Professional Documents

Culture Documents

10 P&id Checklist PDF

10 P&id Checklist PDF

Uploaded by

roman reigns0 ratings0% found this document useful (0 votes)

3 views4 pagesOriginal Title

10 P&ID CHECKLIST.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

3 views4 pages10 P&id Checklist PDF

10 P&id Checklist PDF

Uploaded by

roman reignsCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

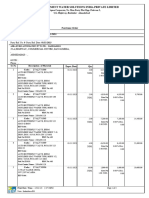

[DIECIL/ENGG/DG-CKL-O1

(CHECK-LIST FOR P & ID Issue Date J23rd June,2005

“DOSHION RevNo [3

Rev Date [10-Sep-09

TOC Date

1 Is Line Velocity Chart followed in P & ID? We No

If not followed, then have you attached supporting document ? Yes No,

2 1s Valve Selection Chart followed ? es No

If not followed, then have you attached supporting document? Yes No

3. Dowe have mentined descriptions like Unit‘Tag No. z No

MOCSize/Cap,Qty.below every major equipments / items ?

4 Are Vessel's frontal valves size & Piping are suitable We No. NA

to Service,B/W flow ?

5 Are Air Release lines suitable to Min, 1/4th to 1/3rd of service flow? [axa No NA

6 Fone pump has to be used for rwo different applications & Yes No

If flow reqdfor other service is less than 1/4 of duty point then

Ensure that recirculation line from pump to tank is shown.

7 Isresin trap/Y-type strainer shown at O/L of Ion Exchange vessel ? Yes. No_ [VA

8 Is Termination Point table are checked properly for our scope ( BL), VE No.

‘Terminations size & connections Flow & Pressure ? .

9) Is dampner shown at discharge of DG Blower ? Yer No [oRLA

10 Is Inlet Raw Water é& Committed outlet Water Quality shown ? Yes No NA

11 Is PVC Pipe shown inside Dosing tank when agitator is provided ? Yes No [OA

12 Is mass balancing done incase of UF in Pretreatment ? Yes No | weak

(Refer Memo:026/ 04-05)

14 Are Pressure Switches Provided at UF Inlet ? (UF-KOCH / ASAIIL) Yes No WA

| Are Sampling Valves shown at following Places ?

A. All Vessels Inlet & Outlet Yee No NA

B UF Product Yes, No | AA

© MCF Outlet Yes No NA

D*RO Product VE No NA

F EDI Product Yes, No. WA

F BF Outlet Yes No i

G Ejector Discharge ‘Yes ‘No BA

+ Incase of more than 4 RO module, provide individual sampling valve at outlet.

WAEngineering\ChecklistiDG-CKLO1-02-PID-GA-R2 1

[DIECIL/ENGG/DG-CKL-O1

2eshion (CHECK-LIST FOR P & 1D Issue Date [23rd June 2005

DOSHION RevNo 2

Rev Date _|os-11-2007

sure that Diaphragm Valve is not be selected for Li Isolation Ve No NA

in 100 Ltrs. HDPE Dosing tanks

16 Are Isolation Valves shown at ORP,Cl,pH when sensor is to be fitted XE ‘No NA

in flowcell ?

17 Are NRVs shown at following places ?

A RO Product,( If DG is Provided ) Yes No | WA

B RO Product If ROM >4) Yes No, NA

C SAC Ontlet (IF DG is provided ) Yes No | A

D Any outlet going to more than 5 Mtr. Height. Yes No | WA

E_ MB Blower Discharge Yes No__[| WA

18 Is RO Reject Line size suitable to Chem. Cleaning Flow ? YS No NA

19 Ensure that RO Rej. Recirculation Fl is field mounted. V& No NA

20 Ensure that RO Rej, Recir. Line is of $$ upto Recir. Control Valve ? va No NA

21 Ensure that RO Rej. Recirculation FTis shown, Yor _[_No NA

22 Ensure Sequence of Recir. Line is RO Rej to BLV+FI+NRV (near pump) [Yer No. NA

23. Ensure that Vaccum breaker is shown at RO & UF Product.(on header) VE No NA

24 Is LLS & HLS shown in Break / Product Water Tanks ? Yes No NA

25 Are Isolation Valves provided in LI of Break / Product Water Tank ? ‘Yes No. VA

26 Is Qverlow lina sizat is ono sive higher than Inlet Line? Yea No__[_NA

* Inany case Overlow flow line should not be more than 10°.

Use two different overlow with small line size in these ease.

