: Generator Set Data SheetDocument3 pagesModel: Frequency: Fuel Type: C1000 D6B 60 Diesel: Generator Set Data SheetIgorNo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- MAK Hydrol CEDocument2 pagesMAK Hydrol CEannamalailubesNo ratings yet

- Mobilgear SHC 3200 6800 PdsDocument2 pagesMobilgear SHC 3200 6800 PdsMohamed SalemNo ratings yet

- MAK Ruby Grease 3Document1 pageMAK Ruby Grease 3Sam90o GamingNo ratings yet

- Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic GreaseDocument3 pagesMobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic GreasedhowardjNo ratings yet

- Mobil Velocite Oil Numbered YDocument2 pagesMobil Velocite Oil Numbered YAndey RibalkoNo ratings yet

- Mak Quenching Oil CDocument1 pageMak Quenching Oil CPaviter SinghNo ratings yet

- GL XX Mobilgear MS SeriesDocument3 pagesGL XX Mobilgear MS Seriesanibal_rios_rivasNo ratings yet

- SRB Grease DetailsDocument2 pagesSRB Grease DetailsSofian AmaraNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriesShailesh BarbateNo ratings yet

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziNo ratings yet

- 01-Tds-.Canroyal Full Synthetic Gear Oil Sae 75W-90 Api GL-5Document1 page01-Tds-.Canroyal Full Synthetic Gear Oil Sae 75W-90 Api GL-5catpilar274No ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriescruelweyNo ratings yet

- GL XX Mobil SHC Grease 460 WTDocument3 pagesGL XX Mobil SHC Grease 460 WTRakka HardiyantaNo ratings yet

- Oli Energol GR-XPDocument2 pagesOli Energol GR-XPakun leptopNo ratings yet

- Navigator GL 4 - SAE 90 - 140Document1 pageNavigator GL 4 - SAE 90 - 140ibrahim maulanaNo ratings yet

- MIRR TO-4 Transmission Oils 50, 40 & 30Document2 pagesMIRR TO-4 Transmission Oils 50, 40 & 30MATHEW JOSENo ratings yet

- MFG 460 - 3M - TDS - 2 - 12.10.22Document1 pageMFG 460 - 3M - TDS - 2 - 12.10.22RUTA TLAXCALA (SHELL)No ratings yet

- Balmerol Autoplex SuperDocument2 pagesBalmerol Autoplex SuperTAPAS CHAKRABORTYNo ratings yet

- GL XX Mobil SHC Grease 460 WTDocument3 pagesGL XX Mobil SHC Grease 460 WTMallikarjunareddy PNo ratings yet

- Mak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial GearsDocument2 pagesMak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial Gearschandan sahooNo ratings yet

- Mak Freezol 68 OilDocument1 pageMak Freezol 68 OilshobhaNo ratings yet

- Chevron Regal RO PDSDocument4 pagesChevron Regal RO PDSVivekyathi BowanNo ratings yet

- GL XX Mobil DTE Oil Double Letter SeriesDocument3 pagesGL XX Mobil DTE Oil Double Letter SeriesMuhammad RipandiNo ratings yet

- Mobil DTE Oil Double Letter SeriesDocument2 pagesMobil DTE Oil Double Letter SeriesEduardo Camacho [Clayton de México]No ratings yet

- Ser 1Document1 pageSer 1rita132No ratings yet

- Balmerol Grease PDFDocument3 pagesBalmerol Grease PDFlifttecNo ratings yet

- Chainguard 280 TDSDocument2 pagesChainguard 280 TDSTeófilo LimasNo ratings yet

- 01-TDS - Canroyal Full-Synthetic Engine Oil Sae 5W-30 Api SP GF-6.Document1 page01-TDS - Canroyal Full-Synthetic Engine Oil Sae 5W-30 Api SP GF-6.catpilar274No ratings yet

- Gpcdoc Gtds Shell Argina T 30 (2005) (En) TdsDocument2 pagesGpcdoc Gtds Shell Argina T 30 (2005) (En) TdsEdgar Leonel CortésNo ratings yet

- MAK Fleet CI4+ 15W-40Document1 pageMAK Fleet CI4+ 15W-40Yogesh BhatiaNo ratings yet

- Gpcdoc Gtds Shell Argina T 40 (2005) (En) TdsDocument2 pagesGpcdoc Gtds Shell Argina T 40 (2005) (En) Tdscesar_lub100% (1)

- Technical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Document2 pagesTechnical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Mohamed IsmailNo ratings yet

- CASTROL TLX Plus RangeDocument2 pagesCASTROL TLX Plus RangeAntonio CardosoNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Ultra Duty 15W40 1Document2 pagesUltra Duty 15W40 1kievegokoolNo ratings yet

- Valvoline Heavy Duty TDL PRO 75W-90-PI SheetDocument2 pagesValvoline Heavy Duty TDL PRO 75W-90-PI SheetJUAN BAUTISTANo ratings yet

- Servo PrimeDocument1 pageServo PrimeRakeshKumarNo ratings yet

- GL XX Mobilgear SHC SeriesDocument3 pagesGL XX Mobilgear SHC Seriesanibal_rios_rivasNo ratings yet

- REPSOL GXR EURO 5W40 v1 1Document1 pageREPSOL GXR EURO 5W40 v1 1Yousra MenotyNo ratings yet

- HT Mobilgear 600 Series EngDocument2 pagesHT Mobilgear 600 Series Engmgamal1080No ratings yet

- PDS CRB Turbo 15W-40 PDFDocument2 pagesPDS CRB Turbo 15W-40 PDFFathan AdnanNo ratings yet

- Multiplant 10W30Document2 pagesMultiplant 10W30carmaNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- Servo Mesh Oil GradesDocument1 pageServo Mesh Oil Gradessrinu rao bandaruNo ratings yet

- Transmission Axle 7 80w 90 TDS v180903Document2 pagesTransmission Axle 7 80w 90 TDS v180903William RobertoNo ratings yet

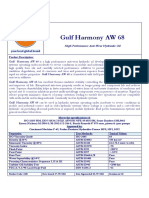

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- Castrol Molub-Alloy 243 ArcticDocument2 pagesCastrol Molub-Alloy 243 ArcticMaciejNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Mobil 226 EDocument3 pagesMobil 226 Emahmoud mohamedNo ratings yet

- Dewmare Marine Oil 4040Document1 pageDewmare Marine Oil 4040ednsmnNo ratings yet

- TDS Castrol Magnatec 10W 40Document3 pagesTDS Castrol Magnatec 10W 40Fariezal Adhi GunawanNo ratings yet

- PDS Pso Gearled EpDocument1 pagePDS Pso Gearled EpMuhammad EhsanNo ratings yet

- SINOPEC船用润滑油产品手册 PDFDocument30 pagesSINOPEC船用润滑油产品手册 PDFWilman OngNo ratings yet

- Shell Argina S 30 - TDSDocument2 pagesShell Argina S 30 - TDSHUM CIREBON DFLTSNo ratings yet

- Shell 5W20Document2 pagesShell 5W20saifalnaimi332No ratings yet

- Lubricants: Unoba EPDocument2 pagesLubricants: Unoba EPQC RegianNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- ReleaseNotes 5.11.02.217Document5 pagesReleaseNotes 5.11.02.217bartusdarNo ratings yet

- Engine ClasificationDocument13 pagesEngine Clasificationvasanth9046No ratings yet

- Neurotransmitters: Intellectual FunctionDocument3 pagesNeurotransmitters: Intellectual FunctionMarissa AsimNo ratings yet

- Fluorescent Lighting FixturesDocument23 pagesFluorescent Lighting FixturesJaville Bartina JamorawonNo ratings yet

- 15001-Fanny CrosbyDocument16 pages15001-Fanny CrosbySharjin AuthorNo ratings yet

- Three Stages Sediment Filter and Uv Light Purifier: A Water Treatment SystemDocument36 pagesThree Stages Sediment Filter and Uv Light Purifier: A Water Treatment SystemMark Allen Tupaz MendozaNo ratings yet

- Prosec Ii+ ManualDocument1 pageProsec Ii+ ManualBachtiar WidyantoroNo ratings yet

- DP Yh 4300 BrochureDocument2 pagesDP Yh 4300 BrochurenamhtsNo ratings yet

- Environmental Hazards Assessment at Pre Saharan Local Scale - Case Study From The Draa Valley MoroccoDocument19 pagesEnvironmental Hazards Assessment at Pre Saharan Local Scale - Case Study From The Draa Valley MoroccoChaymae SahraouiNo ratings yet

- NIV Fs 9108147 e 1911 1 PDFDocument4 pagesNIV Fs 9108147 e 1911 1 PDFliuchenshitaoNo ratings yet

- DC ReskiDocument27 pagesDC ReskiHardiyanti HermanNo ratings yet

- 4 SOEE5010 QuestionnaireDocument2 pages4 SOEE5010 QuestionnairePrince JuniorNo ratings yet

- VO FinalDocument140 pagesVO Finalsudhasesh2000No ratings yet

- RocFall 5 BetaDocument5 pagesRocFall 5 BetaMarcus LindonNo ratings yet

- Course - Design - Policy - 2018 - TrainingDocument23 pagesCourse - Design - Policy - 2018 - TraininggarimagaurNo ratings yet

- Avance Reciente en El Recubrimiento Comestible y Su Efecto en La Calidad de Las Frutas Frescas - Recién CortadasDocument15 pagesAvance Reciente en El Recubrimiento Comestible y Su Efecto en La Calidad de Las Frutas Frescas - Recién CortadasJHON FABER FORERO BARCONo ratings yet

- Solar Tree-Mutai Write UpDocument22 pagesSolar Tree-Mutai Write UpMutai DanielNo ratings yet

- Numinous Japanese GothicDocument22 pagesNuminous Japanese GothicDiana M.No ratings yet

- Set LP - 114719Document9 pagesSet LP - 114719Beverly SombiseNo ratings yet

- Footing Cutting List: Mark Length Width Thickness Spacing Bar Diameter Top&Botom Clear CoverDocument3 pagesFooting Cutting List: Mark Length Width Thickness Spacing Bar Diameter Top&Botom Clear CoverJohn Rhey Almojallas BenedictoNo ratings yet

- Sri Ananda AnjaneyamDocument18 pagesSri Ananda AnjaneyamSailee RNo ratings yet

- ReadiGASS Bro 1709Document4 pagesReadiGASS Bro 1709arunkumar277041No ratings yet

- New WordDocument3 pagesNew WordAwais YousafNo ratings yet

- AAASteele BioDocument21 pagesAAASteele Bioceice2013100% (1)

- L2CP and VLAN TaggingDocument5 pagesL2CP and VLAN TaggingMarko BileNo ratings yet

- OL Lab 9 Organic ChemistryDocument17 pagesOL Lab 9 Organic ChemistryHezekiah AtindaNo ratings yet