27 Areal pumps get flooded suction ? Yes_[ Xo NA

Mention Tag No of Prmps with Negative suctions

28 Areall Intorlocks shown in P & ID? Yor _[_No NA

29 Check instuments selection for field / panel mounted, Yes No NA

30 Ensure that Equipment selection is as per Flow & Pressure requirement. [Yes No NA

W:Engineering\Checklist!G-CKLO1-02-PID-GA-R2 2

aw

fy -woue®)

4

[DIECIL/ENGG/DG-CKL-OL

Loewen CHECK-LIST FOR P & 1D Issue Date [23rd June,2006

DOSHION RevNo [2

|__ Rev Date

31 Ensure that Auto valve is provided in Pump sudion, when ORP dump [Yes No | WA

water is going to any height rather than drain

32, Ensure that Flis shown in UF at Product and Reject or Feed Yes No. DA

33 Ensure that Pressure Gauge is provided at Following Locations

(If Pres. Transmitter is provided then no need to give Pres. Guages )

a Across all Filters and Ion Exchange Vessels wes [No NA

b HPP Suction VE No NA

© RO Feed & RO Reject Yor No) NA

d_ UF Feed,Product and Reject ‘Yes No | WA

e Blower Discharge ‘Yes No WA

f EDLInlet and Outlet Yes! No WK

34 Ensure that Line and Valve size for Rinse,B/W Flow and other Yes, ‘No ANA

services in Filters / Ton Exchange vessels are provided as per flow

requirement ie not as per service flow. LINE & VALVE SIZE SHOULD

BE SMALLER FOR LOWER FLOW TO GET BETTER CONTROL.

35. Ensure thatall revision marks are shown properly in table. S No NA

36 Ensure that Fail safe position is shown for all auto valves. = No. NA

37 Ensure that Air flow regulating valve is considered for all auto valves VE No NA

38. Have you referred Engineoring policy-017/05-06 during selection Yes No NA

of filter.

If not followed, then have you attached supporting document ? Yes No

39 In case of Auto systems, have you provided valve for controlling flow. Yes No

40 Have you used standardized vessel? Ve ‘No

41 Have you used standardized frontol as per the index available al Yes No NA

*\\doshiverver\ innova\ frontal lib!

42 Have you selected standard pump as per policy 020/ 05-06 Yes Wa WA

43 Whether pump is capable of providing both service and backwash flow. [~SE No. WA

If not, will both pump will be working during higher flow requirement? [Yes No NA

| 46 Ensure that MSRL line size is not below 32NB. Yes No NA

W:Engineering\Checklist!DG-CKL01-02-PID-GAR2 3

[DIECIL/ENGG/DG-CKL-01

CHECK-LIST FOR P & ID

Issue Date [23rd June,2005

33

backwash, make sure that both pump logetlwe give Uke reyuited flow.

Ensure that quantity of level indicators are calculated based on tank

7 No

DOSHION Rev No fa

Rew Date _fos-t1-2007

SH Ensure that tag nos are not repeated No_[_NA

59 Ensure that velocity at ejector outlet is as per design requirement, Yes No [ WA

56 Ensure that following documents are supplied at the time first submission

of P& ID (Uf applicable)

a, ROSA report Yes No [ “NA

b Calculation sheet Yes No | oN.A

¢ UF calculation sheet Yes No | NA

47 Ensure that while selecting Ejector (for SAC, SBA & MB) first calculation Yes No] Da

is done for 15

47 Ensure that while selecting Ejector first calculation is done for 1:5, Yes No. WW

Fjector. If Power water flow requirement with 1 :5 Ejector is less

than 0.5 m3/hr, then select Ejector 1:1

48 In case where multiple units are provided (¢.g-Two Pumps, two MGF Yes | No [NA

, two Blowers etc.) have you mentioned whether both are working,

‘working one standby etc.

49 Ensure that agitator selection in Dosing is as per Engineering Policy- Yes No [va

016/05-06

50 Ensure that raw water pump head does not exceed 4 kg/cm2. Yer [No [NA

52 Ensure that pressure drop in each vessel and MCF is considered Ys No NA

between 0.5 to 0.8 kg/cm2, to maintain minimum suction head of

1 kg/cm? of HPP inlet

58. Check that following velocities are considered

a Gravity flow 0.8 m/s Yes No. WA

D_Clavifier sludge outlet -0.5 u/s Yes No | Spa

54 When two pumps are used (1W+15) and both pumps are used during NA

Yes No

height and make of level indicator

Checked By \\ -

Project Engin:

Approved By

Project Manager

WAEngineering\Checklist\DG-CKLO1-02-PID-GA-R2 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1011 Cumulative 1712740961284Document1 page1011 Cumulative 1712740961284roman reignsNo ratings yet

- Exam Fee ReceiptDocument1 pageExam Fee Receiptroman reignsNo ratings yet

- 7.1 BreakingBadDocument1 page7.1 BreakingBadroman reignsNo ratings yet

- 0030 DoshionDocument1 page0030 Doshionroman reignsNo ratings yet

- Doshion Environment Water Solution Ipl: Cash Flow Date - 5/10/2024 Division/Department - IPD ProjectDocument1 pageDoshion Environment Water Solution Ipl: Cash Flow Date - 5/10/2024 Division/Department - IPD Projectroman reignsNo ratings yet

- Po - 170 - Gopani - MCF CartridgeDocument1 pagePo - 170 - Gopani - MCF Cartridgeroman reignsNo ratings yet

- Po - 315 - Aira - Valve AutoDocument2 pagesPo - 315 - Aira - Valve Autoroman reignsNo ratings yet

- 49 Muktipnath PLCDocument2 pages49 Muktipnath PLCroman reignsNo ratings yet